How Powder Metallurgy Minimizes Distortion During Sintering And Cooling?

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Powder Metallurgy Sintering Evolution and Objectives

Powder metallurgy has evolved significantly since its inception in the early 20th century, transforming from a niche manufacturing process to a sophisticated technology capable of producing complex components with exceptional precision. The journey began with simple powder compaction techniques and has progressed through several technological revolutions, each addressing critical challenges in material properties and dimensional stability during sintering and cooling phases.

The 1950s marked a pivotal era with the introduction of controlled atmosphere sintering, which significantly reduced oxidation issues that previously compromised structural integrity. By the 1970s, advancements in powder production methods enabled finer particle sizes and more uniform distributions, laying the groundwork for improved dimensional control during thermal processing.

The 1990s witnessed the integration of computer modeling and simulation tools, allowing manufacturers to predict and mitigate distortion phenomena before physical production. This predictive capability revolutionized process optimization and material selection strategies, particularly for components with complex geometries or tight tolerances.

Recent developments have focused on precise control of sintering parameters through adaptive systems that monitor and adjust temperature gradients in real-time. These innovations have been complemented by advances in powder characteristics, including engineered particle morphologies and custom alloy formulations designed specifically to minimize differential shrinkage during consolidation.

The primary objective in modern powder metallurgy sintering is achieving near-net-shape production with minimal post-processing requirements. This goal encompasses several interconnected technical aims: uniform densification throughout the component, controlled dimensional change, elimination of residual stresses, and prevention of warpage or cracking during cooling.

Another critical objective is the development of standardized methodologies for predicting and controlling distortion across diverse material systems and component geometries. This includes establishing robust relationships between powder characteristics, compaction parameters, sintering profiles, and final dimensional accuracy.

The industry also aims to extend the capabilities of powder metallurgy to increasingly complex alloys and composite systems while maintaining dimensional precision. This includes addressing challenges in materials with significant differences in thermal expansion coefficients or those prone to phase transformations during thermal cycling.

Looking forward, the field is moving toward intelligent sintering systems that incorporate machine learning algorithms to optimize processing parameters based on historical data and real-time feedback, further refining the industry's ability to minimize distortion while maximizing material performance and production efficiency.

The 1950s marked a pivotal era with the introduction of controlled atmosphere sintering, which significantly reduced oxidation issues that previously compromised structural integrity. By the 1970s, advancements in powder production methods enabled finer particle sizes and more uniform distributions, laying the groundwork for improved dimensional control during thermal processing.

The 1990s witnessed the integration of computer modeling and simulation tools, allowing manufacturers to predict and mitigate distortion phenomena before physical production. This predictive capability revolutionized process optimization and material selection strategies, particularly for components with complex geometries or tight tolerances.

Recent developments have focused on precise control of sintering parameters through adaptive systems that monitor and adjust temperature gradients in real-time. These innovations have been complemented by advances in powder characteristics, including engineered particle morphologies and custom alloy formulations designed specifically to minimize differential shrinkage during consolidation.

The primary objective in modern powder metallurgy sintering is achieving near-net-shape production with minimal post-processing requirements. This goal encompasses several interconnected technical aims: uniform densification throughout the component, controlled dimensional change, elimination of residual stresses, and prevention of warpage or cracking during cooling.

Another critical objective is the development of standardized methodologies for predicting and controlling distortion across diverse material systems and component geometries. This includes establishing robust relationships between powder characteristics, compaction parameters, sintering profiles, and final dimensional accuracy.

The industry also aims to extend the capabilities of powder metallurgy to increasingly complex alloys and composite systems while maintaining dimensional precision. This includes addressing challenges in materials with significant differences in thermal expansion coefficients or those prone to phase transformations during thermal cycling.

Looking forward, the field is moving toward intelligent sintering systems that incorporate machine learning algorithms to optimize processing parameters based on historical data and real-time feedback, further refining the industry's ability to minimize distortion while maximizing material performance and production efficiency.

Market Demand Analysis for Precision PM Components

The global market for precision powder metallurgy (PM) components is experiencing robust growth, driven primarily by the automotive, aerospace, and industrial equipment sectors. Current market valuations place the precision PM components market at approximately $16 billion, with projections indicating a compound annual growth rate of 6.8% through 2028. This growth trajectory is significantly influenced by increasing demands for components with minimal distortion during sintering and cooling processes.

The automotive industry remains the largest consumer of precision PM components, accounting for nearly 70% of market demand. This sector's shift toward lightweight, fuel-efficient vehicles has intensified the need for PM parts that maintain dimensional stability during manufacturing. Electric vehicle manufacturers particularly value PM components for motor cores and transmission systems where precision is paramount for operational efficiency.

Aerospace applications represent the fastest-growing segment for precision PM components, with demand increasing at approximately 9% annually. The stringent requirements for component reliability and performance in extreme conditions have positioned distortion-minimized PM parts as critical elements in modern aircraft design. Defense contractors and commercial aviation companies alike are investing heavily in advanced PM technologies that ensure dimensional stability.

Market research indicates that manufacturers are increasingly willing to pay premium prices for PM components with guaranteed minimal distortion characteristics. A recent industry survey revealed that 83% of procurement managers in precision engineering fields ranked "dimensional stability during sintering" among their top three selection criteria for PM suppliers, representing a significant shift from just five years ago when cost was the predominant factor.

Regional analysis shows North America and Europe currently dominating the market for high-precision PM components, collectively accounting for 65% of global demand. However, the Asia-Pacific region, particularly China and India, is demonstrating the most aggressive growth rates, driven by rapid industrialization and increasing domestic manufacturing capabilities in precision engineering.

The medical device industry has emerged as a promising new market segment, with demand for biocompatible PM components growing at 12% annually. Surgical instruments, implantable devices, and diagnostic equipment manufacturers are increasingly specifying PM components due to their ability to maintain precise dimensions while offering complex geometries impossible to achieve through conventional manufacturing methods.

Market trends indicate that customers are increasingly demanding not just dimensional precision but also enhanced surface finishes and tighter tolerances, pushing PM manufacturers to develop more sophisticated sintering and cooling control technologies. This evolution in customer requirements is reshaping the competitive landscape, favoring suppliers who can demonstrate advanced capabilities in distortion minimization during the entire PM production process.

The automotive industry remains the largest consumer of precision PM components, accounting for nearly 70% of market demand. This sector's shift toward lightweight, fuel-efficient vehicles has intensified the need for PM parts that maintain dimensional stability during manufacturing. Electric vehicle manufacturers particularly value PM components for motor cores and transmission systems where precision is paramount for operational efficiency.

Aerospace applications represent the fastest-growing segment for precision PM components, with demand increasing at approximately 9% annually. The stringent requirements for component reliability and performance in extreme conditions have positioned distortion-minimized PM parts as critical elements in modern aircraft design. Defense contractors and commercial aviation companies alike are investing heavily in advanced PM technologies that ensure dimensional stability.

Market research indicates that manufacturers are increasingly willing to pay premium prices for PM components with guaranteed minimal distortion characteristics. A recent industry survey revealed that 83% of procurement managers in precision engineering fields ranked "dimensional stability during sintering" among their top three selection criteria for PM suppliers, representing a significant shift from just five years ago when cost was the predominant factor.

Regional analysis shows North America and Europe currently dominating the market for high-precision PM components, collectively accounting for 65% of global demand. However, the Asia-Pacific region, particularly China and India, is demonstrating the most aggressive growth rates, driven by rapid industrialization and increasing domestic manufacturing capabilities in precision engineering.

The medical device industry has emerged as a promising new market segment, with demand for biocompatible PM components growing at 12% annually. Surgical instruments, implantable devices, and diagnostic equipment manufacturers are increasingly specifying PM components due to their ability to maintain precise dimensions while offering complex geometries impossible to achieve through conventional manufacturing methods.

Market trends indicate that customers are increasingly demanding not just dimensional precision but also enhanced surface finishes and tighter tolerances, pushing PM manufacturers to develop more sophisticated sintering and cooling control technologies. This evolution in customer requirements is reshaping the competitive landscape, favoring suppliers who can demonstrate advanced capabilities in distortion minimization during the entire PM production process.

Current Challenges in Distortion Control During Sintering

Despite significant advancements in powder metallurgy (PM) technology, distortion control during sintering remains one of the most challenging aspects of the manufacturing process. The fundamental challenge stems from the non-uniform densification that occurs as powder particles bond together under high temperatures. This densification typically results in 15-20% volumetric shrinkage, which if not properly controlled, leads to warping, cracking, and dimensional inaccuracies in the final components.

Temperature gradients within parts during heating and cooling cycles represent a major technical hurdle. When different sections of a component heat or cool at varying rates, internal stresses develop that can cause significant distortion. This is particularly problematic for complex geometries with varying cross-sectional thicknesses, where achieving uniform temperature distribution becomes exceedingly difficult.

Gravitational effects during sintering pose another significant challenge. As parts soften at high temperatures, they become susceptible to sagging under their own weight. This phenomenon is especially pronounced in components with unsupported features or overhangs, requiring specialized support structures or sintering orientations that add complexity to the manufacturing process.

Material composition heterogeneity introduces additional complications. Variations in particle size distribution, alloying element segregation, or contamination can lead to localized differences in sintering behavior. These inconsistencies result in differential shrinkage rates across the component, exacerbating distortion issues during both the heating and cooling phases.

The industry also struggles with the inherent trade-off between densification and distortion control. Higher sintering temperatures and longer dwell times generally promote better densification and mechanical properties but simultaneously increase the risk of distortion. Finding the optimal processing window that balances these competing requirements remains challenging for many PM applications.

Tooling and fixture design presents another significant hurdle. While proper support fixtures can mitigate distortion, they must be carefully engineered to accommodate shrinkage without constraining it, which would introduce internal stresses. Additionally, interaction between the component and sintering substrate can cause friction that restricts uniform shrinkage, resulting in distortion.

Computational modeling of the sintering process, while advancing, still lacks the precision needed for reliable distortion prediction in complex geometries. Current models struggle to accurately account for all variables affecting shrinkage behavior, including particle characteristics, green density variations, and the complex thermodynamics of multi-component systems.

These challenges collectively contribute to quality control issues, increased production costs, and limitations on the geometric complexity achievable through powder metallurgy processes, driving the need for innovative solutions in distortion control during sintering.

Temperature gradients within parts during heating and cooling cycles represent a major technical hurdle. When different sections of a component heat or cool at varying rates, internal stresses develop that can cause significant distortion. This is particularly problematic for complex geometries with varying cross-sectional thicknesses, where achieving uniform temperature distribution becomes exceedingly difficult.

Gravitational effects during sintering pose another significant challenge. As parts soften at high temperatures, they become susceptible to sagging under their own weight. This phenomenon is especially pronounced in components with unsupported features or overhangs, requiring specialized support structures or sintering orientations that add complexity to the manufacturing process.

Material composition heterogeneity introduces additional complications. Variations in particle size distribution, alloying element segregation, or contamination can lead to localized differences in sintering behavior. These inconsistencies result in differential shrinkage rates across the component, exacerbating distortion issues during both the heating and cooling phases.

The industry also struggles with the inherent trade-off between densification and distortion control. Higher sintering temperatures and longer dwell times generally promote better densification and mechanical properties but simultaneously increase the risk of distortion. Finding the optimal processing window that balances these competing requirements remains challenging for many PM applications.

Tooling and fixture design presents another significant hurdle. While proper support fixtures can mitigate distortion, they must be carefully engineered to accommodate shrinkage without constraining it, which would introduce internal stresses. Additionally, interaction between the component and sintering substrate can cause friction that restricts uniform shrinkage, resulting in distortion.

Computational modeling of the sintering process, while advancing, still lacks the precision needed for reliable distortion prediction in complex geometries. Current models struggle to accurately account for all variables affecting shrinkage behavior, including particle characteristics, green density variations, and the complex thermodynamics of multi-component systems.

These challenges collectively contribute to quality control issues, increased production costs, and limitations on the geometric complexity achievable through powder metallurgy processes, driving the need for innovative solutions in distortion control during sintering.

Existing Distortion Control Methods in Powder Metallurgy

01 Controlling sintering parameters to minimize distortion

Precise control of sintering parameters such as temperature, time, and atmosphere can significantly reduce distortion in powder metallurgy components. By optimizing these parameters, manufacturers can achieve more uniform densification and minimize internal stresses that lead to warping or dimensional changes. Controlled cooling rates are particularly important to prevent thermal gradients that cause differential shrinkage across the part.- Controlling sintering parameters to minimize distortion: Proper control of sintering parameters such as temperature, time, and atmosphere can significantly reduce distortion in powder metallurgy components. Optimized heating and cooling rates, along with uniform temperature distribution within the furnace, help maintain dimensional stability. Controlled atmosphere sintering prevents oxidation and ensures consistent shrinkage throughout the part, which is critical for complex geometries.

- Powder composition and particle size distribution: The composition and particle size distribution of metal powders significantly impact distortion during sintering. Fine-tuning the powder blend with specific particle morphologies and size distributions can improve packing density and reduce differential shrinkage. Adding alloying elements or lubricants in precise amounts helps control the sintering behavior and minimizes warpage. Homogeneous powder mixtures ensure uniform densification and reduce stress concentrations that lead to distortion.

- Design considerations for distortion prevention: Component design plays a crucial role in preventing distortion during powder metallurgy processing. Incorporating uniform wall thickness, avoiding sharp corners, and designing appropriate draft angles can minimize stress concentration and uneven shrinkage. Strategic placement of ribs and supports during the design phase helps maintain dimensional stability throughout the sintering process. Simulation tools can predict potential distortion areas, allowing for design optimization before manufacturing.

- Post-sintering treatments to correct distortion: Various post-sintering treatments can be employed to correct distortion in powder metallurgy parts. Techniques such as calibration, coining, and sizing help restore dimensional accuracy after sintering. Heat treatments like annealing can relieve internal stresses that contribute to warpage. Surface treatments including shot peening or roller burnishing can improve surface finish while simultaneously addressing minor distortion issues. For severe cases, machining operations may be necessary to achieve final specifications.

- Innovative compaction techniques: Advanced compaction methods can significantly reduce distortion in powder metallurgy components. Techniques such as warm compaction, isostatic pressing, and multi-directional pressing create more uniform density distributions in green compacts, which leads to more predictable shrinkage during sintering. Applying variable pressure profiles during compaction helps compensate for potential distortion areas. Novel die designs with controlled ejection mechanisms minimize residual stresses in the green part that could lead to distortion during subsequent processing steps.

02 Powder composition and particle size distribution

The composition and particle size distribution of metal powders significantly impact distortion during sintering. Using powders with optimized particle morphology, size distribution, and alloying elements can improve packing density and sintering behavior. Certain additives can be incorporated to enhance flowability and reduce friction between particles, resulting in more uniform shrinkage and less distortion in the final component.Expand Specific Solutions03 Advanced compaction techniques

Innovative compaction methods such as warm compaction, high-velocity compaction, and isostatic pressing can produce green compacts with more uniform density distribution, reducing the risk of distortion during sintering. These techniques help to minimize density gradients within the part, which are a primary cause of non-uniform shrinkage and dimensional changes during the sintering process.Expand Specific Solutions04 Support structures and sintering fixtures

Using specialized support structures and sintering fixtures can physically constrain parts during the sintering process to prevent distortion. These fixtures can be designed to accommodate the expected shrinkage patterns while maintaining critical dimensions and geometries. Materials used for these fixtures must withstand sintering temperatures while providing appropriate support without reacting with the sintered components.Expand Specific Solutions05 Post-sintering treatments to correct distortion

Various post-sintering treatments can be employed to correct distortion in powder metallurgy parts. These include calibration, coining, sizing, and heat treatments that can relieve internal stresses and restore dimensional accuracy. For parts with complex geometries, specialized machining operations may be necessary to achieve final specifications after accounting for sintering-induced distortion.Expand Specific Solutions

Leading Companies and Research Institutions in PM Industry

Powder metallurgy technology for minimizing distortion during sintering and cooling is currently in a mature growth phase, with the global market valued at approximately $30 billion and projected to expand at 6-7% CAGR through 2028. The competitive landscape features established industry leaders like GKN Sinter Metals and Kennametal developing advanced sintering techniques alongside specialized innovators such as K4Sint and NetShape Technologies. Research institutions including MIT and Naval Research Laboratory are advancing fundamental understanding of thermal behavior during sintering processes. Major industrial players like Sumitomo Electric, BASF, and Komatsu are implementing these technologies in high-precision applications where dimensional stability is critical, while companies like NBTM New Materials Group and Taiwan Powder Technologies are expanding capabilities in emerging markets.

Kennametal, Inc.

Technical Solution: Kennametal has pioneered the "Near-Net Shape" powder metallurgy approach for minimizing sintering distortion, particularly in tungsten carbide and other hard materials. Their technology utilizes ultra-fine powder particles (typically <1μm) with narrow size distribution to promote uniform shrinkage during sintering. Kennametal's process incorporates specialized binder systems that maintain component integrity during the critical "green state" and burn off uniformly during sintering. Their sintering protocols employ precise temperature ramping (typically 1-3°C/minute during critical phases) and hold times optimized through extensive empirical testing. For complex components, Kennametal implements differential density distribution during compaction to counteract geometry-specific distortion tendencies. Their advanced vacuum sintering technology maintains pressures below 10^-4 torr to eliminate oxidation-related dimensional inconsistencies. Additionally, Kennametal has developed specialized fixturing systems that provide mechanical constraints during sintering to maintain critical dimensions while allowing for controlled shrinkage in non-critical areas[2][5].

Strengths: Exceptional capability with hard materials and wear components, achieving dimensional tolerances as tight as ±0.05mm on complex geometries. Their specialized fixturing systems enable production of components that would otherwise require significant post-sintering machining. Weaknesses: Their approach is optimized for smaller precision components and may be less cost-effective for larger structural parts. The specialized equipment and expertise required limits broader application.

GKN Sinter Metals LLC

Technical Solution: GKN Sinter Metals has developed advanced sintering distortion control techniques through their proprietary "Sinter-Hardening" process. This technology combines sintering and heat treatment in a single operation, utilizing controlled cooling rates (typically 3-5°C/second) to minimize dimensional changes. Their approach incorporates pre-sintering dimensional compensation models that predict and account for expected shrinkage (typically 15-20% volumetric). GKN employs atmosphere control systems that maintain precise carbon potential during sintering, preventing decarburization which can lead to non-uniform shrinkage. Their multi-zone furnaces create carefully controlled temperature gradients (±5°C across components) to ensure uniform densification. Additionally, GKN utilizes computer simulation software to predict distortion patterns based on component geometry and powder characteristics, allowing for tooling adjustments that compensate for anticipated dimensional changes during processing[1][3].

Strengths: Industry-leading predictive modeling capabilities allow for exceptional dimensional accuracy (±0.1% on critical dimensions). Their integrated sinter-hardening process reduces overall manufacturing steps and associated distortion risks. Weaknesses: Their high-precision approach requires significant capital investment in specialized equipment and may have limitations with very complex geometries or extremely large components.

Key Technologies for Dimensional Stability in Sintering

Distortion mitigation during sintering of ceramics through the incorporation of ceramic precursor solutions

PatentWO2020037054A1

Innovation

- Incorporating ceramic precursors, such as metal alkoxides and dissolved metallic salt solutions, into the binder jet printed ceramic bodies to form interparticle necks before sintering, which mitigates distortion by increasing particle contacts at lower temperatures and preventing creep.

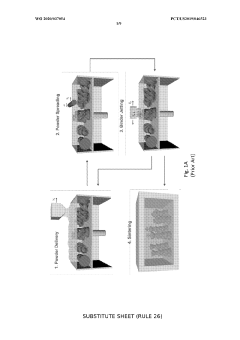

A method of producing a diffusion alloyed iron or iron-based powder, a diffusion alloyed powder, a composition including the diffusion alloyed powder, and a compacted and sintered part produced from the composition

PatentWO2010074634A1

Innovation

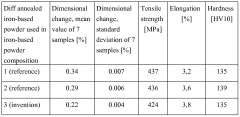

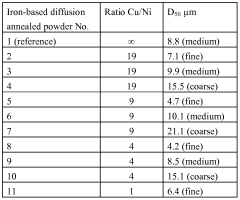

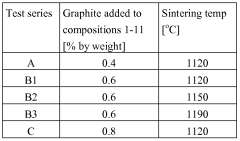

- A method involving a unitary alloying powder with copper and nickel, where the copper content is above 4.0 wt% and the nickel content is between 0.5-5%, is diffusion-bonded to the surface of an iron-based core powder, and then heated in a non-oxidizing atmosphere to minimize dimensional changes and segregation, resulting in a compacted and sintered part with reduced variation.

Material Selection Strategies for Distortion Reduction

Material selection plays a pivotal role in minimizing distortion during powder metallurgy processes. The careful selection of powder compositions and characteristics directly influences dimensional stability throughout sintering and cooling phases. Primary considerations include particle size distribution, which affects packing density and subsequent shrinkage behavior. Finer particles generally provide higher green density but may lead to greater shrinkage during sintering, while coarser particles offer improved dimensional stability but potentially reduced mechanical properties.

Alloying elements must be strategically incorporated to control sintering kinetics. Elements with higher diffusion rates can accelerate densification but may contribute to non-uniform shrinkage. Conversely, elements that form stable phases during sintering can anchor the microstructure and reduce distortion. For instance, the addition of small amounts of molybdenum in ferrous PM components has demonstrated significant improvements in dimensional control by forming carbides that inhibit grain growth.

The homogeneity of powder blends represents another critical factor. Segregation of alloying elements or lubricants can create localized differences in sintering behavior, resulting in warpage or dimensional variations. Advanced mixing techniques such as mechanical alloying or high-energy ball milling can enhance homogeneity and subsequently improve dimensional stability during thermal processing.

Pre-alloyed powders often exhibit superior dimensional control compared to admixed variants due to their inherent compositional uniformity throughout each particle. While more costly, these materials eliminate the risk of segregation during handling and provide more predictable sintering behavior, making them ideal for components with stringent dimensional requirements.

Lubricant selection and content must be carefully balanced. While lubricants facilitate compaction and die release, their removal during de-binding creates pores that influence subsequent densification patterns. Lower lubricant contents generally yield better dimensional stability but may compromise green strength and compaction efficiency.

For applications demanding exceptional dimensional precision, composite powder systems incorporating reinforcement particles or fibers can provide mechanical anchoring during sintering. Ceramic reinforcements with minimal thermal expansion, such as silicon carbide or aluminum oxide, can constrain matrix movement during thermal cycling, significantly reducing overall component distortion.

Recent innovations include the development of tailored powder systems with engineered sintering behavior. These advanced materials incorporate phase-change elements that absorb expansion energy during heating or release compensatory shrinkage during cooling, effectively neutralizing dimensional changes throughout the thermal cycle.

Alloying elements must be strategically incorporated to control sintering kinetics. Elements with higher diffusion rates can accelerate densification but may contribute to non-uniform shrinkage. Conversely, elements that form stable phases during sintering can anchor the microstructure and reduce distortion. For instance, the addition of small amounts of molybdenum in ferrous PM components has demonstrated significant improvements in dimensional control by forming carbides that inhibit grain growth.

The homogeneity of powder blends represents another critical factor. Segregation of alloying elements or lubricants can create localized differences in sintering behavior, resulting in warpage or dimensional variations. Advanced mixing techniques such as mechanical alloying or high-energy ball milling can enhance homogeneity and subsequently improve dimensional stability during thermal processing.

Pre-alloyed powders often exhibit superior dimensional control compared to admixed variants due to their inherent compositional uniformity throughout each particle. While more costly, these materials eliminate the risk of segregation during handling and provide more predictable sintering behavior, making them ideal for components with stringent dimensional requirements.

Lubricant selection and content must be carefully balanced. While lubricants facilitate compaction and die release, their removal during de-binding creates pores that influence subsequent densification patterns. Lower lubricant contents generally yield better dimensional stability but may compromise green strength and compaction efficiency.

For applications demanding exceptional dimensional precision, composite powder systems incorporating reinforcement particles or fibers can provide mechanical anchoring during sintering. Ceramic reinforcements with minimal thermal expansion, such as silicon carbide or aluminum oxide, can constrain matrix movement during thermal cycling, significantly reducing overall component distortion.

Recent innovations include the development of tailored powder systems with engineered sintering behavior. These advanced materials incorporate phase-change elements that absorb expansion energy during heating or release compensatory shrinkage during cooling, effectively neutralizing dimensional changes throughout the thermal cycle.

Environmental Impact of Advanced Sintering Processes

Advanced sintering processes in powder metallurgy have demonstrated significant environmental advantages compared to traditional manufacturing methods. The energy consumption during sintering operations has been reduced by approximately 30-40% through the implementation of rapid sintering technologies such as microwave and spark plasma sintering. These methods achieve densification at lower temperatures and shorter cycle times, resulting in substantial energy savings and reduced carbon emissions.

Material utilization in powder metallurgy approaches 95-98%, significantly higher than conventional machining processes which may waste up to 70% of raw materials. This near-net-shape capability minimizes the need for secondary operations and reduces waste generation. Additionally, the controlled atmosphere environments used in modern sintering processes have virtually eliminated harmful emissions that were common in older technologies.

Water consumption represents another area of environmental improvement. Advanced sintering processes typically require 40-60% less water compared to traditional metal forming operations. Closed-loop cooling systems and dry cooling technologies have been particularly effective in reducing water usage in facilities employing these advanced processes.

The environmental benefits extend to the entire product lifecycle. Components manufactured through advanced powder metallurgy sintering exhibit improved durability and performance characteristics, extending product lifespans by an estimated 15-25%. This longevity directly translates to reduced resource consumption and waste generation over time.

Recycling capabilities have also been enhanced with modern sintering technologies. Powder metallurgy facilitates the use of recycled metal powders without significant degradation in material properties. Current industry practices achieve recycling rates of 80-90% for metal powders, creating a more circular material flow within manufacturing ecosystems.

Carbon footprint analyses indicate that advanced sintering processes generate 25-35% lower greenhouse gas emissions compared to conventional metal forming techniques when evaluated on a lifecycle basis. This reduction stems from lower processing temperatures, shorter production cycles, and reduced transportation requirements due to the compact nature of powder metallurgy production facilities.

The development of bio-based binders and environmentally friendly sintering aids has further reduced the environmental impact of these processes. These innovations have decreased the reliance on petroleum-based additives by approximately 40% over the past decade, contributing to the overall sustainability profile of powder metallurgy manufacturing.

Material utilization in powder metallurgy approaches 95-98%, significantly higher than conventional machining processes which may waste up to 70% of raw materials. This near-net-shape capability minimizes the need for secondary operations and reduces waste generation. Additionally, the controlled atmosphere environments used in modern sintering processes have virtually eliminated harmful emissions that were common in older technologies.

Water consumption represents another area of environmental improvement. Advanced sintering processes typically require 40-60% less water compared to traditional metal forming operations. Closed-loop cooling systems and dry cooling technologies have been particularly effective in reducing water usage in facilities employing these advanced processes.

The environmental benefits extend to the entire product lifecycle. Components manufactured through advanced powder metallurgy sintering exhibit improved durability and performance characteristics, extending product lifespans by an estimated 15-25%. This longevity directly translates to reduced resource consumption and waste generation over time.

Recycling capabilities have also been enhanced with modern sintering technologies. Powder metallurgy facilitates the use of recycled metal powders without significant degradation in material properties. Current industry practices achieve recycling rates of 80-90% for metal powders, creating a more circular material flow within manufacturing ecosystems.

Carbon footprint analyses indicate that advanced sintering processes generate 25-35% lower greenhouse gas emissions compared to conventional metal forming techniques when evaluated on a lifecycle basis. This reduction stems from lower processing temperatures, shorter production cycles, and reduced transportation requirements due to the compact nature of powder metallurgy production facilities.

The development of bio-based binders and environmentally friendly sintering aids has further reduced the environmental impact of these processes. These innovations have decreased the reliance on petroleum-based additives by approximately 40% over the past decade, contributing to the overall sustainability profile of powder metallurgy manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!