How Powder Metallurgy Balances Pressing Pressure With Dimensional Stability?

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Powder Metallurgy Evolution and Objectives

Powder metallurgy (PM) has evolved significantly since its inception in the early 20th century, transforming from a niche manufacturing process to a sophisticated technology critical for producing high-precision components across multiple industries. The journey began with simple metal powder compaction techniques and has progressed to advanced processes capable of creating complex geometries with exceptional material properties. This evolution has been driven by the increasing demand for components with precise dimensional specifications, improved mechanical properties, and cost-effective production methods.

The fundamental challenge in powder metallurgy has always been achieving the optimal balance between applied pressing pressure and the dimensional stability of the final component. Early PM processes struggled with inconsistent density distribution, leading to unpredictable shrinkage during sintering and compromised structural integrity. As the technology matured, researchers and engineers developed more sophisticated approaches to pressure application, powder formulation, and sintering protocols.

By the 1950s and 1960s, significant advancements in powder production techniques enabled more uniform particle size distributions, which proved crucial for achieving consistent density throughout compacted parts. The introduction of warm compaction in the 1980s represented another milestone, allowing for higher green density while maintaining dimensional control. This period also saw the development of improved lubricants and binders that facilitated more uniform pressure distribution during compaction.

Recent decades have witnessed the integration of computational modeling and simulation tools that predict powder behavior under various pressing conditions. These tools have enabled engineers to optimize pressing parameters before physical production, significantly reducing trial-and-error approaches and accelerating development cycles. Simultaneously, innovations in die design and pressing equipment have allowed for more precise control over pressure application, addressing issues like density gradients that previously limited dimensional stability.

The primary objective of modern powder metallurgy research is to develop methodologies that maximize component density while maintaining tight dimensional tolerances across increasingly complex geometries. This includes exploring novel powder compositions, innovative compaction techniques, and advanced sintering protocols that minimize distortion. Additional goals include reducing energy consumption during processing, increasing material utilization efficiency, and expanding the range of achievable material properties.

Looking forward, the field aims to further refine the relationship between pressing parameters and final component characteristics, potentially through the integration of artificial intelligence for real-time process optimization. The ultimate goal remains consistent: to establish predictable, repeatable processes that deliver components with precise dimensions, optimal mechanical properties, and minimal post-processing requirements, all while maintaining economic viability in competitive manufacturing environments.

The fundamental challenge in powder metallurgy has always been achieving the optimal balance between applied pressing pressure and the dimensional stability of the final component. Early PM processes struggled with inconsistent density distribution, leading to unpredictable shrinkage during sintering and compromised structural integrity. As the technology matured, researchers and engineers developed more sophisticated approaches to pressure application, powder formulation, and sintering protocols.

By the 1950s and 1960s, significant advancements in powder production techniques enabled more uniform particle size distributions, which proved crucial for achieving consistent density throughout compacted parts. The introduction of warm compaction in the 1980s represented another milestone, allowing for higher green density while maintaining dimensional control. This period also saw the development of improved lubricants and binders that facilitated more uniform pressure distribution during compaction.

Recent decades have witnessed the integration of computational modeling and simulation tools that predict powder behavior under various pressing conditions. These tools have enabled engineers to optimize pressing parameters before physical production, significantly reducing trial-and-error approaches and accelerating development cycles. Simultaneously, innovations in die design and pressing equipment have allowed for more precise control over pressure application, addressing issues like density gradients that previously limited dimensional stability.

The primary objective of modern powder metallurgy research is to develop methodologies that maximize component density while maintaining tight dimensional tolerances across increasingly complex geometries. This includes exploring novel powder compositions, innovative compaction techniques, and advanced sintering protocols that minimize distortion. Additional goals include reducing energy consumption during processing, increasing material utilization efficiency, and expanding the range of achievable material properties.

Looking forward, the field aims to further refine the relationship between pressing parameters and final component characteristics, potentially through the integration of artificial intelligence for real-time process optimization. The ultimate goal remains consistent: to establish predictable, repeatable processes that deliver components with precise dimensions, optimal mechanical properties, and minimal post-processing requirements, all while maintaining economic viability in competitive manufacturing environments.

Market Demand for Precision PM Components

The global market for precision powder metallurgy (PM) components has been experiencing robust growth, driven primarily by the automotive, aerospace, and industrial equipment sectors. These industries increasingly demand components with tight tolerances, complex geometries, and consistent mechanical properties that traditional manufacturing methods struggle to deliver cost-effectively. The current market size for precision PM components is estimated at $16 billion globally, with projections indicating a compound annual growth rate of 6.8% through 2028.

Automotive manufacturers represent the largest consumer segment, accounting for approximately 70% of precision PM component demand. The push for lightweight vehicles to improve fuel efficiency and reduce emissions has intensified the need for high-strength, dimensionally stable PM parts that can replace heavier cast or machined components. Transmission gears, connecting rods, and valve train components manufactured through PM processes offer significant weight reduction while maintaining necessary strength characteristics.

The aerospace industry presents another rapidly expanding market segment for precision PM components, particularly for applications requiring high-temperature resistance and exceptional dimensional stability. Engine components, structural parts, and landing gear elements manufactured through advanced PM techniques can achieve the stringent performance requirements while reducing overall aircraft weight. This sector's demand is growing at nearly 9% annually, outpacing the overall market.

Industrial equipment manufacturers are increasingly adopting PM components for applications requiring wear resistance and dimensional precision. The ability to maintain tight tolerances during the pressing and sintering processes makes PM ideal for producing gears, bearings, and structural components for industrial machinery. This segment values the reduced need for secondary machining operations, which translates to cost savings and shorter production cycles.

Medical device manufacturing represents an emerging market for precision PM components, with applications in surgical instruments, implantable devices, and diagnostic equipment. The biocompatibility of certain metal powders, combined with the ability to create porous structures for tissue integration, makes PM particularly valuable in this high-value sector.

Regional analysis reveals that North America and Europe currently dominate the market for precision PM components, accounting for approximately 65% of global demand. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at 8.5% annually, driven by rapid industrialization and expanding automotive production.

The market increasingly demands PM components that balance pressing pressure optimization with dimensional stability, as manufacturers seek to reduce material waste, energy consumption, and production costs while meeting ever-tightening specifications. This trend is expected to continue as industries pursue more sustainable and efficient manufacturing processes.

Automotive manufacturers represent the largest consumer segment, accounting for approximately 70% of precision PM component demand. The push for lightweight vehicles to improve fuel efficiency and reduce emissions has intensified the need for high-strength, dimensionally stable PM parts that can replace heavier cast or machined components. Transmission gears, connecting rods, and valve train components manufactured through PM processes offer significant weight reduction while maintaining necessary strength characteristics.

The aerospace industry presents another rapidly expanding market segment for precision PM components, particularly for applications requiring high-temperature resistance and exceptional dimensional stability. Engine components, structural parts, and landing gear elements manufactured through advanced PM techniques can achieve the stringent performance requirements while reducing overall aircraft weight. This sector's demand is growing at nearly 9% annually, outpacing the overall market.

Industrial equipment manufacturers are increasingly adopting PM components for applications requiring wear resistance and dimensional precision. The ability to maintain tight tolerances during the pressing and sintering processes makes PM ideal for producing gears, bearings, and structural components for industrial machinery. This segment values the reduced need for secondary machining operations, which translates to cost savings and shorter production cycles.

Medical device manufacturing represents an emerging market for precision PM components, with applications in surgical instruments, implantable devices, and diagnostic equipment. The biocompatibility of certain metal powders, combined with the ability to create porous structures for tissue integration, makes PM particularly valuable in this high-value sector.

Regional analysis reveals that North America and Europe currently dominate the market for precision PM components, accounting for approximately 65% of global demand. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at 8.5% annually, driven by rapid industrialization and expanding automotive production.

The market increasingly demands PM components that balance pressing pressure optimization with dimensional stability, as manufacturers seek to reduce material waste, energy consumption, and production costs while meeting ever-tightening specifications. This trend is expected to continue as industries pursue more sustainable and efficient manufacturing processes.

Technical Challenges in Pressing Pressure Control

Controlling pressing pressure in powder metallurgy represents one of the most significant technical challenges in the industry. The fundamental issue stems from the inherent trade-off between applying sufficient pressure to achieve desired density while maintaining dimensional stability of the pressed components. When pressure distribution is uneven across the powder mass, it leads to density gradients that manifest as warping, cracking, or dimensional inconsistencies during sintering.

Modern powder metallurgy operations face particular difficulty with complex geometries featuring varying cross-sections. In these cases, pressure gradients become more pronounced, with thicker sections receiving less effective compaction than thinner areas. This phenomenon creates internal stresses that can lead to catastrophic part failure during subsequent processing or in service conditions.

The challenge extends to the microscopic level, where particle morphology significantly impacts pressure transmission. Irregular particles create interlocking structures that impede uniform pressure distribution, while spherical particles may facilitate better flow but often yield lower green strength. Engineers must carefully select powder characteristics based on the specific application requirements, balancing flowability against compressibility.

Temperature control during pressing introduces another layer of complexity. Friction between particles and between the powder and die walls generates heat that can alter material properties in real-time during the pressing operation. Without sophisticated thermal management systems, these temperature fluctuations can lead to inconsistent material behavior across the workpiece.

Die wall friction represents a persistent challenge that directly impacts pressure gradients. As distance from the punch increases, the effective pressure decreases exponentially due to friction losses. Advanced lubricants and die wall treatments have been developed to mitigate this effect, but complete elimination remains elusive, particularly for tall or complex components.

The industry also struggles with scale-up challenges. Processes optimized at laboratory scale often perform differently in production environments due to differences in press characteristics, powder handling systems, and environmental conditions. This necessitates extensive validation testing when transitioning from development to production.

Instrumentation for real-time pressure monitoring within the powder mass remains limited, forcing engineers to rely on indirect measurements and simulation. While computational models have improved dramatically, they still struggle to accurately predict behavior in highly complex geometries or with novel powder formulations.

The balance between pressing speed and quality presents another significant challenge. Higher production rates require faster pressing cycles, which can exacerbate issues with air entrapment and uneven powder flow. This creates a constant tension between manufacturing efficiency and product quality that manufacturers must carefully navigate.

Modern powder metallurgy operations face particular difficulty with complex geometries featuring varying cross-sections. In these cases, pressure gradients become more pronounced, with thicker sections receiving less effective compaction than thinner areas. This phenomenon creates internal stresses that can lead to catastrophic part failure during subsequent processing or in service conditions.

The challenge extends to the microscopic level, where particle morphology significantly impacts pressure transmission. Irregular particles create interlocking structures that impede uniform pressure distribution, while spherical particles may facilitate better flow but often yield lower green strength. Engineers must carefully select powder characteristics based on the specific application requirements, balancing flowability against compressibility.

Temperature control during pressing introduces another layer of complexity. Friction between particles and between the powder and die walls generates heat that can alter material properties in real-time during the pressing operation. Without sophisticated thermal management systems, these temperature fluctuations can lead to inconsistent material behavior across the workpiece.

Die wall friction represents a persistent challenge that directly impacts pressure gradients. As distance from the punch increases, the effective pressure decreases exponentially due to friction losses. Advanced lubricants and die wall treatments have been developed to mitigate this effect, but complete elimination remains elusive, particularly for tall or complex components.

The industry also struggles with scale-up challenges. Processes optimized at laboratory scale often perform differently in production environments due to differences in press characteristics, powder handling systems, and environmental conditions. This necessitates extensive validation testing when transitioning from development to production.

Instrumentation for real-time pressure monitoring within the powder mass remains limited, forcing engineers to rely on indirect measurements and simulation. While computational models have improved dramatically, they still struggle to accurately predict behavior in highly complex geometries or with novel powder formulations.

The balance between pressing speed and quality presents another significant challenge. Higher production rates require faster pressing cycles, which can exacerbate issues with air entrapment and uneven powder flow. This creates a constant tension between manufacturing efficiency and product quality that manufacturers must carefully navigate.

Current Pressure-Dimensional Stability Solutions

01 Composition control for dimensional stability

Controlling the composition of powder metallurgy materials is crucial for achieving dimensional stability. Specific alloying elements and their proportions can significantly reduce shrinkage and dimensional changes during sintering. Optimized compositions can include elements that form stable phases or create controlled microstructures that resist deformation and maintain dimensional accuracy throughout the manufacturing process and during service conditions.- Composition control for dimensional stability: Controlling the composition of powder metallurgy materials is crucial for achieving dimensional stability. Specific alloying elements and their proportions can significantly reduce shrinkage and dimensional changes during sintering. Optimized compositions can include elements that form stable phases or create controlled microstructures that resist deformation during thermal processing and subsequent use.

- Processing parameters optimization: Optimizing processing parameters such as compaction pressure, sintering temperature, time, and atmosphere plays a critical role in achieving dimensional stability in powder metallurgy parts. Controlled heating and cooling rates during sintering minimize distortion and dimensional variations. Proper selection of these parameters helps in achieving uniform density distribution and reducing residual stresses that could lead to dimensional changes.

- Advanced sintering techniques: Advanced sintering techniques such as liquid phase sintering, spark plasma sintering, and hot isostatic pressing can significantly improve the dimensional stability of powder metallurgy components. These techniques allow for better control of densification processes, resulting in more uniform shrinkage and reduced distortion. They also enable the production of near-net-shape components with minimal dimensional variation.

- Particle size and distribution control: The size, shape, and distribution of powder particles significantly impact the dimensional stability of powder metallurgy products. Finer particles generally result in higher shrinkage but more uniform dimensional changes, while bimodal or optimized particle size distributions can minimize overall dimensional variations. Controlling these parameters helps achieve more predictable shrinkage behavior and better dimensional accuracy in the final components.

- Post-processing treatments: Various post-processing treatments can enhance the dimensional stability of powder metallurgy components. These include heat treatments, surface hardening, impregnation with polymers or metals, and mechanical working. Such treatments can relieve residual stresses, stabilize the microstructure, and improve the resistance to dimensional changes during service conditions, particularly under thermal cycling or mechanical loading.

02 Processing parameters optimization

Optimizing processing parameters such as compaction pressure, sintering temperature, time, and atmosphere plays a significant role in achieving dimensional stability in powder metallurgy parts. Controlled heating and cooling rates during sintering can minimize distortion and dimensional changes. Proper selection of these parameters helps in achieving uniform density distribution and controlled microstructure development, which directly impacts the dimensional stability of the final components.Expand Specific Solutions03 Heat treatment techniques

Post-sintering heat treatments are effective methods for enhancing dimensional stability in powder metallurgy components. Techniques such as annealing, tempering, and stress relieving can reduce internal stresses and stabilize the microstructure. These treatments help in achieving consistent dimensions by eliminating residual stresses that might cause warping or dimensional changes during service, particularly in applications involving thermal cycling or mechanical loading.Expand Specific Solutions04 Advanced powder preparation methods

Advanced powder preparation methods significantly impact the dimensional stability of powder metallurgy parts. Techniques such as gas atomization, mechanical alloying, and spheroidization produce powders with controlled particle size distribution, shape, and surface characteristics. These properties influence powder flowability, packing density, and sintering behavior, which in turn affect the dimensional stability of the final components by reducing variability in shrinkage and distortion during processing.Expand Specific Solutions05 Reinforcement and composite approaches

Incorporating reinforcements or creating composite structures in powder metallurgy materials can significantly enhance dimensional stability. The addition of ceramic particles, fibers, or secondary phases can restrict matrix deformation and reduce thermal expansion coefficients. These reinforcements act as dimensional stabilizers by providing structural integrity and resistance to dimensional changes under thermal and mechanical stresses, making them particularly valuable for applications requiring precise dimensional tolerances under varying service conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in PM

The powder metallurgy industry is currently in a mature growth phase, balancing innovation with established processes. The global market is projected to reach approximately $35-40 billion by 2027, driven by automotive and industrial applications requiring precise dimensional stability. Leading companies like GKN Sinter Metals, Dorst Technologies, and Kobe Steel have developed advanced pressing technologies that optimize pressure distribution while maintaining dimensional accuracy. Emerging players such as ADD UP are introducing innovative approaches combining traditional powder metallurgy with additive manufacturing techniques. The technical challenge of balancing pressing pressure with dimensional stability remains critical as manufacturers like Federal-Mogul and Sumitomo Electric Sintered Alloy push material boundaries for increasingly complex components with tighter tolerances.

Dorst Technologies GmbH & Co. KG

Technical Solution: Dorst Technologies has developed the Precision Adaptive Control Environment (PACE) system specifically addressing the pressure-dimension balance challenge in powder metallurgy. Their approach utilizes multi-point servo-electric drives that provide independent control over multiple pressing axes, allowing for precise pressure distribution throughout complex part geometries. The PACE system incorporates predictive modeling software that anticipates material behavior during compaction and automatically adjusts pressure parameters to achieve optimal density while maintaining dimensional specifications. Dorst's technology also features advanced die-wall lubrication systems with zoned application capabilities, reducing friction selectively in critical areas to prevent deformation during ejection while maintaining necessary green strength in structural zones.

Strengths: Exceptional precision for complex geometries; reduced setup time for new parts; ability to handle wide density variations within single components. Weaknesses: High capital investment; requires advanced operator training; limited throughput compared to simpler pressing systems.

GKN Sinter Metals LLC

Technical Solution: GKN Sinter Metals has developed a proprietary Adaptive Pressing Technology (APT) that dynamically adjusts pressing pressure during the compaction process. Their system utilizes real-time feedback from multiple sensors embedded in the die walls to monitor density distribution and adjust pressure parameters accordingly. This technology incorporates a multi-level pressing sequence where initial pressure is applied at lower levels to ensure uniform powder distribution, followed by precisely controlled higher pressure stages to achieve optimal density without compromising dimensional stability. GKN's approach also includes specialized lubricant systems that reduce die wall friction while maintaining green strength, allowing for higher pressures without deformation issues during ejection.

Strengths: Superior density distribution control across complex geometries; reduced spring-back effect; 15-20% improvement in dimensional consistency compared to conventional methods. Weaknesses: Higher initial tooling costs; requires more sophisticated control systems; limited to certain powder types and geometries.

Critical Patents in Powder Compaction Technology

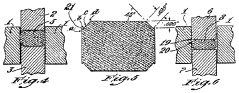

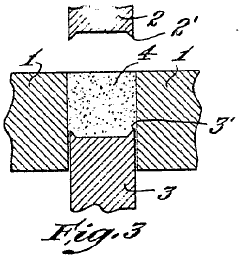

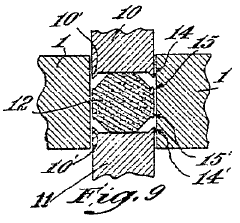

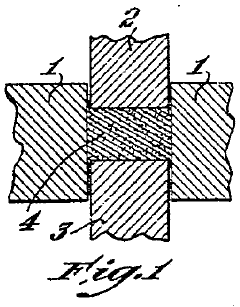

Method of making metal articles by powder metallurgy

PatentInactiveGB676345A

Innovation

- A method involving two or more pressing operations with intervening sintering, using punches with projecting lips to chamfer edges during the first pressing and ensuring no metal is forced into clearance spaces during the final pressing, resulting in burr-free, chamfered metal articles with high density and physical properties.

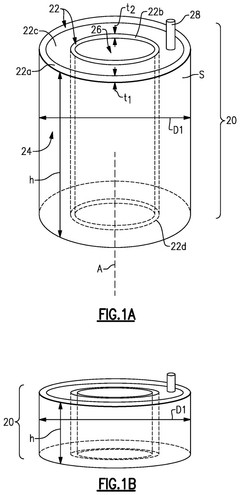

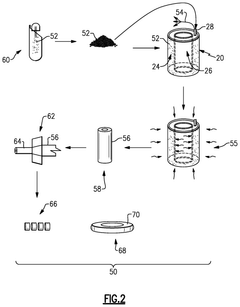

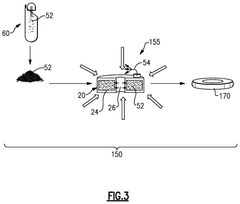

Powder metallurgy method using a four-wall cylindrical canister

PatentActiveUS12233461B2

Innovation

- A powder metallurgy method utilizing a canister with a hermetic chamber that undergoes a hot isostatic pressing process, where the canister is designed to deform under pressure, ensuring uniform heating and pressure application to consolidate the metallic alloy powder into a solid workpiece.

Material Science Advancements for Enhanced Stability

Recent advancements in material science have significantly contributed to enhancing dimensional stability in powder metallurgy processes. The development of novel powder compositions with tailored particle morphologies has been instrumental in achieving better compaction characteristics while maintaining dimensional integrity. These advanced materials exhibit superior flow properties and reduced spring-back effects, which are critical factors in balancing pressing pressure requirements with final component stability.

Nano-structured additives have emerged as game-changers in powder metallurgy, offering unprecedented control over microstructural evolution during sintering. By incorporating carefully designed nano-particles into conventional metal powders, researchers have successfully created composite materials that resist deformation under high pressing pressures while achieving near-theoretical densities. These additives effectively modify grain boundary characteristics, limiting grain growth during sintering and preserving the dimensional specifications established during compaction.

Surface modification technologies have also revolutionized powder metallurgy practices. Techniques such as atomic layer deposition and plasma treatment enable the creation of engineered interfaces between powder particles, promoting controlled interparticle bonding during compaction and sintering. These modified surfaces facilitate optimal pressure distribution throughout the powder mass during compaction, eliminating density gradients that typically lead to non-uniform shrinkage and dimensional instability.

Computational materials science has accelerated the development of stability-enhancing solutions through predictive modeling of powder behavior under various pressing conditions. Machine learning algorithms now enable the optimization of powder compositions and pressing parameters based on desired dimensional outcomes. These digital tools have reduced the empirical nature of powder metallurgy process development, allowing for precise engineering of material properties that balance compressibility with dimensional stability.

Hybrid material systems represent another frontier in stability enhancement. By combining metal powders with carefully selected ceramic or polymer constituents, engineers have created composite systems that leverage the beneficial properties of each component. These hybrids often demonstrate improved elastic recovery characteristics, reducing the dimensional variations that typically occur between the pressing and sintering stages of production.

Temperature-responsive powder systems have been developed to address the challenge of differential thermal expansion during sintering. These advanced materials incorporate phase-change elements that compensate for dimensional changes at critical temperature thresholds, effectively neutralizing the expansion and contraction cycles that traditionally compromise dimensional stability in powder metallurgy components.

Nano-structured additives have emerged as game-changers in powder metallurgy, offering unprecedented control over microstructural evolution during sintering. By incorporating carefully designed nano-particles into conventional metal powders, researchers have successfully created composite materials that resist deformation under high pressing pressures while achieving near-theoretical densities. These additives effectively modify grain boundary characteristics, limiting grain growth during sintering and preserving the dimensional specifications established during compaction.

Surface modification technologies have also revolutionized powder metallurgy practices. Techniques such as atomic layer deposition and plasma treatment enable the creation of engineered interfaces between powder particles, promoting controlled interparticle bonding during compaction and sintering. These modified surfaces facilitate optimal pressure distribution throughout the powder mass during compaction, eliminating density gradients that typically lead to non-uniform shrinkage and dimensional instability.

Computational materials science has accelerated the development of stability-enhancing solutions through predictive modeling of powder behavior under various pressing conditions. Machine learning algorithms now enable the optimization of powder compositions and pressing parameters based on desired dimensional outcomes. These digital tools have reduced the empirical nature of powder metallurgy process development, allowing for precise engineering of material properties that balance compressibility with dimensional stability.

Hybrid material systems represent another frontier in stability enhancement. By combining metal powders with carefully selected ceramic or polymer constituents, engineers have created composite systems that leverage the beneficial properties of each component. These hybrids often demonstrate improved elastic recovery characteristics, reducing the dimensional variations that typically occur between the pressing and sintering stages of production.

Temperature-responsive powder systems have been developed to address the challenge of differential thermal expansion during sintering. These advanced materials incorporate phase-change elements that compensate for dimensional changes at critical temperature thresholds, effectively neutralizing the expansion and contraction cycles that traditionally compromise dimensional stability in powder metallurgy components.

Environmental Impact of PM Manufacturing Processes

Powder metallurgy (PM) manufacturing processes offer significant environmental advantages compared to traditional metal forming techniques. The environmental impact assessment of PM processes reveals lower energy consumption rates, with studies indicating up to 50% reduction in energy usage compared to conventional casting and machining operations. This efficiency stems from the lower processing temperatures required for sintering versus complete melting, as well as the near-net-shape capabilities that minimize material waste.

Material utilization in PM manufacturing approaches 97% efficiency, substantially higher than traditional subtractive manufacturing methods that may waste up to 60% of raw materials. The balance between pressing pressure and dimensional stability directly influences this efficiency—optimized pressing parameters reduce the need for secondary operations and associated energy consumption. Additionally, the precise control of powder compaction minimizes the generation of hazardous waste streams.

PM processes generate significantly lower greenhouse gas emissions compared to conventional metal forming. Research indicates that CO2 emissions can be reduced by approximately 30-40% through PM manufacturing routes. The elimination of cutting fluids in many PM applications further reduces environmental contamination and hazardous waste disposal requirements. When pressing pressure is properly calibrated to achieve dimensional stability, fewer parts require rework, further reducing the environmental footprint.

Water consumption represents another critical environmental consideration. PM processes typically require 50-70% less water than traditional metal manufacturing methods. The closed-loop systems increasingly employed in modern PM facilities capture and recycle process water, minimizing discharge to municipal systems. Proper pressing techniques that achieve first-time dimensional accuracy reduce cleaning requirements and associated water usage.

Recent advancements in binder systems have addressed historical environmental concerns with PM processes. Water-based and biologically derived binders are replacing solvent-based systems, reducing volatile organic compound (VOC) emissions by up to 80%. These environmentally friendly binders maintain the critical balance between pressing pressure and dimensional stability while minimizing atmospheric pollution.

The life cycle assessment of PM components demonstrates additional environmental benefits through weight reduction in final applications. Automotive components manufactured via PM techniques can contribute to vehicle weight reduction of 5-15%, translating to improved fuel efficiency and reduced lifetime emissions. The dimensional stability achieved through optimized pressing techniques ensures these components maintain their performance characteristics throughout their service life.

Material utilization in PM manufacturing approaches 97% efficiency, substantially higher than traditional subtractive manufacturing methods that may waste up to 60% of raw materials. The balance between pressing pressure and dimensional stability directly influences this efficiency—optimized pressing parameters reduce the need for secondary operations and associated energy consumption. Additionally, the precise control of powder compaction minimizes the generation of hazardous waste streams.

PM processes generate significantly lower greenhouse gas emissions compared to conventional metal forming. Research indicates that CO2 emissions can be reduced by approximately 30-40% through PM manufacturing routes. The elimination of cutting fluids in many PM applications further reduces environmental contamination and hazardous waste disposal requirements. When pressing pressure is properly calibrated to achieve dimensional stability, fewer parts require rework, further reducing the environmental footprint.

Water consumption represents another critical environmental consideration. PM processes typically require 50-70% less water than traditional metal manufacturing methods. The closed-loop systems increasingly employed in modern PM facilities capture and recycle process water, minimizing discharge to municipal systems. Proper pressing techniques that achieve first-time dimensional accuracy reduce cleaning requirements and associated water usage.

Recent advancements in binder systems have addressed historical environmental concerns with PM processes. Water-based and biologically derived binders are replacing solvent-based systems, reducing volatile organic compound (VOC) emissions by up to 80%. These environmentally friendly binders maintain the critical balance between pressing pressure and dimensional stability while minimizing atmospheric pollution.

The life cycle assessment of PM components demonstrates additional environmental benefits through weight reduction in final applications. Automotive components manufactured via PM techniques can contribute to vehicle weight reduction of 5-15%, translating to improved fuel efficiency and reduced lifetime emissions. The dimensional stability achieved through optimized pressing techniques ensures these components maintain their performance characteristics throughout their service life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!