How Powder Metallurgy Integrates HIP To Close Pores Without Overaging?

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Powder Metallurgy-HIP Integration Background & Objectives

Powder metallurgy (PM) has evolved significantly since its inception in the early 20th century, transforming from a niche manufacturing process to a mainstream industrial technology. The integration of Hot Isostatic Pressing (HIP) with traditional powder metallurgy represents a pivotal advancement in this field, addressing one of the most persistent challenges in PM: residual porosity. This technological convergence aims to enhance material density without compromising the microstructural integrity through overaging.

The historical trajectory of powder metallurgy shows a continuous pursuit of higher density components with improved mechanical properties. Early PM processes achieved limited densification, typically 85-90% of theoretical density, resulting in components with inherent porosity that compromised performance in demanding applications. The introduction of HIP in the 1950s initially served aerospace and nuclear industries, but its potential for enhancing PM components remained largely unexplored until the 1980s.

Recent technological trends indicate a growing sophistication in the integration of HIP with conventional PM processes. This evolution is driven by increasing demands for high-performance materials in critical applications such as aerospace components, medical implants, and high-stress automotive parts. The market's push for components with near-perfect density while maintaining precise dimensional control has accelerated research in this domain.

The primary technical objective of PM-HIP integration is to achieve near-theoretical density (>99%) in complex-shaped components while preventing microstructural degradation associated with overaging. This involves optimizing process parameters to close internal pores through applied isostatic pressure at elevated temperatures, while carefully controlling the time-temperature profile to preserve desirable microstructural features.

Secondary objectives include reducing production costs compared to traditional machining processes, minimizing material waste, enabling the manufacture of complex geometries that would be difficult or impossible to produce through conventional methods, and developing predictive models for process optimization. These models aim to establish correlations between powder characteristics, compaction parameters, sintering conditions, and HIP parameters.

The technological roadmap for PM-HIP integration focuses on developing advanced process control systems that can dynamically adjust parameters based on real-time monitoring of material densification and microstructural evolution. This approach represents a paradigm shift from traditional fixed-parameter processing to adaptive manufacturing, potentially revolutionizing how high-performance PM components are produced.

Understanding the fundamental mechanisms of pore closure during HIP without triggering excessive grain growth or precipitate coarsening remains a central research challenge, requiring interdisciplinary approaches combining materials science, thermodynamics, and advanced characterization techniques.

The historical trajectory of powder metallurgy shows a continuous pursuit of higher density components with improved mechanical properties. Early PM processes achieved limited densification, typically 85-90% of theoretical density, resulting in components with inherent porosity that compromised performance in demanding applications. The introduction of HIP in the 1950s initially served aerospace and nuclear industries, but its potential for enhancing PM components remained largely unexplored until the 1980s.

Recent technological trends indicate a growing sophistication in the integration of HIP with conventional PM processes. This evolution is driven by increasing demands for high-performance materials in critical applications such as aerospace components, medical implants, and high-stress automotive parts. The market's push for components with near-perfect density while maintaining precise dimensional control has accelerated research in this domain.

The primary technical objective of PM-HIP integration is to achieve near-theoretical density (>99%) in complex-shaped components while preventing microstructural degradation associated with overaging. This involves optimizing process parameters to close internal pores through applied isostatic pressure at elevated temperatures, while carefully controlling the time-temperature profile to preserve desirable microstructural features.

Secondary objectives include reducing production costs compared to traditional machining processes, minimizing material waste, enabling the manufacture of complex geometries that would be difficult or impossible to produce through conventional methods, and developing predictive models for process optimization. These models aim to establish correlations between powder characteristics, compaction parameters, sintering conditions, and HIP parameters.

The technological roadmap for PM-HIP integration focuses on developing advanced process control systems that can dynamically adjust parameters based on real-time monitoring of material densification and microstructural evolution. This approach represents a paradigm shift from traditional fixed-parameter processing to adaptive manufacturing, potentially revolutionizing how high-performance PM components are produced.

Understanding the fundamental mechanisms of pore closure during HIP without triggering excessive grain growth or precipitate coarsening remains a central research challenge, requiring interdisciplinary approaches combining materials science, thermodynamics, and advanced characterization techniques.

Market Demand Analysis for Pore-Free PM Components

The global market for pore-free powder metallurgy (PM) components has been experiencing significant growth, driven primarily by increasing demands from aerospace, automotive, medical, and energy sectors. These industries require components with superior mechanical properties, enhanced fatigue resistance, and extended service life—characteristics that can only be achieved through near-zero porosity.

Market research indicates that the aerospace industry represents the largest demand segment for pore-free PM components, particularly for critical applications such as turbine discs, blades, and structural components. The need for lightweight yet high-strength materials capable of withstanding extreme operating conditions has pushed manufacturers toward advanced PM processes incorporating Hot Isostatic Pressing (HIP).

The automotive sector follows closely, with premium and electric vehicle manufacturers increasingly adopting pore-free PM components for drivetrain systems, transmission parts, and high-performance engine components. This shift is largely motivated by the industry's focus on weight reduction, fuel efficiency, and durability improvements.

Medical implant manufacturers constitute another rapidly growing market segment, with demand for pore-free titanium and cobalt-chrome alloy components rising at approximately 8% annually. The elimination of porosity in these components significantly reduces the risk of implant failure while extending service life—critical factors in medical applications.

Energy sector applications, particularly in oil and gas extraction and nuclear power generation, represent substantial market opportunities. These industries require components capable of withstanding corrosive environments and high-pressure conditions, where porosity can lead to catastrophic failures.

Market analysis reveals regional variations in demand patterns. North America and Europe currently dominate the market for high-end pore-free PM components, primarily due to their established aerospace and medical device industries. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization and increasing adoption of advanced manufacturing technologies in China, Japan, and South Korea.

Customer requirements are evolving toward more stringent specifications regarding porosity levels, with many industries now demanding porosity levels below 0.5% for critical applications. This trend has created a premium market segment for ultra-high-quality PM components where conventional sintering processes cannot meet requirements.

Economic analysis indicates that while pore-free PM components command price premiums of 30-50% compared to conventional PM parts, the total lifecycle cost benefits often justify the investment. Reduced maintenance requirements, extended component life, and improved performance characteristics deliver substantial long-term value to end-users across multiple industries.

Market research indicates that the aerospace industry represents the largest demand segment for pore-free PM components, particularly for critical applications such as turbine discs, blades, and structural components. The need for lightweight yet high-strength materials capable of withstanding extreme operating conditions has pushed manufacturers toward advanced PM processes incorporating Hot Isostatic Pressing (HIP).

The automotive sector follows closely, with premium and electric vehicle manufacturers increasingly adopting pore-free PM components for drivetrain systems, transmission parts, and high-performance engine components. This shift is largely motivated by the industry's focus on weight reduction, fuel efficiency, and durability improvements.

Medical implant manufacturers constitute another rapidly growing market segment, with demand for pore-free titanium and cobalt-chrome alloy components rising at approximately 8% annually. The elimination of porosity in these components significantly reduces the risk of implant failure while extending service life—critical factors in medical applications.

Energy sector applications, particularly in oil and gas extraction and nuclear power generation, represent substantial market opportunities. These industries require components capable of withstanding corrosive environments and high-pressure conditions, where porosity can lead to catastrophic failures.

Market analysis reveals regional variations in demand patterns. North America and Europe currently dominate the market for high-end pore-free PM components, primarily due to their established aerospace and medical device industries. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization and increasing adoption of advanced manufacturing technologies in China, Japan, and South Korea.

Customer requirements are evolving toward more stringent specifications regarding porosity levels, with many industries now demanding porosity levels below 0.5% for critical applications. This trend has created a premium market segment for ultra-high-quality PM components where conventional sintering processes cannot meet requirements.

Economic analysis indicates that while pore-free PM components command price premiums of 30-50% compared to conventional PM parts, the total lifecycle cost benefits often justify the investment. Reduced maintenance requirements, extended component life, and improved performance characteristics deliver substantial long-term value to end-users across multiple industries.

Current Challenges in PM-HIP Porosity Elimination

Despite significant advancements in Powder Metallurgy (PM) combined with Hot Isostatic Pressing (HIP), several critical challenges persist in achieving optimal porosity elimination without causing detrimental overaging effects in the material microstructure. The fundamental challenge lies in the delicate balance between complete pore closure and maintaining desirable mechanical properties, particularly in high-performance alloys used in aerospace, automotive, and medical applications.

Temperature control during the HIP process represents one of the most significant hurdles. The current technology struggles to maintain precise temperature uniformity throughout complex-shaped components, resulting in differential densification rates. This non-uniform densification creates residual stress concentrations that can lead to part distortion or even microcracking during subsequent processing or service conditions.

Pressure distribution optimization remains problematic, especially for components with varying cross-sectional thicknesses. Inadequate pressure transmission to internal features can result in incomplete pore closure in these regions, while excessive pressure elsewhere may induce unwanted phase transformations or grain boundary migration, compromising the material's mechanical integrity.

Time-dependent degradation mechanisms pose another substantial challenge. Extended HIP cycles necessary for complete porosity elimination often trigger overaging phenomena, including precipitate coarsening, grain growth, and undesirable phase transformations. These microstructural changes can significantly reduce strength, ductility, and fatigue resistance of the final component.

The industry also faces difficulties with process parameter optimization for new alloy systems. The traditional empirical approach to developing HIP cycles is time-consuming and costly, particularly for novel powder compositions where the densification mechanisms and kinetics are not well understood. This challenge is exacerbated by the complex interplay between powder characteristics, compaction methods, and subsequent HIP parameters.

Computational modeling limitations further complicate the situation. Current simulation tools struggle to accurately predict the combined effects of temperature, pressure, and time on both porosity elimination and microstructural evolution. This gap in predictive capability makes it difficult to develop optimized HIP cycles that achieve complete densification without overaging.

Economic considerations also present challenges, as the high energy consumption and lengthy cycle times of conventional HIP processes significantly impact production costs and throughput. This economic barrier limits the broader adoption of PM-HIP technology across various industrial sectors, despite its technical advantages for producing high-performance components.

Temperature control during the HIP process represents one of the most significant hurdles. The current technology struggles to maintain precise temperature uniformity throughout complex-shaped components, resulting in differential densification rates. This non-uniform densification creates residual stress concentrations that can lead to part distortion or even microcracking during subsequent processing or service conditions.

Pressure distribution optimization remains problematic, especially for components with varying cross-sectional thicknesses. Inadequate pressure transmission to internal features can result in incomplete pore closure in these regions, while excessive pressure elsewhere may induce unwanted phase transformations or grain boundary migration, compromising the material's mechanical integrity.

Time-dependent degradation mechanisms pose another substantial challenge. Extended HIP cycles necessary for complete porosity elimination often trigger overaging phenomena, including precipitate coarsening, grain growth, and undesirable phase transformations. These microstructural changes can significantly reduce strength, ductility, and fatigue resistance of the final component.

The industry also faces difficulties with process parameter optimization for new alloy systems. The traditional empirical approach to developing HIP cycles is time-consuming and costly, particularly for novel powder compositions where the densification mechanisms and kinetics are not well understood. This challenge is exacerbated by the complex interplay between powder characteristics, compaction methods, and subsequent HIP parameters.

Computational modeling limitations further complicate the situation. Current simulation tools struggle to accurately predict the combined effects of temperature, pressure, and time on both porosity elimination and microstructural evolution. This gap in predictive capability makes it difficult to develop optimized HIP cycles that achieve complete densification without overaging.

Economic considerations also present challenges, as the high energy consumption and lengthy cycle times of conventional HIP processes significantly impact production costs and throughput. This economic barrier limits the broader adoption of PM-HIP technology across various industrial sectors, despite its technical advantages for producing high-performance components.

Current Solutions for Porosity Closure Without Overaging

01 HIP process parameters optimization for pore closure

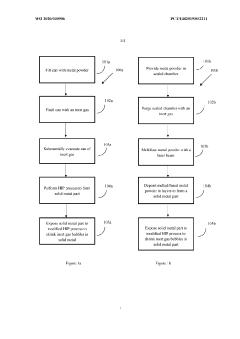

Optimizing Hot Isostatic Pressing (HIP) process parameters such as temperature, pressure, and time is crucial for effective pore closure in powder metallurgy components while preventing overaging. Controlled heating rates and precise temperature management during the HIP cycle allow for complete densification of the material while maintaining desired microstructural properties. The process can be tailored for specific alloys to achieve optimal pore elimination without compromising mechanical properties.- HIP process parameters optimization for pore closure: Optimizing Hot Isostatic Pressing (HIP) process parameters such as temperature, pressure, and time is crucial for effective pore closure while preventing overaging. By carefully controlling these parameters, the densification of powder metallurgy components can be achieved without compromising the microstructure or mechanical properties. Lower temperatures combined with higher pressures can be effective for closing pores while minimizing grain growth and maintaining the desired microstructural characteristics.

- Two-stage HIP treatment for controlled densification: A two-stage HIP treatment approach involves an initial lower temperature HIP cycle focused on pore closure, followed by a controlled heat treatment. This method allows for effective densification in the first stage while managing the microstructural evolution in the second stage. The separation of the densification and aging processes enables better control over the final properties, preventing overaging while ensuring complete pore closure.

- Alloying elements and powder composition for improved HIP response: The composition of the metal powder and specific alloying elements can significantly influence the HIP response and prevent overaging. Certain elements can stabilize the microstructure during the high-temperature HIP process, allowing for effective pore closure while inhibiting excessive grain growth or precipitation. Tailoring the powder composition based on the specific material system can optimize the balance between densification and microstructural stability.

- Pre-HIP treatments and powder preparation techniques: Various pre-HIP treatments and powder preparation techniques can enhance the densification process while preventing overaging. These include controlled oxidation of powder surfaces, specific particle size distributions, and pre-sintering treatments. These preparatory steps can lower the required HIP temperature or time, thereby reducing the risk of overaging while still achieving complete pore closure. Proper degassing and container design also play important roles in optimizing the HIP process.

- Post-HIP treatments for microstructure refinement: Post-HIP treatments can be employed to refine the microstructure after pore closure has been achieved. These treatments may include controlled cooling rates, secondary heat treatments, or thermomechanical processing. By separating the pore closure process from the final microstructure development, overaging can be avoided while still achieving full densification. This approach allows for independent optimization of densification and final material properties.

02 Two-stage HIP treatment for controlled densification

A two-stage HIP treatment approach involves an initial lower temperature phase focused on pore closure followed by a controlled second phase that prevents overaging. This method allows for complete densification while preserving the desired microstructure and mechanical properties. The first stage targets pore elimination while the second stage focuses on optimizing the material's final properties, providing better control over grain growth and precipitation phenomena that could lead to overaging.Expand Specific Solutions03 Alloying elements and additives for improved HIP performance

Specific alloying elements and additives can be incorporated into powder metallurgy materials to enhance pore closure during HIP while inhibiting grain growth and overaging. These elements can form stable precipitates that pin grain boundaries, allowing for complete densification without excessive grain growth. The careful selection of alloying elements can create microstructures that are resistant to overaging even at the elevated temperatures required for effective HIP processing.Expand Specific Solutions04 Rapid cooling techniques post-HIP processing

Implementing rapid cooling techniques immediately after the HIP process can prevent overaging while maintaining the benefits of complete pore closure. These techniques include gas quenching, oil quenching, or water cooling integrated into the HIP cycle. By minimizing the time spent at elevated temperatures after achieving full densification, these methods preserve the optimal microstructure and mechanical properties of the material while ensuring complete pore elimination.Expand Specific Solutions05 Pre-HIP powder treatment and preparation methods

Advanced powder preparation techniques prior to HIP processing can significantly improve pore closure efficiency while reducing the risk of overaging. These methods include powder classification, surface modification, degassing treatments, and controlled pre-sintering. Properly prepared powders require less aggressive HIP parameters to achieve full densification, thereby reducing the risk of overaging during the consolidation process. Optimized particle size distribution and powder morphology contribute to more efficient pore elimination.Expand Specific Solutions

Leading Manufacturers and Research Institutions in PM-HIP

Powder Metallurgy's integration with Hot Isostatic Pressing (HIP) for pore closure without overaging is currently in a mature development stage, with the global market estimated at $30 billion and growing steadily. The technology has reached commercial viability across multiple sectors, particularly aerospace and automotive applications. Leading players demonstrate varying levels of technological sophistication: Höganäs AB and Sandvik Intellectual Property AB have established comprehensive HIP-integrated powder metallurgy solutions; VBN Components and MTC Powder Solutions AB are pioneering advanced materials with optimized microstructures; while academic institutions like Central South University and Beihang University are driving fundamental research on preventing overaging during densification processes. Research collaborations between companies like Quintus Technologies and academic partners are accelerating innovation in controlling densification parameters.

Sandvik Intellectual Property AB

Technical Solution: Sandvik has pioneered an advanced powder metallurgy approach integrating HIP technology called Osprey® HIP process. This technology combines their proprietary metal powder atomization techniques with specialized HIP cycles designed to achieve full density while maintaining optimal microstructure. Their process utilizes precisely controlled heating rates and pressure application sequences that allow for complete pore closure while minimizing grain growth and preventing overaging. Sandvik's approach includes a pre-HIP heat treatment that stabilizes certain precipitates in the material, creating microstructural features that resist coarsening during the subsequent high-temperature HIP cycle. The company has developed material-specific HIP maps that plot the optimal time-temperature-pressure relationships for various alloy systems, particularly focusing on tool steels, superalloys, and titanium alloys. Their technology also incorporates post-HIP rapid cooling capabilities within the HIP vessel itself, allowing for quenching treatments that further refine the microstructure after pore elimination has been achieved. This integrated approach has enabled Sandvik to produce PM components with closed porosity and mechanical properties that match or exceed those of conventionally processed materials.

Strengths: Comprehensive control over the entire powder-to-part process chain; proprietary rapid cooling HIP technology that prevents overaging during the cooling phase; extensive experience with high-performance alloys requiring precise microstructural control. Weaknesses: Higher capital equipment costs compared to conventional sintering; process parameters must be carefully tailored to each specific alloy system; limited throughput compared to conventional PM techniques.

Höganäs AB

Technical Solution: Höganäs AB has developed an integrated powder metallurgy (PM) approach that combines their proprietary metal powder formulations with optimized Hot Isostatic Pressing (HIP) parameters. Their technology utilizes fine-tuned temperature-pressure cycles that allow for pore closure while preventing overaging of the microstructure. The process involves a two-stage HIP treatment where initial densification occurs at lower temperatures (typically 70-80% of the material's melting point) followed by a controlled pressure increase phase that completes pore elimination without excessive grain growth. Höganäs has particularly focused on developing specialized powder compositions with tailored particle size distributions and surface treatments that enhance sinterability and respond optimally to HIP processing. Their Digital Metal® technology combines 3D printing with subsequent HIP treatment, creating near-net-shape components with closed porosity and preserved mechanical properties. The company has also pioneered the use of alloying elements that form precipitates during the HIP cycle, effectively pinning grain boundaries and preventing overaging phenomena while pores are being eliminated.

Strengths: Industry-leading expertise in powder formulation specifically designed for HIP compatibility; proprietary two-stage HIP cycles that balance densification and microstructure preservation; comprehensive material database allowing precise parameter selection for different alloy systems. Weaknesses: Higher cost compared to conventional PM techniques; limited application for extremely large components due to HIP chamber size constraints; requires significant expertise to properly implement the technology.

Key Patents and Innovations in PM-HIP Processing

Hot isostatic pressing process for superalloy powder

PatentInactiveUS20160263655A1

Innovation

- A hot isostatic pressing process involving preparing superalloy powder by gas atomization, sieving to specific sizes, loading into capsules, and subjecting it to controlled temperature and pressure conditions within a hot isostatic press, with a two-stage process to minimize precipitate formation along particle boundaries, including temperatures between the incipient melting and solidus points, and holding times to dissolve low-melting phases.

Hot isostatic pressing consolidation of powder derived parts

PatentWO2020030906A1

Innovation

- A method involving multiple decompression and recompression cycles during hot isostatic pressing, combined with initial and final pressure and temperature control, to reduce porosity in metal components, specifically using inert gases like helium to facilitate diffusion bonding and minimize gas bubble size.

Material-Specific HIP Parameter Optimization

Material-specific HIP parameter optimization represents a critical aspect of successfully integrating Hot Isostatic Pressing into powder metallurgy processes. Different materials exhibit unique responses to temperature, pressure, and time parameters during HIP treatment, necessitating tailored approaches to achieve optimal densification without triggering detrimental overaging effects.

For ferrous alloys, particularly tool steels and stainless steels, optimization typically involves temperatures ranging from 1000°C to 1200°C with pressures between 100-200 MPa. The critical factor for these materials is maintaining precise control over cooling rates post-HIP to preserve desired microstructural characteristics while ensuring complete pore closure. Research indicates that stepped cooling protocols can significantly reduce the risk of overaging while maintaining densification benefits.

Nickel-based superalloys require more nuanced parameter selection, with optimal processing windows typically falling between 1150°C and 1250°C at pressures of 100-150 MPa. These materials are particularly sensitive to holding times, with research demonstrating that shorter cycles (2-4 hours) at higher temperatures often yield superior results compared to extended treatments. The γ' precipitate stability must be carefully preserved through precise temperature control.

Titanium alloys present unique challenges due to their high reactivity and phase transformation characteristics. Optimal HIP parameters generally include temperatures of 850-950°C with pressures of 100-120 MPa. Recent innovations involve modified ramp-up protocols that allow for controlled α-β phase transformations during the HIP cycle, effectively closing pores while maintaining desired mechanical properties.

Aluminum alloys benefit from significantly lower processing temperatures (400-500°C) but require careful control of heating rates to prevent localized melting at grain boundaries. Advanced parameter optimization for these materials often incorporates variable pressure profiles, with initial lower pressures (40-60 MPa) gradually increasing to 100-120 MPa as temperature stabilizes.

Computational modeling has emerged as a valuable tool for parameter optimization across material systems. Finite element simulations coupled with microstructural evolution models now enable predictive determination of optimal HIP parameters based on powder characteristics, component geometry, and desired final properties. These models increasingly incorporate machine learning algorithms to refine parameter selection based on historical processing data.

Industry trends indicate a shift toward material-specific HIP parameter databases that incorporate not only basic processing windows but also detailed information on microstructural evolution during various stages of the HIP cycle. This knowledge-based approach significantly reduces the experimental iterations required for new material systems.

For ferrous alloys, particularly tool steels and stainless steels, optimization typically involves temperatures ranging from 1000°C to 1200°C with pressures between 100-200 MPa. The critical factor for these materials is maintaining precise control over cooling rates post-HIP to preserve desired microstructural characteristics while ensuring complete pore closure. Research indicates that stepped cooling protocols can significantly reduce the risk of overaging while maintaining densification benefits.

Nickel-based superalloys require more nuanced parameter selection, with optimal processing windows typically falling between 1150°C and 1250°C at pressures of 100-150 MPa. These materials are particularly sensitive to holding times, with research demonstrating that shorter cycles (2-4 hours) at higher temperatures often yield superior results compared to extended treatments. The γ' precipitate stability must be carefully preserved through precise temperature control.

Titanium alloys present unique challenges due to their high reactivity and phase transformation characteristics. Optimal HIP parameters generally include temperatures of 850-950°C with pressures of 100-120 MPa. Recent innovations involve modified ramp-up protocols that allow for controlled α-β phase transformations during the HIP cycle, effectively closing pores while maintaining desired mechanical properties.

Aluminum alloys benefit from significantly lower processing temperatures (400-500°C) but require careful control of heating rates to prevent localized melting at grain boundaries. Advanced parameter optimization for these materials often incorporates variable pressure profiles, with initial lower pressures (40-60 MPa) gradually increasing to 100-120 MPa as temperature stabilizes.

Computational modeling has emerged as a valuable tool for parameter optimization across material systems. Finite element simulations coupled with microstructural evolution models now enable predictive determination of optimal HIP parameters based on powder characteristics, component geometry, and desired final properties. These models increasingly incorporate machine learning algorithms to refine parameter selection based on historical processing data.

Industry trends indicate a shift toward material-specific HIP parameter databases that incorporate not only basic processing windows but also detailed information on microstructural evolution during various stages of the HIP cycle. This knowledge-based approach significantly reduces the experimental iterations required for new material systems.

Sustainability Aspects of Advanced PM-HIP Technologies

The integration of sustainability principles into advanced Powder Metallurgy-Hot Isostatic Pressing (PM-HIP) technologies represents a significant evolution in manufacturing practices. These combined processes offer substantial environmental benefits compared to traditional manufacturing methods. The energy consumption of PM-HIP processes, while initially intensive during the high-pressure and high-temperature phases, demonstrates overall efficiency when considering the complete product lifecycle. Studies indicate that PM-HIP technologies can reduce energy usage by up to 30% compared to conventional casting and machining operations, primarily due to near-net-shape capabilities that minimize material waste.

Material efficiency stands as one of the most compelling sustainability advantages of advanced PM-HIP technologies. The process achieves material utilization rates exceeding 95%, significantly higher than traditional subtractive manufacturing methods that typically operate at 60-70% efficiency. This reduction in raw material consumption directly translates to conservation of natural resources and decreased mining impacts, particularly important for critical and rare earth elements commonly used in high-performance applications.

Carbon footprint analyses of PM-HIP manufacturing reveal promising results when optimized for pore closure without overaging. Recent lifecycle assessments demonstrate that despite the energy-intensive nature of the HIP process, the overall carbon emissions can be reduced by 15-25% compared to conventional methods when accounting for reduced material waste, longer component lifespans, and improved performance characteristics. The development of more energy-efficient HIP equipment, including improved insulation systems and heat recovery mechanisms, continues to enhance these sustainability metrics.

Water usage represents another critical sustainability factor where PM-HIP technologies excel. The process requires significantly less cooling water compared to traditional casting operations, with some advanced systems implementing closed-loop water recycling that reduces freshwater consumption by up to 80%. Additionally, the elimination of certain chemical treatments often required in conventional manufacturing further reduces potential water contamination issues.

From a circular economy perspective, PM-HIP components offer excellent recyclability. The high-purity metal powders used in the process can be reclaimed and reprocessed with minimal quality degradation. End-of-life components can be reintroduced into the powder production cycle, creating a more closed-loop material system that aligns with modern sustainability frameworks and extended producer responsibility principles.

Looking forward, research into renewable energy integration with HIP processes and the development of bio-based binders for green parts represents promising directions for further enhancing the sustainability profile of PM-HIP technologies. These innovations, coupled with ongoing efficiency improvements in pore closure techniques that prevent overaging, position advanced PM-HIP as an increasingly sustainable manufacturing approach for high-performance components.

Material efficiency stands as one of the most compelling sustainability advantages of advanced PM-HIP technologies. The process achieves material utilization rates exceeding 95%, significantly higher than traditional subtractive manufacturing methods that typically operate at 60-70% efficiency. This reduction in raw material consumption directly translates to conservation of natural resources and decreased mining impacts, particularly important for critical and rare earth elements commonly used in high-performance applications.

Carbon footprint analyses of PM-HIP manufacturing reveal promising results when optimized for pore closure without overaging. Recent lifecycle assessments demonstrate that despite the energy-intensive nature of the HIP process, the overall carbon emissions can be reduced by 15-25% compared to conventional methods when accounting for reduced material waste, longer component lifespans, and improved performance characteristics. The development of more energy-efficient HIP equipment, including improved insulation systems and heat recovery mechanisms, continues to enhance these sustainability metrics.

Water usage represents another critical sustainability factor where PM-HIP technologies excel. The process requires significantly less cooling water compared to traditional casting operations, with some advanced systems implementing closed-loop water recycling that reduces freshwater consumption by up to 80%. Additionally, the elimination of certain chemical treatments often required in conventional manufacturing further reduces potential water contamination issues.

From a circular economy perspective, PM-HIP components offer excellent recyclability. The high-purity metal powders used in the process can be reclaimed and reprocessed with minimal quality degradation. End-of-life components can be reintroduced into the powder production cycle, creating a more closed-loop material system that aligns with modern sustainability frameworks and extended producer responsibility principles.

Looking forward, research into renewable energy integration with HIP processes and the development of bio-based binders for green parts represents promising directions for further enhancing the sustainability profile of PM-HIP technologies. These innovations, coupled with ongoing efficiency improvements in pore closure techniques that prevent overaging, position advanced PM-HIP as an increasingly sustainable manufacturing approach for high-performance components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!