Powder Metallurgy NDE And SPC: Density, Ultrasonics And Lot Acceptance Criteria

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Powder Metallurgy NDE Background and Objectives

Powder metallurgy (PM) has evolved significantly since its inception in the early 20th century, transforming from a niche manufacturing process to a mainstream industrial technology. The development trajectory has been characterized by continuous improvements in material properties, processing techniques, and quality control methodologies. Non-destructive evaluation (NDE) techniques for powder metallurgy components have become increasingly critical as PM applications have expanded into high-performance and safety-critical sectors such as aerospace, automotive, and medical industries.

The historical progression of PM NDE techniques reflects the industry's growing sophistication. Early quality control relied primarily on destructive testing and basic dimensional inspection, which proved inadequate as performance requirements increased. By the 1970s and 1980s, rudimentary density measurements and basic ultrasonic testing began to emerge, though these methods lacked the precision and reliability needed for advanced applications.

Recent technological advancements have dramatically enhanced NDE capabilities for powder metallurgy. Modern techniques now include advanced ultrasonics, X-ray computed tomography, neutron diffraction, and various spectroscopic methods. These developments have been driven by the need to detect increasingly subtle defects such as micro-porosity, non-uniform density distributions, and material inconsistencies that can significantly impact component performance.

Statistical Process Control (SPC) integration with NDE represents a significant evolutionary step in powder metallurgy quality assurance. This integration enables real-time monitoring of manufacturing processes, allowing for immediate corrective actions and continuous improvement of production parameters. The combination of advanced NDE techniques with sophisticated statistical analysis provides a powerful framework for ensuring consistent product quality.

The primary objectives of current PM NDE and SPC development efforts are multifaceted. First, to establish reliable, non-destructive methods for accurately measuring density variations throughout complex PM components. Second, to develop ultrasonic testing protocols specifically calibrated for the unique microstructural characteristics of sintered materials. Third, to create standardized lot acceptance criteria that balance manufacturing feasibility with performance requirements.

Additionally, the industry aims to implement in-line NDE systems capable of 100% inspection without compromising production efficiency. This represents a shift from traditional sampling-based quality control to comprehensive evaluation of every component. The ultimate goal is to establish predictive quality models that correlate NDE measurements with in-service performance, enabling more precise engineering specifications and improved component reliability.

These technological objectives align with broader industry trends toward digital manufacturing, materials optimization, and enhanced sustainability through reduced material waste and energy consumption. The evolution of PM NDE techniques continues to be a critical enabler for expanding powder metallurgy into increasingly demanding applications.

The historical progression of PM NDE techniques reflects the industry's growing sophistication. Early quality control relied primarily on destructive testing and basic dimensional inspection, which proved inadequate as performance requirements increased. By the 1970s and 1980s, rudimentary density measurements and basic ultrasonic testing began to emerge, though these methods lacked the precision and reliability needed for advanced applications.

Recent technological advancements have dramatically enhanced NDE capabilities for powder metallurgy. Modern techniques now include advanced ultrasonics, X-ray computed tomography, neutron diffraction, and various spectroscopic methods. These developments have been driven by the need to detect increasingly subtle defects such as micro-porosity, non-uniform density distributions, and material inconsistencies that can significantly impact component performance.

Statistical Process Control (SPC) integration with NDE represents a significant evolutionary step in powder metallurgy quality assurance. This integration enables real-time monitoring of manufacturing processes, allowing for immediate corrective actions and continuous improvement of production parameters. The combination of advanced NDE techniques with sophisticated statistical analysis provides a powerful framework for ensuring consistent product quality.

The primary objectives of current PM NDE and SPC development efforts are multifaceted. First, to establish reliable, non-destructive methods for accurately measuring density variations throughout complex PM components. Second, to develop ultrasonic testing protocols specifically calibrated for the unique microstructural characteristics of sintered materials. Third, to create standardized lot acceptance criteria that balance manufacturing feasibility with performance requirements.

Additionally, the industry aims to implement in-line NDE systems capable of 100% inspection without compromising production efficiency. This represents a shift from traditional sampling-based quality control to comprehensive evaluation of every component. The ultimate goal is to establish predictive quality models that correlate NDE measurements with in-service performance, enabling more precise engineering specifications and improved component reliability.

These technological objectives align with broader industry trends toward digital manufacturing, materials optimization, and enhanced sustainability through reduced material waste and energy consumption. The evolution of PM NDE techniques continues to be a critical enabler for expanding powder metallurgy into increasingly demanding applications.

Market Demand Analysis for PM Quality Control

The global powder metallurgy (PM) market has witnessed significant growth in recent years, with increasing demand for quality control solutions. The market for PM quality control technologies, including density measurement, ultrasonic testing, and lot acceptance criteria systems, was valued at approximately $520 million in 2022 and is projected to grow at a CAGR of 6.8% through 2028.

Automotive and aerospace industries remain the primary drivers of this market growth, collectively accounting for over 65% of the demand. These sectors require high-precision PM components with stringent quality standards, creating substantial demand for advanced non-destructive evaluation (NDE) technologies. The automotive industry alone consumes nearly 70% of global PM production, with quality control becoming increasingly critical as vehicle performance and safety requirements intensify.

Market research indicates that manufacturers are facing mounting pressure to implement statistical process control (SPC) systems that can provide real-time quality assurance. This trend is particularly evident in regions with advanced manufacturing capabilities such as North America, Europe, and parts of Asia, where regulatory requirements for component reliability are becoming more stringent.

The demand for ultrasonic testing equipment in PM applications has seen remarkable growth, with sales increasing by 22% between 2020 and 2022. This surge reflects the industry's shift toward non-destructive testing methods that can detect internal defects without compromising product integrity. Manufacturers are increasingly seeking integrated solutions that combine multiple testing methodologies to ensure comprehensive quality assessment.

Density measurement technologies have evolved significantly, with laser-based and X-ray systems gaining market share due to their superior accuracy compared to traditional methods. The market for these advanced density measurement systems grew by 15% in 2022, indicating strong industry adoption.

Customer surveys reveal that 78% of PM component manufacturers consider quality control as their top investment priority for the next five years. This sentiment is driven by end-user demands for zero-defect components, particularly in critical applications such as automotive safety systems and aerospace components.

Regional analysis shows that North America and Europe currently lead in the adoption of advanced PM quality control technologies, but the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with annual growth rates exceeding 10%. This growth is attributed to the rapid expansion of manufacturing capabilities and increasing quality standards in these regions.

Automotive and aerospace industries remain the primary drivers of this market growth, collectively accounting for over 65% of the demand. These sectors require high-precision PM components with stringent quality standards, creating substantial demand for advanced non-destructive evaluation (NDE) technologies. The automotive industry alone consumes nearly 70% of global PM production, with quality control becoming increasingly critical as vehicle performance and safety requirements intensify.

Market research indicates that manufacturers are facing mounting pressure to implement statistical process control (SPC) systems that can provide real-time quality assurance. This trend is particularly evident in regions with advanced manufacturing capabilities such as North America, Europe, and parts of Asia, where regulatory requirements for component reliability are becoming more stringent.

The demand for ultrasonic testing equipment in PM applications has seen remarkable growth, with sales increasing by 22% between 2020 and 2022. This surge reflects the industry's shift toward non-destructive testing methods that can detect internal defects without compromising product integrity. Manufacturers are increasingly seeking integrated solutions that combine multiple testing methodologies to ensure comprehensive quality assessment.

Density measurement technologies have evolved significantly, with laser-based and X-ray systems gaining market share due to their superior accuracy compared to traditional methods. The market for these advanced density measurement systems grew by 15% in 2022, indicating strong industry adoption.

Customer surveys reveal that 78% of PM component manufacturers consider quality control as their top investment priority for the next five years. This sentiment is driven by end-user demands for zero-defect components, particularly in critical applications such as automotive safety systems and aerospace components.

Regional analysis shows that North America and Europe currently lead in the adoption of advanced PM quality control technologies, but the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with annual growth rates exceeding 10%. This growth is attributed to the rapid expansion of manufacturing capabilities and increasing quality standards in these regions.

Current NDE Technologies and Challenges in PM

Non-destructive evaluation (NDE) techniques in powder metallurgy (PM) have evolved significantly over the past decades, yet continue to face unique challenges due to the inherent characteristics of PM components. Current NDE technologies employed in the industry include density measurement methods, ultrasonic testing, X-ray computed tomography, eddy current testing, and magnetic particle inspection.

Density measurement remains the most fundamental quality control parameter in PM, with techniques ranging from the traditional Archimedes method to more advanced resonant frequency and radiation-based methods. The Archimedes principle provides reliable bulk density measurements but cannot detect localized density variations. Resonant frequency analysis offers non-destructive whole-part evaluation but requires complex calibration procedures for different geometries.

Ultrasonic testing has gained prominence for detecting internal defects in PM components. Conventional ultrasonic methods measure sound velocity and attenuation to identify porosity levels and internal flaws. However, the high acoustic attenuation in PM materials, particularly those with residual porosity, significantly limits penetration depth and resolution. Advanced techniques such as laser ultrasonics and phased array ultrasonics are being implemented to overcome these limitations.

X-ray computed tomography (CT) represents the state-of-the-art in PM inspection, providing three-dimensional visualization of internal structures. While offering unparalleled insight into defect morphology and distribution, industrial CT systems remain costly and time-consuming for routine quality control applications. The technology also faces challenges with beam hardening artifacts when examining high-density PM components.

Despite technological advances, several significant challenges persist in PM non-destructive evaluation. The inherent porosity of PM components creates complex acoustic interfaces that scatter ultrasonic waves, reducing detection sensitivity. Variable density distributions within parts complicate the establishment of reliable acceptance criteria and reference standards.

The geometric complexity of modern PM components, often featuring thin walls and intricate internal features, presents accessibility issues for conventional NDE methods. Additionally, the diverse material compositions in PM, including multi-metal systems and metal-ceramic composites, require specialized calibration procedures and interpretation methodologies.

Statistical Process Control (SPC) implementation faces challenges due to the difficulty in establishing appropriate sampling protocols that adequately represent batch variability. Current lot acceptance criteria often rely on destructive testing of representative samples, which may not capture the full spectrum of defects present in production runs.

The industry continues to seek cost-effective, high-throughput NDE solutions that can be integrated into production lines for real-time quality monitoring. Emerging technologies such as terahertz imaging and digital twin modeling show promise but require further development to address the specific challenges of PM components.

Density measurement remains the most fundamental quality control parameter in PM, with techniques ranging from the traditional Archimedes method to more advanced resonant frequency and radiation-based methods. The Archimedes principle provides reliable bulk density measurements but cannot detect localized density variations. Resonant frequency analysis offers non-destructive whole-part evaluation but requires complex calibration procedures for different geometries.

Ultrasonic testing has gained prominence for detecting internal defects in PM components. Conventional ultrasonic methods measure sound velocity and attenuation to identify porosity levels and internal flaws. However, the high acoustic attenuation in PM materials, particularly those with residual porosity, significantly limits penetration depth and resolution. Advanced techniques such as laser ultrasonics and phased array ultrasonics are being implemented to overcome these limitations.

X-ray computed tomography (CT) represents the state-of-the-art in PM inspection, providing three-dimensional visualization of internal structures. While offering unparalleled insight into defect morphology and distribution, industrial CT systems remain costly and time-consuming for routine quality control applications. The technology also faces challenges with beam hardening artifacts when examining high-density PM components.

Despite technological advances, several significant challenges persist in PM non-destructive evaluation. The inherent porosity of PM components creates complex acoustic interfaces that scatter ultrasonic waves, reducing detection sensitivity. Variable density distributions within parts complicate the establishment of reliable acceptance criteria and reference standards.

The geometric complexity of modern PM components, often featuring thin walls and intricate internal features, presents accessibility issues for conventional NDE methods. Additionally, the diverse material compositions in PM, including multi-metal systems and metal-ceramic composites, require specialized calibration procedures and interpretation methodologies.

Statistical Process Control (SPC) implementation faces challenges due to the difficulty in establishing appropriate sampling protocols that adequately represent batch variability. Current lot acceptance criteria often rely on destructive testing of representative samples, which may not capture the full spectrum of defects present in production runs.

The industry continues to seek cost-effective, high-throughput NDE solutions that can be integrated into production lines for real-time quality monitoring. Emerging technologies such as terahertz imaging and digital twin modeling show promise but require further development to address the specific challenges of PM components.

Current Ultrasonic Testing Methods for PM Components

01 Density control methods in powder metallurgy

Various methods can be employed to control and optimize density in powder metallurgy processes. These include adjusting compaction pressure, using specific sintering profiles, and implementing post-processing techniques. Controlled density is crucial for achieving desired mechanical properties in the final product. These methods help manufacturers achieve consistent density throughout the part, which is essential for structural integrity and performance.- Density control methods in powder metallurgy: Various methods can be employed to control and optimize density in powder metallurgy processes. These include adjusting compaction pressure, using specific sintering profiles, and implementing post-processing techniques. By carefully controlling these parameters, manufacturers can achieve desired density levels in the final product, which directly impacts mechanical properties such as strength and durability.

- High-density powder metallurgy components: Techniques for producing high-density components through powder metallurgy involve specialized compaction methods, advanced sintering processes, and sometimes the use of pressure-assisted sintering. These approaches aim to minimize porosity and achieve near-theoretical density in the final parts, resulting in improved mechanical properties and performance characteristics comparable to wrought materials.

- Density measurement and testing in powder metallurgy: Accurate measurement and testing of density in powder metallurgy products is crucial for quality control. Various methods are employed, including Archimedes principle-based measurements, gas pycnometry, and non-destructive testing techniques. These measurements help ensure that components meet specified density requirements and maintain consistent properties across production batches.

- Influence of powder characteristics on final density: The characteristics of metal powders, including particle size distribution, morphology, and composition, significantly influence the achievable density in powder metallurgy products. Finer powders typically allow for higher packing densities but may present flowability challenges. Powder selection and preparation are critical factors in achieving target density specifications in the final sintered components.

- Density gradient management in complex geometries: Managing density gradients in complex-shaped powder metallurgy components presents unique challenges. Techniques such as warm compaction, die-wall lubrication, and multi-directional pressing can help achieve more uniform density distribution throughout the part. Controlling these gradients is essential for preventing distortion during sintering and ensuring consistent mechanical properties across the entire component.

02 High-density powder metallurgy components

Techniques for producing high-density components through powder metallurgy involve specialized compaction methods, advanced sintering processes, and sometimes hot isostatic pressing. These approaches minimize porosity and maximize density to enhance mechanical properties such as strength, hardness, and wear resistance. High-density components are particularly important for applications requiring superior mechanical performance and durability.Expand Specific Solutions03 Density measurement and testing in powder metallurgy

Various methods are used to measure and test density in powder metallurgy products, including Archimedes' principle, gas pycnometry, and image analysis techniques. Accurate density measurement is critical for quality control and ensuring that components meet specified requirements. These testing methods help manufacturers validate their processes and make necessary adjustments to achieve target densities.Expand Specific Solutions04 Density gradient management in powder metallurgy parts

Managing density gradients in powder metallurgy parts involves specialized compaction techniques, die design optimization, and controlled powder flow. Uniform density distribution is essential for preventing warping, cracking, and dimensional variations during sintering. Techniques such as warm compaction, multi-directional pressing, and graduated pressure application help achieve more homogeneous density throughout complex-shaped components.Expand Specific Solutions05 Novel materials and additives for density enhancement

Innovative materials and additives are being developed to enhance density in powder metallurgy products. These include specialized alloying elements, nanoscale additives, and binding agents that improve compaction behavior and sintering characteristics. By incorporating these materials, manufacturers can achieve higher densities at lower processing temperatures or pressures, resulting in energy savings and improved product performance.Expand Specific Solutions

Leading Companies in PM NDE Solutions

Powder Metallurgy NDE and SPC technology is currently in a growth phase, with increasing adoption across aerospace, energy, and manufacturing sectors. The market is expanding at approximately 5-7% annually, driven by demand for high-precision quality control in critical components. Leading players like Lockheed Martin and Schlumberger are advancing ultrasonic testing technologies, while specialized firms such as Sensor Networks and Eddyfi are developing innovative NDT solutions. The technology maturity varies significantly - established companies like GE Infrastructure Technology offer mature solutions, while newer entrants like 3D Lab and Verifi Technologies are introducing disruptive approaches that enhance density measurement precision and lot acceptance criteria standardization.

Eddyfi Corp.

Technical Solution: Eddyfi has developed advanced eddy current array (ECA) technology specifically optimized for powder metallurgy (PM) components. Their solution combines multi-frequency eddy current testing with sophisticated signal processing algorithms to detect density variations, cracks, and inclusions in PM parts. The system employs customized probe configurations that can adapt to complex geometries typical in PM components. Their proprietary software integrates real-time statistical process control (SPC) capabilities, allowing manufacturers to establish lot acceptance criteria based on historical data trends. The technology can detect density variations as small as 2-3% in sintered components, providing quantitative density mapping across the entire part volume. Eddyfi's solution also incorporates automated calibration procedures using reference standards of known densities to ensure measurement consistency across production batches.

Strengths: Superior detection sensitivity for subsurface defects; excellent capability for complex geometries; integrated SPC functionality for real-time quality control. Weaknesses: Higher initial investment compared to conventional methods; requires specialized operator training; performance may be limited in highly magnetic PM materials.

Sensor Networks, Inc.

Technical Solution: Sensor Networks has pioneered an integrated ultrasonic testing platform specifically designed for powder metallurgy applications. Their system utilizes phased array ultrasonic technology (PAUT) combined with proprietary signal processing algorithms to provide comprehensive density analysis and defect detection in PM components. The technology employs multiple ultrasonic frequencies (typically 5-15 MHz) to optimize penetration and resolution based on material characteristics. Their solution includes automated scanning systems that can be integrated directly into production lines, enabling 100% inspection of critical PM components. The platform incorporates advanced data analytics that correlate ultrasonic parameters with density variations, allowing for precise density mapping across complex geometries. Their software suite includes statistical process control tools that automatically generate lot acceptance reports based on predefined quality criteria, with capabilities for trend analysis and process optimization feedback.

Strengths: High-resolution density mapping capabilities; excellent detection of internal voids and inclusions; seamless production line integration. Weaknesses: Requires coupling medium which may be problematic for some PM applications; limited effectiveness in highly porous materials; higher cost compared to simpler testing methods.

Key Innovations in Density Measurement Technologies

High density metal components manufactured by powder metallurgy

PatentInactiveUS5594186A

Innovation

- The use of substantially linear, acicular metal particles with a triangular cross section in the powder metallurgy process, allowing for a single pressing and heating step to achieve a green compact and final component density of at least 95% theoretical density, reducing the need for additional processing steps and minimizing lubricant usage.

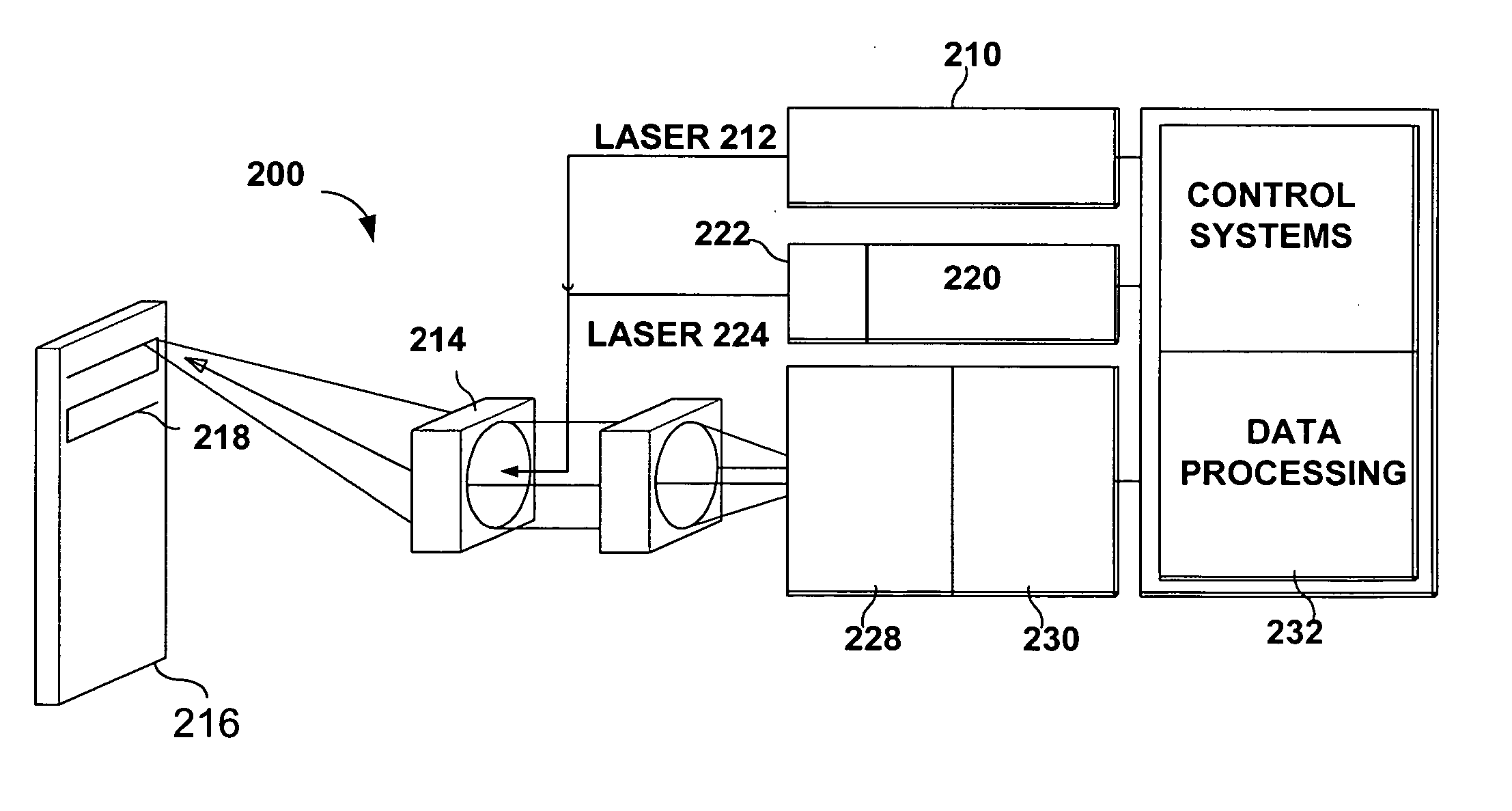

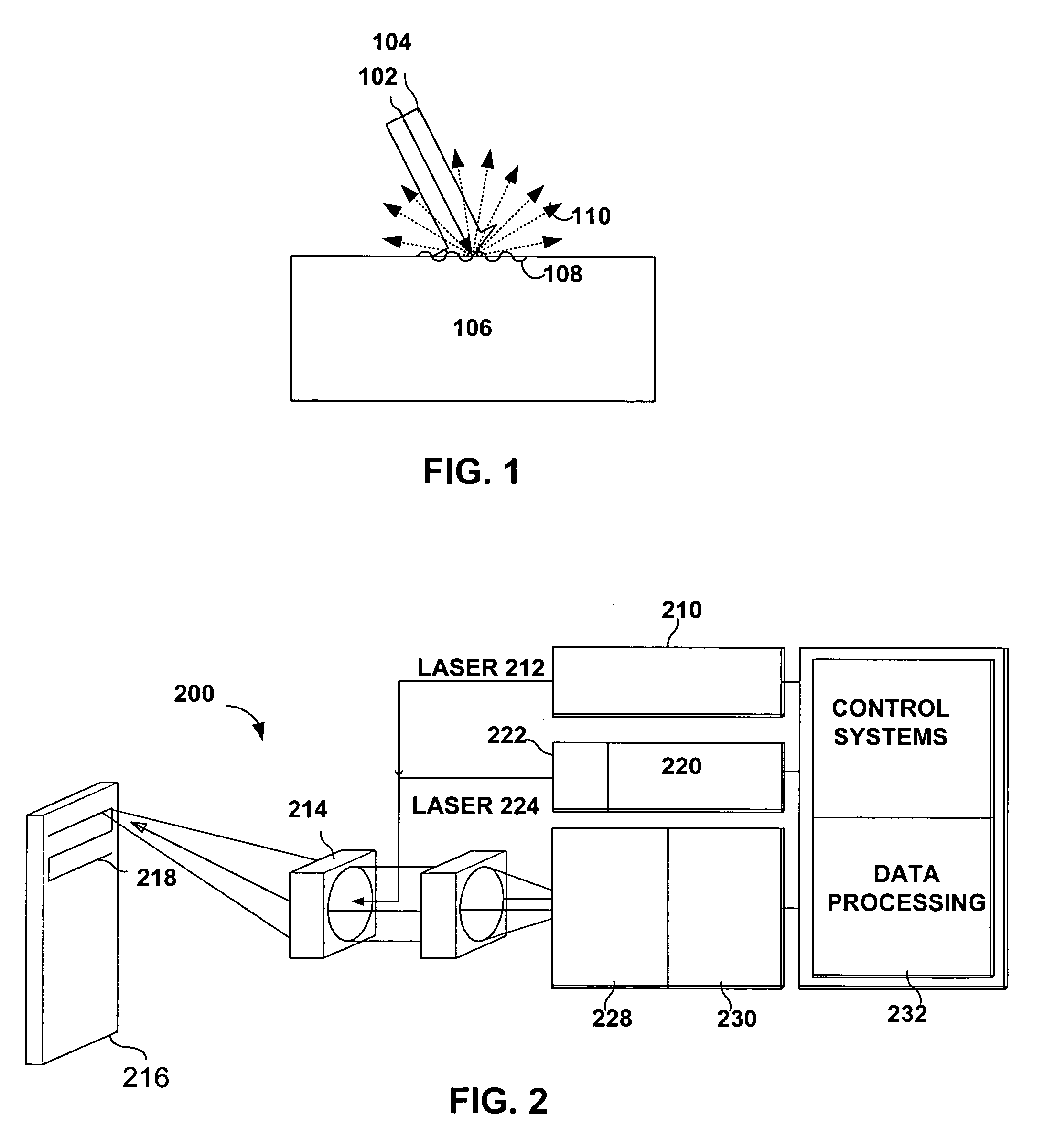

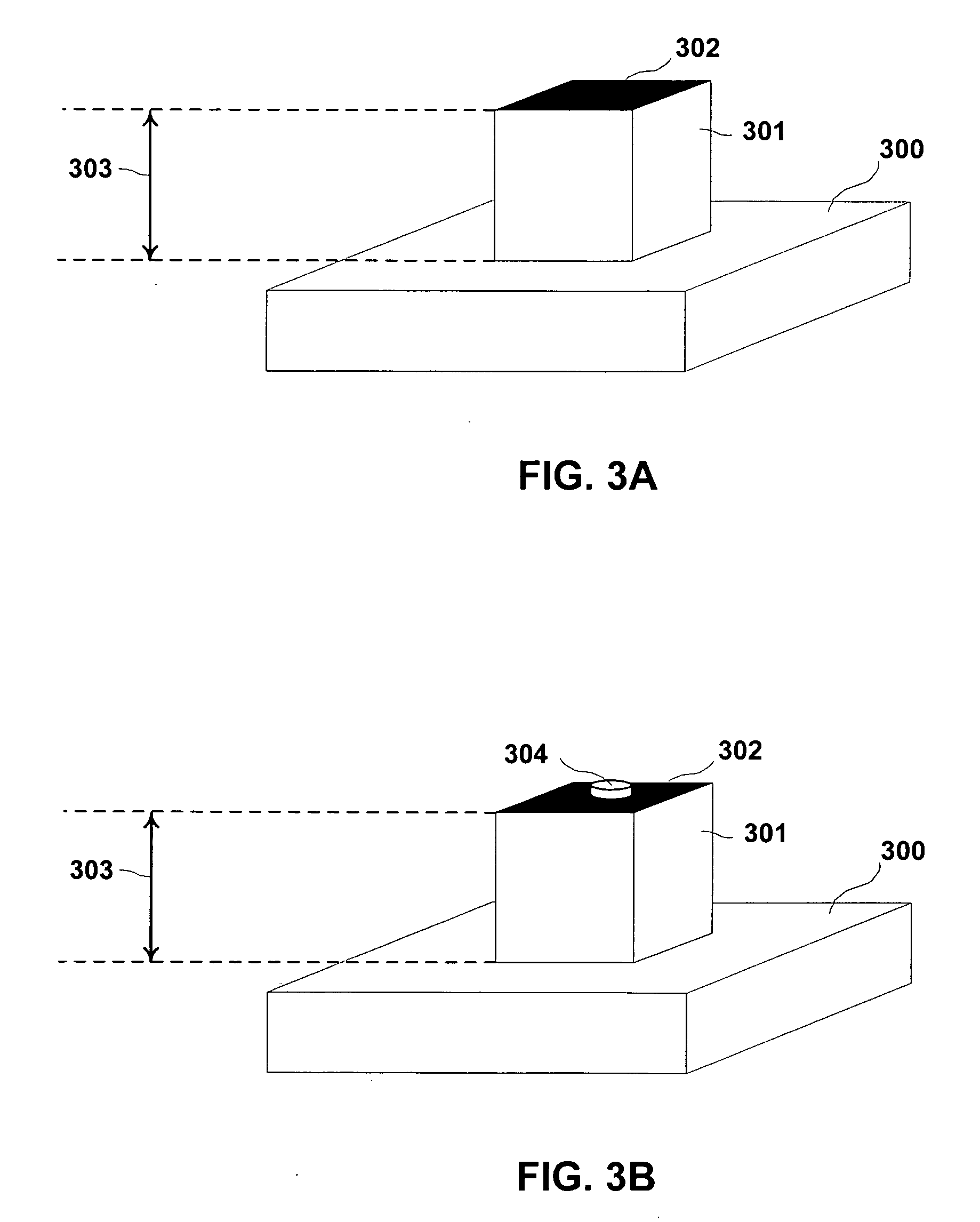

System and method to calibrate multiple sensors

PatentInactiveUS20060219014A1

Innovation

- A multi-mode calibration target that provides both depth and visual contrast, allowing a common focal point for multiple optical components, reducing the need for multiple targets and minimizing setup errors by incorporating a laser diode for narrowband detectors, enabling quick and accurate calibration of multiple sensors.

Statistical Process Control Implementation in PM

Statistical Process Control (SPC) implementation in powder metallurgy (PM) represents a critical advancement in quality assurance methodologies for this manufacturing sector. The integration of SPC techniques into PM processes has evolved significantly over the past decade, moving from basic measurement systems to sophisticated real-time monitoring platforms that leverage advanced statistical algorithms.

The implementation typically begins with the establishment of key process parameters and critical quality characteristics specific to powder metallurgy operations. These include green density measurements, sintered density variations, dimensional stability, and microstructural uniformity. Successful SPC deployment requires careful selection of these control parameters based on their correlation with final product performance and reliability.

Data collection systems form the backbone of effective SPC implementation in PM environments. Modern facilities have transitioned from manual sampling methods to automated sensor networks that continuously monitor process variables. This shift has enabled the collection of statistically significant data volumes necessary for meaningful analysis while minimizing human error and reducing inspection costs.

Control charting methodologies adapted specifically for PM processes constitute another essential component. Traditional Shewhart charts have been supplemented with specialized variations that account for the unique characteristics of powder metallurgy, including non-normal distributions often encountered in density measurements and the inherent variability in powder characteristics between batches.

Process capability indices (Cpk, Ppk) calculation methods have been refined for PM applications, with industry standards establishing minimum thresholds for different product categories. These indices provide quantitative measures of how well a process can meet specification limits and have become standard requirements in quality certification for PM components in automotive and aerospace applications.

Training programs for operators and quality personnel represent a crucial yet often overlooked aspect of SPC implementation. Successful programs incorporate both theoretical statistical concepts and practical applications specific to powder metallurgy operations, ensuring that staff can effectively interpret control charts and respond appropriately to out-of-control conditions.

The integration of SPC with other quality systems such as Design of Experiments (DOE) and Failure Mode and Effects Analysis (FMEA) has created comprehensive quality frameworks within leading PM manufacturers. This systems approach enables continuous improvement cycles that progressively enhance process stability and product quality while reducing variation and defect rates.

The implementation typically begins with the establishment of key process parameters and critical quality characteristics specific to powder metallurgy operations. These include green density measurements, sintered density variations, dimensional stability, and microstructural uniformity. Successful SPC deployment requires careful selection of these control parameters based on their correlation with final product performance and reliability.

Data collection systems form the backbone of effective SPC implementation in PM environments. Modern facilities have transitioned from manual sampling methods to automated sensor networks that continuously monitor process variables. This shift has enabled the collection of statistically significant data volumes necessary for meaningful analysis while minimizing human error and reducing inspection costs.

Control charting methodologies adapted specifically for PM processes constitute another essential component. Traditional Shewhart charts have been supplemented with specialized variations that account for the unique characteristics of powder metallurgy, including non-normal distributions often encountered in density measurements and the inherent variability in powder characteristics between batches.

Process capability indices (Cpk, Ppk) calculation methods have been refined for PM applications, with industry standards establishing minimum thresholds for different product categories. These indices provide quantitative measures of how well a process can meet specification limits and have become standard requirements in quality certification for PM components in automotive and aerospace applications.

Training programs for operators and quality personnel represent a crucial yet often overlooked aspect of SPC implementation. Successful programs incorporate both theoretical statistical concepts and practical applications specific to powder metallurgy operations, ensuring that staff can effectively interpret control charts and respond appropriately to out-of-control conditions.

The integration of SPC with other quality systems such as Design of Experiments (DOE) and Failure Mode and Effects Analysis (FMEA) has created comprehensive quality frameworks within leading PM manufacturers. This systems approach enables continuous improvement cycles that progressively enhance process stability and product quality while reducing variation and defect rates.

Industry Standards and Certification Requirements

The powder metallurgy industry operates under a comprehensive framework of standards and certification requirements that ensure product quality, consistency, and reliability. ASTM International has established several key standards specifically for powder metallurgy, including ASTM B328 for density determination, ASTM B933 for ultrasonic testing of PM components, and ASTM B311 for specific gravity measurements. These standards provide detailed methodologies and acceptance criteria that manufacturers must follow during quality control processes.

ISO certification requirements also play a crucial role in the powder metallurgy sector, with ISO 5755 addressing the classification and testing methods for sintered metal materials. For non-destructive evaluation (NDE) techniques, ISO 22096 provides guidelines for condition monitoring and diagnostics of machines, which can be adapted for powder metallurgy production lines implementing Statistical Process Control (SPC).

The Metal Powder Industries Federation (MPIF) has developed industry-specific standards that address density measurement protocols and lot acceptance criteria. MPIF Standard 35 outlines material standards for PM structural parts, including density requirements for various material compositions. These standards are regularly updated to reflect technological advancements and changing industry needs.

For manufacturers implementing SPC in powder metallurgy processes, compliance with AIAG (Automotive Industry Action Group) standards is often necessary, particularly when supplying components to the automotive sector. These standards specify statistical methods for process monitoring and capability studies that help maintain consistent density and other critical parameters across production lots.

Certification requirements vary by application sector, with aerospace applications governed by the stringent AS9100 standard, which incorporates additional requirements specific to aviation, space, and defense organizations. Medical device applications must comply with ISO 13485, which includes specific requirements for organizations involved in the design, production, and distribution of medical devices.

The implementation of ultrasonic testing for powder metallurgy components must adhere to personnel certification requirements outlined in standards such as SNT-TC-1A or ISO 9712, which specify the qualification and certification of personnel performing non-destructive testing. These certifications ensure that technicians conducting ultrasonic evaluations possess the necessary skills and knowledge to accurately interpret test results.

Emerging standards are being developed to address the integration of digital technologies in powder metallurgy quality control, including guidelines for automated inspection systems and digital data management for lot traceability. These standards will become increasingly important as Industry 4.0 concepts continue to transform manufacturing processes in the powder metallurgy sector.

ISO certification requirements also play a crucial role in the powder metallurgy sector, with ISO 5755 addressing the classification and testing methods for sintered metal materials. For non-destructive evaluation (NDE) techniques, ISO 22096 provides guidelines for condition monitoring and diagnostics of machines, which can be adapted for powder metallurgy production lines implementing Statistical Process Control (SPC).

The Metal Powder Industries Federation (MPIF) has developed industry-specific standards that address density measurement protocols and lot acceptance criteria. MPIF Standard 35 outlines material standards for PM structural parts, including density requirements for various material compositions. These standards are regularly updated to reflect technological advancements and changing industry needs.

For manufacturers implementing SPC in powder metallurgy processes, compliance with AIAG (Automotive Industry Action Group) standards is often necessary, particularly when supplying components to the automotive sector. These standards specify statistical methods for process monitoring and capability studies that help maintain consistent density and other critical parameters across production lots.

Certification requirements vary by application sector, with aerospace applications governed by the stringent AS9100 standard, which incorporates additional requirements specific to aviation, space, and defense organizations. Medical device applications must comply with ISO 13485, which includes specific requirements for organizations involved in the design, production, and distribution of medical devices.

The implementation of ultrasonic testing for powder metallurgy components must adhere to personnel certification requirements outlined in standards such as SNT-TC-1A or ISO 9712, which specify the qualification and certification of personnel performing non-destructive testing. These certifications ensure that technicians conducting ultrasonic evaluations possess the necessary skills and knowledge to accurately interpret test results.

Emerging standards are being developed to address the integration of digital technologies in powder metallurgy quality control, including guidelines for automated inspection systems and digital data management for lot traceability. These standards will become increasingly important as Industry 4.0 concepts continue to transform manufacturing processes in the powder metallurgy sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!