Powder Metallurgy Tribology: Counterface Effects, Oil Retention And Wear Maps

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Powder Metallurgy Tribology Background and Objectives

Powder metallurgy (PM) has evolved significantly over the past century, transforming from a niche manufacturing process to a mainstream industrial technology. The tribological behavior of PM components represents a critical aspect of their performance, particularly in applications where friction, wear, and lubrication are paramount concerns. The historical development of PM tribology can be traced back to the 1920s, with significant advancements occurring post-World War II as industrial applications expanded.

The evolution of PM tribology has been characterized by continuous improvements in material composition, processing techniques, and surface engineering methods. Early research focused primarily on basic wear resistance, while contemporary studies have expanded to include sophisticated analyses of counterface effects, oil retention capabilities, and the development of comprehensive wear maps that predict component behavior under various operating conditions.

Current technological trends in PM tribology include the integration of advanced computational modeling, novel material combinations, and surface modification techniques to enhance tribological performance. The field is increasingly moving toward predictive methodologies that can anticipate wear behavior based on material properties, processing parameters, and operating environments.

The objectives of investigating counterface effects in PM tribology center on understanding the complex interactions between PM components and their mating surfaces. These interactions significantly influence friction coefficients, wear rates, and overall system efficiency. By characterizing these relationships, engineers can optimize material pairings for specific applications.

Oil retention represents another critical area of focus, as the inherent porosity of PM components offers unique opportunities for self-lubrication. Research aims to quantify and enhance the oil retention capabilities of PM materials through controlled porosity, surface treatments, and impregnation techniques. The goal is to develop components that maintain lubrication over extended service periods, reducing maintenance requirements and extending operational life.

The development of wear maps constitutes a systematic approach to characterizing PM tribological behavior across varying conditions. These maps serve as valuable tools for engineers, enabling the prediction of wear mechanisms and rates based on load, speed, temperature, and environmental factors. The objective is to create comprehensive, application-specific wear maps that facilitate informed material selection and component design decisions.

The ultimate technological goal of PM tribology research is to establish a robust framework for designing PM components with optimized tribological properties tailored to specific applications, from automotive powertrains to industrial machinery and aerospace systems. This framework would integrate material science, surface engineering, and tribological principles to enable predictive design capabilities that reduce development cycles and enhance product performance.

The evolution of PM tribology has been characterized by continuous improvements in material composition, processing techniques, and surface engineering methods. Early research focused primarily on basic wear resistance, while contemporary studies have expanded to include sophisticated analyses of counterface effects, oil retention capabilities, and the development of comprehensive wear maps that predict component behavior under various operating conditions.

Current technological trends in PM tribology include the integration of advanced computational modeling, novel material combinations, and surface modification techniques to enhance tribological performance. The field is increasingly moving toward predictive methodologies that can anticipate wear behavior based on material properties, processing parameters, and operating environments.

The objectives of investigating counterface effects in PM tribology center on understanding the complex interactions between PM components and their mating surfaces. These interactions significantly influence friction coefficients, wear rates, and overall system efficiency. By characterizing these relationships, engineers can optimize material pairings for specific applications.

Oil retention represents another critical area of focus, as the inherent porosity of PM components offers unique opportunities for self-lubrication. Research aims to quantify and enhance the oil retention capabilities of PM materials through controlled porosity, surface treatments, and impregnation techniques. The goal is to develop components that maintain lubrication over extended service periods, reducing maintenance requirements and extending operational life.

The development of wear maps constitutes a systematic approach to characterizing PM tribological behavior across varying conditions. These maps serve as valuable tools for engineers, enabling the prediction of wear mechanisms and rates based on load, speed, temperature, and environmental factors. The objective is to create comprehensive, application-specific wear maps that facilitate informed material selection and component design decisions.

The ultimate technological goal of PM tribology research is to establish a robust framework for designing PM components with optimized tribological properties tailored to specific applications, from automotive powertrains to industrial machinery and aerospace systems. This framework would integrate material science, surface engineering, and tribological principles to enable predictive design capabilities that reduce development cycles and enhance product performance.

Market Demand Analysis for PM Tribological Applications

The global market for powder metallurgy (PM) tribological applications has been experiencing steady growth, driven primarily by the automotive, aerospace, and industrial equipment sectors. Current market valuations indicate that the PM components market exceeds $15 billion annually, with tribological applications representing approximately 30% of this value. The demand for PM tribological components is projected to grow at a compound annual growth rate of 5.7% through 2028, outpacing traditional manufacturing methods.

Automotive applications remain the largest consumer of PM tribological components, accounting for over 45% of market demand. This sector's interest stems from the need for lightweight, durable components that can reduce fuel consumption and emissions while maintaining performance standards. Particularly, self-lubricating bearings, valve seats, and transmission components represent high-volume applications where counterface effects and oil retention properties are critical performance factors.

The aerospace industry, though smaller in volume, represents a high-value segment with stringent requirements for tribological performance under extreme conditions. This sector demands PM components with exceptional wear resistance and reliable performance across wide temperature ranges, creating premium pricing opportunities for advanced PM solutions with optimized wear maps.

Industrial equipment manufacturers constitute the third major market segment, with growing demand for maintenance-free bearings and wear-resistant components. This sector particularly values PM components with enhanced oil retention capabilities that can extend service intervals and reduce maintenance costs in heavy machinery applications.

Regional analysis reveals that North America and Europe currently lead in consumption of advanced PM tribological components, though Asia-Pacific markets are showing the fastest growth rates, particularly in China and India where industrial expansion and automotive manufacturing are accelerating rapidly. These emerging markets are expected to account for over 40% of new demand growth in the coming decade.

Customer requirements are increasingly focused on performance predictability, with wear maps becoming essential decision-making tools for engineers. Market research indicates that 78% of design engineers consider reliable wear prediction data a critical factor when selecting PM components for tribological applications. This represents a significant shift from price-driven purchasing toward value-based selection criteria.

Environmental regulations and sustainability initiatives are also reshaping market demands, with growing interest in oil-free and reduced-lubrication PM solutions. This trend is particularly pronounced in European markets, where stringent environmental regulations are driving innovation in self-lubricating PM materials and surface treatments that can optimize counterface interactions while minimizing environmental impact.

Automotive applications remain the largest consumer of PM tribological components, accounting for over 45% of market demand. This sector's interest stems from the need for lightweight, durable components that can reduce fuel consumption and emissions while maintaining performance standards. Particularly, self-lubricating bearings, valve seats, and transmission components represent high-volume applications where counterface effects and oil retention properties are critical performance factors.

The aerospace industry, though smaller in volume, represents a high-value segment with stringent requirements for tribological performance under extreme conditions. This sector demands PM components with exceptional wear resistance and reliable performance across wide temperature ranges, creating premium pricing opportunities for advanced PM solutions with optimized wear maps.

Industrial equipment manufacturers constitute the third major market segment, with growing demand for maintenance-free bearings and wear-resistant components. This sector particularly values PM components with enhanced oil retention capabilities that can extend service intervals and reduce maintenance costs in heavy machinery applications.

Regional analysis reveals that North America and Europe currently lead in consumption of advanced PM tribological components, though Asia-Pacific markets are showing the fastest growth rates, particularly in China and India where industrial expansion and automotive manufacturing are accelerating rapidly. These emerging markets are expected to account for over 40% of new demand growth in the coming decade.

Customer requirements are increasingly focused on performance predictability, with wear maps becoming essential decision-making tools for engineers. Market research indicates that 78% of design engineers consider reliable wear prediction data a critical factor when selecting PM components for tribological applications. This represents a significant shift from price-driven purchasing toward value-based selection criteria.

Environmental regulations and sustainability initiatives are also reshaping market demands, with growing interest in oil-free and reduced-lubrication PM solutions. This trend is particularly pronounced in European markets, where stringent environmental regulations are driving innovation in self-lubricating PM materials and surface treatments that can optimize counterface interactions while minimizing environmental impact.

Current Challenges in PM Surface-Counterface Interactions

The interaction between powder metallurgy (PM) components and their counterfaces presents significant challenges in tribological applications. Current PM materials, despite their advantageous properties such as controlled porosity and self-lubrication capabilities, face substantial limitations when interacting with various counterface materials. The hardness mismatch between PM components and their counterfaces often leads to accelerated wear rates, particularly when softer PM materials interact with harder counterface materials like hardened steel or ceramic surfaces.

Surface topography compatibility represents another critical challenge. The inherent porosity of PM components creates unique surface characteristics that can either enhance or impede tribological performance depending on the counterface material. When PM surfaces interact with smooth counterfaces, the pores can act as debris traps and lubricant reservoirs. However, this same porosity can become problematic when interacting with rough counterfaces, as the asperities may penetrate and damage the PM structure.

Oil retention mechanisms in PM components are significantly affected by counterface properties. While the porous nature of PM materials theoretically provides excellent oil retention capabilities, the actual performance depends heavily on the counterface characteristics. Hydrophilic counterfaces may draw lubricant away from the PM component, while hydrophobic surfaces might prevent proper lubricant distribution across the interface. This dynamic oil migration behavior remains poorly understood and difficult to predict in real-world applications.

Temperature management at the PM-counterface interface presents another substantial challenge. The thermal conductivity differences between PM materials and various counterfaces can create localized hot spots, accelerating lubricant degradation and promoting adhesive wear mechanisms. This thermal mismatch is particularly problematic in high-speed applications where heat generation rates exceed dissipation capabilities.

The development of comprehensive wear maps for PM-counterface combinations remains incomplete. Current models fail to adequately account for the complex interactions between porosity, counterface material properties, lubricant characteristics, and operating conditions. This knowledge gap hampers the ability to predict wear behavior accurately and design optimal PM components for specific tribological applications.

Chemical compatibility between PM materials, their counterfaces, and lubricants introduces additional complications. Certain counterface materials may catalyze lubricant degradation or react with PM constituents under operating conditions. These chemical interactions can lead to unexpected wear mechanisms and premature component failure that are difficult to predict through conventional testing methods.

Surface topography compatibility represents another critical challenge. The inherent porosity of PM components creates unique surface characteristics that can either enhance or impede tribological performance depending on the counterface material. When PM surfaces interact with smooth counterfaces, the pores can act as debris traps and lubricant reservoirs. However, this same porosity can become problematic when interacting with rough counterfaces, as the asperities may penetrate and damage the PM structure.

Oil retention mechanisms in PM components are significantly affected by counterface properties. While the porous nature of PM materials theoretically provides excellent oil retention capabilities, the actual performance depends heavily on the counterface characteristics. Hydrophilic counterfaces may draw lubricant away from the PM component, while hydrophobic surfaces might prevent proper lubricant distribution across the interface. This dynamic oil migration behavior remains poorly understood and difficult to predict in real-world applications.

Temperature management at the PM-counterface interface presents another substantial challenge. The thermal conductivity differences between PM materials and various counterfaces can create localized hot spots, accelerating lubricant degradation and promoting adhesive wear mechanisms. This thermal mismatch is particularly problematic in high-speed applications where heat generation rates exceed dissipation capabilities.

The development of comprehensive wear maps for PM-counterface combinations remains incomplete. Current models fail to adequately account for the complex interactions between porosity, counterface material properties, lubricant characteristics, and operating conditions. This knowledge gap hampers the ability to predict wear behavior accurately and design optimal PM components for specific tribological applications.

Chemical compatibility between PM materials, their counterfaces, and lubricants introduces additional complications. Certain counterface materials may catalyze lubricant degradation or react with PM constituents under operating conditions. These chemical interactions can lead to unexpected wear mechanisms and premature component failure that are difficult to predict through conventional testing methods.

Current Solutions for Oil Retention in PM Components

01 Porous sintered materials with enhanced oil retention properties

Powder metallurgy techniques can be used to create porous sintered materials with specific microstructures designed for optimal oil retention. These materials typically have interconnected pores that act as oil reservoirs, providing continuous lubrication during operation. The porosity level, pore size distribution, and pore connectivity are carefully controlled during the sintering process to maximize oil retention capacity while maintaining adequate mechanical strength. These materials are particularly useful in self-lubricating bearings and bushings where long-term lubrication is required without frequent maintenance.- Porous structure design for oil retention: Powder metallurgy components can be designed with specific porous structures to enhance oil retention capabilities. These structures include interconnected pores, controlled pore size distribution, and engineered porosity gradients that allow for optimal oil storage and release during operation. The porous network acts as a reservoir for lubricating oil, providing continuous lubrication to reduce wear in high-friction applications. This approach is particularly effective in self-lubricating bearings and bushings where consistent oil supply is critical for extended component life.

- Composite materials with enhanced wear resistance: Incorporating specific additives and reinforcement materials into powder metallurgy compositions can significantly improve wear resistance while maintaining oil retention properties. These composites often combine soft phases that retain oil with hard phases that resist wear. Common reinforcements include ceramic particles, carbon-based materials, and intermetallic compounds that create a heterogeneous microstructure optimized for both tribological performance and lubrication. The synergistic effect between the matrix material and reinforcements results in components with superior mechanical properties and extended service life under demanding operating conditions.

- Surface treatment technologies for improved oil retention: Various surface treatment methods can be applied to powder metallurgy components to enhance their oil retention capabilities. These include chemical etching, laser texturing, and specialized impregnation techniques that create micro-reservoirs on the component surface. These treatments modify the surface topography and chemistry to increase wettability and oil adhesion while maintaining wear resistance. The engineered surface features act as microscopic oil depots that continuously release lubricant during operation, reducing friction and extending component life in applications where traditional lubrication methods are insufficient.

- Sintering process optimization for balanced properties: Optimizing the sintering process parameters is crucial for achieving the ideal balance between mechanical strength, wear resistance, and oil retention in powder metallurgy components. Controlled temperature profiles, sintering atmospheres, and cooling rates significantly influence the final microstructure and pore characteristics. Advanced sintering techniques such as liquid phase sintering and spark plasma sintering can be employed to create components with tailored porosity networks that maximize oil retention while maintaining structural integrity. These optimized processes result in components with superior performance in applications requiring both strength and self-lubrication properties.

- Novel lubricant formulations for powder metallurgy applications: Specialized lubricant formulations designed specifically for powder metallurgy components can significantly enhance oil retention and wear performance. These formulations often include additives such as extreme pressure agents, anti-wear compounds, and viscosity modifiers that improve the lubricant's affinity to the porous metal structure. Some advanced approaches incorporate solid lubricants or microencapsulated oil reservoirs directly into the powder mixture before sintering. These innovative lubricant systems provide extended lubrication intervals, reduced maintenance requirements, and improved performance under extreme operating conditions such as high temperatures or heavy loads.

02 Composite materials with wear-resistant coatings

Advanced powder metallurgy processes can produce composite materials with specialized wear-resistant coatings or surface treatments. These composites typically consist of a porous metal matrix that provides oil retention capabilities, combined with a hard, wear-resistant surface layer. The wear-resistant layer can be achieved through various methods including infiltration with harder materials, surface alloying, or specialized heat treatments. This combination results in components that offer both excellent oil retention for lubrication and superior wear resistance, extending the service life of mechanical parts operating under high-stress conditions.Expand Specific Solutions03 Additives and alloying elements for improved performance

Specific additives and alloying elements can be incorporated during the powder metallurgy process to enhance both oil retention and wear resistance properties. Common additives include copper, graphite, molybdenum disulfide, and various ceramic particles. These additives can create a more favorable microstructure for oil retention while simultaneously improving the material's inherent wear resistance. The precise composition and distribution of these additives within the metal matrix are critical factors that determine the final performance characteristics of the component, allowing for customization based on specific application requirements.Expand Specific Solutions04 Processing techniques for optimized oil retention structures

Specialized powder metallurgy processing techniques have been developed to create optimized structures for oil retention while maintaining wear resistance. These techniques include controlled density sintering, selective laser sintering, hot isostatic pressing, and infiltration methods. By carefully controlling processing parameters such as temperature, pressure, time, and cooling rates, manufacturers can create tailored pore structures with specific characteristics. Some advanced processes incorporate multiple steps to first establish the desired porosity for oil retention and then enhance the surface properties for wear resistance, resulting in components with dual functionality.Expand Specific Solutions05 Self-lubricating bearing systems with enhanced durability

Powder metallurgy enables the production of self-lubricating bearing systems that combine excellent oil retention with superior wear resistance. These systems typically feature a carefully engineered porous structure that serves as an oil reservoir, releasing lubricant during operation and reabsorbing it during rest periods. The bearing material often incorporates solid lubricants distributed throughout the matrix to provide additional lubrication when oil supply is limited. Advanced designs may include channels or grooves to facilitate oil flow and distribution across the bearing surface, ensuring consistent lubrication even under challenging operating conditions and extending component lifespan.Expand Specific Solutions

Key Industry Players in PM Tribology Research

Powder Metallurgy Tribology is currently in a growth phase, with the market expected to reach significant expansion due to increasing applications in automotive, aerospace, and industrial sectors. The technology demonstrates moderate maturity with ongoing innovations in oil retention mechanisms and wear resistance. Key players shaping the competitive landscape include Oerlikon Surface Solutions AG with advanced coating technologies, Caterpillar Inc. focusing on heavy-duty applications, Tribotecc GmbH specializing in metal sulfides for friction materials, and Sumitomo Electric Hardmetal Ltd. developing specialized tooling solutions. Research institutions like University of Akron and King Fahd University of Petroleum & Minerals are contributing significant advancements in counterface effects and wear mapping methodologies, creating a dynamic ecosystem of industrial and academic collaboration.

Oerlikon Surface Solutions AG

Technical Solution: Oerlikon has developed advanced powder metallurgy tribology solutions through their integrated approach combining specialized powder formulations with surface engineering technologies. Their proprietary BALINIT® coating systems are specifically designed to enhance the tribological performance of powder metallurgy components by creating optimized counterface interactions that minimize wear while maintaining effective oil retention in the underlying porous structure. Oerlikon's research has established comprehensive wear maps for various powder metallurgy material combinations across diverse operating conditions, enabling precise prediction of tribological behavior in specific applications. Their technology includes tailored surface texturing processes that create controlled micro-reservoirs on powder metallurgy components, enhancing oil retention capabilities while maintaining favorable counterface interactions. Oerlikon's approach incorporates advanced PVD and CVD coating technologies that can be applied to powder metallurgy components post-sintering, creating composite systems with exceptional wear resistance while preserving the beneficial oil retention properties of the substrate. Their research has identified optimal coating architectures that provide both low friction coefficients and high wear resistance when operating against various counterface materials under boundary lubrication conditions.

Strengths: Comprehensive expertise spanning powder metallurgy and surface engineering; advanced coating technologies specifically optimized for tribological applications; sophisticated characterization and testing capabilities. Weaknesses: Higher cost solutions due to additional processing steps; complex quality control requirements; performance highly dependent on coating adhesion and integrity.

Caterpillar, Inc.

Technical Solution: Caterpillar has developed advanced powder metallurgy tribology solutions specifically engineered for heavy equipment applications operating under extreme conditions. Their technology incorporates gradient porosity structures in sintered components, with higher porosity regions strategically positioned to maximize oil retention while maintaining structural integrity in high-stress areas. Caterpillar's research has established comprehensive wear maps for powder metallurgy components interacting with various counterface materials, enabling precise prediction of component lifespans under different operating conditions. Their proprietary infiltration techniques combine the structural benefits of powder metallurgy with enhanced tribological properties by introducing secondary phases that form beneficial tribofilms during operation. Caterpillar's technology includes specialized heat treatment processes that optimize both the mechanical properties and oil retention characteristics of powder metallurgy components, achieving up to 30% longer service life in field applications compared to conventional materials. Their research has identified optimal counterface material combinations that minimize adhesive wear while maintaining efficient boundary lubrication in oil-starved conditions.

Strengths: Extensive real-world validation in demanding applications; integrated approach considering both tribological and structural requirements; sophisticated testing capabilities simulating actual operating conditions. Weaknesses: Solutions primarily optimized for heavy equipment applications; higher initial manufacturing costs; requires specialized production equipment and expertise.

Critical Analysis of PM Wear Mechanism Patents

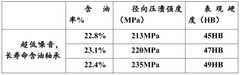

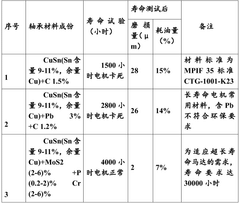

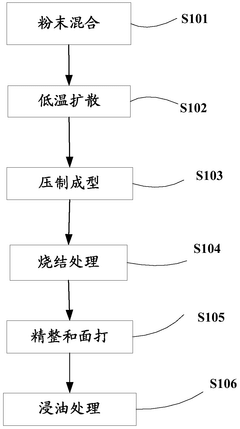

Method for manufacturing ultra-low-noise long-service-life oil-retaining bearing in powder metallurgy

PatentWO2016206259A1

Innovation

- A specific proportion of Sn element powder, reinforcing agent and lubricant is mixed. After low-temperature diffusion, sintering and oil immersion treatment, a sponge-like surface structure and lubricating layer are formed. Combined with Cr element to improve the strength of the matrix, the toothed inner diameter and spherical shape are designed to enhance the Lubricating effect and wear resistance.

Powder metallurgy high-speed steel for large-sized complex tool and preparation method therefor

PatentWO2022011721A1

Innovation

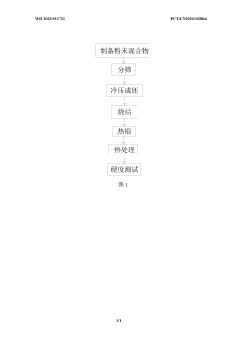

- Grinding technology, cold press forming and electromagnetic heating high-temperature sintering technology are used, combined with forging and heat treatment, to prepare powder metallurgy high-speed steel for large-sized and complex cutting tools, eliminating the need to smelt metal raw materials and improving processing efficiency and strength.

Standardization of PM Wear Maps and Testing Protocols

The standardization of wear maps and testing protocols represents a critical advancement in powder metallurgy (PM) tribology research. Current challenges in comparing tribological data across different studies stem from variations in testing methodologies, specimen preparation, and reporting formats. Establishing standardized wear maps would enable researchers and industry professionals to reliably predict material performance under specific operating conditions.

A comprehensive standardization framework should include precise definitions of wear mechanisms specific to PM materials, considering their unique porosity characteristics and oil retention capabilities. The framework must establish uniform testing parameters including load ranges, sliding speeds, temperature conditions, and environmental factors that reflect real-world applications of PM components.

Testing protocols require standardization across sample preparation methods, ensuring consistent surface finishing, porosity levels, and impregnation procedures when applicable. The counterface material selection process should be systematized to account for the significant influence of counterface properties on PM tribological behavior. This includes standardized roughness measurements and hardness specifications for counterface materials.

Data collection methodologies need standardization to ensure comparable results across different research institutions and manufacturing facilities. This includes uniform procedures for measuring wear volume, wear rate calculation, friction coefficient determination, and oil retention capacity assessment. Advanced imaging techniques for wear surface characterization should follow standardized protocols to facilitate meaningful comparisons.

Reporting formats must be standardized to include essential parameters such as material composition, processing conditions, density, hardness, and microstructural features. The development of digital repositories for PM wear data would significantly enhance accessibility and comparative analysis capabilities across the industry.

International collaboration between academic institutions, industry leaders, and standards organizations is essential for developing these standardized protocols. Organizations such as MPIF (Metal Powder Industries Federation), ASTM International, and ISO should coordinate efforts to establish globally recognized standards for PM tribological testing.

The implementation of standardized wear maps would provide valuable tools for materials selection, component design, and performance prediction in various applications including automotive components, industrial machinery, and consumer products where PM parts experience tribological contact.

A comprehensive standardization framework should include precise definitions of wear mechanisms specific to PM materials, considering their unique porosity characteristics and oil retention capabilities. The framework must establish uniform testing parameters including load ranges, sliding speeds, temperature conditions, and environmental factors that reflect real-world applications of PM components.

Testing protocols require standardization across sample preparation methods, ensuring consistent surface finishing, porosity levels, and impregnation procedures when applicable. The counterface material selection process should be systematized to account for the significant influence of counterface properties on PM tribological behavior. This includes standardized roughness measurements and hardness specifications for counterface materials.

Data collection methodologies need standardization to ensure comparable results across different research institutions and manufacturing facilities. This includes uniform procedures for measuring wear volume, wear rate calculation, friction coefficient determination, and oil retention capacity assessment. Advanced imaging techniques for wear surface characterization should follow standardized protocols to facilitate meaningful comparisons.

Reporting formats must be standardized to include essential parameters such as material composition, processing conditions, density, hardness, and microstructural features. The development of digital repositories for PM wear data would significantly enhance accessibility and comparative analysis capabilities across the industry.

International collaboration between academic institutions, industry leaders, and standards organizations is essential for developing these standardized protocols. Organizations such as MPIF (Metal Powder Industries Federation), ASTM International, and ISO should coordinate efforts to establish globally recognized standards for PM tribological testing.

The implementation of standardized wear maps would provide valuable tools for materials selection, component design, and performance prediction in various applications including automotive components, industrial machinery, and consumer products where PM parts experience tribological contact.

Environmental Impact of PM Tribological Systems

The environmental impact of powder metallurgy (PM) tribological systems represents a critical consideration in modern industrial applications. PM components, widely used in automotive and machinery sectors, interact with the environment throughout their lifecycle, from raw material extraction to end-of-life disposal. These environmental interactions are particularly significant during operational phases where tribological processes occur.

PM tribological systems typically demonstrate reduced environmental footprint compared to conventional manufacturing methods. The sintering process consumes less energy than traditional casting or forging operations, resulting in lower carbon emissions. Additionally, PM manufacturing generates minimal material waste as nearly 95% of the initial powder can be utilized in the final product, significantly reducing resource depletion compared to subtractive manufacturing techniques.

Oil retention characteristics of PM components play a dual environmental role. While improved oil retention reduces the frequency of lubrication and associated maintenance, concerns exist regarding potential leakage of lubricants into the environment. Recent studies indicate that properly designed PM components with optimized porosity can reduce lubricant consumption by up to 30% compared to solid metal counterparts, thereby minimizing the environmental impact associated with lubricant production and disposal.

Wear mechanisms in PM tribological systems directly influence their environmental performance. Excessive wear not only shortens component lifespan, necessitating more frequent replacement and increased resource consumption, but also generates particulate matter that may contaminate surrounding environments. Research demonstrates that PM components with properly engineered wear maps can extend service life by 40-60%, substantially reducing the environmental burden of manufacturing replacement parts.

Counterface effects in PM tribology present another environmental consideration. The interaction between PM components and their counterfaces determines wear rates and system efficiency. Environmentally optimized counterface materials can reduce friction by 15-25%, translating to energy savings and reduced greenhouse gas emissions in applications such as automotive powertrains.

Emerging sustainable practices in PM tribology include the development of bio-based lubricants compatible with PM porosity, recycling of metal powders from end-of-life components, and design optimization for remanufacturing. These approaches align with circular economy principles and can reduce the overall environmental impact of PM tribological systems by up to 40% throughout their lifecycle.

Future research directions should focus on quantifying the environmental benefits of advanced PM tribological systems through comprehensive life cycle assessment methodologies, particularly examining the trade-offs between manufacturing impacts and operational efficiency gains.

PM tribological systems typically demonstrate reduced environmental footprint compared to conventional manufacturing methods. The sintering process consumes less energy than traditional casting or forging operations, resulting in lower carbon emissions. Additionally, PM manufacturing generates minimal material waste as nearly 95% of the initial powder can be utilized in the final product, significantly reducing resource depletion compared to subtractive manufacturing techniques.

Oil retention characteristics of PM components play a dual environmental role. While improved oil retention reduces the frequency of lubrication and associated maintenance, concerns exist regarding potential leakage of lubricants into the environment. Recent studies indicate that properly designed PM components with optimized porosity can reduce lubricant consumption by up to 30% compared to solid metal counterparts, thereby minimizing the environmental impact associated with lubricant production and disposal.

Wear mechanisms in PM tribological systems directly influence their environmental performance. Excessive wear not only shortens component lifespan, necessitating more frequent replacement and increased resource consumption, but also generates particulate matter that may contaminate surrounding environments. Research demonstrates that PM components with properly engineered wear maps can extend service life by 40-60%, substantially reducing the environmental burden of manufacturing replacement parts.

Counterface effects in PM tribology present another environmental consideration. The interaction between PM components and their counterfaces determines wear rates and system efficiency. Environmentally optimized counterface materials can reduce friction by 15-25%, translating to energy savings and reduced greenhouse gas emissions in applications such as automotive powertrains.

Emerging sustainable practices in PM tribology include the development of bio-based lubricants compatible with PM porosity, recycling of metal powders from end-of-life components, and design optimization for remanufacturing. These approaches align with circular economy principles and can reduce the overall environmental impact of PM tribological systems by up to 40% throughout their lifecycle.

Future research directions should focus on quantifying the environmental benefits of advanced PM tribological systems through comprehensive life cycle assessment methodologies, particularly examining the trade-offs between manufacturing impacts and operational efficiency gains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!