Solder Joint Reliability: Intermetallic Evolution, Creep–Fatigue Interactions And Lifetime Prediction

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solder Joint Reliability Background and Objectives

Solder joint reliability has emerged as a critical concern in the electronics industry since the 1960s, evolving significantly with the miniaturization of electronic components and the transition to lead-free solders. Initially, tin-lead (Sn-Pb) solders dominated the industry due to their excellent wetting properties, low melting points, and reasonable mechanical strength. However, environmental and health concerns led to the Restriction of Hazardous Substances (RoHS) directive in 2006, which accelerated the global shift toward lead-free alternatives.

The evolution of solder joint technology has been characterized by increasing complexity in both materials and failure mechanisms. Early reliability studies focused primarily on mechanical fatigue, but modern understanding encompasses a multifaceted interaction between thermal cycling, mechanical stress, and microstructural evolution. The formation and growth of intermetallic compounds (IMCs) at the interface between solder and substrate has become recognized as a fundamental aspect of joint reliability, particularly as these compounds can significantly alter mechanical properties over time.

Recent technological trends have further intensified reliability challenges. The continued miniaturization of electronic packages has resulted in higher current densities and thermal gradients across solder joints. Additionally, emerging applications in harsh environments—such as automotive, aerospace, and industrial settings—subject solder connections to extreme temperature fluctuations, vibration, and mechanical shock. These conditions accelerate creep and fatigue processes, leading to premature failures if not properly addressed in design and material selection.

The primary objective of current solder joint reliability research is to develop comprehensive models that accurately predict lifetime under complex loading conditions. This includes understanding the kinetics of intermetallic formation and growth, characterizing creep-fatigue interaction mechanisms, and establishing accelerated testing protocols that correlate with real-world performance. A particular focus lies on quantifying how microstructural evolution affects mechanical properties throughout the service life of electronic assemblies.

Another critical goal is to establish design guidelines that optimize solder joint reliability for specific applications. This involves determining optimal pad geometries, solder volumes, and reflow profiles that minimize stress concentration and enhance resistance to thermomechanical fatigue. For high-reliability applications, research aims to develop specialized solder alloys with enhanced resistance to electromigration, thermal cycling, and mechanical shock.

The ultimate aim is to bridge the gap between theoretical models and practical implementation, enabling manufacturers to confidently predict and extend the operational lifetime of electronic assemblies across diverse applications and environments. This requires integrating materials science, mechanical engineering, and reliability statistics into cohesive frameworks that can guide both design decisions and qualification standards.

The evolution of solder joint technology has been characterized by increasing complexity in both materials and failure mechanisms. Early reliability studies focused primarily on mechanical fatigue, but modern understanding encompasses a multifaceted interaction between thermal cycling, mechanical stress, and microstructural evolution. The formation and growth of intermetallic compounds (IMCs) at the interface between solder and substrate has become recognized as a fundamental aspect of joint reliability, particularly as these compounds can significantly alter mechanical properties over time.

Recent technological trends have further intensified reliability challenges. The continued miniaturization of electronic packages has resulted in higher current densities and thermal gradients across solder joints. Additionally, emerging applications in harsh environments—such as automotive, aerospace, and industrial settings—subject solder connections to extreme temperature fluctuations, vibration, and mechanical shock. These conditions accelerate creep and fatigue processes, leading to premature failures if not properly addressed in design and material selection.

The primary objective of current solder joint reliability research is to develop comprehensive models that accurately predict lifetime under complex loading conditions. This includes understanding the kinetics of intermetallic formation and growth, characterizing creep-fatigue interaction mechanisms, and establishing accelerated testing protocols that correlate with real-world performance. A particular focus lies on quantifying how microstructural evolution affects mechanical properties throughout the service life of electronic assemblies.

Another critical goal is to establish design guidelines that optimize solder joint reliability for specific applications. This involves determining optimal pad geometries, solder volumes, and reflow profiles that minimize stress concentration and enhance resistance to thermomechanical fatigue. For high-reliability applications, research aims to develop specialized solder alloys with enhanced resistance to electromigration, thermal cycling, and mechanical shock.

The ultimate aim is to bridge the gap between theoretical models and practical implementation, enabling manufacturers to confidently predict and extend the operational lifetime of electronic assemblies across diverse applications and environments. This requires integrating materials science, mechanical engineering, and reliability statistics into cohesive frameworks that can guide both design decisions and qualification standards.

Market Demand Analysis for Reliable Solder Joints

The global market for reliable solder joints has experienced significant growth in recent years, driven primarily by the increasing complexity and miniaturization of electronic devices. The electronics manufacturing industry, valued at approximately $2 trillion globally, relies heavily on dependable solder joint technology, with the solder materials market alone reaching $3.5 billion in 2022 and projected to grow at a CAGR of 4.2% through 2028.

Consumer electronics represents the largest demand segment, accounting for nearly 40% of the market for reliable solder joints. This is followed by automotive electronics at 25%, aerospace and defense at 15%, and industrial equipment at 12%. The remaining 8% is distributed across various other applications including medical devices and telecommunications infrastructure.

The transition to lead-free solders, mandated by regulations such as RoHS and WEEE, has significantly altered market dynamics. SAC (Tin-Silver-Copper) alloys currently dominate the lead-free solder market with approximately 65% market share, though challenges related to their reliability under thermal cycling and mechanical stress continue to drive research into alternative compositions.

Automotive and aerospace sectors demonstrate the most stringent reliability requirements, with demand for solder joints capable of withstanding extreme temperature fluctuations (-55°C to 175°C) and operational lifespans exceeding 15 years. This represents a premium segment of the market where performance outweighs cost considerations.

The miniaturization trend in electronics has created substantial demand for solder joints in increasingly compact dimensions. The average pitch size in consumer electronics has decreased from 0.5mm to below 0.3mm over the past decade, placing greater emphasis on understanding intermetallic compound formation and creep-fatigue interactions at these reduced scales.

Geographic distribution of demand shows Asia-Pacific leading with 58% of global consumption, primarily driven by the concentration of electronics manufacturing in China, Taiwan, South Korea, and Japan. North America accounts for 22% of demand, Europe for 15%, and other regions for the remaining 5%.

Industry surveys indicate that manufacturers are willing to pay a premium of 15-30% for solder materials and processes that can demonstrably extend product lifespan by reducing failure rates. This price elasticity is particularly evident in high-reliability applications where the cost of field failures far exceeds component costs.

The market is increasingly demanding predictive modeling capabilities for solder joint reliability, with 78% of major electronics manufacturers investing in simulation software and accelerated testing methodologies to better understand intermetallic evolution and creep-fatigue interactions before product launch.

Consumer electronics represents the largest demand segment, accounting for nearly 40% of the market for reliable solder joints. This is followed by automotive electronics at 25%, aerospace and defense at 15%, and industrial equipment at 12%. The remaining 8% is distributed across various other applications including medical devices and telecommunications infrastructure.

The transition to lead-free solders, mandated by regulations such as RoHS and WEEE, has significantly altered market dynamics. SAC (Tin-Silver-Copper) alloys currently dominate the lead-free solder market with approximately 65% market share, though challenges related to their reliability under thermal cycling and mechanical stress continue to drive research into alternative compositions.

Automotive and aerospace sectors demonstrate the most stringent reliability requirements, with demand for solder joints capable of withstanding extreme temperature fluctuations (-55°C to 175°C) and operational lifespans exceeding 15 years. This represents a premium segment of the market where performance outweighs cost considerations.

The miniaturization trend in electronics has created substantial demand for solder joints in increasingly compact dimensions. The average pitch size in consumer electronics has decreased from 0.5mm to below 0.3mm over the past decade, placing greater emphasis on understanding intermetallic compound formation and creep-fatigue interactions at these reduced scales.

Geographic distribution of demand shows Asia-Pacific leading with 58% of global consumption, primarily driven by the concentration of electronics manufacturing in China, Taiwan, South Korea, and Japan. North America accounts for 22% of demand, Europe for 15%, and other regions for the remaining 5%.

Industry surveys indicate that manufacturers are willing to pay a premium of 15-30% for solder materials and processes that can demonstrably extend product lifespan by reducing failure rates. This price elasticity is particularly evident in high-reliability applications where the cost of field failures far exceeds component costs.

The market is increasingly demanding predictive modeling capabilities for solder joint reliability, with 78% of major electronics manufacturers investing in simulation software and accelerated testing methodologies to better understand intermetallic evolution and creep-fatigue interactions before product launch.

Current Challenges in Intermetallic Compound Formation

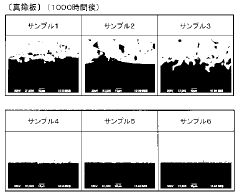

The formation of intermetallic compounds (IMCs) at solder joint interfaces presents significant challenges for electronic reliability. Current research identifies several critical issues that impede our understanding and control of IMC evolution. The primary challenge lies in the complex kinetics of IMC growth, which follows non-linear patterns influenced by multiple factors including temperature cycling, current density, and mechanical stress. These growth mechanisms often deviate from classical diffusion models, making accurate prediction extremely difficult.

Another major challenge is the inherent brittleness of IMCs, particularly Cu6Sn5 and Cu3Sn at copper-tin interfaces, which create mechanical weak points in solder joints. As these compounds grow thicker over time, they significantly reduce joint ductility and increase susceptibility to brittle fracture. This property degradation accelerates under thermal cycling conditions typical in electronic applications, where coefficient of thermal expansion mismatches induce cyclic stresses.

The Kirkendall void formation phenomenon presents a particularly troublesome challenge. These microscopic voids form due to unbalanced diffusion rates between different atomic species, creating porosity that severely compromises mechanical integrity. Recent studies indicate that void formation accelerates under electromigration conditions, creating a complex reliability concern in high-current applications like power electronics and electric vehicles.

Temperature sensitivity further complicates IMC behavior, with growth rates increasing exponentially at elevated temperatures. This creates significant challenges for accelerated life testing methodologies, as the failure mechanisms at accelerated conditions may not accurately represent those occurring during normal operation. The development of accurate acceleration factors remains elusive due to these non-linear relationships.

The interaction between IMC formation and other reliability mechanisms, particularly creep and fatigue, represents perhaps the most significant scientific gap. These mechanisms operate simultaneously in real-world conditions, yet most research examines them in isolation. The synergistic effects between IMC evolution and mechanical degradation mechanisms create complex failure modes that current models struggle to capture accurately.

Miniaturization trends in electronics exacerbate these challenges, as smaller solder joints have higher surface-to-volume ratios, accelerating relative IMC growth rates. In advanced packaging technologies like 3D integration, where joint dimensions approach the microscale, IMCs can constitute a substantial percentage of the total joint volume, fundamentally altering mechanical properties and reliability characteristics.

Another major challenge is the inherent brittleness of IMCs, particularly Cu6Sn5 and Cu3Sn at copper-tin interfaces, which create mechanical weak points in solder joints. As these compounds grow thicker over time, they significantly reduce joint ductility and increase susceptibility to brittle fracture. This property degradation accelerates under thermal cycling conditions typical in electronic applications, where coefficient of thermal expansion mismatches induce cyclic stresses.

The Kirkendall void formation phenomenon presents a particularly troublesome challenge. These microscopic voids form due to unbalanced diffusion rates between different atomic species, creating porosity that severely compromises mechanical integrity. Recent studies indicate that void formation accelerates under electromigration conditions, creating a complex reliability concern in high-current applications like power electronics and electric vehicles.

Temperature sensitivity further complicates IMC behavior, with growth rates increasing exponentially at elevated temperatures. This creates significant challenges for accelerated life testing methodologies, as the failure mechanisms at accelerated conditions may not accurately represent those occurring during normal operation. The development of accurate acceleration factors remains elusive due to these non-linear relationships.

The interaction between IMC formation and other reliability mechanisms, particularly creep and fatigue, represents perhaps the most significant scientific gap. These mechanisms operate simultaneously in real-world conditions, yet most research examines them in isolation. The synergistic effects between IMC evolution and mechanical degradation mechanisms create complex failure modes that current models struggle to capture accurately.

Miniaturization trends in electronics exacerbate these challenges, as smaller solder joints have higher surface-to-volume ratios, accelerating relative IMC growth rates. In advanced packaging technologies like 3D integration, where joint dimensions approach the microscale, IMCs can constitute a substantial percentage of the total joint volume, fundamentally altering mechanical properties and reliability characteristics.

Current Methodologies for Solder Joint Lifetime Prediction

01 Solder joint composition and structure for enhanced reliability

The composition and structure of solder joints significantly impact their reliability and lifetime. Specific alloy compositions can improve mechanical strength and thermal cycling resistance. Advanced solder structures, including reinforced joints and specialized geometries, can distribute stress more effectively and prevent premature failure. These structural improvements help maintain electrical connectivity over extended periods and under various environmental conditions.- Solder joint composition and structure for enhanced reliability: The composition and structure of solder joints significantly impact their reliability and lifetime. Specific alloy compositions can improve mechanical strength and thermal cycling resistance. Advanced solder structures, including reinforced joints and specialized geometries, can distribute stress more effectively and prevent premature failure. These structural improvements help maintain electrical connectivity over extended periods and under various environmental conditions.

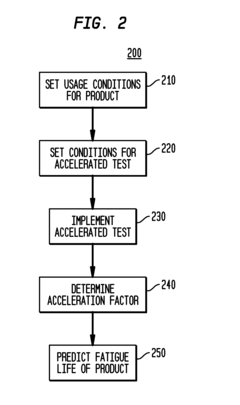

- Testing and prediction methods for solder joint lifetime: Various testing methodologies and predictive models have been developed to assess solder joint reliability. These include accelerated aging tests, thermal cycling, mechanical stress testing, and computational models that simulate real-world conditions. Advanced analytics and machine learning approaches enable more accurate prediction of solder joint failure rates and lifetime expectancy, allowing for better design decisions and reliability planning in electronic assemblies.

- Thermal management techniques for solder joint longevity: Effective thermal management is crucial for extending solder joint lifetime. Techniques include optimized heat dissipation designs, thermal interface materials, and cooling solutions that minimize temperature fluctuations and thermal stress on solder connections. By controlling operating temperatures and reducing thermal cycling severity, these approaches significantly improve joint reliability in high-power and high-density electronic applications.

- Manufacturing process optimization for reliable solder joints: The manufacturing process significantly impacts solder joint reliability. Optimized reflow profiles, controlled cooling rates, proper flux selection, and precise component placement all contribute to forming high-quality joints. Advanced soldering techniques, including vapor phase soldering and selective soldering, can be employed to create more reliable connections. Process monitoring and quality control measures help identify and eliminate factors that could lead to premature joint failure.

- Environmental protection and stress mitigation for solder joints: Protecting solder joints from environmental factors and mechanical stress is essential for long-term reliability. Conformal coatings, encapsulants, and specialized underfill materials shield joints from moisture, contaminants, and oxidation. Mechanical stress relief designs, including compliant leads and flexible interconnects, help absorb vibration and thermal expansion mismatches. These protective measures significantly extend solder joint lifetime in harsh operating environments.

02 Thermal cycling resistance and stress management

Thermal cycling is a primary cause of solder joint failure. Methods to improve resistance to thermal stress include specialized underfill materials, stress-absorbing layers, and thermal management techniques. By controlling the coefficient of thermal expansion mismatch between components and managing heat distribution, the lifetime of solder joints can be significantly extended. These approaches help prevent crack initiation and propagation during temperature fluctuations.Expand Specific Solutions03 Testing and prediction methods for solder joint reliability

Advanced testing methodologies and predictive models help evaluate and forecast solder joint reliability. Accelerated life testing, thermal shock testing, and vibration analysis provide data on potential failure modes. Computational models using finite element analysis can predict stress distribution and lifetime under various conditions. These methods enable manufacturers to identify potential weaknesses and optimize designs before production.Expand Specific Solutions04 Manufacturing processes for reliable solder joints

Manufacturing processes significantly impact solder joint reliability. Controlled reflow profiles, precise flux application, and proper cleaning procedures help prevent defects like voids and cold joints. Advanced soldering techniques such as laser soldering and vapor phase reflow can produce more consistent joints. Process monitoring and quality control systems ensure that solder joints meet reliability standards and reduce variability in production.Expand Specific Solutions05 Environmental protection and coating technologies

Environmental factors like humidity, corrosive gases, and mechanical vibration can degrade solder joints over time. Protective coatings, conformal coatings, and encapsulation materials shield solder joints from these harmful elements. Moisture-resistant formulations and specialized barrier layers prevent oxidation and corrosion. These protective measures significantly extend the functional lifetime of solder joints in harsh operating environments.Expand Specific Solutions

Key Industry Players in Solder Materials and Testing

The solder joint reliability market is currently in a mature growth phase, with increasing demand driven by electronics miniaturization and automotive applications. The global market size is estimated to exceed $1 billion, growing at 4-5% annually due to expanding applications in high-reliability sectors. Technologically, the field shows moderate maturity with ongoing innovation in intermetallic compound formation and lifetime prediction models. Leading companies demonstrate varying technological capabilities: Alpha Assembly Solutions and Nihon Superior focus on specialized solder materials; Texas Instruments and Intel emphasize reliability testing methodologies; while academic institutions like Beijing University of Technology and Beihang University contribute fundamental research on creep-fatigue interactions. Fujitsu, IBM, and Panasonic maintain strong positions through integrated reliability solutions for their electronic products.

Alpha Assembly Solutions, Inc.

Technical Solution: Alpha Assembly Solutions has developed comprehensive solder joint reliability solutions through their materials-first approach to electronic interconnect technology. As a leading solder materials manufacturer, Alpha has created specialized alloy systems designed specifically to control intermetallic compound formation and growth kinetics. Their technology includes proprietary micro-alloying elements that modify the interfacial reaction between solder and substrate materials, resulting in more stable and uniform intermetallic compound layers[9]. Alpha's research has established quantitative relationships between alloy composition, processing parameters, and resulting reliability metrics across various thermal cycling regimes. Their approach includes accelerated testing methodologies that correlate with field performance, allowing for rapid evaluation of new material formulations. Alpha has developed predictive models that incorporate microstructural evolution during thermal aging, particularly focusing on how intermetallic compound morphology changes affect mechanical properties over time. Their lifetime prediction framework integrates materials characterization data with finite element analysis to simulate creep-fatigue interactions under complex loading conditions[10]. Alpha has also pioneered specialized flux chemistries that promote optimal intermetallic compound formation during the initial assembly process, establishing favorable microstructural conditions for long-term reliability.

Strengths: Alpha's solutions benefit from their direct control over solder alloy formulation and manufacturing, allowing for tailored materials solutions to specific reliability challenges. Their extensive materials characterization capabilities provide deep insights into microstructural evolution mechanisms. Weaknesses: Their approach sometimes emphasizes materials solutions over system-level design considerations, potentially overlooking opportunities for reliability enhancement through mechanical design optimization.

International Business Machines Corp.

Technical Solution: IBM has pioneered comprehensive solder joint reliability solutions through their "Physics of Failure" approach to electronic packaging. Their technology focuses on understanding the fundamental mechanisms of intermetallic compound formation and growth kinetics in lead-free solder systems. IBM's methodology combines microstructural characterization with advanced mechanical testing to develop constitutive models that accurately predict creep-fatigue behavior[2]. They've developed proprietary algorithms that incorporate time-dependent and temperature-dependent material properties to model the complex viscoelastic-plastic behavior of solder joints under thermal cycling conditions. IBM's research has identified critical thresholds for intermetallic compound thickness that correlate with reliability degradation, particularly in their server and mainframe systems that require exceptional longevity[4]. Their approach includes multi-scale modeling techniques that bridge atomic-level diffusion processes with macroscopic mechanical behavior, allowing for more accurate lifetime predictions. IBM has also developed specialized non-destructive evaluation techniques to monitor intermetallic evolution in actual field conditions, validating their predictive models with real-world data.

Strengths: IBM's solutions benefit from decades of research in electronic packaging reliability and extensive field data from their server and mainframe systems. Their multi-physics modeling approach captures complex interactions between thermal, mechanical, and microstructural factors. Weaknesses: Their methodologies often require sophisticated computational resources and specialized expertise, making implementation challenging for smaller organizations without similar R&D capabilities.

Critical Research on Creep-Fatigue Interaction Mechanisms

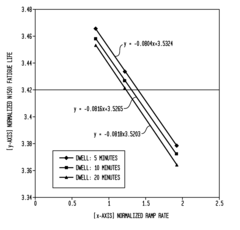

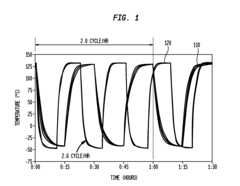

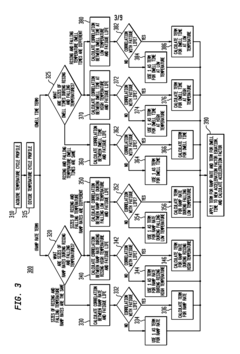

Solder Joint Fatigue Life Prediction Method

PatentInactiveUS20130275096A1

Innovation

- A method using novel acceleration factor equations (Equations 2 and 3) that account for ramp rate, dwell time, and minimum temperature differences between field and laboratory environments to predict solder joint fatigue life, independent of temperature cycle frequency, by determining exponents m1, m2, and m3 from temperature cycle profile data.

Joining structure

PatentInactiveJP2012020331A

Innovation

- Prevention of direct contact between copper material and Sn-Zn based lead-free solder alloy to form intermetallic compounds at the joining interface, improving joining characteristics and reliability.

- Addition of elements with antioxidant effects (such as Mn) to the Sn-Zn based solder alloy to suppress oxidation of the solder surface, resulting in improved durability.

- Prevention of dissimilar metal contact corrosion among the constituent metals of the Sn-Zn based lead-free solder alloy and the joined material to maintain high reliability at the solder joint.

Environmental Impact of Lead-Free Solder Technologies

The transition from traditional lead-based solders to lead-free alternatives represents a significant shift in electronics manufacturing, driven primarily by environmental and health concerns. Lead-free solder technologies have been developed and implemented globally in response to regulatory frameworks such as the European Union's Restriction of Hazardous Substances (RoHS) Directive, which restricts the use of lead in electronic products. This transition has profound environmental implications that extend throughout the entire lifecycle of electronic products.

Lead-free solders, typically based on tin with additions of silver, copper, bismuth, or other elements, offer reduced toxicity compared to traditional tin-lead alloys. The elimination of lead significantly decreases the potential for environmental contamination and associated health risks during manufacturing processes. Workers in production facilities benefit from reduced exposure to lead fumes and particulates, which historically posed serious occupational health hazards in electronics assembly operations.

During the use phase of electronic products, lead-free solders contribute to safer handling and reduced environmental impact in case of damage or improper disposal. However, the environmental benefits must be balanced against certain technical challenges. Lead-free solders generally require higher processing temperatures, resulting in increased energy consumption during manufacturing. This higher energy demand potentially increases the carbon footprint of electronic assembly operations, creating a trade-off between reduced toxicity and increased energy-related environmental impacts.

End-of-life management of electronic products presents another critical environmental consideration. While lead-free solders reduce the leaching of toxic lead into soil and groundwater from landfills, the intermetallic compounds formed in these solders may present their own environmental challenges. The complex metallurgical structures in lead-free solder joints can affect recycling processes and material recovery efficiency. Additionally, some lead-free solder formulations incorporate rare or precious metals like silver, which raises concerns about resource depletion and mining impacts.

The reliability aspects of lead-free solders also have indirect environmental implications. The intermetallic evolution and creep-fatigue behavior of these solders can affect product lifespan, potentially leading to premature failures if not properly managed. Shorter product lifecycles result in increased electronic waste generation, counteracting some of the environmental benefits of lead-free technology. Improving the reliability prediction models for lead-free solder joints is therefore not only a technical necessity but also an environmental imperative.

Life cycle assessment (LCA) studies comparing lead and lead-free soldering technologies reveal complex environmental trade-offs. While lead elimination provides clear toxicity benefits, the overall environmental footprint depends on factors including energy consumption, raw material sourcing, manufacturing processes, and end-of-life management strategies. Ongoing research aims to develop lead-free solder formulations that optimize both reliability and environmental performance, potentially through novel alloy compositions or nanomaterial enhancements that improve mechanical properties while minimizing resource intensity.

Lead-free solders, typically based on tin with additions of silver, copper, bismuth, or other elements, offer reduced toxicity compared to traditional tin-lead alloys. The elimination of lead significantly decreases the potential for environmental contamination and associated health risks during manufacturing processes. Workers in production facilities benefit from reduced exposure to lead fumes and particulates, which historically posed serious occupational health hazards in electronics assembly operations.

During the use phase of electronic products, lead-free solders contribute to safer handling and reduced environmental impact in case of damage or improper disposal. However, the environmental benefits must be balanced against certain technical challenges. Lead-free solders generally require higher processing temperatures, resulting in increased energy consumption during manufacturing. This higher energy demand potentially increases the carbon footprint of electronic assembly operations, creating a trade-off between reduced toxicity and increased energy-related environmental impacts.

End-of-life management of electronic products presents another critical environmental consideration. While lead-free solders reduce the leaching of toxic lead into soil and groundwater from landfills, the intermetallic compounds formed in these solders may present their own environmental challenges. The complex metallurgical structures in lead-free solder joints can affect recycling processes and material recovery efficiency. Additionally, some lead-free solder formulations incorporate rare or precious metals like silver, which raises concerns about resource depletion and mining impacts.

The reliability aspects of lead-free solders also have indirect environmental implications. The intermetallic evolution and creep-fatigue behavior of these solders can affect product lifespan, potentially leading to premature failures if not properly managed. Shorter product lifecycles result in increased electronic waste generation, counteracting some of the environmental benefits of lead-free technology. Improving the reliability prediction models for lead-free solder joints is therefore not only a technical necessity but also an environmental imperative.

Life cycle assessment (LCA) studies comparing lead and lead-free soldering technologies reveal complex environmental trade-offs. While lead elimination provides clear toxicity benefits, the overall environmental footprint depends on factors including energy consumption, raw material sourcing, manufacturing processes, and end-of-life management strategies. Ongoing research aims to develop lead-free solder formulations that optimize both reliability and environmental performance, potentially through novel alloy compositions or nanomaterial enhancements that improve mechanical properties while minimizing resource intensity.

Thermal Cycling Standards and Qualification Procedures

Thermal cycling standards and qualification procedures are essential frameworks for evaluating solder joint reliability in electronic assemblies. The industry has developed several standardized test methods to assess the performance of solder joints under thermal stress conditions that simulate real-world operating environments. These standards provide consistent methodologies for comparing different solder materials, component designs, and assembly processes.

The Joint Electron Device Engineering Council (JEDEC) has established JESD22-A104 as a primary standard for temperature cycling, which defines various test conditions with specific temperature ranges, dwell times, and ramp rates. This standard is widely adopted for qualifying electronic components and assemblies, particularly for consumer electronics and automotive applications where temperature fluctuations are common.

IPC-9701 represents another critical standard specifically focused on performance test methods for surface mount solder attachments. This standard provides guidelines for accelerated thermal cycling tests and offers correlation factors to translate test results into field reliability predictions. The document categorizes different application environments from consumer electronics to military applications, each with corresponding test parameters.

Military and aerospace applications follow more rigorous standards such as MIL-STD-883 Method 1010, which prescribes more extreme temperature ranges (-65°C to +150°C) and higher cycle counts to ensure reliability in harsh operating conditions. These standards are particularly relevant when evaluating intermetallic compound (IMC) evolution in solder joints, as extreme temperature variations accelerate the growth of IMCs and their subsequent impact on mechanical properties.

Automotive electronics qualification typically follows AEC-Q100 standards, which include specific thermal cycling requirements based on different temperature grades. These standards have become increasingly important as modern vehicles incorporate more sophisticated electronics operating in challenging thermal environments, where creep-fatigue interactions in solder joints become critical failure mechanisms.

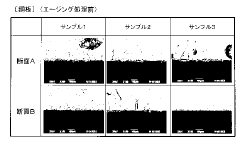

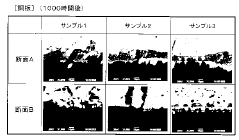

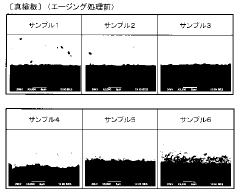

The qualification procedures generally involve sample preparation, pre-conditioning, thermal cycling exposure, and subsequent analysis through various techniques including cross-sectioning, scanning electron microscopy, and electrical continuity testing. Failure analysis typically focuses on crack initiation and propagation patterns, IMC thickness measurements, and microstructural changes that correlate with lifetime prediction models.

Recent developments in qualification procedures have incorporated more sophisticated monitoring techniques, such as in-situ resistance measurements during thermal cycling, which provide real-time data on the degradation of solder joints. This approach enables more accurate lifetime prediction models that account for the complex interactions between creep and fatigue mechanisms in different solder alloy systems.

The Joint Electron Device Engineering Council (JEDEC) has established JESD22-A104 as a primary standard for temperature cycling, which defines various test conditions with specific temperature ranges, dwell times, and ramp rates. This standard is widely adopted for qualifying electronic components and assemblies, particularly for consumer electronics and automotive applications where temperature fluctuations are common.

IPC-9701 represents another critical standard specifically focused on performance test methods for surface mount solder attachments. This standard provides guidelines for accelerated thermal cycling tests and offers correlation factors to translate test results into field reliability predictions. The document categorizes different application environments from consumer electronics to military applications, each with corresponding test parameters.

Military and aerospace applications follow more rigorous standards such as MIL-STD-883 Method 1010, which prescribes more extreme temperature ranges (-65°C to +150°C) and higher cycle counts to ensure reliability in harsh operating conditions. These standards are particularly relevant when evaluating intermetallic compound (IMC) evolution in solder joints, as extreme temperature variations accelerate the growth of IMCs and their subsequent impact on mechanical properties.

Automotive electronics qualification typically follows AEC-Q100 standards, which include specific thermal cycling requirements based on different temperature grades. These standards have become increasingly important as modern vehicles incorporate more sophisticated electronics operating in challenging thermal environments, where creep-fatigue interactions in solder joints become critical failure mechanisms.

The qualification procedures generally involve sample preparation, pre-conditioning, thermal cycling exposure, and subsequent analysis through various techniques including cross-sectioning, scanning electron microscopy, and electrical continuity testing. Failure analysis typically focuses on crack initiation and propagation patterns, IMC thickness measurements, and microstructural changes that correlate with lifetime prediction models.

Recent developments in qualification procedures have incorporated more sophisticated monitoring techniques, such as in-situ resistance measurements during thermal cycling, which provide real-time data on the degradation of solder joints. This approach enables more accurate lifetime prediction models that account for the complex interactions between creep and fatigue mechanisms in different solder alloy systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!