Powder Metallurgy Sustainability: Yield, Reuse And Energy Intensity Assessment

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Powder Metallurgy Evolution and Sustainability Goals

Powder metallurgy has evolved significantly since its inception in the early 20th century, transforming from a niche manufacturing process to a mainstream industrial technology. Initially developed for producing tungsten filaments for incandescent lamps, powder metallurgy has expanded to serve diverse industries including automotive, aerospace, medical, and electronics. This evolution has been characterized by continuous improvements in powder production methods, compaction techniques, and sintering processes.

The technological trajectory of powder metallurgy shows a clear trend toward higher precision, improved material properties, and increased production efficiency. Early developments focused on basic press-and-sinter techniques, while modern advancements include metal injection molding (MIM), hot isostatic pressing (HIP), and additive manufacturing approaches that utilize metal powders. These innovations have significantly expanded the application scope and capabilities of powder metallurgy processes.

In recent years, sustainability has emerged as a critical focus area in powder metallurgy development. The industry faces mounting pressure to reduce its environmental footprint while maintaining economic viability. This shift is driven by global sustainability initiatives, regulatory requirements, and increasing customer demand for environmentally responsible manufacturing processes.

The sustainability goals for powder metallurgy center around three key dimensions: improving material yield, enhancing powder reuse capabilities, and reducing energy intensity throughout the production cycle. Material yield optimization aims to minimize waste during processing, addressing the fact that traditional powder metallurgy operations can lose 10-30% of input materials as scrap. Developing more efficient compaction methods and near-net-shape technologies represents a significant opportunity to improve yield rates.

Powder reuse strategies focus on reclaiming and recycling metal powders that would otherwise be discarded. This includes developing advanced separation and reconditioning technologies to maintain powder quality through multiple use cycles. The challenge lies in ensuring that recycled powders maintain consistent particle size distribution, flowability, and chemical composition to meet stringent quality requirements.

Energy intensity reduction targets the substantial energy consumption in powder production, compaction, and especially sintering operations. Innovations in low-temperature sintering, microwave sintering, and spark plasma sintering offer promising pathways to reduce the energy footprint of powder metallurgy processes. Additionally, process optimization through digitalization and automation presents opportunities for significant energy savings.

The industry's long-term sustainability vision encompasses closed-loop manufacturing systems where material waste approaches zero, energy consumption is minimized, and carbon emissions are substantially reduced or offset. Achieving these ambitious goals requires coordinated efforts across the entire value chain, from powder producers to end-users.

The technological trajectory of powder metallurgy shows a clear trend toward higher precision, improved material properties, and increased production efficiency. Early developments focused on basic press-and-sinter techniques, while modern advancements include metal injection molding (MIM), hot isostatic pressing (HIP), and additive manufacturing approaches that utilize metal powders. These innovations have significantly expanded the application scope and capabilities of powder metallurgy processes.

In recent years, sustainability has emerged as a critical focus area in powder metallurgy development. The industry faces mounting pressure to reduce its environmental footprint while maintaining economic viability. This shift is driven by global sustainability initiatives, regulatory requirements, and increasing customer demand for environmentally responsible manufacturing processes.

The sustainability goals for powder metallurgy center around three key dimensions: improving material yield, enhancing powder reuse capabilities, and reducing energy intensity throughout the production cycle. Material yield optimization aims to minimize waste during processing, addressing the fact that traditional powder metallurgy operations can lose 10-30% of input materials as scrap. Developing more efficient compaction methods and near-net-shape technologies represents a significant opportunity to improve yield rates.

Powder reuse strategies focus on reclaiming and recycling metal powders that would otherwise be discarded. This includes developing advanced separation and reconditioning technologies to maintain powder quality through multiple use cycles. The challenge lies in ensuring that recycled powders maintain consistent particle size distribution, flowability, and chemical composition to meet stringent quality requirements.

Energy intensity reduction targets the substantial energy consumption in powder production, compaction, and especially sintering operations. Innovations in low-temperature sintering, microwave sintering, and spark plasma sintering offer promising pathways to reduce the energy footprint of powder metallurgy processes. Additionally, process optimization through digitalization and automation presents opportunities for significant energy savings.

The industry's long-term sustainability vision encompasses closed-loop manufacturing systems where material waste approaches zero, energy consumption is minimized, and carbon emissions are substantially reduced or offset. Achieving these ambitious goals requires coordinated efforts across the entire value chain, from powder producers to end-users.

Market Demand for Sustainable PM Manufacturing

The global market for sustainable powder metallurgy (PM) manufacturing has experienced significant growth in recent years, driven by increasing environmental regulations, corporate sustainability initiatives, and consumer demand for eco-friendly products. Industries such as automotive, aerospace, and industrial equipment manufacturing are actively seeking sustainable PM solutions to reduce their environmental footprint while maintaining product quality and performance.

Market research indicates that the sustainable PM manufacturing segment is growing at a compound annual growth rate of approximately 7-8%, outpacing the traditional PM market. This accelerated growth reflects the urgent need for resource-efficient manufacturing processes that minimize waste and energy consumption while maximizing material utilization.

The automotive sector represents the largest market for sustainable PM components, accounting for nearly 45% of the total demand. With stringent emission regulations and the shift toward electric vehicles, automotive manufacturers are prioritizing lightweight, high-performance components produced through sustainable manufacturing processes. The ability to reuse metal powders and reduce energy intensity in production aligns perfectly with the automotive industry's sustainability goals.

Aerospace and defense sectors are emerging as high-value markets for sustainable PM manufacturing, with particular emphasis on titanium and nickel-based superalloy components. These industries demand materials with exceptional performance characteristics while facing increasing pressure to reduce environmental impact and resource consumption throughout their supply chains.

Consumer electronics manufacturers are also driving demand for sustainable PM processes, particularly for small, complex components that require precise dimensional control and excellent surface finish. The ability to recover and reuse high-value metal powders is especially attractive in this sector, where materials like silver, gold, and rare earth elements are commonly used.

Regional analysis shows that Europe leads in adoption of sustainable PM practices, followed by North America and rapidly growing markets in Asia-Pacific. European manufacturers face the most stringent environmental regulations, creating strong incentives for implementing sustainable PM technologies. Meanwhile, China's industrial policy increasingly emphasizes resource efficiency and environmental protection, creating substantial growth opportunities in the world's largest manufacturing economy.

End-users are willing to pay premium prices for PM components manufactured using sustainable processes, with surveys indicating price tolerance of 10-15% above conventional manufacturing methods when clear environmental benefits can be demonstrated. This price premium is particularly evident in high-value applications where material performance and reliability are critical.

Market research indicates that the sustainable PM manufacturing segment is growing at a compound annual growth rate of approximately 7-8%, outpacing the traditional PM market. This accelerated growth reflects the urgent need for resource-efficient manufacturing processes that minimize waste and energy consumption while maximizing material utilization.

The automotive sector represents the largest market for sustainable PM components, accounting for nearly 45% of the total demand. With stringent emission regulations and the shift toward electric vehicles, automotive manufacturers are prioritizing lightweight, high-performance components produced through sustainable manufacturing processes. The ability to reuse metal powders and reduce energy intensity in production aligns perfectly with the automotive industry's sustainability goals.

Aerospace and defense sectors are emerging as high-value markets for sustainable PM manufacturing, with particular emphasis on titanium and nickel-based superalloy components. These industries demand materials with exceptional performance characteristics while facing increasing pressure to reduce environmental impact and resource consumption throughout their supply chains.

Consumer electronics manufacturers are also driving demand for sustainable PM processes, particularly for small, complex components that require precise dimensional control and excellent surface finish. The ability to recover and reuse high-value metal powders is especially attractive in this sector, where materials like silver, gold, and rare earth elements are commonly used.

Regional analysis shows that Europe leads in adoption of sustainable PM practices, followed by North America and rapidly growing markets in Asia-Pacific. European manufacturers face the most stringent environmental regulations, creating strong incentives for implementing sustainable PM technologies. Meanwhile, China's industrial policy increasingly emphasizes resource efficiency and environmental protection, creating substantial growth opportunities in the world's largest manufacturing economy.

End-users are willing to pay premium prices for PM components manufactured using sustainable processes, with surveys indicating price tolerance of 10-15% above conventional manufacturing methods when clear environmental benefits can be demonstrated. This price premium is particularly evident in high-value applications where material performance and reliability are critical.

Current Challenges in PM Yield and Energy Efficiency

Powder metallurgy (PM) faces significant challenges in achieving optimal yield and energy efficiency, which directly impact its sustainability profile. Current manufacturing processes exhibit material losses ranging from 5-15% depending on the complexity of parts and production methods employed. These losses occur at various stages including powder handling, compaction, sintering, and finishing operations, with the highest waste generation typically observed during machining and finishing steps.

Energy consumption remains a critical concern across the PM value chain. Conventional sintering processes operate at temperatures between 1100-1400°C, consuming approximately 4-7 kWh/kg of processed material. This energy intensity is particularly problematic as most facilities still rely heavily on fossil fuel-based energy sources, contributing significantly to the industry's carbon footprint. The energy efficiency of atomization processes—a key step in powder production—typically ranges from 25-40%, indicating substantial room for improvement.

Water usage presents another sustainability challenge, particularly in water-based atomization processes which require 8-12 cubic meters of water per ton of powder produced. While closed-loop systems have been implemented in modern facilities, many older operations still utilize open systems with higher consumption rates and contamination risks.

Reuse capabilities for PM waste streams vary considerably by material type and process stage. Metal powders contaminated during handling can often be reclaimed at rates of 60-80%, while mixed metal wastes from machining operations typically achieve only 30-50% recovery rates. The economic viability of reclamation is heavily dependent on material value, with precious metal powders justifying more extensive recovery efforts than commodity materials.

Quality consistency in recycled powders remains problematic, with variations in particle size distribution, flowability, and chemical composition limiting their use in high-precision applications. This often relegates recycled materials to less demanding applications, creating a downcycling effect rather than true circular material flows.

Regulatory pressures are intensifying globally, with the EU's Circular Economy Action Plan and similar initiatives in North America and Asia imposing stricter requirements on waste reduction and energy efficiency. These regulations are expected to tighten further, potentially imposing carbon pricing mechanisms that would significantly impact production economics for energy-intensive PM operations.

Industry benchmarking reveals substantial performance gaps between average facilities and best-in-class operations, with leading manufacturers achieving 30-40% higher material yields and 25-35% lower energy consumption than industry averages. This disparity highlights both the challenges faced by the sector and the significant improvement potential through adoption of optimized processes and technologies.

Energy consumption remains a critical concern across the PM value chain. Conventional sintering processes operate at temperatures between 1100-1400°C, consuming approximately 4-7 kWh/kg of processed material. This energy intensity is particularly problematic as most facilities still rely heavily on fossil fuel-based energy sources, contributing significantly to the industry's carbon footprint. The energy efficiency of atomization processes—a key step in powder production—typically ranges from 25-40%, indicating substantial room for improvement.

Water usage presents another sustainability challenge, particularly in water-based atomization processes which require 8-12 cubic meters of water per ton of powder produced. While closed-loop systems have been implemented in modern facilities, many older operations still utilize open systems with higher consumption rates and contamination risks.

Reuse capabilities for PM waste streams vary considerably by material type and process stage. Metal powders contaminated during handling can often be reclaimed at rates of 60-80%, while mixed metal wastes from machining operations typically achieve only 30-50% recovery rates. The economic viability of reclamation is heavily dependent on material value, with precious metal powders justifying more extensive recovery efforts than commodity materials.

Quality consistency in recycled powders remains problematic, with variations in particle size distribution, flowability, and chemical composition limiting their use in high-precision applications. This often relegates recycled materials to less demanding applications, creating a downcycling effect rather than true circular material flows.

Regulatory pressures are intensifying globally, with the EU's Circular Economy Action Plan and similar initiatives in North America and Asia imposing stricter requirements on waste reduction and energy efficiency. These regulations are expected to tighten further, potentially imposing carbon pricing mechanisms that would significantly impact production economics for energy-intensive PM operations.

Industry benchmarking reveals substantial performance gaps between average facilities and best-in-class operations, with leading manufacturers achieving 30-40% higher material yields and 25-35% lower energy consumption than industry averages. This disparity highlights both the challenges faced by the sector and the significant improvement potential through adoption of optimized processes and technologies.

Existing Methodologies for PM Material Reuse and Recovery

01 Material recovery and recycling in powder metallurgy

Powder metallurgy processes can be optimized for material recovery and recycling, which significantly improves yield and reduces waste. Techniques include collecting and reprocessing metal powders from production scrap, implementing closed-loop recycling systems, and developing methods to reclaim materials from sintered parts. These approaches not only increase resource efficiency but also reduce the environmental impact of powder metallurgy operations by minimizing the need for virgin raw materials.- Material yield optimization in powder metallurgy processes: Various techniques can be employed to optimize material yield in powder metallurgy processes. These include precise control of powder composition, particle size distribution, and compaction parameters. Advanced methods for powder preparation and handling minimize material loss during processing stages. Optimized sintering profiles and post-processing techniques further enhance material utilization, resulting in higher yields and reduced waste in powder metallurgy manufacturing.

- Recycling and reuse of metal powders: Metal powders can be recycled and reused in powder metallurgy processes through various methods. Techniques include collection systems for unused powders, separation of contaminants, and reconditioning treatments to restore powder properties. Specialized equipment enables the recovery of powders from production waste streams, while quality control measures ensure recycled powders meet specifications. These approaches significantly reduce raw material consumption and waste generation in powder metallurgy operations.

- Energy efficiency improvements in powder metallurgy: Energy intensity in powder metallurgy can be reduced through various technological innovations. These include optimized furnace designs with improved insulation and heat recovery systems, precise temperature control algorithms, and reduced sintering times. Alternative energy sources and hybrid heating methods combine conventional and advanced heating technologies. Process integration strategies minimize energy consumption across the production chain, resulting in significant reductions in overall energy requirements.

- Advanced compaction and sintering technologies: Advanced compaction and sintering technologies enhance material utilization and energy efficiency in powder metallurgy. These include high-pressure compaction methods, warm compaction techniques, and controlled atmosphere sintering. Rapid sintering technologies reduce energy consumption while maintaining or improving product quality. Computer-controlled processes optimize parameters in real-time, minimizing material waste and energy use while producing components with superior mechanical properties.

- Sustainable powder production methods: Sustainable powder production methods focus on reducing environmental impact while maintaining economic viability. These include water atomization techniques with closed-loop water systems, gas atomization with inert gas recovery, and mechanical alloying with energy-efficient equipment. Alternative raw material sources such as recycled metals and industrial by-products can be utilized. Process optimization reduces energy consumption and emissions during powder production, contributing to overall sustainability of powder metallurgy.

02 Energy-efficient sintering technologies

Advanced sintering technologies have been developed to reduce energy consumption in powder metallurgy processes. These include microwave sintering, spark plasma sintering, and optimized conventional sintering cycles. By reducing sintering temperatures and times while maintaining or improving product quality, these technologies significantly decrease the energy intensity of powder metallurgy operations. Additionally, heat recovery systems can be implemented to capture and reuse thermal energy from the sintering process.Expand Specific Solutions03 Process optimization for yield improvement

Various process optimizations can substantially improve yield in powder metallurgy operations. These include precise control of powder characteristics, optimized compaction parameters, improved die design, and enhanced lubricant systems. Computer modeling and simulation tools help predict and prevent defects, while real-time monitoring systems enable immediate adjustments to process parameters. These approaches minimize material waste, reduce rejection rates, and increase overall production efficiency.Expand Specific Solutions04 Alternative binding and consolidation methods

Novel binding and consolidation methods offer improvements in yield and energy efficiency compared to traditional powder metallurgy approaches. These include binder jetting, metal injection molding with eco-friendly binders, cold isostatic pressing, and various pressure-assisted techniques. By reducing the need for high-temperature processing or enabling near-net-shape production, these methods minimize material waste and energy consumption while maintaining or improving the mechanical properties of the final products.Expand Specific Solutions05 Waste heat utilization and energy management systems

Implementing comprehensive energy management systems and waste heat utilization techniques can significantly reduce the energy intensity of powder metallurgy operations. These include heat exchangers to recover thermal energy from furnaces, cogeneration systems, optimized furnace loading patterns, and intelligent control systems that minimize idle time and energy consumption during non-productive periods. Additionally, integration with renewable energy sources can further reduce the carbon footprint of powder metallurgy processes.Expand Specific Solutions

Leading Companies and Research Institutions in Sustainable PM

Powder metallurgy sustainability is currently in a growth phase, with the global market expected to reach significant expansion due to increasing demand for sustainable manufacturing processes. The technology maturity varies across applications, with companies like JFE Steel, Kobe Steel, and thyssenkrupp Steel Europe leading in advanced sustainable powder metallurgy processes. Emerging players such as Ningbo Haishu Gulin Xinmu and Qiyang Huarui are developing innovative approaches to yield improvement and energy reduction. Research institutions including University of Science & Technology Beijing and Korea Advanced Institute of Science & Technology are advancing fundamental knowledge in reuse technologies. The industry is transitioning toward more sustainable practices with companies like Tenneco and Caterpillar implementing energy intensity assessment methodologies to reduce environmental impact while maintaining product quality.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed an innovative powder metallurgy sustainability framework called "KOBELCO Green PM" that addresses yield optimization, material reuse, and energy efficiency through multiple integrated technologies. Their water atomization process has been redesigned with optimized nozzle configurations and pressure control systems, improving powder yield by approximately 15% while reducing energy consumption by 20% compared to conventional systems. Kobe's proprietary powder recovery system utilizes cyclonic separation combined with electrostatic precipitation, achieving recovery rates exceeding 99% for fine particles that would typically be lost. The company has implemented a comprehensive powder recycling program that includes specialized treatment processes for contaminated powders, allowing them to be blended back into production streams at controlled ratios without compromising final product quality. Their sintering optimization technology uses variable frequency induction heating with precise temperature control zones, reducing energy consumption by approximately 25% while maintaining or improving material properties. Additionally, Kobe Steel has developed an integrated digital monitoring system that tracks material flow and energy consumption throughout the production process, enabling real-time optimization of process parameters to maximize yield and minimize energy intensity.

Strengths: Highly efficient water atomization technology with significant yield improvements; exceptional powder recovery rates (>99%); advanced recycling capabilities for contaminated materials; optimized sintering technology with substantial energy savings. Weaknesses: Complex implementation requiring significant process modifications; higher initial investment costs; requires specialized technical expertise for optimal operation and maintenance.

Köppern Entwicklungs GmbH

Technical Solution: Köppern has developed advanced High Pressure Grinding Rolls (HPGR) technology specifically optimized for powder metallurgy applications, focusing on sustainability through energy efficiency and material yield improvements. Their process reduces energy consumption by up to 30% compared to conventional grinding methods by applying controlled pressure between two counter-rotating rolls. This creates micro-cracks along grain boundaries rather than pulverizing materials, resulting in significantly lower energy requirements. Köppern's closed-loop system captures and reuses metal powders that would otherwise be lost during processing, achieving material recovery rates exceeding 98%. Their technology incorporates real-time monitoring systems that adjust pressure parameters based on feed characteristics, ensuring consistent particle size distribution while minimizing energy inputs. Additionally, Köppern has implemented heat recovery systems that capture thermal energy generated during compression for reuse in preheating incoming materials, further reducing the overall energy footprint of powder metallurgy operations.

Strengths: Superior energy efficiency with 30% reduction compared to conventional methods; excellent material recovery rates (>98%); advanced process control systems for optimized yield; integrated heat recovery systems. Weaknesses: Higher initial capital investment compared to traditional equipment; requires specialized technical expertise for optimal operation; system optimization can be complex for varying material types.

Key Innovations in Energy-Efficient PM Technologies

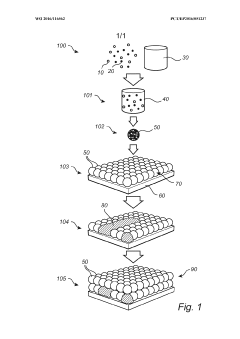

Method for additive manufacturing comprising freeze granulation allowing for flexible alloy design

PatentWO2016116562A1

Innovation

- A method for additive manufacturing that involves mixing particles of different elements with a liquid medium to form a suspension, subjecting it to freeze granulation to create granules of a target alloy composition, and locally synthesizing the alloy on a solid substrate by melting and solidifying these granules, allowing for the production of alloys with any composition and improved homogeneity.

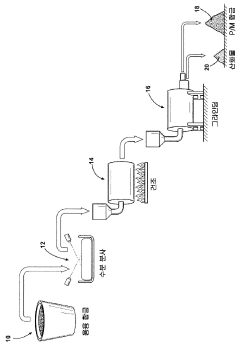

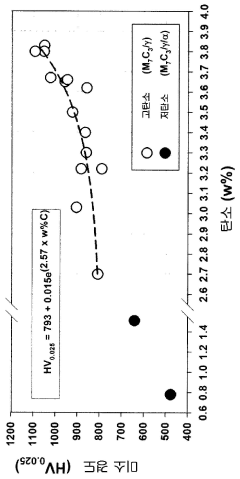

Powder metal compositions for wear and temperature resistance applications and method of producing same

PatentInactiveKR1020150132856A

Innovation

- A method involving a high-carbon, low-oxygen iron-based alloy is atomized using gas injection, followed by mechanical grinding to remove oxide skins, eliminating the need for additional annealing and allowing direct formation of carbides during sintering.

Life Cycle Assessment Frameworks for PM Processes

Life Cycle Assessment (LCA) frameworks provide a systematic approach to evaluate the environmental impacts of powder metallurgy (PM) processes throughout their entire lifecycle. These frameworks typically follow ISO 14040 and 14044 standards, which outline four main phases: goal and scope definition, inventory analysis, impact assessment, and interpretation.

For PM processes, specialized LCA frameworks have been developed to address the unique characteristics of metal powder production, forming, sintering, and post-processing operations. These frameworks incorporate specific metrics for material yield, energy consumption, and waste generation that are particularly relevant to PM manufacturing.

The System Boundary definition is crucial in PM process assessment, as it determines whether the analysis follows a "cradle-to-gate," "gate-to-gate," or "cradle-to-grave" approach. Most PM-focused LCAs adopt a cradle-to-gate perspective, covering raw material extraction through manufacturing but excluding use and end-of-life phases.

Functional Unit selection presents unique challenges in PM assessments due to the diversity of part geometries and applications. Common functional units include per kilogram of finished product, per component, or per functional performance metric (e.g., mechanical strength per unit weight).

Inventory data collection for PM processes requires detailed documentation of material inputs (virgin powders, binders, lubricants), energy consumption across different process steps (atomization, compaction, sintering), and waste streams (rejected parts, captured overspray, filtered particulates). Industry-specific databases like the PM Life Cycle Inventory Database provide standardized datasets for common PM operations.

Impact assessment methodologies for PM processes typically focus on energy intensity, resource depletion, global warming potential, and particulate emissions. The ReCiPe and CML methods are frequently applied due to their comprehensive coverage of impact categories relevant to metal processing.

Comparative frameworks enable benchmarking PM processes against conventional manufacturing methods like casting or machining. These frameworks highlight PM's advantages in material utilization and near-net-shape capabilities, while also identifying areas where energy intensity during sintering may present environmental challenges.

Recent advancements in PM-specific LCA frameworks include the integration of circular economy principles, emphasizing powder reuse pathways and closed-loop material recovery systems. These frameworks provide quantitative methods to assess the sustainability benefits of powder recycling and the environmental trade-offs associated with additional processing steps required for powder reconditioning.

For PM processes, specialized LCA frameworks have been developed to address the unique characteristics of metal powder production, forming, sintering, and post-processing operations. These frameworks incorporate specific metrics for material yield, energy consumption, and waste generation that are particularly relevant to PM manufacturing.

The System Boundary definition is crucial in PM process assessment, as it determines whether the analysis follows a "cradle-to-gate," "gate-to-gate," or "cradle-to-grave" approach. Most PM-focused LCAs adopt a cradle-to-gate perspective, covering raw material extraction through manufacturing but excluding use and end-of-life phases.

Functional Unit selection presents unique challenges in PM assessments due to the diversity of part geometries and applications. Common functional units include per kilogram of finished product, per component, or per functional performance metric (e.g., mechanical strength per unit weight).

Inventory data collection for PM processes requires detailed documentation of material inputs (virgin powders, binders, lubricants), energy consumption across different process steps (atomization, compaction, sintering), and waste streams (rejected parts, captured overspray, filtered particulates). Industry-specific databases like the PM Life Cycle Inventory Database provide standardized datasets for common PM operations.

Impact assessment methodologies for PM processes typically focus on energy intensity, resource depletion, global warming potential, and particulate emissions. The ReCiPe and CML methods are frequently applied due to their comprehensive coverage of impact categories relevant to metal processing.

Comparative frameworks enable benchmarking PM processes against conventional manufacturing methods like casting or machining. These frameworks highlight PM's advantages in material utilization and near-net-shape capabilities, while also identifying areas where energy intensity during sintering may present environmental challenges.

Recent advancements in PM-specific LCA frameworks include the integration of circular economy principles, emphasizing powder reuse pathways and closed-loop material recovery systems. These frameworks provide quantitative methods to assess the sustainability benefits of powder recycling and the environmental trade-offs associated with additional processing steps required for powder reconditioning.

Regulatory Standards and Green Certification for PM Products

The regulatory landscape for powder metallurgy (PM) is evolving rapidly as sustainability becomes a central focus across manufacturing industries. ISO 14001 Environmental Management Systems certification has become increasingly important for PM manufacturers, providing a framework for measuring and improving environmental performance. Companies achieving this certification demonstrate commitment to reducing environmental impacts while potentially gaining competitive advantages in global markets.

The EU's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations significantly impact PM operations, particularly regarding the use of cobalt, nickel, and other potentially hazardous materials. Compliance with these regulations requires comprehensive documentation and sometimes reformulation of PM materials, driving innovation in less toxic alternatives.

Energy efficiency certifications such as ISO 50001 are gaining prominence as energy intensity becomes a key sustainability metric in PM processes. Manufacturers who achieve these certifications can demonstrate quantifiable reductions in energy consumption per unit of production, addressing both environmental concerns and operational costs. The certification process typically involves establishing energy baselines, identifying improvement opportunities, and implementing systematic energy management practices.

Carbon footprint labeling schemes are emerging as voluntary but increasingly expected market differentiators. Several PM industry leaders have adopted Product Environmental Footprint (PEF) methodologies to quantify and communicate the lifecycle environmental impacts of their products. These certifications require rigorous life cycle assessment (LCA) studies that account for raw material extraction, processing, use phase, and end-of-life considerations.

Circular economy certifications represent the newest frontier in PM sustainability standards. The Cradle to Cradle Certified™ Product Standard evaluates products across five sustainability categories including material health and reutilization. For PM manufacturers, achieving these certifications requires demonstrating closed-loop systems for metal powder recovery and reuse, with documented yield improvements and waste reduction metrics.

Regional variations in green certification requirements present challenges for global PM operations. While European standards tend to be the most stringent, emerging markets are rapidly developing their own certification frameworks, sometimes with conflicting requirements. Forward-thinking PM manufacturers are adopting harmonized approaches that satisfy the most comprehensive standards globally, rather than managing compliance on a region-by-region basis.

The EU's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations significantly impact PM operations, particularly regarding the use of cobalt, nickel, and other potentially hazardous materials. Compliance with these regulations requires comprehensive documentation and sometimes reformulation of PM materials, driving innovation in less toxic alternatives.

Energy efficiency certifications such as ISO 50001 are gaining prominence as energy intensity becomes a key sustainability metric in PM processes. Manufacturers who achieve these certifications can demonstrate quantifiable reductions in energy consumption per unit of production, addressing both environmental concerns and operational costs. The certification process typically involves establishing energy baselines, identifying improvement opportunities, and implementing systematic energy management practices.

Carbon footprint labeling schemes are emerging as voluntary but increasingly expected market differentiators. Several PM industry leaders have adopted Product Environmental Footprint (PEF) methodologies to quantify and communicate the lifecycle environmental impacts of their products. These certifications require rigorous life cycle assessment (LCA) studies that account for raw material extraction, processing, use phase, and end-of-life considerations.

Circular economy certifications represent the newest frontier in PM sustainability standards. The Cradle to Cradle Certified™ Product Standard evaluates products across five sustainability categories including material health and reutilization. For PM manufacturers, achieving these certifications requires demonstrating closed-loop systems for metal powder recovery and reuse, with documented yield improvements and waste reduction metrics.

Regional variations in green certification requirements present challenges for global PM operations. While European standards tend to be the most stringent, emerging markets are rapidly developing their own certification frameworks, sometimes with conflicting requirements. Forward-thinking PM manufacturers are adopting harmonized approaches that satisfy the most comprehensive standards globally, rather than managing compliance on a region-by-region basis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!