Powder Metallurgy Sintering Maps: Neck Growth, Pore Morphology And Distortion Limits

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Powder Metallurgy Sintering Evolution and Objectives

Powder metallurgy (PM) has evolved significantly since its inception in the early 20th century, transforming from a niche manufacturing process to a sophisticated technology with applications across numerous industries. The sintering process, a critical step in powder metallurgy, has undergone substantial refinement over decades, with major advancements occurring in the understanding of fundamental mechanisms governing densification and microstructural evolution.

The development of sintering maps represents a pivotal advancement in powder metallurgy science. These maps provide visual representations of the complex relationships between processing parameters, material properties, and resulting microstructures. Early sintering maps focused primarily on densification kinetics, but modern iterations have expanded to include critical factors such as neck growth between particles, pore morphology evolution, and dimensional stability limits.

Historically, sintering was largely an empirical process, with parameters determined through trial and error. The transition toward a more scientific approach began in the 1950s with the development of solid-state diffusion theories. By the 1980s, computational models started to emerge, allowing for more precise predictions of sintering behavior. The 1990s saw the integration of these models with experimental data, leading to the first comprehensive sintering maps.

Recent technological advancements, particularly in in-situ characterization techniques such as high-temperature X-ray tomography and synchrotron radiation analysis, have dramatically enhanced our ability to observe and quantify sintering phenomena in real-time. These observations have been crucial in refining sintering maps to account for complex phenomena like neck growth kinetics under various conditions.

The primary objective of current research in sintering maps is to develop predictive tools that can accurately forecast the evolution of microstructure during sintering across diverse material systems and processing conditions. Specifically, researchers aim to establish quantitative relationships between processing parameters (temperature, time, atmosphere), material characteristics (particle size, composition, initial density), and resulting properties (final density, pore structure, dimensional accuracy).

Another key goal is to integrate these maps into computational frameworks that can guide the design of sintering cycles for novel materials and complex geometries. This includes addressing challenges related to multi-material systems and functionally graded materials, where differential sintering rates can lead to significant distortion and internal stresses.

The ultimate aim is to transition powder metallurgy from a largely experience-based practice to a precisely controlled, science-driven manufacturing technology capable of producing components with predictable properties and minimal post-processing requirements.

The development of sintering maps represents a pivotal advancement in powder metallurgy science. These maps provide visual representations of the complex relationships between processing parameters, material properties, and resulting microstructures. Early sintering maps focused primarily on densification kinetics, but modern iterations have expanded to include critical factors such as neck growth between particles, pore morphology evolution, and dimensional stability limits.

Historically, sintering was largely an empirical process, with parameters determined through trial and error. The transition toward a more scientific approach began in the 1950s with the development of solid-state diffusion theories. By the 1980s, computational models started to emerge, allowing for more precise predictions of sintering behavior. The 1990s saw the integration of these models with experimental data, leading to the first comprehensive sintering maps.

Recent technological advancements, particularly in in-situ characterization techniques such as high-temperature X-ray tomography and synchrotron radiation analysis, have dramatically enhanced our ability to observe and quantify sintering phenomena in real-time. These observations have been crucial in refining sintering maps to account for complex phenomena like neck growth kinetics under various conditions.

The primary objective of current research in sintering maps is to develop predictive tools that can accurately forecast the evolution of microstructure during sintering across diverse material systems and processing conditions. Specifically, researchers aim to establish quantitative relationships between processing parameters (temperature, time, atmosphere), material characteristics (particle size, composition, initial density), and resulting properties (final density, pore structure, dimensional accuracy).

Another key goal is to integrate these maps into computational frameworks that can guide the design of sintering cycles for novel materials and complex geometries. This includes addressing challenges related to multi-material systems and functionally graded materials, where differential sintering rates can lead to significant distortion and internal stresses.

The ultimate aim is to transition powder metallurgy from a largely experience-based practice to a precisely controlled, science-driven manufacturing technology capable of producing components with predictable properties and minimal post-processing requirements.

Market Applications and Industry Demand for PM Components

The global powder metallurgy (PM) market has experienced significant growth, reaching approximately $30 billion in 2022, with projections indicating a compound annual growth rate of 6.5% through 2030. This growth is primarily driven by the automotive industry, which accounts for over 70% of PM component applications. The demand for lightweight, high-performance parts with complex geometries has positioned PM as a preferred manufacturing method for transmission components, connecting rods, and bearing assemblies.

The automotive sector's shift toward electric vehicles has created new opportunities for PM components, particularly in motor housings, battery components, and thermal management systems. These applications require precise control of porosity and dimensional stability—areas where advanced sintering maps provide critical guidance for manufacturers.

Aerospace and defense industries represent the second-largest market for PM components, valued at approximately $5 billion. These sectors demand high-performance materials with exceptional mechanical properties and tight dimensional tolerances. Sintering maps that predict neck growth and distortion limits are essential for meeting the stringent requirements of turbine components, structural parts, and specialized hardware used in extreme environments.

The medical device industry has emerged as a rapidly growing market for PM components, particularly in implantable devices and surgical instruments. This sector values the ability of PM to create porous structures that promote osseointegration while maintaining mechanical integrity. Understanding pore morphology through sintering maps directly translates to improved biocompatibility and functional performance of medical implants.

Industrial equipment manufacturers increasingly adopt PM components for applications requiring wear resistance and self-lubrication properties. The global market for these applications exceeds $3 billion annually, with particular demand in pumps, compressors, and material handling equipment. These applications benefit from precise control of final porosity and dimensional accuracy during sintering.

Consumer electronics represent an emerging application area, with PM components finding use in heat sinks, EMI shielding, and miniaturized mechanical components. This market segment values the ability to produce complex geometries with consistent properties at high volumes—characteristics that depend heavily on understanding sintering behavior through comprehensive sintering maps.

Industry surveys indicate that over 85% of PM component manufacturers consider sintering process optimization as their top technical challenge, highlighting the critical importance of advanced sintering maps that can predict neck growth, pore evolution, and dimensional changes across various material systems and processing conditions.

The automotive sector's shift toward electric vehicles has created new opportunities for PM components, particularly in motor housings, battery components, and thermal management systems. These applications require precise control of porosity and dimensional stability—areas where advanced sintering maps provide critical guidance for manufacturers.

Aerospace and defense industries represent the second-largest market for PM components, valued at approximately $5 billion. These sectors demand high-performance materials with exceptional mechanical properties and tight dimensional tolerances. Sintering maps that predict neck growth and distortion limits are essential for meeting the stringent requirements of turbine components, structural parts, and specialized hardware used in extreme environments.

The medical device industry has emerged as a rapidly growing market for PM components, particularly in implantable devices and surgical instruments. This sector values the ability of PM to create porous structures that promote osseointegration while maintaining mechanical integrity. Understanding pore morphology through sintering maps directly translates to improved biocompatibility and functional performance of medical implants.

Industrial equipment manufacturers increasingly adopt PM components for applications requiring wear resistance and self-lubrication properties. The global market for these applications exceeds $3 billion annually, with particular demand in pumps, compressors, and material handling equipment. These applications benefit from precise control of final porosity and dimensional accuracy during sintering.

Consumer electronics represent an emerging application area, with PM components finding use in heat sinks, EMI shielding, and miniaturized mechanical components. This market segment values the ability to produce complex geometries with consistent properties at high volumes—characteristics that depend heavily on understanding sintering behavior through comprehensive sintering maps.

Industry surveys indicate that over 85% of PM component manufacturers consider sintering process optimization as their top technical challenge, highlighting the critical importance of advanced sintering maps that can predict neck growth, pore evolution, and dimensional changes across various material systems and processing conditions.

Current Sintering Technology Limitations and Challenges

Despite significant advancements in powder metallurgy sintering technology, several critical limitations and challenges persist that impede optimal process control and predictability. The fundamental challenge lies in the complex interplay between neck growth mechanisms, pore evolution, and dimensional stability during the sintering process. Current sintering technologies struggle to simultaneously achieve high densification while maintaining precise dimensional control, particularly for complex geometries and large components.

Temperature gradient management remains problematic in conventional sintering furnaces, leading to non-uniform densification across parts. This heterogeneity in microstructure development directly impacts mechanical properties and can introduce residual stresses that compromise component performance. Even advanced sintering technologies like spark plasma sintering (SPS) and microwave sintering face challenges in scaling up while maintaining uniform heating profiles.

The prediction and control of pore morphology evolution represents another significant limitation. Current models inadequately capture the transition from open to closed porosity and the subsequent pore coarsening phenomena, especially for multi-component powder systems. This limitation becomes particularly evident when dealing with materials exhibiting different diffusion rates or when liquid phase sintering occurs alongside solid-state mechanisms.

Distortion control during sintering continues to challenge manufacturers, with dimensional changes often exceeding 15-20% for certain material systems. The anisotropic shrinkage behavior observed in many powder compacts further complicates dimensional prediction, necessitating expensive trial-and-error approaches for tooling design. This challenge is exacerbated when sintering functionally graded materials or components with varying cross-sectional thicknesses.

The lack of real-time monitoring capabilities presents a substantial barrier to process optimization. Current technologies offer limited in-situ measurement options for tracking neck growth kinetics and pore evolution during the sintering cycle. This deficiency hampers the development of closed-loop control systems that could dynamically adjust sintering parameters based on actual microstructural evolution.

Material-specific challenges also persist, particularly for advanced ceramics, refractory metals, and composite systems. These materials often exhibit complex sintering behaviors that deviate significantly from classical models, making process parameter optimization highly empirical. The sintering of nanopowders introduces additional complications related to agglomeration, enhanced surface energies, and accelerated grain growth that can undermine the benefits of nanostructured materials.

Environmental considerations and energy efficiency requirements further constrain sintering technology development. Traditional sintering processes are energy-intensive, with thermal efficiencies often below 40%. Alternative, more energy-efficient sintering approaches frequently struggle to match the throughput and reliability of conventional methods, limiting their industrial adoption despite their potential sustainability benefits.

Temperature gradient management remains problematic in conventional sintering furnaces, leading to non-uniform densification across parts. This heterogeneity in microstructure development directly impacts mechanical properties and can introduce residual stresses that compromise component performance. Even advanced sintering technologies like spark plasma sintering (SPS) and microwave sintering face challenges in scaling up while maintaining uniform heating profiles.

The prediction and control of pore morphology evolution represents another significant limitation. Current models inadequately capture the transition from open to closed porosity and the subsequent pore coarsening phenomena, especially for multi-component powder systems. This limitation becomes particularly evident when dealing with materials exhibiting different diffusion rates or when liquid phase sintering occurs alongside solid-state mechanisms.

Distortion control during sintering continues to challenge manufacturers, with dimensional changes often exceeding 15-20% for certain material systems. The anisotropic shrinkage behavior observed in many powder compacts further complicates dimensional prediction, necessitating expensive trial-and-error approaches for tooling design. This challenge is exacerbated when sintering functionally graded materials or components with varying cross-sectional thicknesses.

The lack of real-time monitoring capabilities presents a substantial barrier to process optimization. Current technologies offer limited in-situ measurement options for tracking neck growth kinetics and pore evolution during the sintering cycle. This deficiency hampers the development of closed-loop control systems that could dynamically adjust sintering parameters based on actual microstructural evolution.

Material-specific challenges also persist, particularly for advanced ceramics, refractory metals, and composite systems. These materials often exhibit complex sintering behaviors that deviate significantly from classical models, making process parameter optimization highly empirical. The sintering of nanopowders introduces additional complications related to agglomeration, enhanced surface energies, and accelerated grain growth that can undermine the benefits of nanostructured materials.

Environmental considerations and energy efficiency requirements further constrain sintering technology development. Traditional sintering processes are energy-intensive, with thermal efficiencies often below 40%. Alternative, more energy-efficient sintering approaches frequently struggle to match the throughput and reliability of conventional methods, limiting their industrial adoption despite their potential sustainability benefits.

Established Methodologies for Neck Growth and Pore Control

01 Neck growth mechanisms in powder metallurgy sintering

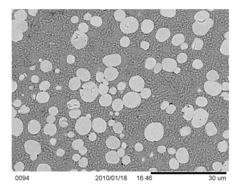

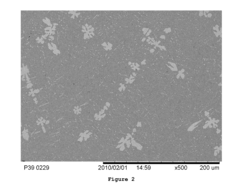

During the sintering process in powder metallurgy, neck growth between adjacent particles is a critical phenomenon that determines the final properties of the sintered component. The formation and growth of these necks involve diffusion mechanisms, including surface diffusion, grain boundary diffusion, and volume diffusion. These mechanisms can be mapped and modeled to predict the sintering behavior and optimize process parameters. Understanding neck growth kinetics helps in controlling densification rates and final microstructure development.- Neck growth mechanisms in powder metallurgy sintering: During the sintering process in powder metallurgy, neck growth between adjacent particles is a critical phenomenon that determines the final properties of the sintered component. This process involves material transport mechanisms such as diffusion and plastic flow at contact points between particles. The formation and growth of these necks significantly influence the mechanical strength, density, and microstructural characteristics of the final product. Understanding and controlling neck growth parameters allows for optimization of sintering conditions to achieve desired material properties.

- Pore morphology control and evolution during sintering: The evolution of pore morphology during the sintering process is fundamental to achieving desired material properties in powder metallurgy. As sintering progresses, pores undergo changes in size, shape, and distribution, which directly impact the final density and mechanical properties of the component. Factors affecting pore evolution include sintering temperature, time, atmosphere, and initial powder characteristics. Advanced techniques for monitoring and controlling pore morphology enable the development of materials with tailored porosity for specific applications, such as filters, bearings, or lightweight structural components.

- Distortion limits and dimensional control in sintered components: Maintaining dimensional accuracy and preventing distortion during sintering is a significant challenge in powder metallurgy. Sintering maps can be used to predict and control dimensional changes, helping to establish the distortion limits for various powder compositions and processing conditions. Factors affecting distortion include non-uniform density distribution in the green compact, differential shrinkage, gravity effects, and thermal gradients during heating and cooling. Advanced simulation tools and experimental methods help in developing sintering protocols that minimize distortion while achieving desired material properties.

- Sintering maps for process optimization: Sintering maps serve as valuable tools for visualizing and understanding the relationships between processing parameters and resulting microstructural features in powder metallurgy. These maps correlate variables such as temperature, time, pressure, and atmosphere with outcomes like densification rate, grain growth, and mechanical properties. By utilizing sintering maps, manufacturers can identify optimal processing windows for specific materials and applications, predict sintering behavior, and troubleshoot processing issues. This approach enables more efficient development of new materials and processes while reducing trial-and-error experimentation.

- Advanced characterization techniques for sintering phenomena: Modern characterization techniques have revolutionized the understanding of sintering phenomena in powder metallurgy. Methods such as in-situ X-ray tomography, electron microscopy, and computational modeling allow for real-time observation and quantification of neck growth, pore evolution, and dimensional changes during sintering. These techniques provide insights into the fundamental mechanisms governing sintering behavior at different scales, from atomic diffusion to macroscopic shrinkage. The data obtained from these advanced characterization methods enables the development of more accurate sintering models and process optimization strategies for complex powder metallurgy components.

02 Pore morphology control and evolution during sintering

The evolution of pore morphology during sintering significantly impacts the mechanical properties of powder metallurgy components. Initial pore characteristics, including size, shape, and distribution, transform throughout the sintering process. Controlled pore evolution can be achieved through specific sintering profiles and powder characteristics. Advanced techniques allow for mapping pore closure rates and predicting final pore structures, which is essential for applications requiring specific porosity levels or pore architectures.Expand Specific Solutions03 Distortion limits and dimensional control in sintered components

Sintering-induced distortion is a major challenge in powder metallurgy, particularly for complex geometries. Distortion limits can be predicted and controlled through sintering maps that correlate process parameters with dimensional changes. Factors affecting distortion include particle size distribution, green density gradients, sintering temperature profiles, and gravitational effects. By understanding these relationships, manufacturers can implement strategies to minimize warpage and achieve tighter dimensional tolerances in sintered parts.Expand Specific Solutions04 Advanced sintering mapping techniques and modeling approaches

Modern sintering maps incorporate computational modeling and simulation techniques to predict microstructural evolution during the sintering process. These maps correlate processing parameters with resulting microstructures and properties, enabling optimization of sintering cycles. Finite element analysis, molecular dynamics simulations, and machine learning approaches are increasingly used to develop comprehensive sintering maps that account for complex interactions between multiple variables. These advanced mapping techniques help in visualizing and understanding the relationships between process parameters and final component characteristics.Expand Specific Solutions05 Novel equipment and methods for sintering process monitoring

Innovative equipment and methodologies have been developed to monitor and control the sintering process in real-time, allowing for the creation of dynamic sintering maps. These include in-situ observation techniques, dilatometry, thermal imaging, and acoustic emission monitoring. Such technologies enable the tracking of neck growth, pore evolution, and dimensional changes during sintering, providing valuable data for process optimization and quality control. The integration of these monitoring systems with automated control mechanisms allows for adaptive sintering processes that can respond to variations in material behavior.Expand Specific Solutions

Leading Companies and Research Institutions in PM Industry

The powder metallurgy sintering maps market is currently in a growth phase, characterized by increasing industrial applications and technological advancements in neck growth, pore morphology, and distortion control. The global market is estimated to reach approximately $30 billion by 2025, driven by automotive, aerospace, and medical applications. Leading players demonstrate varying levels of technical maturity: Höganäs AB, GKN Sinter Metals, and Miba Sinter Austria represent the most advanced tier with comprehensive sintering expertise; JFE Steel, Hitachi Metals Precision, and Plansee SE occupy the mid-tier with specialized applications; while academic institutions like Central South University and MIT contribute significant research innovations. The competitive landscape shows regional strengths with European companies focusing on precision components, Asian manufacturers emphasizing mass production, and North American entities leading in advanced materials research.

Höganäs AB

Technical Solution: Höganäs AB has developed advanced sintering map technology that correlates processing parameters with microstructural evolution during powder metallurgy sintering. Their approach integrates computational modeling with experimental validation to predict neck growth kinetics between powder particles across various temperature profiles. The company's Digital Metal® technology utilizes these sintering maps to optimize binder jet 3D printing processes, allowing precise control over densification rates and pore elimination. Their sintering maps incorporate time-temperature-atmosphere relationships to predict final component properties, including dimensional accuracy within ±0.1% for complex geometries. Höganäs has pioneered the use of in-situ monitoring techniques to validate their sintering models, enabling real-time adjustments to sintering parameters based on observed neck formation and pore evolution patterns. This approach has been particularly successful in their high-performance metal powder applications for automotive and industrial components.

Strengths: Industry-leading expertise in metal powder production provides unique insights into particle characteristics affecting sintering behavior; extensive material database allows for accurate prediction across diverse alloy systems. Weaknesses: Their sintering maps may be optimized primarily for their own powder formulations, potentially limiting applicability with third-party materials; computational models may require significant computing resources for complex geometries.

GKN Sinter Metals LLC

Technical Solution: GKN Sinter Metals has developed a comprehensive sintering map framework called "PM Intelligent Sintering" that integrates multi-physics modeling with empirical data to predict and control microstructural evolution during powder metallurgy processing. Their approach maps the relationship between sintering parameters (temperature, time, atmosphere) and resulting neck growth, pore morphology, and dimensional changes across different material systems. GKN's technology incorporates real-time monitoring systems that track sintering progression through various stages, allowing for dynamic adjustments to minimize distortion in complex geometries. Their sintering maps account for particle size distribution effects on densification kinetics, enabling optimization of powder blends for specific applications. The company has implemented machine learning algorithms that continuously refine their sintering models based on production outcomes, creating increasingly accurate predictive capabilities for new material systems. GKN's approach has been particularly successful in automotive powertrain components, where they've achieved distortion control within 20 microns while maintaining precise pore networks for oil retention.

Strengths: Extensive production experience across diverse component geometries provides robust validation of sintering models; integrated approach connecting powder characteristics to final component properties enables holistic optimization. Weaknesses: Proprietary nature of their sintering maps may limit academic collaboration and broader industry standardization; heavy focus on automotive applications might result in less refined models for other sectors like medical or aerospace.

Critical Patents and Research on Sintering Mechanisms

Hard metal materials

PatentInactiveUS20130039800A1

Innovation

- A liquid host metal slurry with 5-50 volume % of insoluble refractory particles, such as carbides and nitrides of transition metals, is used, which is poured into a mold in an inert atmosphere to produce hard metal materials with improved wear resistance, fracture toughness, and corrosion resistance, while maintaining the balance of properties.

Mechanical component and production method therefor

PatentWO2019181976A1

Innovation

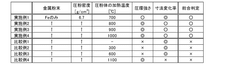

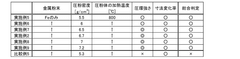

- A porous sintered body with a metallographic structure formed by neck bonding of metal powder particles and pores, where the pores are mainly at the grain boundaries, is created by heating the green compact to a temperature range of 45 to 65% of the metal powder's melting point, reducing dimensional changes and energy consumption, and ensuring a radial crushing strength of 150 MPa or more without spherical pores.

Material-Specific Sintering Behavior Analysis

The sintering behavior of different materials varies significantly due to their unique physical and chemical properties. In powder metallurgy, understanding these material-specific behaviors is crucial for optimizing sintering processes and achieving desired microstructural characteristics.

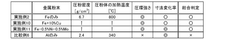

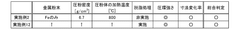

Metallic materials demonstrate distinct sintering patterns based on their crystal structure and atomic bonding. Iron-based alloys, commonly used in structural components, typically require higher sintering temperatures (1100-1350°C) and exhibit relatively uniform neck growth between particles. The presence of alloying elements like nickel or chromium can significantly alter sintering kinetics by forming solid solutions or intermetallic compounds at particle interfaces.

Copper and copper alloys display excellent sinterability at lower temperatures (800-950°C) due to their high atomic mobility. Their sintering maps reveal accelerated neck formation and growth, with characteristic pore rounding occurring earlier in the sintering cycle compared to ferrous materials. This behavior makes copper-based powders particularly suitable for applications requiring high density and electrical conductivity.

Aluminum and its alloys present unique challenges in powder metallurgy sintering due to their persistent oxide layers. Their sintering maps show limited neck growth at conventional temperatures, often requiring specialized techniques such as liquid phase sintering or the addition of sintering aids to achieve satisfactory densification. The pore morphology evolution in aluminum systems tends to be more irregular and sensitive to processing parameters.

Ceramic materials exhibit fundamentally different sintering mechanisms compared to metals. Materials like alumina (Al₂O₃) and zirconia (ZrO₂) require substantially higher sintering temperatures (1400-1700°C) and demonstrate slower neck growth kinetics. Their sintering maps reveal distinctive stages of pore evolution, with initial rapid neck formation followed by prolonged pore elimination phases.

Composite systems, such as metal-ceramic mixtures or cemented carbides, display complex sintering behaviors that cannot be predicted by simple interpolation of their constituent materials. The interaction between dissimilar particles creates unique neck growth patterns and pore structures that must be carefully mapped and controlled to prevent distortion or cracking during sintering.

Advanced materials like titanium alloys and superalloys exhibit highly specialized sintering behaviors that are particularly sensitive to atmospheric conditions and heating rates. Their sintering maps must account for phase transformations and potential reactions with trace impurities that can dramatically alter neck formation and pore evolution pathways.

Metallic materials demonstrate distinct sintering patterns based on their crystal structure and atomic bonding. Iron-based alloys, commonly used in structural components, typically require higher sintering temperatures (1100-1350°C) and exhibit relatively uniform neck growth between particles. The presence of alloying elements like nickel or chromium can significantly alter sintering kinetics by forming solid solutions or intermetallic compounds at particle interfaces.

Copper and copper alloys display excellent sinterability at lower temperatures (800-950°C) due to their high atomic mobility. Their sintering maps reveal accelerated neck formation and growth, with characteristic pore rounding occurring earlier in the sintering cycle compared to ferrous materials. This behavior makes copper-based powders particularly suitable for applications requiring high density and electrical conductivity.

Aluminum and its alloys present unique challenges in powder metallurgy sintering due to their persistent oxide layers. Their sintering maps show limited neck growth at conventional temperatures, often requiring specialized techniques such as liquid phase sintering or the addition of sintering aids to achieve satisfactory densification. The pore morphology evolution in aluminum systems tends to be more irregular and sensitive to processing parameters.

Ceramic materials exhibit fundamentally different sintering mechanisms compared to metals. Materials like alumina (Al₂O₃) and zirconia (ZrO₂) require substantially higher sintering temperatures (1400-1700°C) and demonstrate slower neck growth kinetics. Their sintering maps reveal distinctive stages of pore evolution, with initial rapid neck formation followed by prolonged pore elimination phases.

Composite systems, such as metal-ceramic mixtures or cemented carbides, display complex sintering behaviors that cannot be predicted by simple interpolation of their constituent materials. The interaction between dissimilar particles creates unique neck growth patterns and pore structures that must be carefully mapped and controlled to prevent distortion or cracking during sintering.

Advanced materials like titanium alloys and superalloys exhibit highly specialized sintering behaviors that are particularly sensitive to atmospheric conditions and heating rates. Their sintering maps must account for phase transformations and potential reactions with trace impurities that can dramatically alter neck formation and pore evolution pathways.

Environmental Impact and Energy Efficiency in PM Processes

Powder metallurgy (PM) processes, while offering significant advantages in material efficiency compared to traditional manufacturing methods, still face important environmental and energy consumption challenges. The sintering phase, central to neck growth and pore morphology control, is particularly energy-intensive, typically requiring sustained high temperatures between 70-90% of the material's melting point for extended periods.

Recent environmental impact assessments of PM processes reveal that sintering operations account for approximately 65-75% of the total energy consumption in the powder metallurgy production chain. This energy intensity translates directly to carbon emissions, with conventional sintering furnaces generating between 0.8-1.2 kg CO2 equivalent per kilogram of sintered product, depending on energy sources and process efficiency.

Innovations in sintering technology have begun addressing these environmental concerns through several pathways. Microwave-assisted sintering has demonstrated energy savings of 30-40% compared to conventional methods while achieving comparable neck growth characteristics and maintaining desired pore morphology. Similarly, spark plasma sintering (SPS) techniques reduce energy consumption by up to 50% by applying localized electrical current directly through the powder compact, dramatically shortening processing times from hours to minutes.

The relationship between sintering parameters and energy efficiency is increasingly mapped through computational modeling. These sintering maps now incorporate energy consumption metrics alongside traditional parameters like neck growth ratios and densification rates. Such integrated approaches allow manufacturers to identify optimal processing windows that minimize distortion while maximizing energy efficiency.

Water-based binder systems have replaced solvent-based alternatives in many PM applications, reducing volatile organic compound (VOC) emissions by up to 90%. Additionally, closed-loop water recycling systems in modern PM facilities have decreased water consumption by 60-70% compared to operations from a decade ago.

Material recovery systems have also evolved significantly, with advanced powder reclamation technologies now capable of recovering 95-98% of unused powders with minimal degradation in powder characteristics. This high recovery rate substantially reduces the environmental footprint associated with raw material extraction and processing.

The industry is moving toward comprehensive life cycle assessment (LCA) approaches that consider environmental impacts from powder production through sintering to final product disposal. These assessments reveal that optimized sintering cycles not only improve product quality through controlled neck growth and pore morphology but also significantly reduce lifetime environmental impact through energy savings and extended product durability.

Recent environmental impact assessments of PM processes reveal that sintering operations account for approximately 65-75% of the total energy consumption in the powder metallurgy production chain. This energy intensity translates directly to carbon emissions, with conventional sintering furnaces generating between 0.8-1.2 kg CO2 equivalent per kilogram of sintered product, depending on energy sources and process efficiency.

Innovations in sintering technology have begun addressing these environmental concerns through several pathways. Microwave-assisted sintering has demonstrated energy savings of 30-40% compared to conventional methods while achieving comparable neck growth characteristics and maintaining desired pore morphology. Similarly, spark plasma sintering (SPS) techniques reduce energy consumption by up to 50% by applying localized electrical current directly through the powder compact, dramatically shortening processing times from hours to minutes.

The relationship between sintering parameters and energy efficiency is increasingly mapped through computational modeling. These sintering maps now incorporate energy consumption metrics alongside traditional parameters like neck growth ratios and densification rates. Such integrated approaches allow manufacturers to identify optimal processing windows that minimize distortion while maximizing energy efficiency.

Water-based binder systems have replaced solvent-based alternatives in many PM applications, reducing volatile organic compound (VOC) emissions by up to 90%. Additionally, closed-loop water recycling systems in modern PM facilities have decreased water consumption by 60-70% compared to operations from a decade ago.

Material recovery systems have also evolved significantly, with advanced powder reclamation technologies now capable of recovering 95-98% of unused powders with minimal degradation in powder characteristics. This high recovery rate substantially reduces the environmental footprint associated with raw material extraction and processing.

The industry is moving toward comprehensive life cycle assessment (LCA) approaches that consider environmental impacts from powder production through sintering to final product disposal. These assessments reveal that optimized sintering cycles not only improve product quality through controlled neck growth and pore morphology but also significantly reduce lifetime environmental impact through energy savings and extended product durability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!