Powder Metallurgy Titanium: Oxygen/Nitrogen Control, Alpha-Case And Mechanical Robustness

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PM Titanium Background and Objectives

Powder Metallurgy (PM) titanium has emerged as a transformative manufacturing approach in the aerospace, automotive, and biomedical industries over the past five decades. The evolution of PM titanium technology began in the 1970s with rudimentary powder production methods and has since advanced significantly through innovations in powder atomization, compaction techniques, and sintering processes. This manufacturing route offers substantial advantages over conventional titanium processing, including near-net-shape capabilities, reduced material waste, and potential cost savings of 30-50% compared to traditional wrought processing.

The global titanium market, valued at approximately $24 billion in 2022, is projected to grow at a CAGR of 3.2% through 2030, with PM titanium representing an increasingly important segment. This growth is driven by expanding applications in lightweight structures, corrosion-resistant components, and biocompatible medical implants, where the unique properties of titanium are essential.

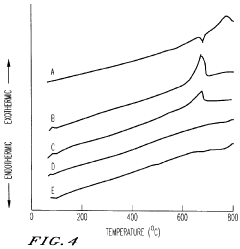

Despite its promise, PM titanium faces critical challenges related to interstitial element contamination. Oxygen and nitrogen, which titanium readily absorbs during powder processing and sintering, significantly impact mechanical properties. Even small increases in oxygen content (from 0.1 to 0.3 wt%) can double the yield strength while reducing ductility by up to 50%. This delicate balance between strength and ductility represents a fundamental challenge in PM titanium development.

Alpha-case formation—a hard, oxygen-enriched surface layer—presents another significant obstacle. This brittle layer can initiate cracks under mechanical loading, compromising component integrity. Current mitigation strategies include protective atmospheres, chemical milling, and modified sintering protocols, though each carries technical and economic tradeoffs.

The primary objective of current PM titanium research is to develop robust processing methodologies that enable precise control of oxygen and nitrogen levels throughout the manufacturing chain. This includes innovations in powder handling, compaction techniques, and sintering environments that minimize contamination while maintaining economic viability. Secondary objectives focus on alpha-case prevention strategies and post-processing techniques to enhance mechanical robustness.

Recent technological breakthroughs, including field-assisted sintering technology (FAST), metal injection molding (MIM) adaptations for titanium, and advanced powder characterization methods, have accelerated progress toward these goals. These innovations aim to position PM titanium as a mainstream manufacturing route capable of delivering components with performance comparable to wrought titanium but at significantly reduced costs and with greater design flexibility.

The global titanium market, valued at approximately $24 billion in 2022, is projected to grow at a CAGR of 3.2% through 2030, with PM titanium representing an increasingly important segment. This growth is driven by expanding applications in lightweight structures, corrosion-resistant components, and biocompatible medical implants, where the unique properties of titanium are essential.

Despite its promise, PM titanium faces critical challenges related to interstitial element contamination. Oxygen and nitrogen, which titanium readily absorbs during powder processing and sintering, significantly impact mechanical properties. Even small increases in oxygen content (from 0.1 to 0.3 wt%) can double the yield strength while reducing ductility by up to 50%. This delicate balance between strength and ductility represents a fundamental challenge in PM titanium development.

Alpha-case formation—a hard, oxygen-enriched surface layer—presents another significant obstacle. This brittle layer can initiate cracks under mechanical loading, compromising component integrity. Current mitigation strategies include protective atmospheres, chemical milling, and modified sintering protocols, though each carries technical and economic tradeoffs.

The primary objective of current PM titanium research is to develop robust processing methodologies that enable precise control of oxygen and nitrogen levels throughout the manufacturing chain. This includes innovations in powder handling, compaction techniques, and sintering environments that minimize contamination while maintaining economic viability. Secondary objectives focus on alpha-case prevention strategies and post-processing techniques to enhance mechanical robustness.

Recent technological breakthroughs, including field-assisted sintering technology (FAST), metal injection molding (MIM) adaptations for titanium, and advanced powder characterization methods, have accelerated progress toward these goals. These innovations aim to position PM titanium as a mainstream manufacturing route capable of delivering components with performance comparable to wrought titanium but at significantly reduced costs and with greater design flexibility.

Market Analysis for PM Titanium Applications

The global market for powder metallurgy (PM) titanium applications continues to expand significantly, driven by increasing demand across aerospace, automotive, medical, and industrial sectors. The market value for PM titanium components reached approximately $2.1 billion in 2022 and is projected to grow at a compound annual growth rate of 8.7% through 2030, according to industry analyses.

Aerospace remains the dominant application sector, accounting for nearly 45% of the PM titanium market. The industry's push for lightweight, high-strength components with complex geometries has accelerated adoption, particularly in non-critical structural components and engine parts. Boeing and Airbus have both increased their utilization of PM titanium parts by over 30% in their newest aircraft models.

The medical implant sector represents the fastest-growing application area, with a growth rate exceeding 12% annually. PM titanium's biocompatibility, coupled with the ability to create porous structures that promote osseointegration, has revolutionized implant design. Dental implants, orthopedic prostheses, and cranial implants are leading this growth segment.

Automotive applications are gaining momentum as manufacturers seek weight reduction solutions to improve fuel efficiency and meet emissions standards. High-end and performance vehicles have begun incorporating PM titanium components in valve trains, connecting rods, and suspension systems. While currently representing only about 15% of the market, this sector shows significant growth potential as production costs decrease.

Industrial applications, including chemical processing equipment, heat exchangers, and specialized tooling, constitute approximately 20% of the market. The corrosion resistance and high-temperature stability of titanium make these components particularly valuable in aggressive operating environments.

Regional analysis reveals North America and Europe as the largest markets, collectively accounting for over 60% of global consumption. However, the Asia-Pacific region, particularly China and Japan, demonstrates the highest growth rates, driven by expanding aerospace and medical industries coupled with significant government investments in advanced manufacturing capabilities.

Market challenges primarily revolve around production costs and quality control issues related to oxygen and nitrogen contamination. The industry has identified that reducing production costs by 25-30% would significantly accelerate adoption in price-sensitive sectors like automotive and consumer goods. Recent technological advancements in oxygen/nitrogen control during processing have begun addressing these challenges, potentially opening new market segments previously constrained by cost barriers.

Aerospace remains the dominant application sector, accounting for nearly 45% of the PM titanium market. The industry's push for lightweight, high-strength components with complex geometries has accelerated adoption, particularly in non-critical structural components and engine parts. Boeing and Airbus have both increased their utilization of PM titanium parts by over 30% in their newest aircraft models.

The medical implant sector represents the fastest-growing application area, with a growth rate exceeding 12% annually. PM titanium's biocompatibility, coupled with the ability to create porous structures that promote osseointegration, has revolutionized implant design. Dental implants, orthopedic prostheses, and cranial implants are leading this growth segment.

Automotive applications are gaining momentum as manufacturers seek weight reduction solutions to improve fuel efficiency and meet emissions standards. High-end and performance vehicles have begun incorporating PM titanium components in valve trains, connecting rods, and suspension systems. While currently representing only about 15% of the market, this sector shows significant growth potential as production costs decrease.

Industrial applications, including chemical processing equipment, heat exchangers, and specialized tooling, constitute approximately 20% of the market. The corrosion resistance and high-temperature stability of titanium make these components particularly valuable in aggressive operating environments.

Regional analysis reveals North America and Europe as the largest markets, collectively accounting for over 60% of global consumption. However, the Asia-Pacific region, particularly China and Japan, demonstrates the highest growth rates, driven by expanding aerospace and medical industries coupled with significant government investments in advanced manufacturing capabilities.

Market challenges primarily revolve around production costs and quality control issues related to oxygen and nitrogen contamination. The industry has identified that reducing production costs by 25-30% would significantly accelerate adoption in price-sensitive sectors like automotive and consumer goods. Recent technological advancements in oxygen/nitrogen control during processing have begun addressing these challenges, potentially opening new market segments previously constrained by cost barriers.

Current Challenges in O/N Control for PM Titanium

Oxygen and nitrogen contamination represents one of the most significant challenges in powder metallurgy (PM) titanium processing. The high affinity of titanium for these interstitial elements creates a persistent technical barrier that impacts both production efficiency and final product quality. Current PM titanium production methods struggle with oxygen content typically ranging from 0.15-0.30 wt% and nitrogen levels between 0.03-0.08 wt%, which exceed the optimal thresholds for aerospace and medical applications.

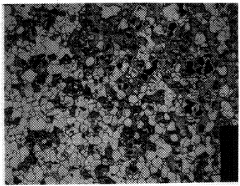

The primary contamination pathways occur during multiple processing stages. Raw powder production introduces initial contamination, with hydride-dehydride (HDH) powders typically containing higher oxygen levels than gas atomized (GA) powders. During powder handling and storage, even brief exposure to atmospheric conditions can significantly increase interstitial content due to titanium's reactive surface. The compaction and sintering stages further exacerbate this issue, as elevated temperatures accelerate diffusion rates of oxygen and nitrogen.

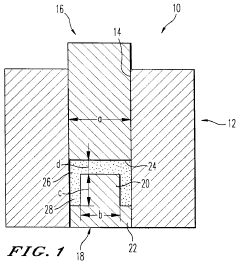

Conventional approaches to mitigate these challenges include vacuum processing and inert gas environments, but these solutions face practical limitations. Vacuum systems require substantial capital investment and maintenance, while even high-purity inert gases (99.999%) contain trace oxygen and nitrogen that accumulate during extended processing cycles. The economic viability of ultra-high purity processing environments remains questionable for mass production scenarios.

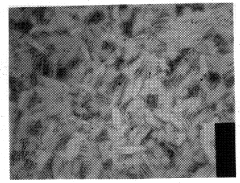

Alpha-case formation presents another critical challenge, manifesting as a hard, brittle surface layer enriched with oxygen and nitrogen. This layer significantly compromises mechanical properties, particularly fatigue resistance and ductility. Current removal methods such as chemical milling and mechanical machining add production steps and material waste, reducing overall process efficiency and increasing costs.

The detection and quantification of interstitial elements pose additional technical difficulties. While inert gas fusion and combustion analysis provide accurate bulk measurements, they cannot identify localized concentration gradients or alpha-case depth without destructive testing. Non-destructive evaluation methods for interstitial contamination remain underdeveloped, limiting in-process quality control capabilities.

Industry standards for acceptable interstitial levels vary significantly across applications, creating confusion in material specification and qualification. The aerospace sector typically requires oxygen below 0.15 wt% and nitrogen below 0.03 wt%, while medical implant standards may permit slightly higher levels but demand exceptional consistency. This variability complicates supply chain management and quality assurance protocols for PM titanium producers serving multiple markets.

The primary contamination pathways occur during multiple processing stages. Raw powder production introduces initial contamination, with hydride-dehydride (HDH) powders typically containing higher oxygen levels than gas atomized (GA) powders. During powder handling and storage, even brief exposure to atmospheric conditions can significantly increase interstitial content due to titanium's reactive surface. The compaction and sintering stages further exacerbate this issue, as elevated temperatures accelerate diffusion rates of oxygen and nitrogen.

Conventional approaches to mitigate these challenges include vacuum processing and inert gas environments, but these solutions face practical limitations. Vacuum systems require substantial capital investment and maintenance, while even high-purity inert gases (99.999%) contain trace oxygen and nitrogen that accumulate during extended processing cycles. The economic viability of ultra-high purity processing environments remains questionable for mass production scenarios.

Alpha-case formation presents another critical challenge, manifesting as a hard, brittle surface layer enriched with oxygen and nitrogen. This layer significantly compromises mechanical properties, particularly fatigue resistance and ductility. Current removal methods such as chemical milling and mechanical machining add production steps and material waste, reducing overall process efficiency and increasing costs.

The detection and quantification of interstitial elements pose additional technical difficulties. While inert gas fusion and combustion analysis provide accurate bulk measurements, they cannot identify localized concentration gradients or alpha-case depth without destructive testing. Non-destructive evaluation methods for interstitial contamination remain underdeveloped, limiting in-process quality control capabilities.

Industry standards for acceptable interstitial levels vary significantly across applications, creating confusion in material specification and qualification. The aerospace sector typically requires oxygen below 0.15 wt% and nitrogen below 0.03 wt%, while medical implant standards may permit slightly higher levels but demand exceptional consistency. This variability complicates supply chain management and quality assurance protocols for PM titanium producers serving multiple markets.

Current O/N Control Methodologies

01 Alloying elements and composition optimization

The mechanical robustness of powder metallurgy titanium can be significantly enhanced through careful selection and optimization of alloying elements. Various elements such as aluminum, vanadium, molybdenum, and iron are added in specific proportions to create titanium alloys with superior strength, ductility, and fatigue resistance. The composition optimization involves precise control of element ratios to achieve desired mechanical properties while maintaining processability through powder metallurgy techniques.- Alloying elements and composition optimization: The mechanical robustness of powder metallurgy titanium can be significantly enhanced through careful selection and optimization of alloying elements. Various elements such as aluminum, vanadium, molybdenum, and iron are added in specific proportions to create titanium alloys with improved strength, ductility, and fatigue resistance. The composition optimization involves balancing these elements to achieve desired mechanical properties while maintaining processability in powder metallurgy operations.

- Advanced powder processing techniques: Specialized powder processing techniques are crucial for enhancing the mechanical robustness of titanium components. These include methods such as high-energy ball milling, gas atomization, plasma rotating electrode process (PREP), and hydride-dehydride processing. These techniques help achieve optimal powder characteristics including particle size distribution, morphology, and purity, which directly influence the final mechanical properties of the sintered titanium components.

- Sintering parameters and densification strategies: The mechanical robustness of powder metallurgy titanium components is heavily dependent on sintering parameters and densification strategies. Techniques such as hot isostatic pressing (HIP), spark plasma sintering, and pressure-assisted sintering are employed to achieve near full density. Controlling sintering temperature, time, pressure, and atmosphere helps minimize porosity and optimize grain structure, resulting in superior mechanical properties including improved strength, hardness, and fatigue resistance.

- Microstructure control and heat treatment: Controlling the microstructure of powder metallurgy titanium through specific heat treatment protocols is essential for enhancing mechanical robustness. Post-sintering heat treatments including solution treatment, aging, annealing, and quenching are applied to manipulate the phase composition, grain size, and distribution of strengthening phases. These treatments help achieve an optimal balance of strength, ductility, and toughness in the final titanium components.

- Reinforcement with secondary phases and composites: The mechanical robustness of powder metallurgy titanium can be further enhanced through reinforcement with secondary phases and development of titanium-based composites. Techniques include incorporation of ceramic particles (TiC, TiB2), carbon nanotubes, or other reinforcing elements into the titanium matrix. These reinforcements improve wear resistance, hardness, and high-temperature strength while maintaining the lightweight characteristics of titanium components.

02 Advanced powder processing techniques

Innovative powder processing methods play a crucial role in improving the mechanical robustness of titanium components. These techniques include specialized milling processes, powder classification, spheroidization treatments, and surface modification of powder particles. Advanced processing enables the production of fine, uniform powder with controlled morphology and minimal contamination, which directly translates to enhanced mechanical properties in the final sintered components.Expand Specific Solutions03 Sintering parameters and densification strategies

The mechanical properties of powder metallurgy titanium components are heavily influenced by sintering parameters and densification strategies. Optimized temperature profiles, pressure conditions, sintering atmospheres, and holding times contribute to achieving near-full density parts with minimal porosity. Advanced techniques such as hot isostatic pressing, spark plasma sintering, and microwave sintering can further enhance densification and mechanical robustness of titanium components.Expand Specific Solutions04 Microstructure control and grain refinement

Controlling the microstructure and achieving grain refinement are essential for enhancing the mechanical robustness of powder metallurgy titanium. Various techniques are employed to manipulate the grain size, phase distribution, and crystallographic orientation. These include rapid solidification, thermomechanical treatments, and the addition of grain refiners. Fine-grained microstructures with homogeneous phase distribution result in superior strength, hardness, and fatigue resistance in titanium components.Expand Specific Solutions05 Post-processing treatments for property enhancement

Various post-processing treatments are applied to powder metallurgy titanium components to further enhance their mechanical robustness. These include heat treatments for stress relief and phase transformation, surface hardening techniques, shot peening for improved fatigue resistance, and hot/cold working processes. Such treatments can significantly improve strength, ductility, wear resistance, and overall mechanical performance of titanium components manufactured through powder metallurgy routes.Expand Specific Solutions

Leading Companies in PM Titanium Industry

Powder Metallurgy Titanium technology is currently in a growth phase, with the market expanding due to increasing demand in aerospace, medical, and automotive sectors. The global market size is estimated to reach $5-7 billion by 2027, growing at 8-10% CAGR. Technologically, oxygen/nitrogen control and alpha-case prevention remain challenging, with varying maturity levels across players. Leading research institutions like University of Science & Technology Beijing, Central South University, and Institute of Metal Research CAS are advancing fundamental research, while commercial entities including VSMPO-Avisma, Titanium Metals Corp., and Toho Titanium are developing proprietary solutions. Lockheed Martin and RTX Corp. are driving application-specific innovations, particularly in mechanical robustness enhancement for aerospace applications.

Publichnoe Aktsionernoe Obshchestvo Korporatsiia Vsmpo-Avisma

Technical Solution: VSMPO-AVISMA has developed a proprietary vacuum distillation process for powder metallurgy titanium production that significantly reduces oxygen and nitrogen contamination. Their technology utilizes high-vacuum conditions (10^-5 torr) combined with controlled heating cycles to effectively remove interstitial elements. The company employs a unique two-stage sintering approach where initial consolidation occurs at lower temperatures (800-900°C) to limit oxygen diffusion, followed by higher temperature sintering (1200-1300°C) under ultra-high vacuum to achieve full densification while minimizing alpha-case formation. Their process incorporates specialized surface treatment techniques including chemical etching with hydrofluoric-nitric acid solutions to remove surface-concentrated alpha-case layers without compromising dimensional accuracy. VSMPO-AVISMA has also pioneered the use of hydrogen as a temporary alloying element to enhance sintering kinetics while simultaneously reducing oxygen content through water vapor formation.

Strengths: Industry-leading vacuum metallurgy capabilities allow for exceptional purity control; Vertical integration from titanium sponge to finished products ensures quality throughout production chain. Weaknesses: High energy consumption for vacuum processes increases production costs; Limited scalability for complex geometries compared to conventional manufacturing methods.

Titanium Metals Corp.

Technical Solution: Titanium Metals Corporation (TIMET) has developed an advanced powder metallurgy process called TIMET Powder Metallurgy (TPM) specifically designed to address oxygen/nitrogen control challenges. Their approach utilizes hydrogen-deoxidation technology where titanium hydride powder is created as an intermediate step, allowing for significant oxygen reduction during subsequent processing. The process incorporates proprietary gettering agents that preferentially bind with oxygen during sintering, effectively reducing overall oxygen content to below 0.15 wt%. For alpha-case mitigation, TIMET employs a protective atmosphere sintering technique using argon with precisely controlled partial pressures of nitrogen and oxygen below 10 ppm. Their manufacturing protocol includes specialized post-sintering heat treatments that redistribute remaining interstitial elements away from grain boundaries, minimizing their embrittling effects. TIMET has also pioneered a surface modification technique that creates a diffusion barrier layer, preventing oxygen penetration during high-temperature processing while maintaining dimensional stability.

Strengths: Exceptional control over interstitial element content resulting in superior mechanical properties; Established supply chain and production infrastructure enables consistent quality at commercial scale. Weaknesses: Higher production costs compared to conventional titanium manufacturing; Process requires specialized equipment and expertise limiting widespread adoption.

Alpha-Case Prevention Technologies

Method for preparing oxygen-free passivated titanium or titanium-alloy powder product by means of gas-solid fluidization

PatentActiveUS20210308765A1

Innovation

- A gas-solid fluidization method involving the vaporization of low-boiling-point metal halides to form an oxygen-free passivation layer on the surface of titanium powder, eliminating the need for organic solvents and allowing for uniform deposition, thereby controlling oxygen adsorption and enhancing sintering densification.

Method for forming titanium alloys by powder metallurgy

PatentInactiveUS5930583A

Innovation

- A method involving the mixing of titanium or alloy powder with a low-melting point metal or alloy powder, followed by press forming near the melting point of the low-melting point metal, and subsequent sintering in an inert atmosphere to achieve a compact with uniform pressure distribution and inhibit cracking, allowing for the formation of a high-density titanium alloy with complex shapes at reduced costs.

Environmental Impact Assessment

The powder metallurgy (PM) titanium industry faces significant environmental challenges that require comprehensive assessment and strategic management. Traditional titanium processing methods, particularly those involving melting, are energy-intensive operations that generate substantial carbon emissions. In contrast, PM titanium manufacturing offers potential environmental advantages through reduced energy consumption and material waste, with studies indicating energy savings of up to 30-50% compared to conventional methods.

The control of oxygen and nitrogen during PM titanium processing presents specific environmental considerations. Contamination prevention systems, including inert gas chambers and specialized handling equipment, consume additional energy but are essential for maintaining product quality. However, these systems can be optimized through closed-loop gas recycling technologies, reducing both resource consumption and environmental impact while maintaining necessary atmospheric control.

Alpha-case formation prevention techniques often involve chemical treatments that generate hazardous waste streams requiring specialized disposal protocols. Current industry practices typically produce 0.5-2 kg of chemical waste per kilogram of titanium processed. Advanced treatment technologies, including ion exchange systems and chemical recovery processes, can reduce this environmental burden by capturing and neutralizing harmful compounds before discharge.

Water usage represents another significant environmental factor in PM titanium production. The industry currently consumes approximately 10-15 cubic meters of water per ton of titanium powder processed, primarily for cooling and cleaning operations. Implementation of water recycling systems can reduce consumption by up to 70%, significantly decreasing the industry's water footprint while maintaining processing efficiency.

Raw material extraction for titanium powder production generates substantial environmental impacts upstream in the supply chain. Mining operations for titanium minerals disturb approximately 0.8-1.2 hectares of land per thousand tons of titanium produced. Sustainable sourcing initiatives, including rehabilitation programs and responsible mining certifications, are becoming increasingly important for environmentally conscious manufacturers seeking to minimize ecological disruption throughout the value chain.

Waste management strategies for PM titanium production must address both solid waste (including rejected parts and contaminated powders) and process emissions. Current recycling technologies can recover 85-95% of titanium powder waste for reprocessing, significantly reducing landfill contributions. Additionally, advanced filtration systems can capture 99% of particulate emissions, protecting air quality in surrounding communities while meeting increasingly stringent environmental regulations worldwide.

The control of oxygen and nitrogen during PM titanium processing presents specific environmental considerations. Contamination prevention systems, including inert gas chambers and specialized handling equipment, consume additional energy but are essential for maintaining product quality. However, these systems can be optimized through closed-loop gas recycling technologies, reducing both resource consumption and environmental impact while maintaining necessary atmospheric control.

Alpha-case formation prevention techniques often involve chemical treatments that generate hazardous waste streams requiring specialized disposal protocols. Current industry practices typically produce 0.5-2 kg of chemical waste per kilogram of titanium processed. Advanced treatment technologies, including ion exchange systems and chemical recovery processes, can reduce this environmental burden by capturing and neutralizing harmful compounds before discharge.

Water usage represents another significant environmental factor in PM titanium production. The industry currently consumes approximately 10-15 cubic meters of water per ton of titanium powder processed, primarily for cooling and cleaning operations. Implementation of water recycling systems can reduce consumption by up to 70%, significantly decreasing the industry's water footprint while maintaining processing efficiency.

Raw material extraction for titanium powder production generates substantial environmental impacts upstream in the supply chain. Mining operations for titanium minerals disturb approximately 0.8-1.2 hectares of land per thousand tons of titanium produced. Sustainable sourcing initiatives, including rehabilitation programs and responsible mining certifications, are becoming increasingly important for environmentally conscious manufacturers seeking to minimize ecological disruption throughout the value chain.

Waste management strategies for PM titanium production must address both solid waste (including rejected parts and contaminated powders) and process emissions. Current recycling technologies can recover 85-95% of titanium powder waste for reprocessing, significantly reducing landfill contributions. Additionally, advanced filtration systems can capture 99% of particulate emissions, protecting air quality in surrounding communities while meeting increasingly stringent environmental regulations worldwide.

Cost-Benefit Analysis of PM Titanium Production

The economic viability of Powder Metallurgy (PM) titanium production represents a critical factor in its industrial adoption. Traditional titanium processing methods, such as the Kroll process followed by vacuum arc remelting and subsequent thermomechanical processing, incur substantial costs that limit titanium's broader application despite its exceptional properties.

PM titanium production offers significant cost reduction potential through near-net-shape manufacturing, which minimizes material waste and reduces expensive machining operations. Analysis indicates that material utilization in PM approaches can reach 90-95% compared to 10-20% in conventional methods, translating to substantial raw material savings of approximately 30-40% per component.

Energy consumption presents another major cost factor. Conventional titanium processing requires multiple high-temperature operations, whereas PM consolidation techniques like hot isostatic pressing (HIP) or direct powder rolling can reduce energy requirements by an estimated 25-35%. This energy efficiency translates to both cost savings and reduced carbon footprint, enhancing the sustainability profile of titanium production.

Equipment investment represents a significant initial barrier, with specialized powder handling systems, oxygen/nitrogen control chambers, and consolidation equipment requiring capital expenditures of $5-15 million depending on production scale. However, amortization analysis demonstrates that these investments can be recovered within 3-5 years for medium-volume production facilities through operational savings.

The costs associated with oxygen and nitrogen control systems must be weighed against the mechanical property benefits. Implementation of advanced gas monitoring and purification systems adds approximately 15-20% to production costs but enables the manufacture of components with superior fatigue resistance and ductility. This premium becomes justifiable for aerospace and medical applications where performance requirements outweigh cost considerations.

Alpha-case mitigation techniques, such as protective coatings or controlled atmosphere processing, add 5-10% to production costs but eliminate expensive post-processing operations that would otherwise be necessary to remove contaminated surface layers. The net effect is a 7-12% reduction in total component cost when considering the entire manufacturing chain.

Market analysis reveals that PM titanium components currently command a 15-30% price premium over conventional titanium products due to their enhanced performance characteristics and reduced material waste. This premium is expected to decrease to 5-10% as production volumes increase and technology matures, further improving the cost-benefit ratio for industrial applications.

PM titanium production offers significant cost reduction potential through near-net-shape manufacturing, which minimizes material waste and reduces expensive machining operations. Analysis indicates that material utilization in PM approaches can reach 90-95% compared to 10-20% in conventional methods, translating to substantial raw material savings of approximately 30-40% per component.

Energy consumption presents another major cost factor. Conventional titanium processing requires multiple high-temperature operations, whereas PM consolidation techniques like hot isostatic pressing (HIP) or direct powder rolling can reduce energy requirements by an estimated 25-35%. This energy efficiency translates to both cost savings and reduced carbon footprint, enhancing the sustainability profile of titanium production.

Equipment investment represents a significant initial barrier, with specialized powder handling systems, oxygen/nitrogen control chambers, and consolidation equipment requiring capital expenditures of $5-15 million depending on production scale. However, amortization analysis demonstrates that these investments can be recovered within 3-5 years for medium-volume production facilities through operational savings.

The costs associated with oxygen and nitrogen control systems must be weighed against the mechanical property benefits. Implementation of advanced gas monitoring and purification systems adds approximately 15-20% to production costs but enables the manufacture of components with superior fatigue resistance and ductility. This premium becomes justifiable for aerospace and medical applications where performance requirements outweigh cost considerations.

Alpha-case mitigation techniques, such as protective coatings or controlled atmosphere processing, add 5-10% to production costs but eliminate expensive post-processing operations that would otherwise be necessary to remove contaminated surface layers. The net effect is a 7-12% reduction in total component cost when considering the entire manufacturing chain.

Market analysis reveals that PM titanium components currently command a 15-30% price premium over conventional titanium products due to their enhanced performance characteristics and reduced material waste. This premium is expected to decrease to 5-10% as production volumes increase and technology matures, further improving the cost-benefit ratio for industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!