How Solder Joint Reliability Balances Standoff Height And Board Flex To Resist Shock?

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solder Joint Reliability Background and Objectives

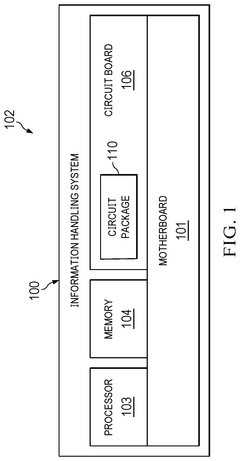

Solder joint reliability has emerged as a critical factor in the electronics manufacturing industry, evolving significantly since the introduction of surface mount technology in the 1980s. This evolution has been driven by increasingly complex electronic assemblies, miniaturization trends, and the transition to lead-free solders following environmental regulations such as RoHS. The fundamental challenge in solder joint reliability lies in maintaining electrical and mechanical integrity under various stress conditions, particularly mechanical shock events that are inevitable during product handling, transportation, and usage.

The relationship between standoff height and board flex represents a critical design consideration that directly impacts solder joint performance under shock conditions. Historically, this relationship was less scrutinized when through-hole technology dominated, but has become paramount with the proliferation of ball grid arrays (BGAs), chip scale packages (CSPs), and other advanced packaging technologies that feature reduced standoff heights.

Industry data indicates that solder joint failures account for approximately 70% of electronic assembly failures in high-reliability applications, with shock-induced failures representing a significant subset of these incidents. The economic impact of these failures extends beyond simple component replacement costs to include warranty claims, field repairs, and potential safety concerns in critical applications such as automotive, aerospace, and medical devices.

The technical objective of this research is to establish a comprehensive understanding of the mechanical behavior of solder joints during shock events, with specific focus on quantifying the optimal balance between standoff height and board flexibility. This includes developing predictive models that can accurately forecast solder joint performance under various shock profiles and establishing design guidelines that maximize reliability while maintaining manufacturability.

Current industry standards such as IPC-9701, JEDEC JESD22-B111, and MIL-STD-810G provide testing methodologies for shock resistance, but lack specific guidance on the interrelationship between standoff height and board flex parameters. This research aims to bridge this knowledge gap by correlating theoretical models with empirical test data across various package types and board configurations.

The long-term objective extends beyond immediate reliability improvements to developing adaptive design methodologies that can accommodate emerging packaging technologies and increasingly demanding operating environments. This includes exploring novel solder alloy compositions, reinforcement techniques, and geometric optimizations that can enhance shock resistance without compromising other reliability aspects such as thermal cycling performance or manufacturability.

By establishing a scientific foundation for the relationship between standoff height, board flex, and shock resistance, this research seeks to enable more robust electronic assemblies while supporting the industry's continued trend toward higher density, lower profile, and more mechanically challenging applications.

The relationship between standoff height and board flex represents a critical design consideration that directly impacts solder joint performance under shock conditions. Historically, this relationship was less scrutinized when through-hole technology dominated, but has become paramount with the proliferation of ball grid arrays (BGAs), chip scale packages (CSPs), and other advanced packaging technologies that feature reduced standoff heights.

Industry data indicates that solder joint failures account for approximately 70% of electronic assembly failures in high-reliability applications, with shock-induced failures representing a significant subset of these incidents. The economic impact of these failures extends beyond simple component replacement costs to include warranty claims, field repairs, and potential safety concerns in critical applications such as automotive, aerospace, and medical devices.

The technical objective of this research is to establish a comprehensive understanding of the mechanical behavior of solder joints during shock events, with specific focus on quantifying the optimal balance between standoff height and board flexibility. This includes developing predictive models that can accurately forecast solder joint performance under various shock profiles and establishing design guidelines that maximize reliability while maintaining manufacturability.

Current industry standards such as IPC-9701, JEDEC JESD22-B111, and MIL-STD-810G provide testing methodologies for shock resistance, but lack specific guidance on the interrelationship between standoff height and board flex parameters. This research aims to bridge this knowledge gap by correlating theoretical models with empirical test data across various package types and board configurations.

The long-term objective extends beyond immediate reliability improvements to developing adaptive design methodologies that can accommodate emerging packaging technologies and increasingly demanding operating environments. This includes exploring novel solder alloy compositions, reinforcement techniques, and geometric optimizations that can enhance shock resistance without compromising other reliability aspects such as thermal cycling performance or manufacturability.

By establishing a scientific foundation for the relationship between standoff height, board flex, and shock resistance, this research seeks to enable more robust electronic assemblies while supporting the industry's continued trend toward higher density, lower profile, and more mechanically challenging applications.

Market Demands for Robust Electronic Interconnections

The electronic manufacturing industry is witnessing unprecedented demand for robust interconnection solutions as devices become increasingly miniaturized while being deployed in more challenging environments. Market research indicates that the global electronic components market, particularly for mission-critical applications, prioritizes solder joint reliability as a fundamental requirement. This demand is driven by multiple sectors including automotive electronics, aerospace systems, medical devices, and consumer electronics, all requiring products that can withstand mechanical shock events.

Consumer electronics manufacturers face intense pressure to produce thinner, lighter devices with enhanced durability. The smartphone market exemplifies this trend, with devices becoming progressively slimmer while consumers expect them to survive multiple drop events. This has created a significant market pull for advanced solder joint technologies that can maintain reliability despite reduced standoff heights.

The automotive electronics sector represents another major market driver, with the average vehicle now containing over 100 electronic control units. These components must withstand severe vibration and shock conditions while maintaining functionality over a 10-15 year lifespan. The emergence of electric vehicles has further intensified this demand, as battery management systems require exceptionally reliable solder connections that can endure thermal cycling and mechanical stress.

Aerospace and defense applications present perhaps the most stringent requirements, where electronic failures can have catastrophic consequences. These sectors demand solder joint solutions that can withstand extreme acceleration forces, vibration profiles, and thermal conditions. The market value proposition centers on total reliability rather than cost optimization.

Medical device manufacturers represent a growing market segment seeking enhanced solder joint reliability. Implantable devices and portable medical equipment must maintain functionality despite patient movement and potential impact events. The regulatory environment in this sector further emphasizes the need for proven reliability solutions.

Industrial IoT applications are expanding the market for robust interconnections into new environments. As sensors and control systems are deployed in manufacturing facilities, infrastructure monitoring, and remote locations, they face varied mechanical stresses that conventional solder joints may not adequately address.

Market analysis reveals that manufacturers are increasingly willing to invest in advanced materials and design methodologies that optimize the relationship between standoff height and board flex parameters. This represents a shift from purely cost-driven decisions to performance-based specifications that recognize the total cost implications of field failures. The market clearly signals that solutions balancing these parameters to enhance shock resistance will command premium positioning in the electronic manufacturing value chain.

Consumer electronics manufacturers face intense pressure to produce thinner, lighter devices with enhanced durability. The smartphone market exemplifies this trend, with devices becoming progressively slimmer while consumers expect them to survive multiple drop events. This has created a significant market pull for advanced solder joint technologies that can maintain reliability despite reduced standoff heights.

The automotive electronics sector represents another major market driver, with the average vehicle now containing over 100 electronic control units. These components must withstand severe vibration and shock conditions while maintaining functionality over a 10-15 year lifespan. The emergence of electric vehicles has further intensified this demand, as battery management systems require exceptionally reliable solder connections that can endure thermal cycling and mechanical stress.

Aerospace and defense applications present perhaps the most stringent requirements, where electronic failures can have catastrophic consequences. These sectors demand solder joint solutions that can withstand extreme acceleration forces, vibration profiles, and thermal conditions. The market value proposition centers on total reliability rather than cost optimization.

Medical device manufacturers represent a growing market segment seeking enhanced solder joint reliability. Implantable devices and portable medical equipment must maintain functionality despite patient movement and potential impact events. The regulatory environment in this sector further emphasizes the need for proven reliability solutions.

Industrial IoT applications are expanding the market for robust interconnections into new environments. As sensors and control systems are deployed in manufacturing facilities, infrastructure monitoring, and remote locations, they face varied mechanical stresses that conventional solder joints may not adequately address.

Market analysis reveals that manufacturers are increasingly willing to invest in advanced materials and design methodologies that optimize the relationship between standoff height and board flex parameters. This represents a shift from purely cost-driven decisions to performance-based specifications that recognize the total cost implications of field failures. The market clearly signals that solutions balancing these parameters to enhance shock resistance will command premium positioning in the electronic manufacturing value chain.

Current Challenges in Solder Joint Technology

The solder joint reliability landscape faces significant challenges as electronic devices continue to evolve toward miniaturization while simultaneously demanding enhanced durability. Current solder joint technology struggles with the fundamental tension between standoff height optimization and board flex resistance, particularly in shock scenarios. This technical contradiction represents one of the industry's most pressing concerns, as insufficient solutions lead to premature product failures and reliability issues.

A primary challenge lies in the material properties of modern lead-free solders, which exhibit higher melting points and greater brittleness compared to traditional tin-lead compositions. These characteristics make joints more susceptible to cracking under mechanical stress, especially during drop or shock events. The industry's transition to lead-free solders, while environmentally necessary, has introduced significant reliability complications that remain incompletely resolved.

Component miniaturization has further exacerbated these challenges by reducing the physical size of solder joints. Smaller joints contain less material to absorb mechanical energy, making them inherently more vulnerable to failure. This trend toward smaller form factors conflicts directly with reliability requirements, creating a technical paradox that demands innovative solutions.

The relationship between standoff height and shock resistance presents another critical challenge. Higher standoff heights generally improve shock resistance by allowing greater flexibility and stress distribution, but they conflict with miniaturization goals and can introduce other reliability issues such as increased susceptibility to vibration damage. Conversely, lower standoff heights support miniaturization but concentrate stress during shock events, accelerating failure.

Manufacturing inconsistencies compound these technical difficulties. Variations in solder paste deposition, reflow profiles, and component placement create unpredictable standoff heights across a single board, leading to reliability disparities that are difficult to model or predict. These process variations introduce significant complexity into reliability engineering calculations.

Environmental factors further complicate solder joint reliability. Temperature cycling, humidity, and operational vibrations interact with shock events in complex ways that current modeling approaches struggle to fully capture. The cumulative effect of these environmental stressors on the standoff height-board flex relationship remains poorly understood despite its critical importance to product reliability.

Testing methodologies present additional challenges, as accelerated life testing may not accurately represent real-world failure modes. The industry lacks standardized approaches for evaluating the complex interplay between standoff height and board flex under varied shock conditions, making comparative analysis difficult and hindering the development of universal design guidelines.

A primary challenge lies in the material properties of modern lead-free solders, which exhibit higher melting points and greater brittleness compared to traditional tin-lead compositions. These characteristics make joints more susceptible to cracking under mechanical stress, especially during drop or shock events. The industry's transition to lead-free solders, while environmentally necessary, has introduced significant reliability complications that remain incompletely resolved.

Component miniaturization has further exacerbated these challenges by reducing the physical size of solder joints. Smaller joints contain less material to absorb mechanical energy, making them inherently more vulnerable to failure. This trend toward smaller form factors conflicts directly with reliability requirements, creating a technical paradox that demands innovative solutions.

The relationship between standoff height and shock resistance presents another critical challenge. Higher standoff heights generally improve shock resistance by allowing greater flexibility and stress distribution, but they conflict with miniaturization goals and can introduce other reliability issues such as increased susceptibility to vibration damage. Conversely, lower standoff heights support miniaturization but concentrate stress during shock events, accelerating failure.

Manufacturing inconsistencies compound these technical difficulties. Variations in solder paste deposition, reflow profiles, and component placement create unpredictable standoff heights across a single board, leading to reliability disparities that are difficult to model or predict. These process variations introduce significant complexity into reliability engineering calculations.

Environmental factors further complicate solder joint reliability. Temperature cycling, humidity, and operational vibrations interact with shock events in complex ways that current modeling approaches struggle to fully capture. The cumulative effect of these environmental stressors on the standoff height-board flex relationship remains poorly understood despite its critical importance to product reliability.

Testing methodologies present additional challenges, as accelerated life testing may not accurately represent real-world failure modes. The industry lacks standardized approaches for evaluating the complex interplay between standoff height and board flex under varied shock conditions, making comparative analysis difficult and hindering the development of universal design guidelines.

Existing Standoff Height and Board Flex Solutions

01 Solder composition for improved reliability

The composition of solder materials significantly impacts joint reliability. Various alloy formulations can enhance mechanical strength, thermal cycling resistance, and overall durability of solder connections. Advanced compositions may include specific ratios of tin, silver, copper, and other elements to optimize performance characteristics such as creep resistance and fatigue life. These specialized formulations help prevent common failure modes like cracking and delamination under thermal and mechanical stress conditions.- Solder composition and material selection: The reliability of solder joints is significantly influenced by the composition of solder materials used. Various alloys and additives can enhance mechanical strength, thermal cycling resistance, and overall durability of the joints. Proper material selection considers factors such as melting point, wettability, and resistance to thermal fatigue. Advanced solder compositions may incorporate nanoparticles or specific metal ratios to improve performance under stress conditions and prevent common failure modes.

- Testing and reliability assessment methods: Various testing methodologies are employed to evaluate solder joint reliability, including thermal cycling tests, drop tests, and vibration analysis. Advanced inspection techniques such as X-ray imaging, acoustic microscopy, and electrical resistance monitoring help identify potential failure points before they manifest. Accelerated life testing protocols simulate years of operational stress in shorter timeframes, while statistical models predict long-term reliability based on test data. These assessment methods are crucial for qualifying solder joints for different application environments.

- Design optimization for solder joint reliability: The physical design and geometry of solder joints significantly impact their reliability. Optimized pad designs, controlled standoff heights, and strategic placement of joints can distribute stress more effectively. Thermal management considerations in the design phase help mitigate temperature-related failures. Computer-aided design tools enable simulation of mechanical stresses and thermal behavior before physical implementation, allowing engineers to identify and address potential weak points in the solder joint architecture.

- Manufacturing process control: Precise control of the soldering process parameters is essential for reliable joint formation. Factors such as temperature profiles, cooling rates, and atmosphere conditions during soldering significantly affect joint quality. Automated inspection systems monitor process consistency and detect anomalies in real-time. Advanced manufacturing techniques incorporate controlled preheating, optimized flux application, and post-soldering cleaning processes to minimize defects such as voids, cold joints, and insufficient wetting that could compromise reliability.

- Environmental and operational stress mitigation: Solder joints must withstand various environmental and operational stresses throughout their lifecycle. Protective coatings and encapsulants shield joints from moisture, corrosive substances, and mechanical impacts. Stress relief designs incorporate flexible elements that absorb thermal expansion differences between connected components. Specialized formulations address specific environmental challenges such as high-temperature operation, vibration, or exposure to harsh chemicals, extending the reliable service life of the solder connections under demanding conditions.

02 Testing and evaluation methods for solder joint reliability

Various testing methodologies are employed to assess and predict solder joint reliability. These include thermal cycling tests, drop tests, vibration analysis, and accelerated aging techniques that simulate real-world conditions. Advanced analytical tools such as X-ray inspection, scanning electron microscopy, and finite element analysis help identify potential failure modes and validate reliability improvements. These evaluation methods enable quantitative assessment of joint performance and lifespan under different operating conditions.Expand Specific Solutions03 Structural design for enhanced solder joint reliability

The physical design and geometry of solder joints significantly impact their reliability. Optimized pad designs, controlled standoff heights, and strategic reinforcement structures can distribute stress more effectively and prevent premature failures. Innovations in joint architecture include specialized shapes, underfill technologies, and support structures that enhance mechanical integrity. These design approaches help mitigate common failure mechanisms such as thermal fatigue and mechanical shock damage.Expand Specific Solutions04 Manufacturing process optimization for reliable solder joints

Manufacturing processes significantly impact solder joint reliability. Controlled heating profiles, precise flux application, and optimized reflow parameters help create consistent, high-quality connections. Advanced techniques such as vapor phase soldering, selective soldering, and specialized preheating methods can reduce defects like voids, cold joints, and insufficient wetting. Process monitoring systems and statistical process control help maintain quality and reliability across production volumes.Expand Specific Solutions05 Environmental protection and reliability enhancement coatings

Protective coatings and encapsulation materials can significantly enhance solder joint reliability by preventing environmental degradation. Conformal coatings, underfills, and specialized encapsulants protect against moisture, oxidation, and contaminants that can cause corrosion and electrical failures. These materials also provide mechanical reinforcement that helps absorb shock and vibration. Advanced coating formulations offer improved adhesion, flexibility, and thermal compatibility with solder materials.Expand Specific Solutions

Leading Companies in Solder Technology and Testing

The solder joint reliability market is currently in a growth phase, with increasing demand driven by electronics miniaturization and automotive applications. The market is projected to expand significantly as industries adopt more sophisticated electronic components requiring reliable solder connections under mechanical stress conditions. Technologically, the field is advancing through innovations balancing standoff height optimization and board flex resistance to enhance shock absorption. Leading companies like Senju Metal Industry, Indium Corporation, and Nihon Superior are developing advanced solder materials with improved mechanical properties, while electronics manufacturers including Huawei, Dell, and Panasonic are implementing enhanced design methodologies. Automotive players such as Honda and Toyota are particularly focused on high-reliability solutions for vehicle electronics operating in vibration-intensive environments, driving further innovation in this specialized field.

Senju Metal Industry Co., Ltd.

Technical Solution: Senju Metal has developed advanced solder alloys specifically engineered to optimize standoff height while maintaining flexibility under shock conditions. Their M758 series incorporates nano-particle reinforcement technology that creates a more robust microstructure capable of absorbing mechanical stress during board flex events. The company's patented "Reliability Enhancement System" utilizes controlled solidification processes to create solder joints with columnar grain structures that provide superior resistance to crack propagation. Their research has demonstrated that maintaining a standoff height between 75-125μm with their specialized alloys can increase thermal cycling reliability by up to 40% while simultaneously improving drop shock resistance. Senju has also pioneered the use of specialized flux chemistries that promote optimal intermetallic compound formation, creating stronger interfaces between solder and substrate that better withstand mechanical shock.

Strengths: Industry-leading expertise in metallurgical engineering of solder alloys; comprehensive testing capabilities for shock resistance validation; strong presence in automotive and industrial electronics markets. Weaknesses: Higher cost compared to standard solder solutions; requires specific process parameters that may necessitate equipment modifications.

The Indium Corporation of America

Technical Solution: Indium Corporation has developed a comprehensive approach to solder joint reliability through their "Balanced Reliability Framework" that specifically addresses the relationship between standoff height and board flex resistance. Their proprietary Durafuse™ LT solder paste technology combines multiple alloy systems that work synergistically to create joints with both strength and ductility. This technology maintains critical standoff heights even under high-temperature operating conditions, preventing the collapse that often leads to premature failure during shock events. Indium's research has established that maintaining standoff heights of 100-150μm using their specialized formulations can increase shock resistance by up to 65% compared to conventional SAC alloys. Their engineers have also developed advanced computational models that predict optimal standoff heights based on specific board materials, component types, and expected mechanical stress profiles, allowing for application-specific optimization.

Strengths: Extensive R&D capabilities focused specifically on reliability engineering; broad product portfolio allowing customized solutions for different shock resistance requirements; strong technical support services. Weaknesses: Solutions often require more complex assembly processes; premium pricing structure compared to standard industry offerings.

Critical Patents in Shock-Resistant Solder Joints

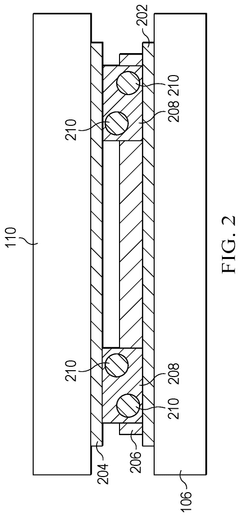

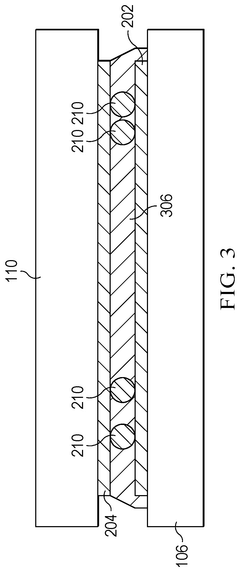

Solder preforms with embedded beads to act as standoffs

PatentPendingUS20250149487A1

Innovation

- The implementation of solder preforms with embedded beads that act as mechanical standoffs between the circuit board and the package, allowing for increased solder joint height during the reflow process to enhance reliability and reduce voids.

Environmental Impact of Solder Materials

The environmental impact of solder materials has become increasingly significant in the context of solder joint reliability engineering. Traditional tin-lead solders, once the industry standard, have been largely phased out due to their toxic properties and environmental persistence. Lead, in particular, poses serious environmental hazards through soil and water contamination, potentially entering food chains and causing long-term ecosystem damage.

The transition to lead-free solders, primarily driven by regulations like the European Union's Restriction of Hazardous Substances (RoHS) directive, has introduced new environmental considerations. While eliminating lead represents a positive step, many lead-free alternatives contain metals like silver and copper that have their own environmental footprints associated with mining, refining, and disposal processes.

Manufacturing processes for solder materials contribute significantly to their overall environmental impact. Energy consumption during solder production and application generates substantial carbon emissions. Additionally, flux components in solder pastes often contain volatile organic compounds (VOCs) that can contribute to air pollution and ozone depletion when released during the soldering process.

The relationship between solder joint reliability and environmental impact becomes particularly evident when considering standoff height and board flex parameters. Higher standoff heights generally require more solder material, increasing the environmental footprint per connection. However, insufficient standoff height may lead to premature failures under shock conditions, necessitating repairs or replacements that generate additional waste and environmental burden.

End-of-life considerations present another critical environmental dimension. Electronic waste containing solder joints represents one of the fastest-growing waste streams globally. The recoverability and recyclability of different solder compositions vary significantly, with some newer formulations designed specifically for improved environmental performance throughout their lifecycle.

Recent innovations in solder materials include bio-derived flux components, halogen-free formulations, and compositions optimized for lower processing temperatures. These advancements aim to reduce energy consumption and minimize harmful emissions while maintaining the mechanical properties necessary for shock resistance. The development of solder materials that can achieve optimal standoff height with minimal material usage represents an important direction for environmentally conscious design.

The transition to lead-free solders, primarily driven by regulations like the European Union's Restriction of Hazardous Substances (RoHS) directive, has introduced new environmental considerations. While eliminating lead represents a positive step, many lead-free alternatives contain metals like silver and copper that have their own environmental footprints associated with mining, refining, and disposal processes.

Manufacturing processes for solder materials contribute significantly to their overall environmental impact. Energy consumption during solder production and application generates substantial carbon emissions. Additionally, flux components in solder pastes often contain volatile organic compounds (VOCs) that can contribute to air pollution and ozone depletion when released during the soldering process.

The relationship between solder joint reliability and environmental impact becomes particularly evident when considering standoff height and board flex parameters. Higher standoff heights generally require more solder material, increasing the environmental footprint per connection. However, insufficient standoff height may lead to premature failures under shock conditions, necessitating repairs or replacements that generate additional waste and environmental burden.

End-of-life considerations present another critical environmental dimension. Electronic waste containing solder joints represents one of the fastest-growing waste streams globally. The recoverability and recyclability of different solder compositions vary significantly, with some newer formulations designed specifically for improved environmental performance throughout their lifecycle.

Recent innovations in solder materials include bio-derived flux components, halogen-free formulations, and compositions optimized for lower processing temperatures. These advancements aim to reduce energy consumption and minimize harmful emissions while maintaining the mechanical properties necessary for shock resistance. The development of solder materials that can achieve optimal standoff height with minimal material usage represents an important direction for environmentally conscious design.

Thermal Cycling Effects on Joint Longevity

Thermal cycling represents one of the most significant environmental stressors affecting solder joint reliability in electronic assemblies. As components and printed circuit boards (PCBs) experience temperature fluctuations, the mismatch in coefficients of thermal expansion (CTE) between different materials creates cyclic stress on solder joints. This phenomenon directly impacts the relationship between standoff height and board flex resistance, ultimately determining the longevity of solder connections under shock conditions.

Research indicates that thermal cycling accelerates fatigue mechanisms in solder joints, with failure typically occurring through crack initiation and propagation at the interface between the solder and component or board. Higher standoff heights generally provide better thermal cycling reliability by distributing strain over a larger solder volume, reducing localized stress concentration. Studies have shown that an increase in standoff height from 0.1mm to 0.3mm can improve thermal cycling lifetime by 30-50% for typical lead-free solder compositions.

The microstructural evolution of solder joints during thermal cycling significantly influences their mechanical properties and shock resistance. As joints undergo repeated heating and cooling, intermetallic compound (IMC) layers grow at the interfaces, changing the joint's mechanical characteristics. These IMC layers, while necessary for proper bonding, become increasingly brittle with thermal aging, reducing the joint's ability to absorb mechanical shock through plastic deformation.

Temperature range severity directly correlates with joint degradation rates. Cycling between -40°C and +125°C induces approximately three times more damage per cycle than cycling between 0°C and +100°C. This accelerated degradation particularly affects the relationship between standoff height and board flex resistance, as thermally fatigued joints with compromised mechanical properties become more susceptible to shock-induced failures regardless of initial geometric design parameters.

Modern lead-free solder compositions exhibit different thermal cycling behavior compared to traditional tin-lead solders. SAC305 (Sn-3.0Ag-0.5Cu) and other lead-free alloys typically show higher initial strength but experience more rapid degradation under thermal cycling conditions. This characteristic necessitates careful consideration of standoff height design to compensate for the accelerated aging effects, particularly in applications experiencing both thermal cycling and mechanical shock.

Conformal coatings and underfill materials can significantly modify thermal cycling effects on joint reliability. These materials constrain board flex while providing thermal stress distribution, effectively altering the optimal standoff height requirements. Research demonstrates that properly applied underfill can extend thermal cycling lifetime by 5-10 times while simultaneously improving shock resistance, creating a complex interrelationship between material selection, standoff height, and board design parameters.

Research indicates that thermal cycling accelerates fatigue mechanisms in solder joints, with failure typically occurring through crack initiation and propagation at the interface between the solder and component or board. Higher standoff heights generally provide better thermal cycling reliability by distributing strain over a larger solder volume, reducing localized stress concentration. Studies have shown that an increase in standoff height from 0.1mm to 0.3mm can improve thermal cycling lifetime by 30-50% for typical lead-free solder compositions.

The microstructural evolution of solder joints during thermal cycling significantly influences their mechanical properties and shock resistance. As joints undergo repeated heating and cooling, intermetallic compound (IMC) layers grow at the interfaces, changing the joint's mechanical characteristics. These IMC layers, while necessary for proper bonding, become increasingly brittle with thermal aging, reducing the joint's ability to absorb mechanical shock through plastic deformation.

Temperature range severity directly correlates with joint degradation rates. Cycling between -40°C and +125°C induces approximately three times more damage per cycle than cycling between 0°C and +100°C. This accelerated degradation particularly affects the relationship between standoff height and board flex resistance, as thermally fatigued joints with compromised mechanical properties become more susceptible to shock-induced failures regardless of initial geometric design parameters.

Modern lead-free solder compositions exhibit different thermal cycling behavior compared to traditional tin-lead solders. SAC305 (Sn-3.0Ag-0.5Cu) and other lead-free alloys typically show higher initial strength but experience more rapid degradation under thermal cycling conditions. This characteristic necessitates careful consideration of standoff height design to compensate for the accelerated aging effects, particularly in applications experiencing both thermal cycling and mechanical shock.

Conformal coatings and underfill materials can significantly modify thermal cycling effects on joint reliability. These materials constrain board flex while providing thermal stress distribution, effectively altering the optimal standoff height requirements. Research demonstrates that properly applied underfill can extend thermal cycling lifetime by 5-10 times while simultaneously improving shock resistance, creating a complex interrelationship between material selection, standoff height, and board design parameters.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!