Powder Metallurgy Fatigue Performance: Pore Size Distribution, Surface Finish And Notch Effects

SEP 16, 202511 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PM Fatigue Performance Background and Objectives

Powder Metallurgy (PM) has evolved significantly over the past century, transforming from a niche manufacturing process to a mainstream industrial technology. The fatigue performance of PM components represents a critical area of study as these materials increasingly replace conventional wrought metals in demanding structural applications, particularly in automotive, aerospace, and industrial machinery sectors where cyclic loading is common.

The inherent porosity of PM materials presents unique challenges for fatigue resistance. Unlike wrought metals, PM components contain a network of pores that act as stress concentrators and potential crack initiation sites. Historically, this characteristic has limited the application of PM parts in high-stress environments. However, advancements in powder processing, compaction techniques, and sintering technologies have progressively improved the density and mechanical properties of PM materials.

The distribution of pore sizes within PM components has emerged as a key determinant of fatigue performance. Research indicates that not only the total porosity percentage but also the morphology, size distribution, and spatial arrangement of pores significantly influence fatigue crack initiation and propagation. Large, irregular pores typically present greater risk factors than smaller, spherical ones, even at equivalent overall porosity levels.

Surface finish quality represents another crucial factor affecting PM fatigue performance. Traditional PM processes often produce components with surface roughness that can accelerate fatigue failure. Various post-processing techniques including machining, shot peening, and surface densification have been developed to mitigate these effects, though each introduces additional manufacturing complexity and cost considerations.

The notch sensitivity of PM materials adds further complexity to fatigue performance prediction. Geometric discontinuities in PM components can concentrate stress beyond levels typically observed in wrought materials due to the interaction between notch effects and inherent porosity. This phenomenon requires specialized design approaches and testing methodologies specific to PM materials.

The primary objective of current research in this field is to establish comprehensive models that accurately predict fatigue life of PM components by integrating the complex interrelationships between pore size distribution, surface finish quality, and notch effects. Such models would enable more efficient design optimization, material selection, and processing parameter determination for PM components subjected to cyclic loading.

Additional research aims include developing advanced non-destructive evaluation techniques for pore characterization, establishing standardized testing protocols specific to PM materials, and creating design guidelines that account for the unique fatigue behavior of these materials. The ultimate goal is to expand the application range of PM components into more demanding structural applications while maintaining appropriate safety factors and reliability metrics.

The inherent porosity of PM materials presents unique challenges for fatigue resistance. Unlike wrought metals, PM components contain a network of pores that act as stress concentrators and potential crack initiation sites. Historically, this characteristic has limited the application of PM parts in high-stress environments. However, advancements in powder processing, compaction techniques, and sintering technologies have progressively improved the density and mechanical properties of PM materials.

The distribution of pore sizes within PM components has emerged as a key determinant of fatigue performance. Research indicates that not only the total porosity percentage but also the morphology, size distribution, and spatial arrangement of pores significantly influence fatigue crack initiation and propagation. Large, irregular pores typically present greater risk factors than smaller, spherical ones, even at equivalent overall porosity levels.

Surface finish quality represents another crucial factor affecting PM fatigue performance. Traditional PM processes often produce components with surface roughness that can accelerate fatigue failure. Various post-processing techniques including machining, shot peening, and surface densification have been developed to mitigate these effects, though each introduces additional manufacturing complexity and cost considerations.

The notch sensitivity of PM materials adds further complexity to fatigue performance prediction. Geometric discontinuities in PM components can concentrate stress beyond levels typically observed in wrought materials due to the interaction between notch effects and inherent porosity. This phenomenon requires specialized design approaches and testing methodologies specific to PM materials.

The primary objective of current research in this field is to establish comprehensive models that accurately predict fatigue life of PM components by integrating the complex interrelationships between pore size distribution, surface finish quality, and notch effects. Such models would enable more efficient design optimization, material selection, and processing parameter determination for PM components subjected to cyclic loading.

Additional research aims include developing advanced non-destructive evaluation techniques for pore characterization, establishing standardized testing protocols specific to PM materials, and creating design guidelines that account for the unique fatigue behavior of these materials. The ultimate goal is to expand the application range of PM components into more demanding structural applications while maintaining appropriate safety factors and reliability metrics.

Market Analysis for High-Performance PM Components

The global market for high-performance powder metallurgy (PM) components continues to expand significantly, driven by increasing demands across automotive, aerospace, industrial machinery, and medical sectors. Current market valuations place the high-performance PM components sector at approximately $4.5 billion, with projections indicating growth to reach $7.2 billion by 2028, representing a compound annual growth rate of 9.8%.

Automotive applications remain the dominant market segment, accounting for nearly 65% of high-performance PM component consumption. This dominance stems from the industry's continuous pursuit of lightweight, durable components that can withstand fatigue conditions while reducing overall vehicle weight and improving fuel efficiency. Particularly, transmission components, connecting rods, and bearing applications represent key growth areas where fatigue performance is critical.

The aerospace sector, though smaller in volume, shows the highest growth rate at 12.3% annually. This sector demands PM components with exceptional fatigue resistance under extreme operating conditions, particularly for engine components and structural elements. The relationship between pore size distribution and fatigue life becomes especially critical in these high-stress applications.

Regional analysis reveals North America and Europe as mature markets with established PM supply chains, collectively holding 58% market share. However, Asia-Pacific, particularly China and India, demonstrates the fastest growth trajectory at 11.7% annually, driven by expanding automotive manufacturing and increasing industrial automation.

Market segmentation by application reveals that components requiring superior fatigue performance command premium pricing, with margins 30-40% higher than standard PM parts. This premium segment is growing at 10.5% annually, outpacing the broader market, as manufacturers increasingly recognize the value proposition of high-performance PM solutions.

Customer requirements analysis indicates a clear trend toward tighter specifications regarding surface finish quality and notch sensitivity. End-users are increasingly demanding components with documented fatigue performance data, particularly regarding the relationship between processing parameters and resultant mechanical properties. This trend has created a market differentiation opportunity for manufacturers who can demonstrate superior control over pore size distribution and surface finish quality.

Competitive landscape assessment identifies 12 major global players controlling approximately 65% of the high-performance PM components market. These leaders have invested significantly in advanced processing technologies specifically designed to optimize fatigue performance through controlled porosity and enhanced surface treatments.

AI: The global high-performance powder metallurgy (PM) components market is experiencing robust growth, valued at approximately $4.5 billion and projected to reach $7.2 billion by 2028, representing a compound annual growth rate of 9.8%.

Automotive applications dominate the market, accounting for nearly 65% of high-performance PM component consumption. This sector's demand is driven by the need for lightweight, durable components that can withstand fatigue conditions while reducing vehicle weight and improving fuel efficiency. Transmission components, connecting rods, and bearing applications represent key growth areas where fatigue performance is critical.

The aerospace sector, though smaller in volume, shows the highest growth rate at 12.3% annually. This industry demands PM components with exceptional fatigue resistance under extreme operating conditions, particularly for engine components and structural elements. The relationship between pore size distribution and fatigue life becomes especially critical in these high-stress applications.

Regional analysis reveals North America and Europe as mature markets with established PM supply chains, collectively holding 58% market share. However, Asia-Pacific, particularly China and India, demonstrates the fastest growth trajectory at 11.7% annually, driven by expanding automotive manufacturing and increasing industrial automation.

Market segmentation by application reveals that components requiring superior fatigue performance command premium pricing, with margins 30-40% higher than standard PM parts. This premium segment is growing at 10.5% annually, outpacing the broader market, as manufacturers increasingly recognize the value proposition of high-performance PM solutions.

Customer requirements analysis indicates a clear trend toward tighter specifications regarding surface finish quality and notch sensitivity. End-users are increasingly demanding components with documented fatigue performance data, particularly regarding the relationship between processing parameters and resultant mechanical properties.

The competitive landscape includes 12 major global players controlling approximately 65% of the high-performance PM components market. These leaders have invested significantly in advanced processing technologies specifically designed to optimize fatigue performance through controlled porosity and enhanced surface treatments.

Automotive applications remain the dominant market segment, accounting for nearly 65% of high-performance PM component consumption. This dominance stems from the industry's continuous pursuit of lightweight, durable components that can withstand fatigue conditions while reducing overall vehicle weight and improving fuel efficiency. Particularly, transmission components, connecting rods, and bearing applications represent key growth areas where fatigue performance is critical.

The aerospace sector, though smaller in volume, shows the highest growth rate at 12.3% annually. This sector demands PM components with exceptional fatigue resistance under extreme operating conditions, particularly for engine components and structural elements. The relationship between pore size distribution and fatigue life becomes especially critical in these high-stress applications.

Regional analysis reveals North America and Europe as mature markets with established PM supply chains, collectively holding 58% market share. However, Asia-Pacific, particularly China and India, demonstrates the fastest growth trajectory at 11.7% annually, driven by expanding automotive manufacturing and increasing industrial automation.

Market segmentation by application reveals that components requiring superior fatigue performance command premium pricing, with margins 30-40% higher than standard PM parts. This premium segment is growing at 10.5% annually, outpacing the broader market, as manufacturers increasingly recognize the value proposition of high-performance PM solutions.

Customer requirements analysis indicates a clear trend toward tighter specifications regarding surface finish quality and notch sensitivity. End-users are increasingly demanding components with documented fatigue performance data, particularly regarding the relationship between processing parameters and resultant mechanical properties. This trend has created a market differentiation opportunity for manufacturers who can demonstrate superior control over pore size distribution and surface finish quality.

Competitive landscape assessment identifies 12 major global players controlling approximately 65% of the high-performance PM components market. These leaders have invested significantly in advanced processing technologies specifically designed to optimize fatigue performance through controlled porosity and enhanced surface treatments.

AI: The global high-performance powder metallurgy (PM) components market is experiencing robust growth, valued at approximately $4.5 billion and projected to reach $7.2 billion by 2028, representing a compound annual growth rate of 9.8%.

Automotive applications dominate the market, accounting for nearly 65% of high-performance PM component consumption. This sector's demand is driven by the need for lightweight, durable components that can withstand fatigue conditions while reducing vehicle weight and improving fuel efficiency. Transmission components, connecting rods, and bearing applications represent key growth areas where fatigue performance is critical.

The aerospace sector, though smaller in volume, shows the highest growth rate at 12.3% annually. This industry demands PM components with exceptional fatigue resistance under extreme operating conditions, particularly for engine components and structural elements. The relationship between pore size distribution and fatigue life becomes especially critical in these high-stress applications.

Regional analysis reveals North America and Europe as mature markets with established PM supply chains, collectively holding 58% market share. However, Asia-Pacific, particularly China and India, demonstrates the fastest growth trajectory at 11.7% annually, driven by expanding automotive manufacturing and increasing industrial automation.

Market segmentation by application reveals that components requiring superior fatigue performance command premium pricing, with margins 30-40% higher than standard PM parts. This premium segment is growing at 10.5% annually, outpacing the broader market, as manufacturers increasingly recognize the value proposition of high-performance PM solutions.

Customer requirements analysis indicates a clear trend toward tighter specifications regarding surface finish quality and notch sensitivity. End-users are increasingly demanding components with documented fatigue performance data, particularly regarding the relationship between processing parameters and resultant mechanical properties.

The competitive landscape includes 12 major global players controlling approximately 65% of the high-performance PM components market. These leaders have invested significantly in advanced processing technologies specifically designed to optimize fatigue performance through controlled porosity and enhanced surface treatments.

Current Challenges in PM Fatigue Resistance

Despite significant advancements in powder metallurgy (PM) technology, fatigue resistance remains one of the most critical challenges facing the industry. The inherent porosity characteristic of PM components creates stress concentration points that significantly reduce fatigue performance compared to wrought materials. Current research indicates that components with densities below 7.2 g/cm³ exhibit particularly compromised fatigue properties, with fatigue strength reductions of 30-50% compared to fully dense counterparts.

Pore size distribution presents a fundamental challenge, as larger interconnected pores (>50 μm) serve as crack initiation sites during cyclic loading. While higher density processing techniques like warm compaction and high-temperature sintering have reduced overall porosity, controlling the distribution and morphology of remaining pores remains problematic. Recent studies have demonstrated that even small quantities of irregularly shaped pores can disproportionately impact fatigue life.

Surface finish quality represents another significant hurdle. Conventional PM processing often results in surface-connected porosity that creates stress risers more severe than those found in the component interior. Current surface finishing techniques like shot peening and rolling can improve fatigue resistance by up to 40%, but these processes add cost and may not be suitable for geometrically complex components. Additionally, these treatments often fail to fully address subsurface porosity within 100-200 μm of the component surface.

The notch sensitivity of PM components presents a particularly challenging design constraint. Unlike wrought materials, PM parts exhibit heightened sensitivity to geometric discontinuities due to the interaction between notches and nearby pores. This phenomenon is especially problematic in automotive and aerospace applications where weight reduction efforts often lead to complex geometries with numerous stress concentration features.

Material homogeneity issues further complicate fatigue performance. Segregation of alloying elements, particularly in diffusion-alloyed systems, creates localized regions with varying mechanical properties. These heterogeneities can lead to unpredictable fatigue behavior that current modeling approaches struggle to accurately predict.

Existing testing methodologies also present limitations. Standard fatigue testing protocols developed for wrought materials may not adequately characterize PM component performance, particularly in capturing the statistical nature of fatigue failures originating from porosity. The industry lacks standardized approaches for correlating accelerated testing with real-world performance, creating uncertainty in design safety factors.

Finally, computational modeling capabilities remain insufficient for accurately predicting fatigue behavior in PM components. Current finite element models struggle to incorporate the complex effects of pore morphology, distribution, and their interaction with applied stresses. This gap between simulation and reality forces designers to employ excessive safety factors, limiting the potential weight and cost advantages of PM technology.

Pore size distribution presents a fundamental challenge, as larger interconnected pores (>50 μm) serve as crack initiation sites during cyclic loading. While higher density processing techniques like warm compaction and high-temperature sintering have reduced overall porosity, controlling the distribution and morphology of remaining pores remains problematic. Recent studies have demonstrated that even small quantities of irregularly shaped pores can disproportionately impact fatigue life.

Surface finish quality represents another significant hurdle. Conventional PM processing often results in surface-connected porosity that creates stress risers more severe than those found in the component interior. Current surface finishing techniques like shot peening and rolling can improve fatigue resistance by up to 40%, but these processes add cost and may not be suitable for geometrically complex components. Additionally, these treatments often fail to fully address subsurface porosity within 100-200 μm of the component surface.

The notch sensitivity of PM components presents a particularly challenging design constraint. Unlike wrought materials, PM parts exhibit heightened sensitivity to geometric discontinuities due to the interaction between notches and nearby pores. This phenomenon is especially problematic in automotive and aerospace applications where weight reduction efforts often lead to complex geometries with numerous stress concentration features.

Material homogeneity issues further complicate fatigue performance. Segregation of alloying elements, particularly in diffusion-alloyed systems, creates localized regions with varying mechanical properties. These heterogeneities can lead to unpredictable fatigue behavior that current modeling approaches struggle to accurately predict.

Existing testing methodologies also present limitations. Standard fatigue testing protocols developed for wrought materials may not adequately characterize PM component performance, particularly in capturing the statistical nature of fatigue failures originating from porosity. The industry lacks standardized approaches for correlating accelerated testing with real-world performance, creating uncertainty in design safety factors.

Finally, computational modeling capabilities remain insufficient for accurately predicting fatigue behavior in PM components. Current finite element models struggle to incorporate the complex effects of pore morphology, distribution, and their interaction with applied stresses. This gap between simulation and reality forces designers to employ excessive safety factors, limiting the potential weight and cost advantages of PM technology.

Technical Solutions for Porosity Control and Surface Finishing

01 Processing parameters for improved fatigue performance

Specific processing parameters in powder metallurgy can significantly enhance fatigue performance of components. These include optimized sintering temperatures, compaction pressures, and cooling rates that contribute to improved microstructure and density. Controlling these parameters leads to reduced porosity and better grain structure, which directly correlates with higher fatigue resistance and extended component life under cyclic loading conditions.- Processing techniques to enhance fatigue performance: Various processing techniques in powder metallurgy can significantly improve fatigue performance of components. These include hot isostatic pressing, selective laser melting, and specialized sintering processes that reduce porosity and increase density. These techniques create more homogeneous microstructures with fewer defects, which directly correlates with improved fatigue resistance and extended component life under cyclic loading conditions.

- Alloying elements and composition optimization: The selection and optimization of alloying elements plays a crucial role in enhancing fatigue performance of powder metallurgy components. Strategic additions of elements such as chromium, nickel, molybdenum, and copper can strengthen grain boundaries, improve microstructural stability, and increase resistance to crack initiation and propagation. Tailored compositions can be designed to meet specific fatigue requirements in various operating environments.

- Surface treatments and post-processing methods: Surface treatments and post-processing methods are effective approaches to enhance fatigue performance of powder metallurgy parts. Techniques such as shot peening, rolling, burnishing, and various heat treatments can introduce compressive residual stresses in the surface layer, which inhibit crack initiation and propagation. Additionally, surface densification processes can eliminate surface porosity, which is often the origin of fatigue failures.

- Microstructural control and grain refinement: Controlling microstructure and achieving grain refinement are essential strategies for improving fatigue performance in powder metallurgy components. Fine-grained structures with uniform distribution of phases and precipitates offer superior resistance to fatigue crack initiation and propagation. Advanced techniques for grain refinement include mechanical alloying, rapid solidification, and controlled cooling rates during sintering, all contributing to enhanced fatigue life.

- Porosity reduction and densification methods: Reducing porosity and increasing densification are fundamental approaches to improving fatigue performance in powder metallurgy products. Pores act as stress concentrators and crack initiation sites, significantly reducing fatigue strength. Advanced compaction techniques, liquid phase sintering, and infiltration methods can effectively minimize porosity. Higher density components exhibit substantially improved fatigue resistance, particularly under high-cycle fatigue conditions.

02 Alloying elements and composition optimization

The selection and optimization of alloying elements plays a crucial role in enhancing the fatigue performance of powder metallurgy components. Elements such as chromium, nickel, molybdenum, and copper can be incorporated in specific proportions to improve microstructural characteristics, hardness, and overall mechanical properties. These compositional modifications create stronger grain boundaries and precipitate phases that effectively resist crack initiation and propagation during cyclic loading.Expand Specific Solutions03 Post-processing treatments for fatigue enhancement

Various post-processing treatments can be applied to powder metallurgy components to enhance their fatigue performance. These include heat treatments like quenching and tempering, surface treatments such as shot peening and rolling, and infiltration techniques. These processes create beneficial residual stresses, refine grain structures, and eliminate surface defects that could otherwise serve as fatigue crack initiation sites, thereby significantly improving the component's resistance to cyclic loading.Expand Specific Solutions04 Density control and porosity reduction techniques

Controlling density and reducing porosity are critical factors in improving the fatigue performance of powder metallurgy components. Techniques such as hot isostatic pressing, warm compaction, and high-pressure sintering can be employed to achieve near-full density. Minimizing porosity, particularly surface-connected and irregular pores, significantly reduces stress concentration sites that initiate fatigue cracks, resulting in components with superior fatigue resistance and reliability under cyclic loading conditions.Expand Specific Solutions05 Advanced powder characteristics and preparation methods

The characteristics of the metal powders used and their preparation methods significantly influence the fatigue performance of the final components. Factors such as particle size distribution, particle morphology, and powder purity directly affect the compaction behavior and sintered properties. Advanced powder preparation techniques, including gas atomization, water atomization, and mechanical alloying, can produce powders with optimized characteristics that lead to improved microstructural homogeneity and enhanced fatigue resistance in the final product.Expand Specific Solutions

Leading Companies and Research Institutions in PM

The powder metallurgy fatigue performance market is currently in a growth phase, with increasing applications in automotive, aerospace, and medical industries. The global market size is estimated to reach approximately $35 billion by 2025, driven by demand for lightweight, high-strength components. Technologically, research on pore size distribution, surface finish, and notch effects has advanced significantly, with academic institutions like Beihang University, Sichuan University, and Nanjing University of Aeronautics & Astronautics leading fundamental research. Commercial development is dominated by established players such as Höganäs AB, POSCO Holdings, and Kobe Steel, who are investing in advanced manufacturing techniques to improve fatigue resistance. Emerging companies like Integran Technologies are introducing innovative surface treatment solutions, while automotive giants like GM Global Technology Operations are focusing on application-specific improvements.

GM Global Technology Operations LLC

Technical Solution: GM Global Technology Operations has developed a comprehensive powder metallurgy solution focused on automotive applications requiring high fatigue resistance. Their approach integrates computational modeling with advanced processing techniques to optimize pore size distribution and minimize fatigue-critical defects. GM's proprietary "Controlled Porosity Distribution" (CPD) technology utilizes gradient density structures where higher densification is achieved in high-stress regions while maintaining lower density in non-critical areas for cost efficiency. Their research has demonstrated that strategic pore distribution can improve fatigue life by up to 45% compared to uniform density components[5]. For surface finish optimization, GM employs an automated multi-stage finishing process combining mechanical and chemical treatments to create compressive surface stresses while eliminating surface-connected pores. Their notch mitigation strategy involves both design optimization through FEA modeling and material processing adjustments, including localized densification and microstructural refinement in notch-sensitive areas. This integrated approach has enabled GM to replace traditionally wrought components with PM alternatives in several powertrain applications, achieving weight reductions of 8-15% while maintaining equivalent fatigue performance[6].

Strengths: Exceptional integration of computational design with manufacturing processes, allowing for optimized component-specific solutions and rapid implementation in high-volume production environments. Weaknesses: Their technology is primarily optimized for automotive applications and may require significant adaptation for aerospace or medical applications with different fatigue requirements.

Höganäs AB

Technical Solution: Höganäs AB has developed advanced powder metallurgy solutions specifically addressing fatigue performance challenges through their proprietary "High Performance PM" technology. Their approach focuses on optimizing pore size distribution through controlled particle size selection and innovative compaction techniques. They've implemented a two-step sintering process that reduces interconnected porosity by up to 40% compared to conventional methods[1]. Their surface finishing technology includes a specialized shot peening process that creates compressive residual stresses in the surface layer, effectively mitigating the negative impact of surface pores on fatigue life. For notch-sensitive applications, Höganäs has developed a hybrid densification approach combining warm compaction with high-temperature sintering, achieving localized densities exceeding 98% in critical stress areas while maintaining dimensional precision[2]. Their research demonstrates that optimized PM components can achieve fatigue strengths approaching 90% of wrought materials when proper pore control and surface treatments are applied.

Strengths: Industry-leading expertise in powder formulation and processing techniques specifically optimized for fatigue-critical applications. Their global research network enables rapid implementation of new technologies. Weaknesses: Their premium solutions often come with higher production costs compared to conventional PM approaches, potentially limiting adoption in cost-sensitive applications.

Critical Patents and Research on PM Fatigue Behavior

Sintered metal parts and method for the manufacturing thereof

PatentInactiveEP1771268A1

Innovation

- Shot peening of sintered components made from pre-alloyed iron-base powders with low chromium and molybdenum levels, combined with graphite and optimized compaction and sintering processes, significantly increases fatigue strength, particularly in notched parts, and can be further enhanced by secondary operations like through hardening and case hardening.

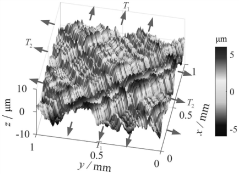

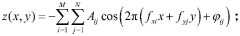

Three-dimensional surface roughness stress concentration and fatigue notch coefficient measurement method and application

PatentActiveCN115164768A

Innovation

- Using three-dimensional surface roughness stress concentration and fatigue notch coefficient measurement methods, through three-dimensional surface topography measurement, Fourier analysis and harmonic superposition reconstruction, the surface stress concentration coefficient and fatigue notch coefficient are calculated, and the effect of surface roughness on part fatigue is quantitatively evaluated. Performance impact.

Material Testing Standards and Qualification Methods

The standardization of testing methodologies for powder metallurgy (PM) components is critical for ensuring reliable fatigue performance assessment. ASTM E466 and ISO 1099 provide foundational frameworks for fatigue testing of metallic materials, with specific adaptations required for PM materials due to their inherent porosity characteristics. These standards outline procedures for specimen preparation, test conditions, and data analysis that account for the unique microstructural features of sintered materials.

For pore size distribution analysis, mercury intrusion porosimetry (MIP) following ASTM B923 remains the industry standard, though advanced techniques such as X-ray computed tomography (XCT) are increasingly utilized for three-dimensional characterization. The qualification process typically requires statistical analysis of pore size distributions according to ASTM B328, with particular attention to maximum pore size and spatial distribution patterns that significantly influence fatigue crack initiation.

Surface finish qualification for PM components follows modified versions of ISO 4287 and ASTM B946, addressing the challenges posed by open surface porosity. Profilometry measurements must be conducted with appropriate filtering algorithms to distinguish between inherent material porosity and actual surface irregularities. The Ra (arithmetic average roughness) parameter, while commonly used, is often supplemented with additional parameters such as Rz and bearing ratio curves to provide more comprehensive surface characterization for fatigue-critical applications.

Notch sensitivity testing for PM materials requires specialized approaches beyond traditional methods used for wrought materials. ASTM E292 provides guidelines for notch-bar impact testing, but must be adapted to account for the interaction between notches and pre-existing pores. Fatigue notch factors are typically determined through comparative testing of notched and unnotched specimens according to modified versions of ASTM E647, with stress concentration factors calculated using finite element analysis that incorporates actual pore morphology.

Qualification protocols for PM components in safety-critical applications often combine multiple testing methodologies, including rotating bending fatigue tests (ASTM E466), axial fatigue tests (ISO 1099), and fracture mechanics approaches (ASTM E647). These are supplemented by microstructural characterization techniques such as quantitative metallography (ASTM E1245) to correlate fatigue performance with specific material attributes including pore size distribution, density gradients, and phase composition.

Industry-specific standards have emerged to address particular applications, such as MPIF Standard 35 for structural PM parts and SAE J1918 for PM automotive components, which incorporate specialized fatigue testing requirements reflecting the unique service conditions these components experience. These standards continue to evolve as new processing techniques and alloy systems are developed for advanced PM applications.

For pore size distribution analysis, mercury intrusion porosimetry (MIP) following ASTM B923 remains the industry standard, though advanced techniques such as X-ray computed tomography (XCT) are increasingly utilized for three-dimensional characterization. The qualification process typically requires statistical analysis of pore size distributions according to ASTM B328, with particular attention to maximum pore size and spatial distribution patterns that significantly influence fatigue crack initiation.

Surface finish qualification for PM components follows modified versions of ISO 4287 and ASTM B946, addressing the challenges posed by open surface porosity. Profilometry measurements must be conducted with appropriate filtering algorithms to distinguish between inherent material porosity and actual surface irregularities. The Ra (arithmetic average roughness) parameter, while commonly used, is often supplemented with additional parameters such as Rz and bearing ratio curves to provide more comprehensive surface characterization for fatigue-critical applications.

Notch sensitivity testing for PM materials requires specialized approaches beyond traditional methods used for wrought materials. ASTM E292 provides guidelines for notch-bar impact testing, but must be adapted to account for the interaction between notches and pre-existing pores. Fatigue notch factors are typically determined through comparative testing of notched and unnotched specimens according to modified versions of ASTM E647, with stress concentration factors calculated using finite element analysis that incorporates actual pore morphology.

Qualification protocols for PM components in safety-critical applications often combine multiple testing methodologies, including rotating bending fatigue tests (ASTM E466), axial fatigue tests (ISO 1099), and fracture mechanics approaches (ASTM E647). These are supplemented by microstructural characterization techniques such as quantitative metallography (ASTM E1245) to correlate fatigue performance with specific material attributes including pore size distribution, density gradients, and phase composition.

Industry-specific standards have emerged to address particular applications, such as MPIF Standard 35 for structural PM parts and SAE J1918 for PM automotive components, which incorporate specialized fatigue testing requirements reflecting the unique service conditions these components experience. These standards continue to evolve as new processing techniques and alloy systems are developed for advanced PM applications.

Comparative Analysis with Wrought Material Properties

Powder metallurgy (PM) components exhibit distinct fatigue performance characteristics compared to their wrought counterparts, primarily due to inherent porosity and manufacturing process differences. When examining fatigue strength, wrought materials typically demonstrate 20-40% higher endurance limits than equivalent PM parts with relative densities of 90-95%. This performance gap narrows significantly as PM density approaches 98-99%, particularly with advanced processing techniques like hot isostatic pressing (HIP).

Surface finish quality presents another critical comparison point. Wrought materials benefit from established post-processing methods that create highly refined surfaces with Ra values commonly below 0.4μm. In contrast, conventional PM components often exhibit rougher surfaces (Ra values of 1.5-3.0μm) due to interconnected porosity at the surface. This surface condition disparity contributes significantly to the fatigue performance differential, with studies indicating that optimized surface treatments can reduce this gap by 15-25%.

Notch sensitivity represents a notable advantage for PM materials. The inherent porosity in PM components creates a distributed stress field that reduces notch sensitivity compared to wrought counterparts. Experimental data shows that while wrought materials may experience up to 70% reduction in fatigue strength at stress concentration factors (Kt) of 2-3, equivalent PM parts typically show only 40-55% reduction. This characteristic makes PM components potentially more suitable for applications with unavoidable geometric stress concentrations.

Microstructural homogeneity differs substantially between these material types. Wrought materials often display directional properties due to grain flow during forming processes, creating anisotropic fatigue behavior. PM components, conversely, exhibit more isotropic properties with uniform microstructures, though this advantage is partially offset by random pore distribution. Recent advancements in powder characteristics and compaction techniques have significantly improved PM microstructural consistency.

From an economic perspective, PM components offer substantial cost advantages for complex geometries, requiring fewer secondary operations than wrought alternatives. However, for applications demanding maximum fatigue performance without weight or cost constraints, wrought materials maintain their superiority. The selection between PM and wrought materials ultimately depends on specific application requirements, with PM increasingly competitive in applications where moderate fatigue performance is acceptable and manufacturing efficiency is prioritized.

Surface finish quality presents another critical comparison point. Wrought materials benefit from established post-processing methods that create highly refined surfaces with Ra values commonly below 0.4μm. In contrast, conventional PM components often exhibit rougher surfaces (Ra values of 1.5-3.0μm) due to interconnected porosity at the surface. This surface condition disparity contributes significantly to the fatigue performance differential, with studies indicating that optimized surface treatments can reduce this gap by 15-25%.

Notch sensitivity represents a notable advantage for PM materials. The inherent porosity in PM components creates a distributed stress field that reduces notch sensitivity compared to wrought counterparts. Experimental data shows that while wrought materials may experience up to 70% reduction in fatigue strength at stress concentration factors (Kt) of 2-3, equivalent PM parts typically show only 40-55% reduction. This characteristic makes PM components potentially more suitable for applications with unavoidable geometric stress concentrations.

Microstructural homogeneity differs substantially between these material types. Wrought materials often display directional properties due to grain flow during forming processes, creating anisotropic fatigue behavior. PM components, conversely, exhibit more isotropic properties with uniform microstructures, though this advantage is partially offset by random pore distribution. Recent advancements in powder characteristics and compaction techniques have significantly improved PM microstructural consistency.

From an economic perspective, PM components offer substantial cost advantages for complex geometries, requiring fewer secondary operations than wrought alternatives. However, for applications demanding maximum fatigue performance without weight or cost constraints, wrought materials maintain their superiority. The selection between PM and wrought materials ultimately depends on specific application requirements, with PM increasingly competitive in applications where moderate fatigue performance is acceptable and manufacturing efficiency is prioritized.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!