How Solder Joint Reliability Improves Under Power Cycling With Optimized Heat Spreading?

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solder Joint Reliability Background and Objectives

Solder joint reliability has been a critical concern in the electronics industry since the advent of surface mount technology in the 1980s. The evolution of this technology has been driven by the increasing complexity and miniaturization of electronic components, coupled with the demand for higher performance and reliability. Solder joints serve as both electrical and mechanical connections in electronic assemblies, making their reliability fundamental to the overall functionality and longevity of electronic devices.

The historical progression of solder joint technology has seen significant shifts, particularly with the transition from tin-lead to lead-free solders following environmental regulations like the European Union's Restriction of Hazardous Substances (RoHS) directive. This transition presented new challenges in reliability due to the different mechanical and thermal properties of lead-free alloys, including higher melting points and increased susceptibility to thermal fatigue.

Power cycling, the repeated heating and cooling of electronic components during operation, represents one of the most severe stressors on solder joint integrity. The thermal expansion mismatch between different materials in an electronic assembly creates cyclic strain on solder joints, leading to fatigue and eventual failure. This phenomenon has become increasingly problematic as power densities in modern electronics continue to rise, resulting in more extreme temperature fluctuations during operation.

Heat spreading optimization has emerged as a promising approach to mitigate these reliability challenges. By effectively managing heat distribution across electronic assemblies, the thermal gradients and peak temperatures experienced by solder joints can be significantly reduced. This approach aims to minimize the thermomechanical stress that drives fatigue failure mechanisms.

The primary objective of research in this field is to develop comprehensive models and design methodologies that can predict and enhance solder joint reliability under power cycling conditions through optimized heat spreading. This includes understanding the complex interplay between material properties, geometric configurations, thermal management strategies, and reliability outcomes.

Secondary goals include establishing standardized testing protocols that accurately reflect real-world operating conditions, developing new solder alloy compositions with enhanced thermal fatigue resistance, and creating design guidelines for electronic packaging that incorporate heat spreading considerations from the earliest stages of development.

The technological trajectory in this domain is moving toward predictive modeling capabilities that can inform design decisions before physical prototyping, as well as adaptive thermal management systems that can dynamically respond to changing operational conditions to maximize solder joint longevity. These advancements are essential for supporting the next generation of high-reliability electronics in critical applications such as automotive, aerospace, medical devices, and telecommunications infrastructure.

The historical progression of solder joint technology has seen significant shifts, particularly with the transition from tin-lead to lead-free solders following environmental regulations like the European Union's Restriction of Hazardous Substances (RoHS) directive. This transition presented new challenges in reliability due to the different mechanical and thermal properties of lead-free alloys, including higher melting points and increased susceptibility to thermal fatigue.

Power cycling, the repeated heating and cooling of electronic components during operation, represents one of the most severe stressors on solder joint integrity. The thermal expansion mismatch between different materials in an electronic assembly creates cyclic strain on solder joints, leading to fatigue and eventual failure. This phenomenon has become increasingly problematic as power densities in modern electronics continue to rise, resulting in more extreme temperature fluctuations during operation.

Heat spreading optimization has emerged as a promising approach to mitigate these reliability challenges. By effectively managing heat distribution across electronic assemblies, the thermal gradients and peak temperatures experienced by solder joints can be significantly reduced. This approach aims to minimize the thermomechanical stress that drives fatigue failure mechanisms.

The primary objective of research in this field is to develop comprehensive models and design methodologies that can predict and enhance solder joint reliability under power cycling conditions through optimized heat spreading. This includes understanding the complex interplay between material properties, geometric configurations, thermal management strategies, and reliability outcomes.

Secondary goals include establishing standardized testing protocols that accurately reflect real-world operating conditions, developing new solder alloy compositions with enhanced thermal fatigue resistance, and creating design guidelines for electronic packaging that incorporate heat spreading considerations from the earliest stages of development.

The technological trajectory in this domain is moving toward predictive modeling capabilities that can inform design decisions before physical prototyping, as well as adaptive thermal management systems that can dynamically respond to changing operational conditions to maximize solder joint longevity. These advancements are essential for supporting the next generation of high-reliability electronics in critical applications such as automotive, aerospace, medical devices, and telecommunications infrastructure.

Market Demand for Enhanced Thermal Management Solutions

The thermal management solutions market is experiencing unprecedented growth driven by the increasing power density and miniaturization trends in electronic devices. As semiconductor components continue to shrink while processing capabilities expand, the challenge of effectively dissipating heat has become critical across multiple industries. Current market analysis indicates that the global thermal management market is projected to grow at a compound annual growth rate of over 8% through 2028, with particular acceleration in sectors requiring high-reliability electronics.

Power electronics applications in automotive, aerospace, renewable energy, and data centers are primary drivers for enhanced thermal management solutions. The electric vehicle market, growing at over 25% annually, demands increasingly reliable power modules that can withstand thousands of thermal cycles without failure. Similarly, the renewable energy sector requires inverters and power conversion systems with extended lifespans under variable operating conditions, creating substantial demand for advanced thermal solutions.

Consumer electronics manufacturers are facing mounting pressure to extend product lifetimes while reducing warranty claims related to thermal failures. This has created a significant market pull for optimized heat spreading technologies that can improve solder joint reliability under power cycling conditions. Industry surveys indicate that approximately 65% of electronic failures are temperature-related, with solder joint failure being among the most common failure mechanisms.

The data center industry represents another major market segment demanding enhanced thermal management. With the exponential growth in cloud computing and AI applications, data centers are operating at higher power densities than ever before. The reliability of server components under continuous power cycling has become a critical concern, with operators willing to invest in premium thermal solutions that can demonstrate improved mean time between failures.

Military and aerospace applications present a specialized but lucrative market segment where thermal reliability requirements are exceptionally stringent. These sectors demand solutions that can function reliably in extreme environments and under severe thermal cycling conditions, with some applications requiring operational reliability for over 20 years without maintenance.

The market is also being shaped by regulatory pressures and sustainability initiatives. Energy efficiency regulations in major markets are pushing manufacturers to optimize thermal management while reducing overall power consumption. Additionally, the growing focus on product longevity as part of sustainability efforts is creating demand for thermal solutions that can extend electronic product lifespans through improved reliability under thermal stress conditions.

Power electronics applications in automotive, aerospace, renewable energy, and data centers are primary drivers for enhanced thermal management solutions. The electric vehicle market, growing at over 25% annually, demands increasingly reliable power modules that can withstand thousands of thermal cycles without failure. Similarly, the renewable energy sector requires inverters and power conversion systems with extended lifespans under variable operating conditions, creating substantial demand for advanced thermal solutions.

Consumer electronics manufacturers are facing mounting pressure to extend product lifetimes while reducing warranty claims related to thermal failures. This has created a significant market pull for optimized heat spreading technologies that can improve solder joint reliability under power cycling conditions. Industry surveys indicate that approximately 65% of electronic failures are temperature-related, with solder joint failure being among the most common failure mechanisms.

The data center industry represents another major market segment demanding enhanced thermal management. With the exponential growth in cloud computing and AI applications, data centers are operating at higher power densities than ever before. The reliability of server components under continuous power cycling has become a critical concern, with operators willing to invest in premium thermal solutions that can demonstrate improved mean time between failures.

Military and aerospace applications present a specialized but lucrative market segment where thermal reliability requirements are exceptionally stringent. These sectors demand solutions that can function reliably in extreme environments and under severe thermal cycling conditions, with some applications requiring operational reliability for over 20 years without maintenance.

The market is also being shaped by regulatory pressures and sustainability initiatives. Energy efficiency regulations in major markets are pushing manufacturers to optimize thermal management while reducing overall power consumption. Additionally, the growing focus on product longevity as part of sustainability efforts is creating demand for thermal solutions that can extend electronic product lifespans through improved reliability under thermal stress conditions.

Current Challenges in Solder Joint Reliability

Solder joint reliability remains a critical concern in electronic packaging, with several persistent challenges impeding optimal performance under power cycling conditions. The thermal expansion mismatch between different materials in electronic assemblies creates significant stress on solder joints during heating and cooling cycles. This coefficient of thermal expansion (CTE) mismatch is particularly problematic in applications with high power density components, where temperature gradients can be extreme and rapid.

The increasing miniaturization of electronic devices compounds these challenges, as smaller solder joints must withstand the same or greater mechanical stresses while having reduced physical volume and surface area for bonding. This trend toward higher integration density creates inherent reliability vulnerabilities that become more pronounced under power cycling conditions.

Intermetallic compound (IMC) formation at the solder-substrate interface presents another significant challenge. While some IMC formation is necessary for proper bonding, excessive growth during thermal cycling can lead to brittle interfaces that are prone to crack initiation and propagation. The rate of IMC formation accelerates at elevated temperatures, making this particularly problematic in high-power applications where thermal management is already challenging.

Current lead-free solder compositions, while environmentally preferable, often exhibit inferior thermal fatigue resistance compared to traditional lead-based solders. These lead-free alternatives typically have higher melting points, different wetting behaviors, and distinct microstructural evolution under thermal stress, all of which can compromise reliability during power cycling if not properly managed.

Voiding within solder joints represents another persistent challenge, as these voids can act as stress concentrators and crack initiation sites. Power cycling exacerbates this issue by creating conditions where voids can coalesce and grow, further reducing the effective cross-sectional area of the joint and accelerating failure mechanisms.

The industry also faces significant challenges in accurately predicting solder joint lifetime under complex power cycling profiles. Current reliability models often fail to account for the combined effects of electromigration, thermomigration, and stress migration that occur simultaneously during actual operation. This modeling gap makes it difficult to design optimal heat spreading solutions without extensive empirical testing.

Manufacturing process variations introduce additional reliability concerns, as inconsistencies in solder paste deposition, reflow profiles, and cooling rates can create joints with varying microstructures and mechanical properties. These variations become particularly problematic when designing heat spreading solutions, as the thermal performance may vary significantly across supposedly identical assemblies.

The increasing miniaturization of electronic devices compounds these challenges, as smaller solder joints must withstand the same or greater mechanical stresses while having reduced physical volume and surface area for bonding. This trend toward higher integration density creates inherent reliability vulnerabilities that become more pronounced under power cycling conditions.

Intermetallic compound (IMC) formation at the solder-substrate interface presents another significant challenge. While some IMC formation is necessary for proper bonding, excessive growth during thermal cycling can lead to brittle interfaces that are prone to crack initiation and propagation. The rate of IMC formation accelerates at elevated temperatures, making this particularly problematic in high-power applications where thermal management is already challenging.

Current lead-free solder compositions, while environmentally preferable, often exhibit inferior thermal fatigue resistance compared to traditional lead-based solders. These lead-free alternatives typically have higher melting points, different wetting behaviors, and distinct microstructural evolution under thermal stress, all of which can compromise reliability during power cycling if not properly managed.

Voiding within solder joints represents another persistent challenge, as these voids can act as stress concentrators and crack initiation sites. Power cycling exacerbates this issue by creating conditions where voids can coalesce and grow, further reducing the effective cross-sectional area of the joint and accelerating failure mechanisms.

The industry also faces significant challenges in accurately predicting solder joint lifetime under complex power cycling profiles. Current reliability models often fail to account for the combined effects of electromigration, thermomigration, and stress migration that occur simultaneously during actual operation. This modeling gap makes it difficult to design optimal heat spreading solutions without extensive empirical testing.

Manufacturing process variations introduce additional reliability concerns, as inconsistencies in solder paste deposition, reflow profiles, and cooling rates can create joints with varying microstructures and mechanical properties. These variations become particularly problematic when designing heat spreading solutions, as the thermal performance may vary significantly across supposedly identical assemblies.

Current Heat Spreading Optimization Techniques

01 Solder joint composition and structure for improved reliability

The composition and structure of solder joints significantly impact their reliability. Various alloy compositions and structural designs can enhance mechanical strength, thermal cycling resistance, and overall durability. Innovations in this area include specialized solder materials, reinforced joint structures, and optimized geometries that distribute stress more effectively, resulting in longer-lasting and more reliable connections in electronic assemblies.- Solder joint composition and materials: The reliability of solder joints is significantly influenced by the composition and materials used. Various alloy formulations can enhance mechanical strength, thermal cycling resistance, and overall durability. Advanced materials such as lead-free solders with specific additives can improve joint integrity under stress conditions. The selection of appropriate solder materials based on application requirements is crucial for ensuring long-term reliability in electronic assemblies.

- Testing and evaluation methods for solder joint reliability: Various testing methodologies are employed to evaluate and predict solder joint reliability. These include thermal cycling tests, mechanical stress tests, vibration analysis, and accelerated aging procedures. Advanced analytical techniques such as X-ray inspection, acoustic microscopy, and electrical resistance monitoring help identify potential failure modes before they occur in field applications. Reliability models based on test data can predict joint performance under various operating conditions.

- Design considerations for reliable solder joints: The physical design of solder joints significantly impacts their reliability. Factors such as pad geometry, component placement, thermal management, and stress distribution must be carefully considered. Optimized designs can reduce stress concentration, improve thermal performance, and enhance mechanical stability. Design strategies that accommodate thermal expansion mismatches between components and substrates are particularly important for preventing premature joint failures.

- Manufacturing process optimization for solder joint reliability: Manufacturing processes significantly impact solder joint reliability. Precise control of reflow profiles, proper flux selection, controlled cooling rates, and cleanliness during assembly are critical factors. Advanced soldering techniques such as vapor phase soldering, selective soldering, and controlled atmosphere soldering can enhance joint quality. Process monitoring and statistical process control methods help maintain consistent joint formation and minimize defects that could lead to reliability issues.

- Environmental and operational factors affecting solder joint reliability: Environmental and operational conditions significantly impact solder joint longevity. Thermal cycling, humidity, vibration, mechanical shock, and electrical loading all contribute to potential failure mechanisms. Protective measures such as conformal coatings, underfills, and encapsulants can enhance reliability in harsh environments. Understanding the specific environmental stresses in the intended application is essential for selecting appropriate materials and design approaches to ensure long-term solder joint reliability.

02 Testing and evaluation methods for solder joint reliability

Advanced testing and evaluation methods are essential for assessing solder joint reliability. These include accelerated aging tests, thermal cycling, mechanical stress testing, and non-destructive inspection techniques. Modern approaches incorporate real-time monitoring systems, predictive modeling, and data analytics to identify potential failure modes before they occur in field applications, enabling more reliable electronic assemblies.Expand Specific Solutions03 Manufacturing processes to enhance solder joint reliability

Specialized manufacturing processes can significantly improve solder joint reliability. These include controlled reflow profiles, precise component placement, optimized flux chemistry, and post-soldering treatments. Advanced techniques such as vacuum soldering, laser soldering, and selective soldering can be employed to address specific reliability challenges in different applications, resulting in more consistent and durable connections.Expand Specific Solutions04 Environmental and thermal stress resistance in solder joints

Enhancing solder joint resistance to environmental and thermal stresses is crucial for reliability. This includes developing solutions that withstand extreme temperature fluctuations, humidity, vibration, and mechanical shock. Specialized coatings, encapsulants, and underfill materials can be applied to protect solder joints from environmental factors, while thermal management techniques help mitigate the effects of temperature cycling on joint integrity.Expand Specific Solutions05 Novel interconnect technologies for next-generation solder reliability

Emerging interconnect technologies are being developed to address the reliability challenges of modern electronics. These include copper pillar bumps, through-silicon vias (TSVs), sintered silver connections, and hybrid bonding approaches. Such technologies offer advantages over traditional solder joints in terms of electrical performance, thermal management, and mechanical reliability, particularly for high-density and high-performance applications.Expand Specific Solutions

Leading Companies in Thermal Management Industry

The solder joint reliability under power cycling with optimized heat spreading is currently in a growth phase, with increasing market demand driven by electronics miniaturization and higher power densities. The global market is expanding as thermal management becomes critical in semiconductor packaging. Leading companies like Indium Corporation, Senju Metal Industry, and DUKSAN HI METAL are advancing solder materials technology, while system integrators such as IBM, Siemens, and Bosch are implementing these solutions in high-reliability applications. Research institutions including Georgia Tech and National University of Singapore are contributing to fundamental understanding of thermal cycling effects. The technology is maturing rapidly with innovations in heat spreading materials and designs from companies like Mitsubishi Materials and Delta Electronics, creating a competitive landscape focused on reliability enhancement for next-generation electronics.

Senju Metal Industry Co., Ltd.

Technical Solution: Senju Metal Industry has pioneered innovative solder joint reliability solutions through their M776 series of lead-free solders specifically designed for power cycling applications. Their approach incorporates nano-particle reinforcement within the solder matrix, creating a composite material that significantly enhances thermal conductivity while maintaining mechanical flexibility. This technology distributes heat more efficiently across the joint interface, reducing localized hot spots that typically lead to premature failure. Senju's research indicates their reinforced solders demonstrate up to 30% improvement in thermal cycling reliability compared to conventional SAC alloys[2]. The company has also developed specialized flux formulations that enhance wetting characteristics, ensuring optimal thermal contact between components. Their patented "Reliability Enhanced Solder Technology" (REST) incorporates carefully controlled microalloying elements that strengthen grain boundaries, significantly improving resistance to thermomechanical fatigue during power cycling conditions while maintaining excellent heat spreading properties.

Strengths: Exceptional thermal cycling endurance; nano-reinforced structure provides superior mechanical stability; excellent wetting characteristics ensure optimal thermal contact. Weaknesses: Higher initial cost than standard solders; requires precise process control during manufacturing; limited availability in some regions.

The Indium Corporation of America

Technical Solution: Indium Corporation has developed advanced solder materials specifically engineered for improved thermal cycling reliability. Their approach focuses on low-temperature solder alloys with optimized microstructures that enhance heat spreading capabilities. The company's InFORMS® (Reinforced Matrixed Solder Composite) technology combines a reinforcing matrix with solder alloy, creating standoff height control while improving thermal performance under power cycling conditions. This technology maintains bondline thickness during reflow, resulting in more consistent and reliable solder joints. Their research demonstrates that these specialized preforms can reduce thermal resistance by up to 20% compared to standard solder materials[1], leading to significantly improved reliability under power cycling conditions. Additionally, Indium Corporation has developed specialized thermal interface materials (TIMs) that work in conjunction with their solder solutions to create comprehensive thermal management systems for high-power electronics applications.

Strengths: Superior thermal conductivity compared to standard solders; maintains consistent bondline thickness; reduces thermal resistance; excellent for high-power applications. Weaknesses: Higher cost than conventional solders; may require specialized processing equipment; limited compatibility with certain substrate materials.

Key Innovations in Power Cycling Reliability

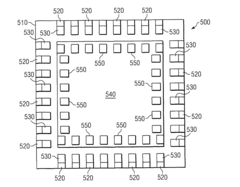

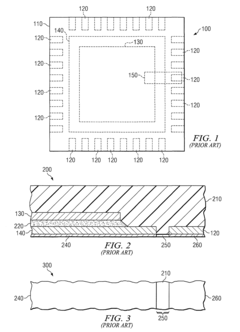

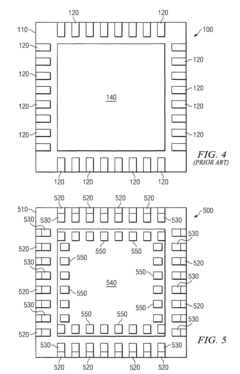

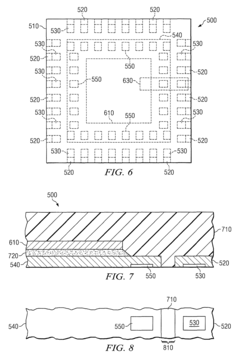

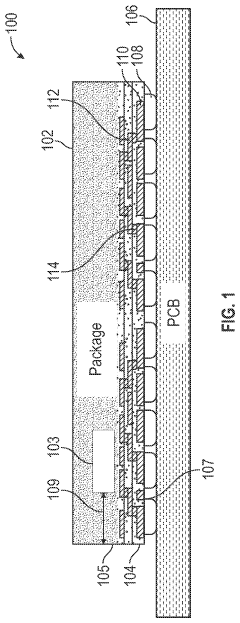

System and method for improving solder joint reliability in an integrated circuit package

PatentInactiveUS8524531B2

Innovation

- The introduction of solder slots on the terminals and die pad of QFN packages, which are filled with solder during the reflow process, enhances the solder bond strength against lateral forces, thereby increasing the reliability of the solder joint.

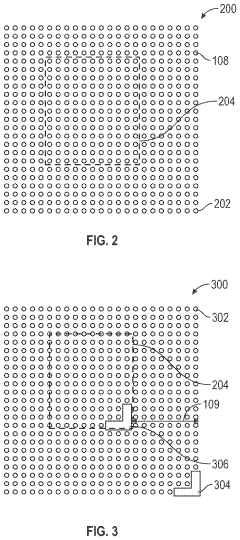

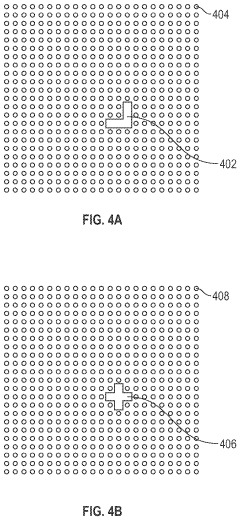

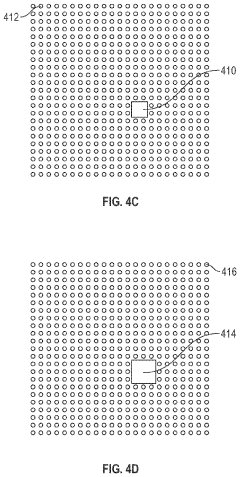

Solder joint design for improved package reliability

PatentPendingUS20240063141A1

Innovation

- Incorporating additional solder joints of varying shapes and sizes at strategic locations on the semiconductor package, which act as mechanical supports and increase the interfacial area with bonding pads, thereby enhancing mechanical strength and reliability.

Materials Science Advancements for Solder Joints

Recent advancements in materials science have significantly contributed to enhancing solder joint reliability under power cycling conditions. Traditional solder materials like tin-lead (SnPb) alloys have been largely replaced by lead-free alternatives such as SAC (tin-silver-copper) alloys due to environmental regulations. However, these lead-free solders often exhibit different mechanical properties and thermal behaviors that affect their reliability under thermal stress.

The microstructure of solder joints plays a crucial role in determining their performance during power cycling. Research has shown that controlling grain size and intermetallic compound (IMC) formation can substantially improve reliability. Nano-reinforced composite solders represent a breakthrough in this field, where nanoparticles of materials like carbon nanotubes, graphene, or ceramic oxides are incorporated into the solder matrix to enhance mechanical strength and thermal conductivity.

Thermal interface materials (TIMs) have evolved significantly to complement solder joint performance. Advanced polymer-based TIMs with enhanced thermal conductivity help distribute heat more evenly across solder joints, reducing localized thermal stress. Metal-matrix composites and phase-change materials are being integrated into packaging designs to work synergistically with solder joints for improved thermal management.

Surface finish technologies have also progressed to enhance solder wettability and bond strength. Electroless nickel immersion gold (ENIG), immersion silver, and organic solderability preservatives (OSP) provide superior surface properties that contribute to more reliable solder connections. These finishes help maintain consistent intermetallic formation during reflow processes and subsequent power cycling.

The development of flexible substrate materials that can accommodate coefficient of thermal expansion (CTE) mismatches has further enhanced solder joint reliability. Materials like polyimide-based flexible circuits and low-CTE ceramic substrates help reduce mechanical stress on solder joints during thermal cycling, extending their operational lifetime in high-power applications.

Additive manufacturing techniques are enabling novel approaches to solder joint design. 3D-printed solder preforms with engineered geometries can optimize stress distribution and heat dissipation. These customized structures can be tailored to specific thermal profiles, providing targeted solutions for challenging power cycling environments.

The microstructure of solder joints plays a crucial role in determining their performance during power cycling. Research has shown that controlling grain size and intermetallic compound (IMC) formation can substantially improve reliability. Nano-reinforced composite solders represent a breakthrough in this field, where nanoparticles of materials like carbon nanotubes, graphene, or ceramic oxides are incorporated into the solder matrix to enhance mechanical strength and thermal conductivity.

Thermal interface materials (TIMs) have evolved significantly to complement solder joint performance. Advanced polymer-based TIMs with enhanced thermal conductivity help distribute heat more evenly across solder joints, reducing localized thermal stress. Metal-matrix composites and phase-change materials are being integrated into packaging designs to work synergistically with solder joints for improved thermal management.

Surface finish technologies have also progressed to enhance solder wettability and bond strength. Electroless nickel immersion gold (ENIG), immersion silver, and organic solderability preservatives (OSP) provide superior surface properties that contribute to more reliable solder connections. These finishes help maintain consistent intermetallic formation during reflow processes and subsequent power cycling.

The development of flexible substrate materials that can accommodate coefficient of thermal expansion (CTE) mismatches has further enhanced solder joint reliability. Materials like polyimide-based flexible circuits and low-CTE ceramic substrates help reduce mechanical stress on solder joints during thermal cycling, extending their operational lifetime in high-power applications.

Additive manufacturing techniques are enabling novel approaches to solder joint design. 3D-printed solder preforms with engineered geometries can optimize stress distribution and heat dissipation. These customized structures can be tailored to specific thermal profiles, providing targeted solutions for challenging power cycling environments.

Environmental Impact of Thermal Management Solutions

The optimization of heat spreading in electronic assemblies not only enhances solder joint reliability but also carries significant environmental implications. Traditional thermal management solutions often rely on materials with considerable ecological footprints, such as copper heat sinks and aluminum cooling plates, which require energy-intensive mining and manufacturing processes.

Advanced heat spreading technologies designed to improve solder joint reliability can simultaneously reduce environmental impact through several mechanisms. By extending component lifespan and reducing failure rates, these solutions directly decrease electronic waste generation—a growing environmental concern with over 50 million tons produced globally each year. When solder joints maintain integrity for longer periods under power cycling conditions, fewer devices require replacement or repair.

Material selection for thermal management presents another environmental consideration. Novel composite materials and phase-change solutions often utilize lower quantities of rare or environmentally problematic elements compared to conventional approaches. For instance, graphene-based thermal interface materials offer superior thermal conductivity while requiring significantly less raw material than traditional metal-based solutions.

Energy efficiency represents perhaps the most substantial environmental benefit of optimized heat spreading. Electronic assemblies with improved thermal management operate at lower temperatures, reducing power consumption during operation. Studies indicate that for every 10°C reduction in operating temperature, energy efficiency can improve by 2-4% in many semiconductor applications. This translates to reduced carbon emissions throughout the product lifecycle.

Manufacturing processes for advanced thermal management solutions are evolving toward more sustainable approaches. Additive manufacturing techniques enable precise material deposition, minimizing waste compared to traditional subtractive processes. Additionally, some newer thermal interface materials can be applied at lower temperatures, reducing energy requirements during assembly.

End-of-life considerations must also factor into environmental assessments of thermal management solutions. Heat spreading technologies incorporating easily separable components facilitate recycling efforts. Conversely, highly integrated or composite materials may present recycling challenges despite their operational benefits. Lifecycle assessment studies suggest that the environmental benefits of extended product lifespan typically outweigh the potential recycling difficulties for most electronic applications.

Regulatory frameworks increasingly recognize the environmental implications of thermal management choices. The European Union's Ecodesign Directive and similar regulations worldwide are beginning to incorporate thermal efficiency requirements, driving innovation toward more environmentally responsible heat spreading solutions that simultaneously enhance solder joint reliability.

Advanced heat spreading technologies designed to improve solder joint reliability can simultaneously reduce environmental impact through several mechanisms. By extending component lifespan and reducing failure rates, these solutions directly decrease electronic waste generation—a growing environmental concern with over 50 million tons produced globally each year. When solder joints maintain integrity for longer periods under power cycling conditions, fewer devices require replacement or repair.

Material selection for thermal management presents another environmental consideration. Novel composite materials and phase-change solutions often utilize lower quantities of rare or environmentally problematic elements compared to conventional approaches. For instance, graphene-based thermal interface materials offer superior thermal conductivity while requiring significantly less raw material than traditional metal-based solutions.

Energy efficiency represents perhaps the most substantial environmental benefit of optimized heat spreading. Electronic assemblies with improved thermal management operate at lower temperatures, reducing power consumption during operation. Studies indicate that for every 10°C reduction in operating temperature, energy efficiency can improve by 2-4% in many semiconductor applications. This translates to reduced carbon emissions throughout the product lifecycle.

Manufacturing processes for advanced thermal management solutions are evolving toward more sustainable approaches. Additive manufacturing techniques enable precise material deposition, minimizing waste compared to traditional subtractive processes. Additionally, some newer thermal interface materials can be applied at lower temperatures, reducing energy requirements during assembly.

End-of-life considerations must also factor into environmental assessments of thermal management solutions. Heat spreading technologies incorporating easily separable components facilitate recycling efforts. Conversely, highly integrated or composite materials may present recycling challenges despite their operational benefits. Lifecycle assessment studies suggest that the environmental benefits of extended product lifespan typically outweigh the potential recycling difficulties for most electronic applications.

Regulatory frameworks increasingly recognize the environmental implications of thermal management choices. The European Union's Ecodesign Directive and similar regulations worldwide are beginning to incorporate thermal efficiency requirements, driving innovation toward more environmentally responsible heat spreading solutions that simultaneously enhance solder joint reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!