Powder Metallurgy Dimensional Capability: GD&T For Press–Sinter Processes

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Powder Metallurgy Evolution and Precision Goals

Powder metallurgy (PM) has evolved significantly since its inception in the early 20th century, transforming from a niche manufacturing process to a sophisticated technology capable of producing complex components with increasingly tight tolerances. The journey began with simple structural parts and has progressed to high-precision components used in critical applications across automotive, aerospace, and medical industries.

The evolution of powder metallurgy can be traced through several distinct phases. Initially, PM was primarily utilized for producing simple bushings and bearings where dimensional precision was not critical. By the mid-20th century, advancements in powder production techniques and compaction methods enabled the creation of more complex geometries, though dimensional control remained relatively coarse by today's standards.

The 1970s and 1980s marked a significant turning point with the introduction of improved atomization processes, resulting in finer and more uniform metal powders. This period also saw the development of more sophisticated pressing equipment and sintering furnaces with better atmosphere control, leading to enhanced dimensional stability in the final products.

Recent decades have witnessed exponential growth in PM capabilities, driven by computational modeling of powder behavior during compaction and sintering, advanced process control systems, and the integration of automation. These developments have pushed the boundaries of what is achievable in terms of dimensional accuracy and surface finish.

Today's powder metallurgy aims to achieve dimensional tolerances comparable to those of machined components while maintaining the economic and material efficiency advantages inherent to the process. Current precision goals include achieving tolerances as tight as ±0.05mm for critical dimensions in press-sinter operations, with even tighter tolerances possible through secondary operations.

The industry is now focused on implementing Geometric Dimensioning and Tolerancing (GD&T) principles specifically tailored for powder metallurgy processes. This represents a paradigm shift from traditional linear dimensioning to a more comprehensive approach that accounts for the unique characteristics of pressed and sintered components, including the effects of density variations, spring-back, and sintering shrinkage.

Looking forward, the technological trajectory points toward even greater precision, with research efforts concentrated on real-time monitoring and adaptive control of the entire PM process chain. The ultimate goal is to establish powder metallurgy as a net-shape or near-net-shape manufacturing technology capable of meeting the most demanding dimensional and geometric specifications across all industrial sectors, while minimizing the need for costly secondary operations.

The evolution of powder metallurgy can be traced through several distinct phases. Initially, PM was primarily utilized for producing simple bushings and bearings where dimensional precision was not critical. By the mid-20th century, advancements in powder production techniques and compaction methods enabled the creation of more complex geometries, though dimensional control remained relatively coarse by today's standards.

The 1970s and 1980s marked a significant turning point with the introduction of improved atomization processes, resulting in finer and more uniform metal powders. This period also saw the development of more sophisticated pressing equipment and sintering furnaces with better atmosphere control, leading to enhanced dimensional stability in the final products.

Recent decades have witnessed exponential growth in PM capabilities, driven by computational modeling of powder behavior during compaction and sintering, advanced process control systems, and the integration of automation. These developments have pushed the boundaries of what is achievable in terms of dimensional accuracy and surface finish.

Today's powder metallurgy aims to achieve dimensional tolerances comparable to those of machined components while maintaining the economic and material efficiency advantages inherent to the process. Current precision goals include achieving tolerances as tight as ±0.05mm for critical dimensions in press-sinter operations, with even tighter tolerances possible through secondary operations.

The industry is now focused on implementing Geometric Dimensioning and Tolerancing (GD&T) principles specifically tailored for powder metallurgy processes. This represents a paradigm shift from traditional linear dimensioning to a more comprehensive approach that accounts for the unique characteristics of pressed and sintered components, including the effects of density variations, spring-back, and sintering shrinkage.

Looking forward, the technological trajectory points toward even greater precision, with research efforts concentrated on real-time monitoring and adaptive control of the entire PM process chain. The ultimate goal is to establish powder metallurgy as a net-shape or near-net-shape manufacturing technology capable of meeting the most demanding dimensional and geometric specifications across all industrial sectors, while minimizing the need for costly secondary operations.

Market Demand for High-Precision PM Components

The global market for high-precision powder metallurgy (PM) components has been experiencing significant growth, driven by increasing demands across multiple industries. Automotive sector remains the largest consumer of PM components, accounting for over 70% of the total market share. The need for lightweight, high-strength components to improve fuel efficiency and reduce emissions has propelled the adoption of precision PM parts in modern vehicles.

Aerospace and defense industries have emerged as rapidly growing markets for high-precision PM components. These sectors require parts with exceptional dimensional accuracy, surface finish, and mechanical properties that can withstand extreme operating conditions. The ability of advanced PM processes to deliver complex geometries with tight tolerances makes them particularly valuable in these applications.

Medical device manufacturing represents another expanding market segment. The biocompatibility of certain metal powders, combined with the ability to create intricate structures with controlled porosity, has made PM processes increasingly important for implantable devices and surgical instruments. Market analysts project this segment to grow at a compound annual rate exceeding 8% through 2028.

Industrial equipment manufacturers are increasingly turning to high-precision PM components to replace traditionally machined parts. The near-net-shape capabilities of modern PM processes significantly reduce material waste and secondary machining operations, offering both economic and environmental benefits. This trend is particularly evident in fluid power systems, power transmission equipment, and industrial automation.

Consumer electronics represents a relatively new but rapidly expanding application area. The miniaturization trend in electronic devices demands components with increasingly tight tolerances and complex geometries that can be efficiently produced through advanced PM techniques.

Market research indicates that customers across all industries are demanding tighter dimensional tolerances, improved surface finishes, and enhanced mechanical properties from PM components. The ability to consistently achieve geometric dimensioning and tolerancing (GD&T) specifications comparable to those of machined components has become a key differentiator for PM suppliers.

Regional analysis shows North America and Europe currently leading in high-precision PM component consumption, though Asia-Pacific markets are growing at the fastest rate. China, in particular, has made significant investments in advanced PM manufacturing capabilities to support its expanding automotive and electronics industries.

The market trend clearly points toward increasing integration of PM components in critical applications where dimensional precision directly impacts performance, reliability, and safety. This evolution is driving PM manufacturers to adopt more sophisticated process controls and inspection methodologies to meet increasingly stringent GD&T requirements.

Aerospace and defense industries have emerged as rapidly growing markets for high-precision PM components. These sectors require parts with exceptional dimensional accuracy, surface finish, and mechanical properties that can withstand extreme operating conditions. The ability of advanced PM processes to deliver complex geometries with tight tolerances makes them particularly valuable in these applications.

Medical device manufacturing represents another expanding market segment. The biocompatibility of certain metal powders, combined with the ability to create intricate structures with controlled porosity, has made PM processes increasingly important for implantable devices and surgical instruments. Market analysts project this segment to grow at a compound annual rate exceeding 8% through 2028.

Industrial equipment manufacturers are increasingly turning to high-precision PM components to replace traditionally machined parts. The near-net-shape capabilities of modern PM processes significantly reduce material waste and secondary machining operations, offering both economic and environmental benefits. This trend is particularly evident in fluid power systems, power transmission equipment, and industrial automation.

Consumer electronics represents a relatively new but rapidly expanding application area. The miniaturization trend in electronic devices demands components with increasingly tight tolerances and complex geometries that can be efficiently produced through advanced PM techniques.

Market research indicates that customers across all industries are demanding tighter dimensional tolerances, improved surface finishes, and enhanced mechanical properties from PM components. The ability to consistently achieve geometric dimensioning and tolerancing (GD&T) specifications comparable to those of machined components has become a key differentiator for PM suppliers.

Regional analysis shows North America and Europe currently leading in high-precision PM component consumption, though Asia-Pacific markets are growing at the fastest rate. China, in particular, has made significant investments in advanced PM manufacturing capabilities to support its expanding automotive and electronics industries.

The market trend clearly points toward increasing integration of PM components in critical applications where dimensional precision directly impacts performance, reliability, and safety. This evolution is driving PM manufacturers to adopt more sophisticated process controls and inspection methodologies to meet increasingly stringent GD&T requirements.

Current Capabilities and Challenges in PM Dimensional Control

Powder metallurgy (PM) processes currently achieve dimensional tolerances ranging from IT7 to IT11 according to ISO standards, with most commercial applications falling within IT8-IT10. This capability represents significant progress over historical PM dimensional control, yet remains less precise than competing manufacturing methods such as machining (IT5-IT7) or precision casting (IT7-IT9). The dimensional precision varies considerably across different part features, with straight-pressed dimensions typically achieving ±0.1% tolerance while dimensions affected by sintering typically limited to ±0.3-0.5%.

The industry faces several persistent challenges in dimensional control. Density variations within pressed components lead to differential shrinkage during sintering, creating geometric distortions particularly in complex parts with varying cross-sections. This phenomenon is especially problematic for tight geometric tolerancing requirements. Material-specific factors also impact dimensional capability, with iron-based PM parts generally exhibiting better dimensional stability than copper or aluminum-based systems due to their sintering characteristics.

Process variables introduce significant complexity to dimensional control efforts. Compaction pressure distribution, tooling wear, powder segregation, and lubricant distribution all affect green density homogeneity. During sintering, temperature gradients within furnaces, atmosphere composition fluctuations, and cooling rate variations further complicate dimensional predictability. These variables create challenges for implementing geometric dimensioning and tolerancing (GD&T) principles in PM production.

Current industry practices rely heavily on empirical approaches rather than predictive modeling. Most manufacturers develop dimensional control strategies through iterative trial-and-error processes, building proprietary databases of material-specific shrinkage factors. This approach limits standardization across the industry and increases development costs for new components. The lack of comprehensive simulation tools that accurately predict dimensional changes throughout the entire PM process chain represents a significant technological gap.

GD&T implementation in PM processes remains underdeveloped compared to other manufacturing methods. While basic dimensional tolerancing is well-established, more complex geometric controls such as flatness, cylindricity, and position tolerancing present significant challenges. The inherent variability in PM processes often necessitates secondary operations to achieve tight geometric tolerances, reducing the cost advantages of the PM approach.

Recent advances in process monitoring and control systems have improved dimensional capabilities, with in-line density measurement, real-time press control systems, and advanced sintering furnaces with precise atmosphere and temperature control. However, these technologies have not been fully integrated into comprehensive dimensional management systems. The industry continues to struggle with translating traditional GD&T frameworks into PM-specific guidelines that account for the unique characteristics of powder consolidation and sintering processes.

The industry faces several persistent challenges in dimensional control. Density variations within pressed components lead to differential shrinkage during sintering, creating geometric distortions particularly in complex parts with varying cross-sections. This phenomenon is especially problematic for tight geometric tolerancing requirements. Material-specific factors also impact dimensional capability, with iron-based PM parts generally exhibiting better dimensional stability than copper or aluminum-based systems due to their sintering characteristics.

Process variables introduce significant complexity to dimensional control efforts. Compaction pressure distribution, tooling wear, powder segregation, and lubricant distribution all affect green density homogeneity. During sintering, temperature gradients within furnaces, atmosphere composition fluctuations, and cooling rate variations further complicate dimensional predictability. These variables create challenges for implementing geometric dimensioning and tolerancing (GD&T) principles in PM production.

Current industry practices rely heavily on empirical approaches rather than predictive modeling. Most manufacturers develop dimensional control strategies through iterative trial-and-error processes, building proprietary databases of material-specific shrinkage factors. This approach limits standardization across the industry and increases development costs for new components. The lack of comprehensive simulation tools that accurately predict dimensional changes throughout the entire PM process chain represents a significant technological gap.

GD&T implementation in PM processes remains underdeveloped compared to other manufacturing methods. While basic dimensional tolerancing is well-established, more complex geometric controls such as flatness, cylindricity, and position tolerancing present significant challenges. The inherent variability in PM processes often necessitates secondary operations to achieve tight geometric tolerances, reducing the cost advantages of the PM approach.

Recent advances in process monitoring and control systems have improved dimensional capabilities, with in-line density measurement, real-time press control systems, and advanced sintering furnaces with precise atmosphere and temperature control. However, these technologies have not been fully integrated into comprehensive dimensional management systems. The industry continues to struggle with translating traditional GD&T frameworks into PM-specific guidelines that account for the unique characteristics of powder consolidation and sintering processes.

GD&T Implementation Strategies for Press-Sinter Processes

01 Dimensional control techniques in powder metallurgy

Various techniques are employed to achieve precise dimensional control in powder metallurgy press-sinter processes. These include optimized die design, controlled powder compaction parameters, and precise sintering temperature profiles. Advanced monitoring systems can be implemented to track dimensional changes during the sintering process, allowing for real-time adjustments to maintain dimensional accuracy. These techniques collectively enhance the dimensional capability of powder metallurgy components.- Dimensional control techniques in powder metallurgy: Various techniques are employed to achieve precise dimensional control in powder metallurgy press-sinter processes. These include optimized die design, controlled powder compaction parameters, and precise sintering temperature profiles. Advanced monitoring systems can be implemented to track dimensional changes during the sintering process, allowing for real-time adjustments to maintain dimensional accuracy. These techniques collectively enhance the dimensional capability of powder metallurgy components.

- Advanced powder formulations for improved dimensional stability: Specialized powder formulations can significantly improve the dimensional stability of press-sintered components. These formulations may include pre-alloyed powders, binder additions, and lubricants that minimize dimensional changes during sintering. The particle size distribution and morphology of the powder are carefully controlled to achieve uniform shrinkage. Some formulations incorporate additives that create controlled microstructural changes during sintering to counteract dimensional variations.

- Equipment innovations for enhanced dimensional precision: Modern powder metallurgy equipment incorporates innovations specifically designed to enhance dimensional precision. These include high-precision pressing equipment with advanced force distribution systems, controlled-atmosphere sintering furnaces with precise temperature gradient control, and automated handling systems that minimize part distortion. Digital control systems enable repeatable process parameters, while specialized tooling designs accommodate the unique dimensional challenges of complex geometries.

- Post-processing methods to achieve tight tolerances: Various post-processing methods can be applied to press-sintered components to achieve tighter dimensional tolerances. These include sizing operations, calibration processes, and controlled machining techniques. Some methods involve secondary sintering steps under specific conditions to refine dimensions. Heat treatment processes can also be tailored to minimize distortion while achieving desired mechanical properties, thereby maintaining dimensional accuracy in the final component.

- Process monitoring and quality control systems: Advanced process monitoring and quality control systems are essential for maintaining dimensional capability in powder metallurgy processes. These systems incorporate in-line measurement technologies, statistical process control methods, and predictive modeling to identify and correct dimensional variations. Non-destructive testing techniques allow for comprehensive dimensional verification without compromising part integrity. Integrated data management systems enable traceability and continuous process improvement to consistently achieve tight dimensional tolerances.

02 Advanced powder formulations for improved dimensional stability

Specialized powder formulations can significantly improve the dimensional stability of press-sintered components. These formulations may include pre-alloyed powders, binder additions, or lubricants that minimize shrinkage during sintering. Some formulations incorporate particle size distributions specifically designed to optimize packing density during compaction, which leads to more predictable dimensional changes during sintering. These advanced powder compositions enable manufacturers to achieve tighter tolerances in final components.Expand Specific Solutions03 Equipment innovations for dimensional precision

Modern powder metallurgy equipment incorporates innovations specifically designed to enhance dimensional capability. These include precision-controlled hydraulic or electric presses with advanced force distribution systems, automated powder feeding mechanisms that ensure uniform fill density, and intelligent sintering furnaces with precise temperature and atmosphere control. Some systems feature integrated measurement and feedback systems that can make real-time adjustments to process parameters based on dimensional monitoring.Expand Specific Solutions04 Post-processing methods to achieve final dimensions

Various post-processing methods can be employed to achieve final dimensional specifications in powder metallurgy components. These include sizing operations, where components are pressed again after sintering to achieve precise dimensions, calibration processes to correct any warpage or distortion, and finishing operations such as machining or grinding for critical surfaces. Some advanced processes incorporate heat treatments specifically designed to minimize dimensional changes while achieving desired mechanical properties.Expand Specific Solutions05 Simulation and modeling for dimensional prediction

Computer simulation and modeling techniques are increasingly used to predict and control dimensional changes during powder metallurgy processes. Finite element analysis can model powder compaction behavior, density distributions, and subsequent dimensional changes during sintering. These predictive tools allow manufacturers to optimize process parameters before production, reducing trial and error approaches. Advanced simulation software can account for material-specific behaviors, thermal gradients, and other factors affecting dimensional capability, enabling more precise component design and process planning.Expand Specific Solutions

Leading Manufacturers and Research Institutions in PM

Powder Metallurgy Dimensional Capability is currently in a mature growth phase, with the global market valued at approximately $30 billion and projected to expand at 5-7% CAGR. The technology has reached significant maturity in traditional press-sinter processes, with leading companies like Höganäs AB, GKN Sinter Metals, and JFE Steel establishing dimensional control standards. However, innovation continues through advanced players including EOS GmbH and 3D Systems in additive manufacturing applications, while Robert Bosch and Timken drive precision requirements in automotive and industrial components. The integration of GD&T principles with powder metallurgy processes represents a convergence point where established manufacturers and new technology providers are competing to achieve tighter tolerances and more complex geometries while maintaining cost-effectiveness in high-volume production.

Höganäs AB

Technical Solution: Höganäs AB has developed advanced powder metallurgy (PM) dimensional control systems that integrate statistical process control with their proprietary powder formulations. Their technology solution focuses on achieving tight dimensional tolerances through optimized powder characteristics and controlled sintering processes. They've implemented a comprehensive GD&T (Geometric Dimensioning and Tolerancing) framework specifically adapted for press-sinter processes that accounts for the unique shrinkage patterns in PM components. Their approach includes specialized powder blends with tailored particle size distributions and lubricant systems that minimize dimensional variation during compaction. Additionally, Höganäs has developed sintering protocols that control dimensional changes through precise temperature profiles and atmosphere control, resulting in components with predictable dimensional characteristics suitable for precision applications.

Strengths: Industry-leading powder formulations specifically designed for dimensional stability; extensive material science expertise; global technical support network. Weaknesses: Their solutions may require specialized equipment and higher material costs compared to conventional PM approaches; implementation requires significant process knowledge.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has implemented a comprehensive dimensional control system for powder metallurgy components used in their precision automotive and industrial applications. Their technology solution integrates advanced process monitoring with adaptive control systems throughout the PM production chain. Bosch's approach begins with rigorous powder characterization and extends through compaction, sintering, and finishing operations with continuous feedback loops. They've developed specialized GD&T frameworks for PM components that account for the unique challenges of sintered materials, including anisotropic shrinkage and density-dependent dimensional variations. Their system incorporates in-line measurement technologies that provide real-time dimensional data, allowing for process adjustments before tolerance deviations occur. Bosch has also implemented advanced statistical process control methodologies specifically adapted for powder metallurgy variables, enabling predictive maintenance and process optimization. Their dimensional management approach includes specialized fixture designs for post-sintering operations that reference optimal datum structures for PM components.

Strengths: Integration of dimensional control with broader manufacturing systems; extensive application experience across diverse component types; robust quality management infrastructure. Weaknesses: Solutions may be optimized for Bosch's specific component requirements; implementation requires significant organizational commitment and resources.

Critical Patents and Research in PM Dimensional Control

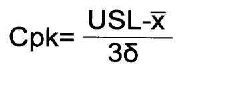

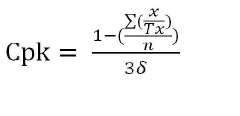

Method of evaluating the geometric tolerance process capability for the condition of the product to be processed

PatentActiveKR1020210152336A

Innovation

- A method for evaluating geometric tolerance process capability that involves dynamic calculation of assembly allowances by considering maximum permissible tolerances, using a geometric tolerance measuring instrument to input drawing and product dimensions, measure tolerances, calculate assembly ratios, and derive process capability indices.

Powder mixture and process for the preparation of a powdermetallurgical component

PatentInactiveEP0602630A1

Innovation

- A powder mixture comprising dimensionally stable powder and a compound powder that sinters or melts at sintering temperature, with the compound powder's proportion limited to no more than 25% by volume, ensuring the bulk powder remains dimensionally stable and forming solid bridges between particles, thereby preventing shrinkage and maintaining component dimensions.

Material-Process Interaction Effects on Dimensional Accuracy

The interaction between powder materials and processing parameters in powder metallurgy significantly impacts dimensional accuracy of final components. Material characteristics such as particle size distribution, morphology, and composition directly influence how powders respond during compaction and sintering phases. Finer particles typically yield better dimensional precision but may reduce flow properties and increase friction during pressing, creating density gradients that lead to non-uniform shrinkage.

Powder composition plays a critical role in dimensional stability, with different alloying elements exhibiting varied expansion or contraction behaviors during sintering. For instance, carbon content in ferrous PM parts dramatically affects dimensional change, with higher carbon levels typically increasing shrinkage rates. Similarly, copper additions in iron-based systems cause dimensional expansion that must be carefully controlled to maintain tolerances.

Lubricant type and concentration represent another crucial material-process interaction factor. While lubricants reduce die wall friction and improve density uniformity, their removal during sintering creates additional dimensional variability that must be accounted for in GD&T specifications. Typical lubricant concentrations of 0.5-1.0% by weight can influence dimensional change by 0.05-0.15%.

Process parameters interact with material properties in complex ways that affect dimensional outcomes. Compaction pressure distribution determines green density gradients throughout the part, which subsequently influence localized shrinkage rates during sintering. Higher compaction pressures generally improve dimensional consistency but may introduce elastic recovery effects (springback) that must be compensated for in tooling design.

Sintering temperature profiles and atmospheres create material-specific responses that impact dimensional accuracy. The sintering temperature relative to a material's melting point (typically 70-90% of absolute melting temperature) determines diffusion rates and subsequent dimensional changes. Atmosphere composition affects oxidation/reduction reactions that can either inhibit or enhance dimensional stability depending on the base material system.

Cooling rates after sintering introduce thermal gradients that can cause distortion, particularly in geometrically complex parts with varying cross-sections. Materials with higher thermal expansion coefficients are especially susceptible to these effects, requiring carefully controlled cooling protocols to maintain dimensional specifications.

Understanding these material-process interactions enables manufacturers to develop robust GD&T frameworks that account for the inherent variability in powder metallurgy processes, ultimately improving dimensional capability and part quality consistency.

Powder composition plays a critical role in dimensional stability, with different alloying elements exhibiting varied expansion or contraction behaviors during sintering. For instance, carbon content in ferrous PM parts dramatically affects dimensional change, with higher carbon levels typically increasing shrinkage rates. Similarly, copper additions in iron-based systems cause dimensional expansion that must be carefully controlled to maintain tolerances.

Lubricant type and concentration represent another crucial material-process interaction factor. While lubricants reduce die wall friction and improve density uniformity, their removal during sintering creates additional dimensional variability that must be accounted for in GD&T specifications. Typical lubricant concentrations of 0.5-1.0% by weight can influence dimensional change by 0.05-0.15%.

Process parameters interact with material properties in complex ways that affect dimensional outcomes. Compaction pressure distribution determines green density gradients throughout the part, which subsequently influence localized shrinkage rates during sintering. Higher compaction pressures generally improve dimensional consistency but may introduce elastic recovery effects (springback) that must be compensated for in tooling design.

Sintering temperature profiles and atmospheres create material-specific responses that impact dimensional accuracy. The sintering temperature relative to a material's melting point (typically 70-90% of absolute melting temperature) determines diffusion rates and subsequent dimensional changes. Atmosphere composition affects oxidation/reduction reactions that can either inhibit or enhance dimensional stability depending on the base material system.

Cooling rates after sintering introduce thermal gradients that can cause distortion, particularly in geometrically complex parts with varying cross-sections. Materials with higher thermal expansion coefficients are especially susceptible to these effects, requiring carefully controlled cooling protocols to maintain dimensional specifications.

Understanding these material-process interactions enables manufacturers to develop robust GD&T frameworks that account for the inherent variability in powder metallurgy processes, ultimately improving dimensional capability and part quality consistency.

Quality Assurance Systems for PM Manufacturing

Quality Assurance Systems for PM Manufacturing in the context of dimensional capability and GD&T for press-sinter processes require comprehensive frameworks that address the unique challenges of powder metallurgy production. These systems must account for the inherent variability in powder characteristics, compaction behavior, and sintering shrinkage that significantly impact final component dimensions.

Effective quality assurance for PM manufacturing begins with raw material control, where powder characteristics such as particle size distribution, flow properties, and chemical composition are rigorously monitored. Statistical process control (SPC) methods adapted specifically for PM processes help manufacturers track critical parameters during production, enabling early detection of process drift before dimensional specifications are compromised.

In-process measurement systems play a crucial role in PM quality assurance. Advanced optical and contact measurement technologies, calibrated to account for the unique surface characteristics of green and sintered components, provide real-time dimensional feedback. These systems must be integrated with production equipment to enable automatic adjustments when dimensional trends approach tolerance limits.

Documentation and traceability systems form another essential component of PM quality assurance. Modern systems employ digital platforms that track each batch of powder through the entire manufacturing process, recording process parameters, dimensional measurements, and environmental conditions that might affect final component dimensions. This comprehensive data collection facilitates root cause analysis when dimensional issues arise.

Capability studies specifically designed for PM processes help manufacturers understand the realistic dimensional tolerances achievable with their specific equipment and material combinations. These studies account for the anisotropic shrinkage behavior during sintering and provide statistical confidence levels for meeting GD&T requirements across production runs.

Supplier qualification programs ensure that incoming materials and outsourced processes meet the stringent requirements necessary for dimensional control. These programs typically include audit protocols, material certification requirements, and performance monitoring systems that evaluate suppliers based on their contribution to final dimensional quality.

Employee training programs focused on PM-specific dimensional control techniques represent another critical aspect of quality assurance. These programs emphasize the unique relationships between process parameters and dimensional outcomes in powder metallurgy, ensuring that operators understand how their actions impact final component dimensions.

Continuous improvement methodologies adapted for PM manufacturing complete the quality assurance framework. These methodologies utilize statistical analysis of historical production data to identify opportunities for enhancing dimensional capability through process refinements, tooling improvements, or material modifications.

Effective quality assurance for PM manufacturing begins with raw material control, where powder characteristics such as particle size distribution, flow properties, and chemical composition are rigorously monitored. Statistical process control (SPC) methods adapted specifically for PM processes help manufacturers track critical parameters during production, enabling early detection of process drift before dimensional specifications are compromised.

In-process measurement systems play a crucial role in PM quality assurance. Advanced optical and contact measurement technologies, calibrated to account for the unique surface characteristics of green and sintered components, provide real-time dimensional feedback. These systems must be integrated with production equipment to enable automatic adjustments when dimensional trends approach tolerance limits.

Documentation and traceability systems form another essential component of PM quality assurance. Modern systems employ digital platforms that track each batch of powder through the entire manufacturing process, recording process parameters, dimensional measurements, and environmental conditions that might affect final component dimensions. This comprehensive data collection facilitates root cause analysis when dimensional issues arise.

Capability studies specifically designed for PM processes help manufacturers understand the realistic dimensional tolerances achievable with their specific equipment and material combinations. These studies account for the anisotropic shrinkage behavior during sintering and provide statistical confidence levels for meeting GD&T requirements across production runs.

Supplier qualification programs ensure that incoming materials and outsourced processes meet the stringent requirements necessary for dimensional control. These programs typically include audit protocols, material certification requirements, and performance monitoring systems that evaluate suppliers based on their contribution to final dimensional quality.

Employee training programs focused on PM-specific dimensional control techniques represent another critical aspect of quality assurance. These programs emphasize the unique relationships between process parameters and dimensional outcomes in powder metallurgy, ensuring that operators understand how their actions impact final component dimensions.

Continuous improvement methodologies adapted for PM manufacturing complete the quality assurance framework. These methodologies utilize statistical analysis of historical production data to identify opportunities for enhancing dimensional capability through process refinements, tooling improvements, or material modifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!