Solder Joint Reliability: Harsh Environment THB/HAST Exposure, Corrosion Paths And Protection

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solder Joint Reliability Background and Objectives

Solder joint reliability has emerged as a critical concern in the electronics industry since the 1970s, with significant advancements in understanding and improvement methodologies developing over subsequent decades. The evolution of this field has been primarily driven by the miniaturization of electronic components, increasing functional density, and the transition to lead-free solders following environmental regulations such as the European Union's Restriction of Hazardous Substances (RoHS) directive implemented in 2006.

The technological trajectory has shifted from traditional tin-lead solders to various lead-free alternatives, predominantly tin-silver-copper (SAC) alloys. This transition has introduced new challenges in reliability, particularly when electronic assemblies are exposed to harsh environmental conditions. Temperature-Humidity-Bias (THB) and Highly Accelerated Stress Test (HAST) have become standard methodologies for evaluating solder joint performance under accelerated environmental stress conditions.

Recent industry trends indicate growing concerns regarding the long-term reliability of electronic assemblies in increasingly demanding applications such as automotive electronics, aerospace systems, and industrial equipment operating in hostile environments. Statistical data shows that approximately 30% of electronic failures in field applications can be attributed to solder joint degradation, with corrosion accounting for a significant portion of these failures.

The primary objective of this research is to comprehensively investigate solder joint reliability mechanisms under harsh environmental conditions, specifically focusing on THB and HAST exposure scenarios. The study aims to identify and characterize the predominant corrosion pathways that lead to solder joint degradation and subsequent failure in high-humidity, high-temperature, and electrically biased conditions.

Furthermore, this research seeks to evaluate existing protection methodologies and develop innovative approaches to enhance solder joint resistance to environmental degradation. This includes assessment of conformal coatings, encapsulation materials, and novel solder alloy compositions with inherently superior corrosion resistance properties.

The expected outcomes include establishing correlations between accelerated test results and real-world performance, developing predictive models for solder joint lifetime under varying environmental conditions, and formulating design guidelines for enhancing solder joint reliability in harsh environments. These findings will contribute to the development of more robust electronic assemblies with extended operational lifetimes in challenging applications.

This research addresses the growing industry need for reliable electronics in emerging markets such as electric vehicles, renewable energy systems, and IoT devices deployed in diverse environmental conditions, where traditional reliability approaches may prove inadequate.

The technological trajectory has shifted from traditional tin-lead solders to various lead-free alternatives, predominantly tin-silver-copper (SAC) alloys. This transition has introduced new challenges in reliability, particularly when electronic assemblies are exposed to harsh environmental conditions. Temperature-Humidity-Bias (THB) and Highly Accelerated Stress Test (HAST) have become standard methodologies for evaluating solder joint performance under accelerated environmental stress conditions.

Recent industry trends indicate growing concerns regarding the long-term reliability of electronic assemblies in increasingly demanding applications such as automotive electronics, aerospace systems, and industrial equipment operating in hostile environments. Statistical data shows that approximately 30% of electronic failures in field applications can be attributed to solder joint degradation, with corrosion accounting for a significant portion of these failures.

The primary objective of this research is to comprehensively investigate solder joint reliability mechanisms under harsh environmental conditions, specifically focusing on THB and HAST exposure scenarios. The study aims to identify and characterize the predominant corrosion pathways that lead to solder joint degradation and subsequent failure in high-humidity, high-temperature, and electrically biased conditions.

Furthermore, this research seeks to evaluate existing protection methodologies and develop innovative approaches to enhance solder joint resistance to environmental degradation. This includes assessment of conformal coatings, encapsulation materials, and novel solder alloy compositions with inherently superior corrosion resistance properties.

The expected outcomes include establishing correlations between accelerated test results and real-world performance, developing predictive models for solder joint lifetime under varying environmental conditions, and formulating design guidelines for enhancing solder joint reliability in harsh environments. These findings will contribute to the development of more robust electronic assemblies with extended operational lifetimes in challenging applications.

This research addresses the growing industry need for reliable electronics in emerging markets such as electric vehicles, renewable energy systems, and IoT devices deployed in diverse environmental conditions, where traditional reliability approaches may prove inadequate.

Market Demand for Harsh Environment Electronics

The demand for electronics capable of operating in harsh environments has been steadily increasing across multiple industries. Particularly, the reliability of solder joints under Temperature Humidity Bias (THB) and Highly Accelerated Stress Test (HAST) conditions has become a critical concern for manufacturers and end-users alike. These harsh environment applications represent a significant and growing market segment within the broader electronics industry.

The automotive electronics market stands as one of the primary drivers for harsh environment-resistant components, with projections indicating growth from $300 billion in 2022 to over $430 billion by 2028. Modern vehicles contain upwards of 100 electronic control units, all requiring reliable solder joints that can withstand temperature fluctuations, vibration, and humidity exposure throughout the vehicle's operational lifetime.

Aerospace and defense sectors present another substantial market for harsh environment electronics, valued at approximately $215 billion globally. These applications demand components that can function reliably in extreme conditions including high altitude, rapid temperature changes, and prolonged exposure to corrosive environments. The failure of solder joints in these applications can lead to catastrophic consequences, making reliability a non-negotiable requirement.

Industrial automation and control systems represent a third major market segment, currently valued at $180 billion with consistent annual growth rates of 6-8%. As manufacturing facilities increasingly deploy electronics in challenging environments with high humidity, chemical exposure, and temperature variations, the demand for corrosion-resistant solder joints has intensified.

The telecommunications infrastructure market, particularly with the ongoing 5G deployment, requires electronics that can withstand outdoor installation conditions. This market segment, valued at $250 billion, increasingly specifies components with enhanced environmental protection as base stations and network equipment face direct exposure to environmental stressors.

Consumer electronics manufacturers are also recognizing the value proposition of harsh environment protection, especially for wearable devices and outdoor-use products. This trend has expanded the addressable market for corrosion-resistant technologies beyond traditional industrial applications.

Market research indicates that customers are willing to pay a premium of 15-25% for components with proven reliability under harsh conditions, creating significant value opportunities for companies that can develop effective protection methods against THB/HAST exposure. The total addressable market for specialized protective coatings and advanced solder materials is estimated to exceed $8 billion annually, with double-digit growth rates anticipated over the next five years.

The automotive electronics market stands as one of the primary drivers for harsh environment-resistant components, with projections indicating growth from $300 billion in 2022 to over $430 billion by 2028. Modern vehicles contain upwards of 100 electronic control units, all requiring reliable solder joints that can withstand temperature fluctuations, vibration, and humidity exposure throughout the vehicle's operational lifetime.

Aerospace and defense sectors present another substantial market for harsh environment electronics, valued at approximately $215 billion globally. These applications demand components that can function reliably in extreme conditions including high altitude, rapid temperature changes, and prolonged exposure to corrosive environments. The failure of solder joints in these applications can lead to catastrophic consequences, making reliability a non-negotiable requirement.

Industrial automation and control systems represent a third major market segment, currently valued at $180 billion with consistent annual growth rates of 6-8%. As manufacturing facilities increasingly deploy electronics in challenging environments with high humidity, chemical exposure, and temperature variations, the demand for corrosion-resistant solder joints has intensified.

The telecommunications infrastructure market, particularly with the ongoing 5G deployment, requires electronics that can withstand outdoor installation conditions. This market segment, valued at $250 billion, increasingly specifies components with enhanced environmental protection as base stations and network equipment face direct exposure to environmental stressors.

Consumer electronics manufacturers are also recognizing the value proposition of harsh environment protection, especially for wearable devices and outdoor-use products. This trend has expanded the addressable market for corrosion-resistant technologies beyond traditional industrial applications.

Market research indicates that customers are willing to pay a premium of 15-25% for components with proven reliability under harsh conditions, creating significant value opportunities for companies that can develop effective protection methods against THB/HAST exposure. The total addressable market for specialized protective coatings and advanced solder materials is estimated to exceed $8 billion annually, with double-digit growth rates anticipated over the next five years.

Current Challenges in THB/HAST Exposure Conditions

Temperature-Humidity Bias (THB) and Highly Accelerated Stress Test (HAST) represent critical reliability testing methodologies designed to evaluate electronic component performance under extreme environmental conditions. However, these testing protocols present significant challenges that impact both test accuracy and practical implementation in industry settings.

The primary challenge in THB/HAST exposure conditions lies in the acceleration factor determination. Current models struggle to establish accurate correlations between accelerated test conditions and real-world operational environments, leading to potential overdesign or underestimation of reliability requirements. This disconnect creates uncertainty in product lifetime predictions and reliability assessments, particularly for new material combinations and miniaturized packaging technologies.

Test standardization presents another substantial hurdle. Despite industry standards like JEDEC JESD22-A101 and IPC-9701, significant variations exist in test implementation across different organizations. These inconsistencies in temperature ranges (typically 85-130°C), humidity levels (85-95% RH), and bias voltage application methods create difficulties in comparing results across different studies and establishing universal reliability benchmarks.

The complex failure mechanisms induced during THB/HAST testing further complicate reliability assessment. Multiple degradation pathways often occur simultaneously, including electrochemical migration, intermetallic compound formation, and oxidation processes. The interaction between these mechanisms creates synergistic effects that current analytical models fail to capture adequately, resulting in unpredictable failure patterns.

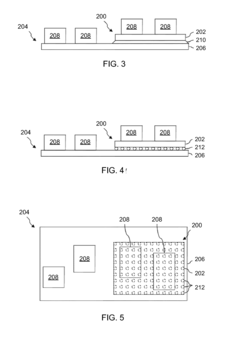

Miniaturization trends in electronic packaging exacerbate these challenges. As solder joint dimensions decrease below 100μm in advanced packaging technologies, traditional THB/HAST methodologies become increasingly inadequate. The accelerated diffusion pathways in these microscale structures create failure modes that may not manifest in conventional test specimens, questioning the validity of established testing protocols for next-generation electronics.

Material compatibility issues further complicate THB/HAST testing. The introduction of lead-free solders, conformal coatings, and novel substrate materials has created complex material interaction scenarios under harsh environmental conditions. Current test methodologies often fail to account for these material-specific degradation mechanisms, particularly the galvanic corrosion acceleration that occurs between dissimilar metals in high-humidity environments.

Finally, real-time monitoring limitations present significant technical barriers. Conventional THB/HAST chambers provide limited capabilities for in-situ observation of degradation processes, forcing researchers to rely on post-mortem analysis. This approach obscures the progressive nature of failure mechanisms and prevents the development of early detection methodologies that could enhance reliability prediction models.

The primary challenge in THB/HAST exposure conditions lies in the acceleration factor determination. Current models struggle to establish accurate correlations between accelerated test conditions and real-world operational environments, leading to potential overdesign or underestimation of reliability requirements. This disconnect creates uncertainty in product lifetime predictions and reliability assessments, particularly for new material combinations and miniaturized packaging technologies.

Test standardization presents another substantial hurdle. Despite industry standards like JEDEC JESD22-A101 and IPC-9701, significant variations exist in test implementation across different organizations. These inconsistencies in temperature ranges (typically 85-130°C), humidity levels (85-95% RH), and bias voltage application methods create difficulties in comparing results across different studies and establishing universal reliability benchmarks.

The complex failure mechanisms induced during THB/HAST testing further complicate reliability assessment. Multiple degradation pathways often occur simultaneously, including electrochemical migration, intermetallic compound formation, and oxidation processes. The interaction between these mechanisms creates synergistic effects that current analytical models fail to capture adequately, resulting in unpredictable failure patterns.

Miniaturization trends in electronic packaging exacerbate these challenges. As solder joint dimensions decrease below 100μm in advanced packaging technologies, traditional THB/HAST methodologies become increasingly inadequate. The accelerated diffusion pathways in these microscale structures create failure modes that may not manifest in conventional test specimens, questioning the validity of established testing protocols for next-generation electronics.

Material compatibility issues further complicate THB/HAST testing. The introduction of lead-free solders, conformal coatings, and novel substrate materials has created complex material interaction scenarios under harsh environmental conditions. Current test methodologies often fail to account for these material-specific degradation mechanisms, particularly the galvanic corrosion acceleration that occurs between dissimilar metals in high-humidity environments.

Finally, real-time monitoring limitations present significant technical barriers. Conventional THB/HAST chambers provide limited capabilities for in-situ observation of degradation processes, forcing researchers to rely on post-mortem analysis. This approach obscures the progressive nature of failure mechanisms and prevents the development of early detection methodologies that could enhance reliability prediction models.

Existing Protection Methods Against Environmental Corrosion

01 Solder composition for improved reliability

The composition of solder materials significantly impacts joint reliability. Advanced alloys with specific metal combinations can enhance mechanical strength, thermal cycling resistance, and reduce intermetallic compound formation. These specialized compositions can include lead-free alternatives that maintain or exceed traditional solder performance while addressing environmental concerns. Additives and dopants can be incorporated to improve wetting properties and reduce oxidation, resulting in more reliable connections under various operating conditions.- Solder joint composition and structure for improved reliability: The composition and structure of solder joints significantly impact their reliability. Various alloy compositions and structural designs can enhance mechanical strength, thermal cycling resistance, and overall durability. Innovations in this area include specialized solder materials, reinforced joint structures, and optimized geometries that distribute stress more effectively, reducing failure rates in electronic assemblies.

- Testing and evaluation methods for solder joint reliability: Advanced testing and evaluation methods are crucial for assessing solder joint reliability. These include accelerated aging tests, thermal cycling, mechanical stress testing, and non-destructive inspection techniques. Modern approaches incorporate data analytics and predictive modeling to forecast potential failure points and estimate service life under various operating conditions, enabling more reliable electronic assemblies.

- Manufacturing processes to enhance solder joint reliability: Specialized manufacturing processes can significantly improve solder joint reliability. These include controlled reflow profiles, precise component placement, optimized flux chemistry, and advanced soldering techniques. Process innovations such as vapor phase soldering, selective soldering, and specialized preheating methods help reduce defects like voids, cold joints, and insufficient wetting that compromise reliability.

- Environmental and thermal stress resistance in solder joints: Enhancing solder joint resistance to environmental and thermal stresses is essential for long-term reliability. This includes developing solutions to mitigate thermal fatigue, oxidation, corrosion, and mechanical stress from temperature cycling. Approaches include specialized coatings, encapsulants, underfills, and design strategies that accommodate thermal expansion mismatches between components and substrates.

- Reinforcement and protection technologies for solder joints: Various reinforcement and protection technologies can extend solder joint lifespan and reliability. These include underfill materials, conformal coatings, edge bonding, corner staking, and specialized encapsulants. These technologies provide mechanical support, environmental protection, and stress distribution benefits that significantly enhance the durability of solder connections in harsh operating environments and high-reliability applications.

02 Structural design of solder joints

The physical structure and geometry of solder joints significantly affect their reliability. Optimized designs can distribute stress more evenly, reducing failure points during thermal cycling or mechanical shock. Techniques such as controlled standoff height, specialized pad designs, and reinforcement structures can enhance joint durability. Strategic placement and sizing of solder connections based on stress modeling helps prevent premature failures in electronic assemblies, particularly in applications subject to vibration or thermal expansion mismatches.Expand Specific Solutions03 Testing and reliability assessment methods

Advanced testing methodologies are crucial for evaluating solder joint reliability. These include accelerated aging tests, thermal cycling, mechanical stress testing, and various analytical techniques to predict long-term performance. Non-destructive evaluation methods such as X-ray inspection, acoustic microscopy, and electrical resistance monitoring allow for quality assessment without damaging components. Computational models and simulation tools help predict failure modes and optimize designs before physical implementation, reducing development time and improving reliability outcomes.Expand Specific Solutions04 Manufacturing process optimization

The manufacturing process significantly impacts solder joint reliability. Controlled reflow profiles, precise temperature management, and proper flux selection are critical factors. Advanced soldering techniques such as vapor phase reflow, selective soldering, and specialized preheating methods can reduce defects and improve joint quality. Process monitoring systems that track key parameters during assembly help maintain consistency and identify potential issues before they affect product reliability. Post-soldering treatments like controlled cooling and cleaning processes further enhance joint durability.Expand Specific Solutions05 Environmental protection and reliability enhancement

Protecting solder joints from environmental factors is essential for long-term reliability. Conformal coatings, encapsulants, and specialized packaging techniques shield connections from moisture, contaminants, and corrosive elements. Underfill materials help distribute mechanical stress and protect against thermal cycling damage. Advanced surface treatments and preparation methods improve initial bond strength and long-term stability. These protective measures are particularly important in harsh operating environments such as automotive, aerospace, and outdoor applications where temperature extremes and environmental exposure accelerate degradation.Expand Specific Solutions

Leading Companies in Solder Joint Reliability Research

The solder joint reliability market under harsh environments is in a growth phase, driven by increasing demand for electronics in extreme conditions. The market is expanding as industries like automotive, aerospace, and telecommunications require more robust electronic components. Technologically, the field is moderately mature but evolving rapidly, with companies like Indium Corporation, Texas Instruments, and Senju Metal Industry leading innovation in solder materials and protection methods. Japanese firms such as NIPPON STEEL and Kobe Steel contribute significant metallurgical expertise, while research institutions like Tianjin University and Korea Electronics Technology Institute advance fundamental understanding of corrosion mechanisms. Western companies like Bosch and 3M focus on practical applications and protective solutions, creating a competitive landscape balanced between material science advancement and application-specific developments.

The Indium Corporation of America

Technical Solution: Indium Corporation has developed advanced solder materials specifically engineered for harsh environment reliability. Their approach focuses on specialized alloy formulations that resist corrosion during THB (Temperature Humidity Bias) and HAST (Highly Accelerated Stress Test) conditions. The company's research has led to the development of high-reliability solder pastes containing corrosion inhibitors and unique flux chemistries that form protective barriers against moisture ingress. Their technology includes water-soluble and no-clean flux formulations that leave minimal ionic residues, reducing electrochemical migration pathways. Indium's solutions incorporate conformal coating compatibility, ensuring that post-assembly protective measures can be effectively applied without compromising the solder joint integrity. The company has also pioneered vacuum soldering techniques that minimize void formation, which can serve as initiation sites for corrosion in harsh environments.

Strengths: Industry-leading expertise in specialized solder materials for extreme environments; comprehensive approach combining alloy formulation, flux chemistry, and application techniques. Weaknesses: Some solutions may require specialized equipment for implementation; higher cost compared to standard solder materials.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed a multi-layered approach to solder joint reliability in harsh environments. Their research focuses on both material selection and structural design to mitigate THB/HAST failure mechanisms. TI employs specialized underfill materials with hydrophobic properties to create moisture barriers around critical solder connections. Their technology includes proprietary surface finish combinations that minimize galvanic corrosion potential between dissimilar metals. TI has pioneered advanced package designs with optimized stand-off heights and solder joint geometries that reduce stress concentration during thermal cycling in high-humidity environments. The company utilizes plasma cleaning processes prior to assembly to enhance intermetallic compound formation and reduce flux residues that could contribute to corrosion pathways. TI's approach also incorporates selective application of parylene conformal coatings with precisely controlled thickness to protect solder joints while maintaining thermal performance.

Strengths: Comprehensive system-level approach combining materials science, package design, and manufacturing processes; extensive reliability testing capabilities. Weaknesses: Solutions may be optimized primarily for semiconductor applications rather than broader electronic assembly scenarios.

Critical Failure Mechanisms and Corrosion Pathways Analysis

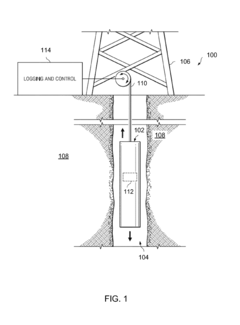

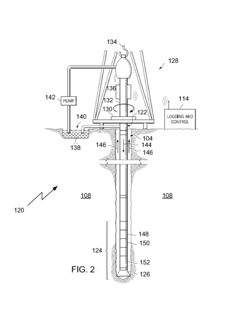

Soldered components for downhole use

PatentInactiveEP3067142A1

Innovation

- A method involving the application of a manganese layer adjacent to a metallic finish layer on electrically conductive components, followed by the application of a solder alloy comprising copper, silver, and tin, which enhances the stability of the diffusion barrier and mitigates the formation of interfacial intermetallic layers that weaken the solder joint.

Bonding wire for semiconductor devices

PatentActiveCN107962313B

Innovation

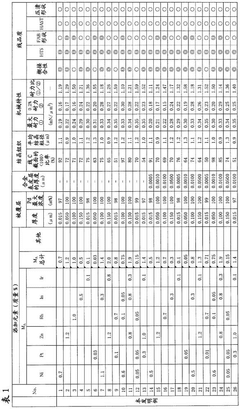

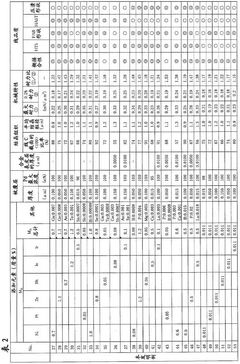

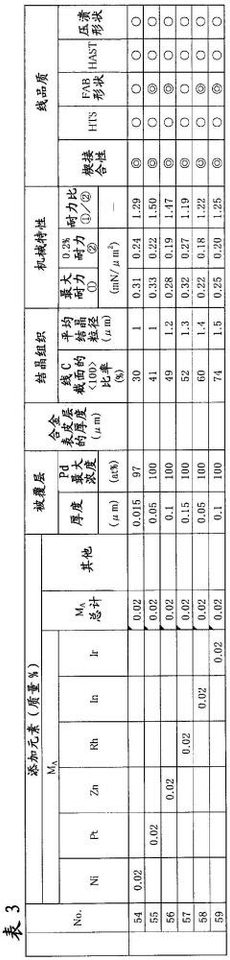

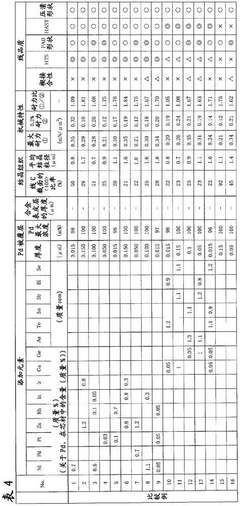

- The Cu alloy core material is used and a Pd coating layer is formed on its surface, including elements that impart connection reliability in high temperature environments, such as Ni, Zn, Rh, In, Ir, Pt, etc., to control the crystal orientation and crystal grain size to improve the The endurance ratio of the bonding wire is in the range of 1.1 to 1.6.

Material Science Advancements for Corrosion Resistance

Recent advancements in materials science have significantly contributed to improving solder joint reliability in harsh environments. Traditional solder materials, primarily tin-lead (Sn-Pb) alloys, have been largely replaced by lead-free alternatives due to environmental regulations. These newer materials, however, often exhibit different corrosion behaviors when exposed to temperature-humidity-bias (THB) or highly accelerated stress test (HAST) conditions.

The development of nano-enhanced solder materials represents a breakthrough in corrosion resistance. By incorporating nanoparticles such as silver (Ag), copper (Cu), and nickel (Ni) into lead-free solder compositions, researchers have achieved improved mechanical properties and corrosion resistance. These nanoparticles modify the microstructure of the solder joint, creating more stable intermetallic compounds that are less susceptible to degradation under harsh environmental conditions.

Conformal coating technologies have evolved substantially, with new polymeric materials offering superior protection against moisture ingress. Advanced silicone-based coatings with hydrophobic properties provide effective barriers against humidity while maintaining flexibility across wide temperature ranges. Parylene coatings, applied through vapor deposition polymerization, create pinhole-free protective layers that conform perfectly to complex geometries of solder joints.

Composite materials combining organic and inorganic components have emerged as promising solutions for corrosion protection. Sol-gel derived hybrid coatings incorporate silica nanoparticles within organic matrices, creating dense networks that significantly reduce ion migration pathways. These materials offer excellent adhesion to various substrate materials while providing effective corrosion inhibition.

Self-healing materials represent the cutting edge of corrosion protection science. These innovative materials contain encapsulated healing agents that are released when coating integrity is compromised. Upon exposure to environmental factors that typically cause corrosion, these agents polymerize or form protective complexes, automatically repairing the protective barrier and extending solder joint lifetime.

Surface modification techniques have advanced to create inherently corrosion-resistant interfaces. Plasma treatment processes alter the surface chemistry of substrate materials, enhancing adhesion properties and reducing susceptibility to moisture penetration. These treatments modify surface energy characteristics, creating more stable interfaces between solder joints and protective coatings.

Graphene and other two-dimensional materials have demonstrated exceptional potential as corrosion barriers. Their impermeable atomic structure prevents the diffusion of corrosive species to the protected surface. When incorporated into composite coatings or applied as thin films, these materials provide remarkable protection against electrochemical corrosion mechanisms that typically affect solder joints in high-humidity environments.

The development of nano-enhanced solder materials represents a breakthrough in corrosion resistance. By incorporating nanoparticles such as silver (Ag), copper (Cu), and nickel (Ni) into lead-free solder compositions, researchers have achieved improved mechanical properties and corrosion resistance. These nanoparticles modify the microstructure of the solder joint, creating more stable intermetallic compounds that are less susceptible to degradation under harsh environmental conditions.

Conformal coating technologies have evolved substantially, with new polymeric materials offering superior protection against moisture ingress. Advanced silicone-based coatings with hydrophobic properties provide effective barriers against humidity while maintaining flexibility across wide temperature ranges. Parylene coatings, applied through vapor deposition polymerization, create pinhole-free protective layers that conform perfectly to complex geometries of solder joints.

Composite materials combining organic and inorganic components have emerged as promising solutions for corrosion protection. Sol-gel derived hybrid coatings incorporate silica nanoparticles within organic matrices, creating dense networks that significantly reduce ion migration pathways. These materials offer excellent adhesion to various substrate materials while providing effective corrosion inhibition.

Self-healing materials represent the cutting edge of corrosion protection science. These innovative materials contain encapsulated healing agents that are released when coating integrity is compromised. Upon exposure to environmental factors that typically cause corrosion, these agents polymerize or form protective complexes, automatically repairing the protective barrier and extending solder joint lifetime.

Surface modification techniques have advanced to create inherently corrosion-resistant interfaces. Plasma treatment processes alter the surface chemistry of substrate materials, enhancing adhesion properties and reducing susceptibility to moisture penetration. These treatments modify surface energy characteristics, creating more stable interfaces between solder joints and protective coatings.

Graphene and other two-dimensional materials have demonstrated exceptional potential as corrosion barriers. Their impermeable atomic structure prevents the diffusion of corrosive species to the protected surface. When incorporated into composite coatings or applied as thin films, these materials provide remarkable protection against electrochemical corrosion mechanisms that typically affect solder joints in high-humidity environments.

Industry Standards and Testing Protocols for Reliability Validation

The reliability assessment of solder joints in harsh environments necessitates standardized testing protocols to ensure consistency and comparability of results across the industry. Several international standards organizations have developed comprehensive guidelines specifically addressing the reliability validation of electronic assemblies under temperature-humidity-bias (THB) and highly accelerated stress test (HAST) conditions.

IPC-9701, "Performance Test Methods and Qualification Requirements for Surface Mount Solder Attachments," provides detailed procedures for evaluating solder joint reliability under various environmental stresses. This standard includes specific protocols for temperature cycling, humidity testing, and mechanical stress testing that are widely adopted in the electronics manufacturing industry.

JEDEC standard JESD22-A101 outlines the methodology for steady-state temperature humidity bias life test, which is crucial for understanding the long-term reliability of solder joints under constant humidity and temperature conditions. Complementing this, JESD22-A110 describes the HAST test procedures, which accelerate the effects of humidity under elevated temperature and pressure.

IEC 60068 series, particularly IEC 60068-2-67 and IEC 60068-2-78, establish testing methods for determining the suitability of electronic components for use in humid environments. These standards define specific parameters for temperature, humidity, and test duration that correlate with real-world exposure scenarios.

The automotive industry employs more stringent standards due to the harsh operating environments vehicles encounter. AEC-Q100 includes specific reliability tests for automotive-grade integrated circuits, with detailed protocols for humidity testing under bias conditions that exceed consumer electronics requirements.

Testing protocols typically specify pre-conditioning procedures, exposure conditions (temperature, relative humidity, pressure), electrical bias application methods, and post-exposure analysis techniques. Most standards require visual inspection, electrical continuity testing, and cross-sectional analysis to identify corrosion pathways and failure mechanisms.

Recent advancements in testing methodologies have introduced in-situ monitoring techniques that allow for real-time observation of resistance changes during environmental exposure. These approaches provide valuable insights into the progression of corrosion and the effectiveness of protection methods without interrupting the test.

Correlation factors between accelerated testing and real-world performance remain a critical area of ongoing research, as the industry seeks to develop more accurate predictive models for solder joint reliability. The development of standardized metrics for quantifying the effectiveness of various protection methods represents another frontier in reliability validation protocols.

IPC-9701, "Performance Test Methods and Qualification Requirements for Surface Mount Solder Attachments," provides detailed procedures for evaluating solder joint reliability under various environmental stresses. This standard includes specific protocols for temperature cycling, humidity testing, and mechanical stress testing that are widely adopted in the electronics manufacturing industry.

JEDEC standard JESD22-A101 outlines the methodology for steady-state temperature humidity bias life test, which is crucial for understanding the long-term reliability of solder joints under constant humidity and temperature conditions. Complementing this, JESD22-A110 describes the HAST test procedures, which accelerate the effects of humidity under elevated temperature and pressure.

IEC 60068 series, particularly IEC 60068-2-67 and IEC 60068-2-78, establish testing methods for determining the suitability of electronic components for use in humid environments. These standards define specific parameters for temperature, humidity, and test duration that correlate with real-world exposure scenarios.

The automotive industry employs more stringent standards due to the harsh operating environments vehicles encounter. AEC-Q100 includes specific reliability tests for automotive-grade integrated circuits, with detailed protocols for humidity testing under bias conditions that exceed consumer electronics requirements.

Testing protocols typically specify pre-conditioning procedures, exposure conditions (temperature, relative humidity, pressure), electrical bias application methods, and post-exposure analysis techniques. Most standards require visual inspection, electrical continuity testing, and cross-sectional analysis to identify corrosion pathways and failure mechanisms.

Recent advancements in testing methodologies have introduced in-situ monitoring techniques that allow for real-time observation of resistance changes during environmental exposure. These approaches provide valuable insights into the progression of corrosion and the effectiveness of protection methods without interrupting the test.

Correlation factors between accelerated testing and real-world performance remain a critical area of ongoing research, as the industry seeks to develop more accurate predictive models for solder joint reliability. The development of standardized metrics for quantifying the effectiveness of various protection methods represents another frontier in reliability validation protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!