Solder Joint Reliability: Underfill Selection, Stress Transfer And Moisture Robustness

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solder Joint Reliability Background and Objectives

Solder joint reliability has been a critical concern in the electronics packaging industry since the introduction of surface mount technology in the 1980s. The evolution of this technology has been driven by the continuous miniaturization of electronic components, increasing functionality requirements, and the transition to lead-free solders due to environmental regulations such as RoHS and WEEE directives. These factors have significantly altered the mechanical behavior and reliability characteristics of solder interconnections in electronic assemblies.

The historical progression of solder joint reliability research began with simple thermal cycling tests and has evolved to encompass sophisticated multi-physics modeling approaches. Early studies focused primarily on fatigue life prediction using empirical models like Coffin-Manson and Engelmaier. As computational capabilities advanced, finite element analysis became instrumental in understanding stress distribution and failure mechanisms in complex geometries.

Underfill technology emerged as a critical solution to enhance solder joint reliability, particularly in flip-chip applications. Initially developed in the 1990s, underfill materials have undergone significant evolution from simple epoxy formulations to specialized compounds with tailored thermal, mechanical, and moisture resistance properties. The selection of appropriate underfill materials has become increasingly complex as package sizes decrease and operating conditions become more demanding.

Stress transfer mechanisms between different materials in electronic packages represent a fundamental aspect of reliability engineering. The coefficient of thermal expansion (CTE) mismatch between silicon dies, substrate materials, and solder alloys creates significant thermomechanical stresses during temperature cycling. Understanding these stress transfer pathways is essential for developing robust design solutions and predicting service life accurately.

Moisture robustness has gained prominence as electronic devices are exposed to increasingly harsh environmental conditions. Moisture ingress can lead to various failure mechanisms, including interfacial delamination, popcorn cracking during reflow, and electrochemical migration. The interaction between moisture and underfill materials adds another layer of complexity to reliability assessment.

The primary objectives of current research in solder joint reliability include: developing predictive models that accurately capture the complex interplay between underfill properties and solder joint performance; establishing standardized test methodologies that correlate with field conditions; optimizing underfill selection criteria for emerging package technologies such as 2.5D and 3D integration; and enhancing moisture resistance without compromising other reliability aspects.

Additionally, there is growing interest in understanding reliability implications for new solder alloy compositions, particularly those developed to address the limitations of first-generation lead-free solders. The industry aims to establish comprehensive design guidelines that incorporate underfill selection, stress management strategies, and moisture protection measures to ensure robust electronic assemblies across diverse application environments.

The historical progression of solder joint reliability research began with simple thermal cycling tests and has evolved to encompass sophisticated multi-physics modeling approaches. Early studies focused primarily on fatigue life prediction using empirical models like Coffin-Manson and Engelmaier. As computational capabilities advanced, finite element analysis became instrumental in understanding stress distribution and failure mechanisms in complex geometries.

Underfill technology emerged as a critical solution to enhance solder joint reliability, particularly in flip-chip applications. Initially developed in the 1990s, underfill materials have undergone significant evolution from simple epoxy formulations to specialized compounds with tailored thermal, mechanical, and moisture resistance properties. The selection of appropriate underfill materials has become increasingly complex as package sizes decrease and operating conditions become more demanding.

Stress transfer mechanisms between different materials in electronic packages represent a fundamental aspect of reliability engineering. The coefficient of thermal expansion (CTE) mismatch between silicon dies, substrate materials, and solder alloys creates significant thermomechanical stresses during temperature cycling. Understanding these stress transfer pathways is essential for developing robust design solutions and predicting service life accurately.

Moisture robustness has gained prominence as electronic devices are exposed to increasingly harsh environmental conditions. Moisture ingress can lead to various failure mechanisms, including interfacial delamination, popcorn cracking during reflow, and electrochemical migration. The interaction between moisture and underfill materials adds another layer of complexity to reliability assessment.

The primary objectives of current research in solder joint reliability include: developing predictive models that accurately capture the complex interplay between underfill properties and solder joint performance; establishing standardized test methodologies that correlate with field conditions; optimizing underfill selection criteria for emerging package technologies such as 2.5D and 3D integration; and enhancing moisture resistance without compromising other reliability aspects.

Additionally, there is growing interest in understanding reliability implications for new solder alloy compositions, particularly those developed to address the limitations of first-generation lead-free solders. The industry aims to establish comprehensive design guidelines that incorporate underfill selection, stress management strategies, and moisture protection measures to ensure robust electronic assemblies across diverse application environments.

Market Demand Analysis for Reliable Solder Joint Solutions

The global market for reliable solder joint solutions has been experiencing significant growth, driven primarily by the increasing complexity and miniaturization of electronic devices. The current market size for advanced packaging solutions, including underfill materials and related technologies, exceeds $3 billion annually with a compound annual growth rate of 7.2% projected through 2028.

Consumer electronics represents the largest segment demanding reliable solder joint solutions, accounting for approximately 40% of the market share. This is followed by automotive electronics at 25%, aerospace and defense at 15%, and industrial electronics at 12%. The remaining market share is distributed among medical devices and other specialized applications.

The demand for underfill materials specifically has seen remarkable growth due to their critical role in enhancing solder joint reliability. This segment is expected to reach $1.2 billion by 2025, reflecting the industry's recognition of underfill's importance in stress transfer management and moisture protection.

Market research indicates that manufacturers are increasingly prioritizing reliability over cost considerations, particularly in high-value applications where failure is not an option. A survey of electronics manufacturers revealed that 78% consider solder joint reliability as "extremely important" in their product development process, with 65% willing to invest in premium solutions that offer superior performance.

The automotive sector demonstrates the fastest-growing demand for reliable solder joint solutions, driven by the rapid electrification of vehicles and the integration of advanced driver assistance systems. These applications require exceptional thermal cycling resistance and moisture robustness due to the harsh operating environments vehicles encounter.

Regional analysis shows Asia-Pacific dominating the market with 52% share, followed by North America (24%) and Europe (18%). China and Taiwan lead manufacturing capacity, while North America and Europe focus on research and development of next-generation solutions.

Customer requirements are evolving toward underfill materials that offer faster curing times, improved reworkability, and enhanced thermal conductivity. Additionally, there is growing demand for environmentally friendly formulations that comply with global regulations such as RoHS and REACH.

The market is also witnessing increased interest in specialized underfill solutions for specific applications, such as edge computing devices, 5G infrastructure, and Internet of Things (IoT) endpoints, where reliability under varying environmental conditions is paramount.

Consumer electronics represents the largest segment demanding reliable solder joint solutions, accounting for approximately 40% of the market share. This is followed by automotive electronics at 25%, aerospace and defense at 15%, and industrial electronics at 12%. The remaining market share is distributed among medical devices and other specialized applications.

The demand for underfill materials specifically has seen remarkable growth due to their critical role in enhancing solder joint reliability. This segment is expected to reach $1.2 billion by 2025, reflecting the industry's recognition of underfill's importance in stress transfer management and moisture protection.

Market research indicates that manufacturers are increasingly prioritizing reliability over cost considerations, particularly in high-value applications where failure is not an option. A survey of electronics manufacturers revealed that 78% consider solder joint reliability as "extremely important" in their product development process, with 65% willing to invest in premium solutions that offer superior performance.

The automotive sector demonstrates the fastest-growing demand for reliable solder joint solutions, driven by the rapid electrification of vehicles and the integration of advanced driver assistance systems. These applications require exceptional thermal cycling resistance and moisture robustness due to the harsh operating environments vehicles encounter.

Regional analysis shows Asia-Pacific dominating the market with 52% share, followed by North America (24%) and Europe (18%). China and Taiwan lead manufacturing capacity, while North America and Europe focus on research and development of next-generation solutions.

Customer requirements are evolving toward underfill materials that offer faster curing times, improved reworkability, and enhanced thermal conductivity. Additionally, there is growing demand for environmentally friendly formulations that comply with global regulations such as RoHS and REACH.

The market is also witnessing increased interest in specialized underfill solutions for specific applications, such as edge computing devices, 5G infrastructure, and Internet of Things (IoT) endpoints, where reliability under varying environmental conditions is paramount.

Current Underfill Technologies and Challenges

Underfill technology has evolved significantly over the past two decades, becoming a critical component in electronic packaging for enhancing solder joint reliability. Currently, capillary underfill remains the most widely adopted technology in the industry, where liquid encapsulant is dispensed along one or more edges of a component after solder reflow, relying on capillary action to fill the gap between the component and substrate. This method offers excellent reliability but faces challenges in processing time and flow rate control, particularly as device geometries continue to shrink.

No-flow underfill technology represents an alternative approach where the underfill material is applied before component placement and solder reflow. While this method streamlines the manufacturing process by combining reflow and underfill curing steps, it introduces complexities in material formulation as the underfill must remain stable during reflow temperatures without impeding solder joint formation. Current no-flow materials often struggle with achieving optimal filler content without compromising flow characteristics.

Wafer-level underfill has emerged as an advanced solution for high-volume manufacturing, where underfill is applied at the wafer level before die singulation. This approach offers significant throughput advantages but presents challenges in material compatibility with wafer processing and requires specialized equipment integration into the semiconductor manufacturing line.

The chemical composition of modern underfills has become increasingly sophisticated, with epoxy-based systems dominating the market due to their excellent adhesion properties and thermal stability. These systems typically incorporate silica fillers (ranging from 60-70% by weight) to control coefficient of thermal expansion (CTE) and enhance thermal conductivity. However, achieving the optimal balance between filler content, viscosity, and flow characteristics remains a significant challenge.

Moisture sensitivity presents a critical challenge for current underfill technologies. As electronic devices become more compact and are deployed in increasingly harsh environments, underfill materials must maintain their mechanical and electrical properties under varying humidity conditions. Current materials often exhibit hygroscopic tendencies, leading to potential delamination, adhesion loss, or changes in mechanical properties when exposed to moisture.

Stress transfer mechanisms between underfill, solder joints, and surrounding components remain incompletely understood, particularly in complex multi-material systems. Current analytical models struggle to accurately predict stress distributions across temperature cycles, especially at material interfaces where stress concentration often leads to failure initiation.

Reworkability continues to be a significant limitation for many current underfill technologies. As electronic assemblies increase in value and complexity, the ability to remove and replace components without damaging the underlying substrate becomes increasingly important. Traditional high-performance underfills typically form strong chemical bonds that make rework processes difficult or impossible without causing collateral damage.

No-flow underfill technology represents an alternative approach where the underfill material is applied before component placement and solder reflow. While this method streamlines the manufacturing process by combining reflow and underfill curing steps, it introduces complexities in material formulation as the underfill must remain stable during reflow temperatures without impeding solder joint formation. Current no-flow materials often struggle with achieving optimal filler content without compromising flow characteristics.

Wafer-level underfill has emerged as an advanced solution for high-volume manufacturing, where underfill is applied at the wafer level before die singulation. This approach offers significant throughput advantages but presents challenges in material compatibility with wafer processing and requires specialized equipment integration into the semiconductor manufacturing line.

The chemical composition of modern underfills has become increasingly sophisticated, with epoxy-based systems dominating the market due to their excellent adhesion properties and thermal stability. These systems typically incorporate silica fillers (ranging from 60-70% by weight) to control coefficient of thermal expansion (CTE) and enhance thermal conductivity. However, achieving the optimal balance between filler content, viscosity, and flow characteristics remains a significant challenge.

Moisture sensitivity presents a critical challenge for current underfill technologies. As electronic devices become more compact and are deployed in increasingly harsh environments, underfill materials must maintain their mechanical and electrical properties under varying humidity conditions. Current materials often exhibit hygroscopic tendencies, leading to potential delamination, adhesion loss, or changes in mechanical properties when exposed to moisture.

Stress transfer mechanisms between underfill, solder joints, and surrounding components remain incompletely understood, particularly in complex multi-material systems. Current analytical models struggle to accurately predict stress distributions across temperature cycles, especially at material interfaces where stress concentration often leads to failure initiation.

Reworkability continues to be a significant limitation for many current underfill technologies. As electronic assemblies increase in value and complexity, the ability to remove and replace components without damaging the underlying substrate becomes increasingly important. Traditional high-performance underfills typically form strong chemical bonds that make rework processes difficult or impossible without causing collateral damage.

Current Stress Transfer Mitigation Approaches

01 Solder composition and material selection

The reliability of solder joints can be significantly improved through careful selection of solder materials and compositions. Various alloys and additives can enhance mechanical strength, thermal cycling resistance, and overall durability of the joints. Specific elements can be incorporated to reduce brittleness, improve ductility, and prevent crack propagation. Advanced composite solders with reinforcing particles or specialized metallurgical structures provide superior performance in demanding applications.- Solder composition and material selection: The reliability of solder joints can be significantly improved through careful selection of solder materials and compositions. Various alloys and additives can enhance mechanical strength, thermal cycling resistance, and overall durability of the joints. Specific elements can be incorporated to reduce brittleness and improve ductility, while certain composite materials can provide better resistance to thermal fatigue and mechanical stress.

- Testing and reliability assessment methods: Advanced testing methodologies are crucial for evaluating solder joint reliability. These include thermal cycling tests, mechanical stress tests, and accelerated aging procedures that can predict long-term performance. Computational models and simulation techniques help in analyzing failure mechanisms and optimizing joint design. Real-time monitoring systems can detect early signs of joint degradation, allowing for preventive maintenance.

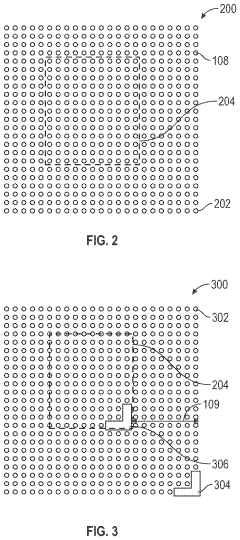

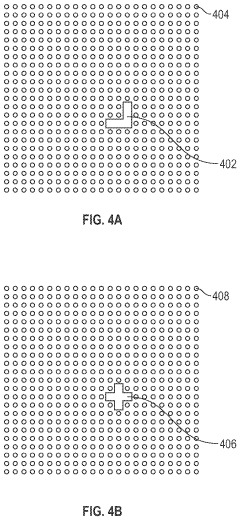

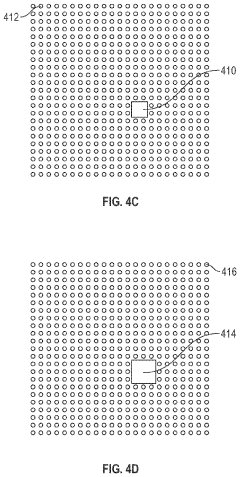

- Structural design improvements: The physical structure and geometry of solder joints significantly impact their reliability. Innovative designs that distribute stress more evenly can prevent premature failures. Features such as reinforced corners, optimized pad designs, and specialized joint shapes can enhance mechanical strength and thermal performance. Multi-layer structures and strategic placement of joints can also improve overall system reliability.

- Manufacturing process optimization: The manufacturing process significantly affects solder joint reliability. Precise control of temperature profiles during reflow, proper flux selection, and controlled cooling rates can prevent defects such as voids and cold joints. Advanced soldering techniques, including laser soldering and selective soldering, can improve joint quality. Cleanliness of surfaces and proper handling procedures also contribute to more reliable connections.

- Environmental protection and coating technologies: Protective coatings and encapsulation methods can shield solder joints from environmental factors that accelerate degradation. Conformal coatings protect against moisture, dust, and chemical contaminants, while specialized underfills provide mechanical support and thermal stress relief. These protective measures are particularly important in harsh operating environments with temperature extremes, high humidity, or corrosive atmospheres.

02 Testing and reliability assessment methods

Various testing methodologies have been developed to evaluate and predict solder joint reliability. These include thermal cycling tests, mechanical stress tests, and accelerated aging procedures that simulate real-world conditions. Advanced analytical techniques such as finite element analysis and computational modeling help identify potential failure modes before they occur. Non-destructive inspection methods allow for quality control and reliability assessment without damaging the connections.Expand Specific Solutions03 Structural design improvements

The physical design and geometry of solder joints significantly impact their reliability. Optimized pad designs, specialized joint shapes, and strategic reinforcement structures can distribute stress more effectively and prevent failure. Techniques such as corner rounding, standoff height optimization, and thermal stress relief features enhance durability under thermal cycling and mechanical stress. Novel interconnect architectures provide improved reliability for specific application environments.Expand Specific Solutions04 Manufacturing process optimization

Refined manufacturing processes significantly enhance solder joint reliability. Controlled heating profiles, precise flux application, and optimized reflow parameters prevent defects such as voids, cold joints, and insufficient wetting. Advanced soldering techniques including vapor phase soldering, selective soldering, and specialized preheating methods improve joint formation. Process monitoring systems with real-time feedback mechanisms ensure consistent quality and reliability across production runs.Expand Specific Solutions05 Environmental protection and coating technologies

Protective coatings and encapsulation methods significantly extend solder joint reliability by shielding connections from environmental factors. Conformal coatings, underfill materials, and specialized encapsulants prevent moisture ingress, chemical contamination, and oxidation. These protective layers also provide mechanical reinforcement and thermal stress mitigation. Advanced coating formulations offer selective protection while maintaining reworkability and allowing for thermal dissipation where needed.Expand Specific Solutions

Key Industry Players in Underfill Materials and Solutions

The solder joint reliability market is currently in a growth phase, with increasing demand driven by miniaturization trends in electronics and automotive applications. The global market size is expanding steadily as electronic devices become more complex and require higher reliability standards. From a technical maturity perspective, the field shows varied development levels across different solutions. Industry leaders like Intel, Texas Instruments, and Taiwan Semiconductor Manufacturing Co. have established advanced underfill technologies addressing stress transfer challenges, while companies such as Infineon Technologies and Senju Metal Industry focus on moisture robustness innovations. IBM and Huawei are advancing research in stress modeling and simulation. The competitive landscape features both established semiconductor giants and specialized materials companies like DUKSAN HI METAL and Resonac Corp., creating a dynamic environment where collaboration between device manufacturers and materials specialists drives innovation.

Intel Corp.

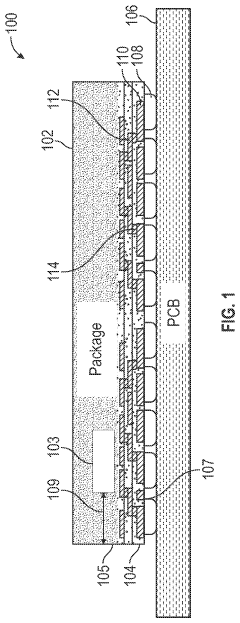

Technical Solution: Intel has developed a comprehensive approach to solder joint reliability through their Advanced Packaging Technology. Their solution incorporates capillary underfill materials with optimized viscosity and filler content specifically designed for flip-chip applications. The company employs non-conductive adhesives with controlled coefficient of thermal expansion (CTE) to minimize stress on solder joints during thermal cycling. Intel's research has demonstrated that their proprietary underfill formulations can withstand up to 1000 thermal cycles (-40°C to 125°C) without significant degradation in electrical performance. Their technology also incorporates moisture-resistant polymers that maintain mechanical properties even after extended exposure to 85°C/85% relative humidity conditions. Intel's approach includes precise dispensing techniques that ensure complete void-free underfill coverage, critical for preventing moisture ingress and ensuring uniform stress distribution.

Strengths: Superior thermal cycling reliability with proven performance in high-performance computing applications; advanced dispensing technology enabling void-free underfill coverage. Weaknesses: Higher implementation costs compared to standard solutions; requires specialized equipment for optimal application; longer processing time due to precise dispensing requirements.

Interuniversitair Micro-Electronica Centrum VZW

Technical Solution: IMEC has pioneered advanced research in solder joint reliability through their innovative "stress-decoupling" underfill technology. Their approach utilizes nano-composite materials incorporating both rigid and elastomeric phases to create underfills with tailored mechanical properties. IMEC's research has demonstrated that their underfill formulations can reduce stress on solder joints by up to 45% during thermal cycling between -40°C and 150°C. A distinguishing feature of IMEC's technology is their "interface-engineered" underfill system, which employs specialized coupling agents to enhance adhesion at critical interfaces while maintaining appropriate flexibility. Their studies have shown that this approach can extend solder joint lifetime by 3-4x compared to conventional underfills. For moisture robustness, IMEC has developed multi-layer barrier systems that combine hydrophobic base materials with nanoparticle fillers that effectively block moisture pathways. Their testing has demonstrated less than 0.15% weight gain after 1000 hours of exposure to 85°C/85% relative humidity conditions, significantly outperforming industry standard materials.

Strengths: Cutting-edge materials science approach with superior stress management; excellent moisture barrier properties; highly customizable for specific application requirements. Weaknesses: Currently at research/pre-commercial scale; potentially higher costs for specialized nano-materials; more complex qualification process due to novel material systems.

Critical Patents in Moisture-Resistant Underfill Technology

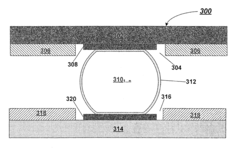

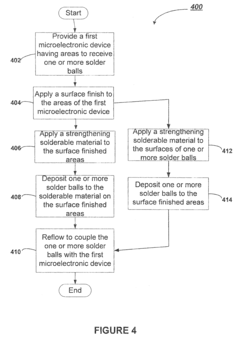

Solder joint reliability in microelectronic packaging

PatentActiveUS8436470B2

Innovation

- Local strengthening of solder joints by applying a solder material containing copper (Cu) or nickel (Ni) at the interface between microelectronic devices and solder balls, reducing the thickness of defect-rich layers and intermetallic compounds that weaken the joints, while allowing the use of traditional bulk solder alloys.

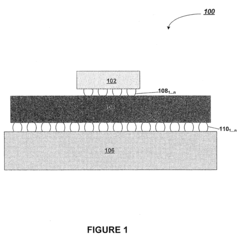

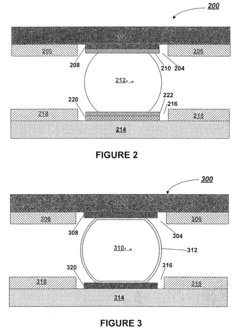

Solder joint design for improved package reliability

PatentPendingUS20240063141A1

Innovation

- Incorporating additional solder joints of varying shapes and sizes at strategic locations on the semiconductor package, which act as mechanical supports and increase the interfacial area with bonding pads, thereby enhancing mechanical strength and reliability.

Environmental Impact of Underfill Materials

The environmental impact of underfill materials has become increasingly significant as electronic manufacturing faces greater scrutiny regarding sustainability and ecological footprint. Traditional underfill formulations often contain epoxy resins with various additives including silica fillers, curing agents, and flame retardants that pose environmental concerns throughout their lifecycle. These materials typically contain halogenated compounds and other potentially hazardous substances that can leach into soil and water systems when improperly disposed of electronic waste.

Manufacturing processes for underfill materials consume substantial energy and generate emissions that contribute to air pollution and greenhouse gas accumulation. The production of silica fillers, a common component in underfills, requires high-temperature processing that is particularly energy-intensive. Additionally, the solvents used in underfill formulations often include volatile organic compounds (VOCs) that contribute to atmospheric pollution and potential health hazards for manufacturing workers.

End-of-life considerations present another critical environmental challenge. Most current underfill materials are thermoset polymers that cannot be easily recycled or separated from other electronic components during disposal. This characteristic significantly complicates electronic waste management and contributes to the growing global e-waste crisis, as these materials persist in landfills for extended periods.

Recent industry developments have focused on creating more environmentally friendly alternatives. Bio-based epoxy resins derived from renewable resources such as vegetable oils represent a promising direction, potentially reducing dependency on petroleum-based materials. Some manufacturers have also developed halogen-free formulations that eliminate the most environmentally persistent toxic compounds while maintaining necessary flame retardancy properties.

Water-soluble underfill materials represent another innovative approach, facilitating easier component separation during recycling processes. These materials can be removed with water-based solutions rather than harsh chemical solvents, reducing both environmental impact and worker exposure to hazardous substances. Additionally, reworkable underfills that can be removed and replaced without damaging components extend product lifecycles and reduce waste generation.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have significantly influenced underfill material formulations, pushing manufacturers toward less toxic alternatives. Similar regulations in other regions have created a global trend toward greener underfill solutions that balance performance requirements with environmental responsibility.

Manufacturing processes for underfill materials consume substantial energy and generate emissions that contribute to air pollution and greenhouse gas accumulation. The production of silica fillers, a common component in underfills, requires high-temperature processing that is particularly energy-intensive. Additionally, the solvents used in underfill formulations often include volatile organic compounds (VOCs) that contribute to atmospheric pollution and potential health hazards for manufacturing workers.

End-of-life considerations present another critical environmental challenge. Most current underfill materials are thermoset polymers that cannot be easily recycled or separated from other electronic components during disposal. This characteristic significantly complicates electronic waste management and contributes to the growing global e-waste crisis, as these materials persist in landfills for extended periods.

Recent industry developments have focused on creating more environmentally friendly alternatives. Bio-based epoxy resins derived from renewable resources such as vegetable oils represent a promising direction, potentially reducing dependency on petroleum-based materials. Some manufacturers have also developed halogen-free formulations that eliminate the most environmentally persistent toxic compounds while maintaining necessary flame retardancy properties.

Water-soluble underfill materials represent another innovative approach, facilitating easier component separation during recycling processes. These materials can be removed with water-based solutions rather than harsh chemical solvents, reducing both environmental impact and worker exposure to hazardous substances. Additionally, reworkable underfills that can be removed and replaced without damaging components extend product lifecycles and reduce waste generation.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have significantly influenced underfill material formulations, pushing manufacturers toward less toxic alternatives. Similar regulations in other regions have created a global trend toward greener underfill solutions that balance performance requirements with environmental responsibility.

Thermal Cycling Performance Assessment Methods

Thermal cycling represents one of the most critical reliability tests for solder joint assessment in electronic packaging. The methodology for evaluating thermal cycling performance has evolved significantly over the past decades, incorporating both experimental approaches and computational modeling techniques. Standard thermal cycling tests typically subject electronic assemblies to temperature extremes ranging from -40°C to 125°C, with controlled ramp rates and dwell times at temperature extremes.

The acceleration factor concept plays a fundamental role in thermal cycling assessment, allowing engineers to correlate test results with real-world conditions. This relationship is commonly expressed through modified Coffin-Manson equations, which incorporate temperature range, mean temperature, dwell time, and frequency parameters. Recent advancements have refined these models to account for non-linear material behaviors under varying thermal conditions.

In-situ monitoring techniques have revolutionized thermal cycling assessment by enabling real-time observation of failure progression. Resistance monitoring remains the industry standard, where a small current passes through daisy-chained solder joints while continuously measuring resistance changes. A typical failure criterion defines failure as a 20% increase in resistance sustained for multiple consecutive readings. Advanced techniques now include acoustic emission detection and digital image correlation for strain field mapping during cycling.

Cross-sectional analysis serves as a complementary method for post-test evaluation, revealing microstructural changes and crack propagation patterns within solder joints. Modern approaches combine focused ion beam milling with scanning electron microscopy to create three-dimensional reconstructions of failure interfaces. These techniques have proven particularly valuable for understanding the interaction between underfill materials and solder joints during thermal excursions.

Finite element analysis (FEA) has become an indispensable tool for predicting thermal cycling performance before physical testing. Contemporary models incorporate viscoelastic and viscoplastic material properties, allowing for accurate simulation of creep behavior in solder alloys. The integration of moisture effects into these models represents a significant advancement, as hygroscopic expansion of underfill materials can substantially alter stress distributions within the package.

Weibull statistical analysis provides the framework for interpreting thermal cycling test data, characterizing both the characteristic lifetime (η) and shape parameter (β) of the failure distribution. Two-parameter and three-parameter Weibull models offer different approaches to reliability prediction, with the latter incorporating a failure-free period that better represents certain package configurations with underfill protection.

The acceleration factor concept plays a fundamental role in thermal cycling assessment, allowing engineers to correlate test results with real-world conditions. This relationship is commonly expressed through modified Coffin-Manson equations, which incorporate temperature range, mean temperature, dwell time, and frequency parameters. Recent advancements have refined these models to account for non-linear material behaviors under varying thermal conditions.

In-situ monitoring techniques have revolutionized thermal cycling assessment by enabling real-time observation of failure progression. Resistance monitoring remains the industry standard, where a small current passes through daisy-chained solder joints while continuously measuring resistance changes. A typical failure criterion defines failure as a 20% increase in resistance sustained for multiple consecutive readings. Advanced techniques now include acoustic emission detection and digital image correlation for strain field mapping during cycling.

Cross-sectional analysis serves as a complementary method for post-test evaluation, revealing microstructural changes and crack propagation patterns within solder joints. Modern approaches combine focused ion beam milling with scanning electron microscopy to create three-dimensional reconstructions of failure interfaces. These techniques have proven particularly valuable for understanding the interaction between underfill materials and solder joints during thermal excursions.

Finite element analysis (FEA) has become an indispensable tool for predicting thermal cycling performance before physical testing. Contemporary models incorporate viscoelastic and viscoplastic material properties, allowing for accurate simulation of creep behavior in solder alloys. The integration of moisture effects into these models represents a significant advancement, as hygroscopic expansion of underfill materials can substantially alter stress distributions within the package.

Weibull statistical analysis provides the framework for interpreting thermal cycling test data, characterizing both the characteristic lifetime (η) and shape parameter (β) of the failure distribution. Two-parameter and three-parameter Weibull models offer different approaches to reliability prediction, with the latter incorporating a failure-free period that better represents certain package configurations with underfill protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!