Solder Joint Reliability: Conformal Coating Interactions, Moisture Traps And Rework Limits

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solder Joint Reliability Background and Objectives

Solder joint reliability has evolved significantly over the past decades, driven by the electronics industry's continuous pursuit of miniaturization, increased functionality, and enhanced durability. Initially focused on through-hole technology in the 1970s and 1980s, the field has progressively shifted toward surface mount technology (SMT), which presents unique challenges for joint integrity. The transition from tin-lead to lead-free solders following the implementation of RoHS regulations in 2006 marked a pivotal point in this evolution, necessitating comprehensive reevaluation of reliability parameters.

The interaction between solder joints and conformal coatings represents a complex technical domain that has gained increasing attention as electronic devices face more demanding operational environments. Historically, conformal coatings were primarily employed for moisture and contamination protection, with limited consideration for their mechanical and chemical interactions with solder joints. Recent research has revealed that these interactions significantly impact long-term reliability, particularly in high-humidity, temperature-cycling, and vibration-intensive applications.

Moisture trapping phenomena at the interface between conformal coatings and solder joints has emerged as a critical reliability concern. Early studies in the 1990s identified basic mechanisms of moisture ingress, but modern high-density assemblies with complex geometries have introduced new pathways for moisture accumulation that can accelerate electrochemical migration and corrosion processes. The industry has progressively developed more sophisticated models to predict these effects, though significant gaps in understanding remain.

Rework limitations represent another evolving aspect of solder joint reliability. As assemblies become more complex and component densities increase, the ability to successfully rework solder joints without compromising reliability has become increasingly challenging. Traditional rework processes developed for tin-lead solders often prove inadequate for lead-free joints, particularly when conformal coatings are present. The number of viable rework cycles has generally decreased, necessitating more precise first-pass manufacturing processes.

The primary objectives of current research in this field include: developing comprehensive models that accurately predict the long-term reliability of solder joints in the presence of conformal coatings; establishing standardized test methodologies that effectively evaluate moisture-related failure mechanisms; creating new coating formulations that minimize adverse interactions with modern solder alloys; and defining science-based rework limits that balance manufacturing flexibility with reliability requirements. These objectives align with the broader industry goals of extending electronic product lifespans, reducing field failures, and supporting sustainability initiatives through reduced electronic waste.

The interaction between solder joints and conformal coatings represents a complex technical domain that has gained increasing attention as electronic devices face more demanding operational environments. Historically, conformal coatings were primarily employed for moisture and contamination protection, with limited consideration for their mechanical and chemical interactions with solder joints. Recent research has revealed that these interactions significantly impact long-term reliability, particularly in high-humidity, temperature-cycling, and vibration-intensive applications.

Moisture trapping phenomena at the interface between conformal coatings and solder joints has emerged as a critical reliability concern. Early studies in the 1990s identified basic mechanisms of moisture ingress, but modern high-density assemblies with complex geometries have introduced new pathways for moisture accumulation that can accelerate electrochemical migration and corrosion processes. The industry has progressively developed more sophisticated models to predict these effects, though significant gaps in understanding remain.

Rework limitations represent another evolving aspect of solder joint reliability. As assemblies become more complex and component densities increase, the ability to successfully rework solder joints without compromising reliability has become increasingly challenging. Traditional rework processes developed for tin-lead solders often prove inadequate for lead-free joints, particularly when conformal coatings are present. The number of viable rework cycles has generally decreased, necessitating more precise first-pass manufacturing processes.

The primary objectives of current research in this field include: developing comprehensive models that accurately predict the long-term reliability of solder joints in the presence of conformal coatings; establishing standardized test methodologies that effectively evaluate moisture-related failure mechanisms; creating new coating formulations that minimize adverse interactions with modern solder alloys; and defining science-based rework limits that balance manufacturing flexibility with reliability requirements. These objectives align with the broader industry goals of extending electronic product lifespans, reducing field failures, and supporting sustainability initiatives through reduced electronic waste.

Market Demand Analysis for Reliable Electronics Assembly

The global electronics assembly market is experiencing robust growth driven by increasing demand for reliable electronic components across multiple industries. The market size for electronic manufacturing services (EMS) reached approximately $500 billion in 2022, with projections indicating a compound annual growth rate of 7.5% through 2028. Within this broader market, the demand for reliable solder joint solutions represents a critical segment, as solder joint failures account for nearly 70% of all electronic assembly failures.

The automotive electronics sector demonstrates particularly strong demand for enhanced solder joint reliability solutions, with the market expected to reach $382 billion by 2026. As vehicles incorporate more sophisticated electronic systems, including advanced driver-assistance systems (ADAS) and autonomous driving capabilities, the consequences of solder joint failures become increasingly severe, potentially affecting safety-critical functions.

Consumer electronics manufacturers are similarly prioritizing solder joint reliability improvements, especially as devices become smaller and more complex. The smartphone market alone, valued at $520 billion, requires increasingly reliable assembly techniques to maintain product quality while reducing form factors and increasing functionality.

Aerospace and defense applications represent another significant market driver, with particularly stringent requirements for solder joint reliability. This sector values solutions addressing conformal coating interactions and moisture-related challenges, as equipment often operates in extreme environmental conditions where traditional assembly methods may prove inadequate.

Medical device manufacturing represents a growing market segment demanding highly reliable electronics assembly, projected to reach $208 billion by 2025. The life-critical nature of many medical devices necessitates exceptional solder joint reliability, with particular emphasis on solutions that maintain integrity through sterilization processes and extended operational lifetimes.

Market research indicates growing customer awareness regarding the specific challenges of conformal coating interactions with solder joints, moisture entrapment issues, and rework limitations. Approximately 65% of electronics manufacturers report experiencing reliability issues related to these specific challenges, creating substantial demand for innovative solutions addressing these concerns.

The industrial Internet of Things (IIoT) market expansion, projected to reach $110 billion by 2025, further amplifies demand for reliable electronics assembly solutions. As connected devices proliferate in industrial environments characterized by vibration, temperature fluctuations, and chemical exposure, the need for robust solder joint solutions becomes increasingly critical to prevent costly system failures and downtime.

The automotive electronics sector demonstrates particularly strong demand for enhanced solder joint reliability solutions, with the market expected to reach $382 billion by 2026. As vehicles incorporate more sophisticated electronic systems, including advanced driver-assistance systems (ADAS) and autonomous driving capabilities, the consequences of solder joint failures become increasingly severe, potentially affecting safety-critical functions.

Consumer electronics manufacturers are similarly prioritizing solder joint reliability improvements, especially as devices become smaller and more complex. The smartphone market alone, valued at $520 billion, requires increasingly reliable assembly techniques to maintain product quality while reducing form factors and increasing functionality.

Aerospace and defense applications represent another significant market driver, with particularly stringent requirements for solder joint reliability. This sector values solutions addressing conformal coating interactions and moisture-related challenges, as equipment often operates in extreme environmental conditions where traditional assembly methods may prove inadequate.

Medical device manufacturing represents a growing market segment demanding highly reliable electronics assembly, projected to reach $208 billion by 2025. The life-critical nature of many medical devices necessitates exceptional solder joint reliability, with particular emphasis on solutions that maintain integrity through sterilization processes and extended operational lifetimes.

Market research indicates growing customer awareness regarding the specific challenges of conformal coating interactions with solder joints, moisture entrapment issues, and rework limitations. Approximately 65% of electronics manufacturers report experiencing reliability issues related to these specific challenges, creating substantial demand for innovative solutions addressing these concerns.

The industrial Internet of Things (IIoT) market expansion, projected to reach $110 billion by 2025, further amplifies demand for reliable electronics assembly solutions. As connected devices proliferate in industrial environments characterized by vibration, temperature fluctuations, and chemical exposure, the need for robust solder joint solutions becomes increasingly critical to prevent costly system failures and downtime.

Current Challenges in Conformal Coating Applications

Conformal coating applications in electronics manufacturing face several significant challenges that impact solder joint reliability and overall product performance. The industry continues to grapple with coating material selection issues, as different environments and applications require specific coating properties. Engineers must balance protection requirements against factors such as thermal cycling resistance, chemical compatibility, and rework potential, often leading to compromised solutions.

Application precision presents another major hurdle. As electronic assemblies become increasingly dense with miniaturized components, achieving consistent coating coverage without creating problematic areas becomes exceedingly difficult. Selective coating processes frequently struggle with boundary definition, resulting in coating material migration into unintended areas or insufficient coverage of critical regions requiring protection.

Moisture entrapment represents one of the most insidious challenges in conformal coating applications. When coating materials are improperly applied or cured, they can create microscopic voids or channels that actually trap moisture rather than repel it. This trapped moisture accelerates corrosion processes and can lead to catastrophic failures in solder joints through various electrochemical mechanisms. The industry lacks standardized methods for detecting these moisture traps before field deployment.

Thermal management complications arise as conformal coatings inherently affect heat dissipation properties of electronic assemblies. Thicker coating layers provide better environmental protection but simultaneously act as thermal insulators, potentially leading to localized hotspots that accelerate solder joint fatigue. This creates a difficult engineering tradeoff between environmental protection and thermal performance.

Rework limitations constitute a significant economic and technical challenge. Once applied, many conformal coatings prove extremely difficult to remove without damaging underlying components or solder joints. This substantially increases repair costs and can render some assemblies effectively unrepairable. Current removal techniques often employ harsh chemicals that may compromise the integrity of solder joints or printed circuit board materials.

Quality control and inspection difficulties persist throughout the industry. Traditional visual inspection methods prove inadequate for detecting subtle coating defects that may lead to reliability issues. Advanced inspection technologies like ultraviolet fluorescence and automated optical inspection systems help but cannot identify all potential failure modes, particularly those related to coating-solder interactions at the microscopic level.

Regulatory compliance adds another layer of complexity as environmental regulations increasingly restrict the use of certain coating materials and solvents. Manufacturers must continuously reformulate products while maintaining performance characteristics, often resulting in unintended consequences for solder joint reliability.

Application precision presents another major hurdle. As electronic assemblies become increasingly dense with miniaturized components, achieving consistent coating coverage without creating problematic areas becomes exceedingly difficult. Selective coating processes frequently struggle with boundary definition, resulting in coating material migration into unintended areas or insufficient coverage of critical regions requiring protection.

Moisture entrapment represents one of the most insidious challenges in conformal coating applications. When coating materials are improperly applied or cured, they can create microscopic voids or channels that actually trap moisture rather than repel it. This trapped moisture accelerates corrosion processes and can lead to catastrophic failures in solder joints through various electrochemical mechanisms. The industry lacks standardized methods for detecting these moisture traps before field deployment.

Thermal management complications arise as conformal coatings inherently affect heat dissipation properties of electronic assemblies. Thicker coating layers provide better environmental protection but simultaneously act as thermal insulators, potentially leading to localized hotspots that accelerate solder joint fatigue. This creates a difficult engineering tradeoff between environmental protection and thermal performance.

Rework limitations constitute a significant economic and technical challenge. Once applied, many conformal coatings prove extremely difficult to remove without damaging underlying components or solder joints. This substantially increases repair costs and can render some assemblies effectively unrepairable. Current removal techniques often employ harsh chemicals that may compromise the integrity of solder joints or printed circuit board materials.

Quality control and inspection difficulties persist throughout the industry. Traditional visual inspection methods prove inadequate for detecting subtle coating defects that may lead to reliability issues. Advanced inspection technologies like ultraviolet fluorescence and automated optical inspection systems help but cannot identify all potential failure modes, particularly those related to coating-solder interactions at the microscopic level.

Regulatory compliance adds another layer of complexity as environmental regulations increasingly restrict the use of certain coating materials and solvents. Manufacturers must continuously reformulate products while maintaining performance characteristics, often resulting in unintended consequences for solder joint reliability.

Current Moisture Management Techniques in PCB Assembly

01 Solder joint composition and structure

The reliability of solder joints is significantly influenced by their composition and structure. Various alloy compositions can be used to enhance mechanical strength and thermal resistance. The microstructure of the solder joint, including grain size and intermetallic compound formation, affects its long-term performance. Proper design of the joint structure, including thickness and geometry, can distribute stress more effectively and improve reliability under thermal cycling and mechanical stress conditions.- Solder joint composition and structure: The reliability of solder joints is significantly influenced by their composition and structure. Various alloy compositions can be used to enhance mechanical strength and thermal resistance. The microstructure of the solder joint, including grain size and intermetallic compound formation, plays a crucial role in determining long-term reliability. Structural modifications such as reinforced solder joints with specific geometries can improve resistance to thermal cycling and mechanical stress.

- Thermal cycling and fatigue resistance: Solder joints are subject to thermal cycling during operation, which can lead to fatigue and eventual failure. Methods to improve thermal cycling resistance include optimizing the coefficient of thermal expansion matching between components, implementing stress relief designs, and using specialized solder materials with enhanced fatigue resistance. Testing protocols that simulate accelerated thermal cycling conditions help predict the long-term reliability of solder joints under various operating environments.

- Testing and quality assessment methods: Various testing methodologies are employed to assess solder joint reliability. These include non-destructive techniques such as X-ray inspection, acoustic microscopy, and electrical resistance monitoring. Destructive testing methods like cross-sectioning and pull/shear strength tests provide additional data on joint integrity. Advanced analytical techniques help identify failure mechanisms and predict service life. Statistical models and machine learning approaches are increasingly used to analyze test data and improve reliability predictions.

- Environmental factors affecting reliability: Environmental conditions significantly impact solder joint reliability. Humidity, temperature fluctuations, vibration, and corrosive atmospheres can accelerate degradation. Protective coatings and encapsulation materials are used to shield solder joints from environmental stressors. The presence of contaminants during the soldering process can lead to void formation and reduced reliability. Proper cleaning procedures and controlled manufacturing environments help mitigate these risks and extend the operational life of solder joints.

- Advanced manufacturing techniques: Innovative manufacturing processes can enhance solder joint reliability. Precise temperature control during reflow soldering, optimized cooling rates, and specialized flux formulations contribute to improved joint quality. Laser soldering and selective soldering techniques allow for better control of heat distribution, reducing thermal stress on sensitive components. Automated optical inspection systems integrated into production lines enable real-time quality monitoring and process adjustment, resulting in more consistent and reliable solder joints.

02 Testing and evaluation methods

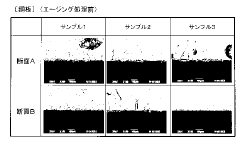

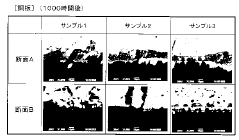

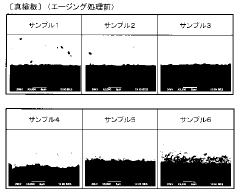

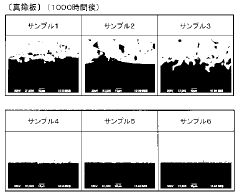

Various testing methodologies are employed to evaluate solder joint reliability. These include thermal cycling tests, drop tests, vibration tests, and accelerated aging tests that simulate real-world conditions. Advanced analytical techniques such as X-ray inspection, scanning electron microscopy, and acoustic microscopy help identify defects and failure mechanisms. Computational models and simulation tools can predict solder joint behavior under different stress conditions, enabling reliability assessment before physical implementation.Expand Specific Solutions03 Thermal management techniques

Thermal management is crucial for solder joint reliability as temperature fluctuations cause expansion and contraction that stress the joints. Techniques include using materials with matched coefficients of thermal expansion, incorporating thermal interface materials, designing effective heat dissipation paths, and implementing thermal barriers. Controlled heating and cooling profiles during manufacturing and operation can minimize thermal stress and extend solder joint lifespan.Expand Specific Solutions04 Manufacturing process optimization

The manufacturing process significantly impacts solder joint reliability. Optimized reflow profiles with controlled heating and cooling rates prevent defects like voids and cold joints. Surface preparation techniques, including proper cleaning and application of flux, improve wetting and bonding. Precise component placement and alignment prevent stress concentration. Post-soldering treatments such as annealing can enhance microstructural stability and joint strength.Expand Specific Solutions05 Environmental protection and reliability enhancement

Environmental factors significantly affect solder joint reliability. Protective coatings and encapsulants shield joints from moisture, contaminants, and oxidation. Conformal coatings provide barrier protection against environmental stresses. Underfill materials distribute mechanical stress and protect against thermal cycling damage. Design considerations for harsh environment applications include selecting appropriate solder alloys and protective measures based on specific environmental challenges such as high humidity, temperature extremes, or corrosive atmospheres.Expand Specific Solutions

Key Industry Players in Conformal Coating Solutions

The solder joint reliability market is currently in a growth phase, with increasing demand driven by electronics miniaturization and harsh environment applications. The global market size is expanding steadily as industries adopt more sophisticated electronic systems requiring higher reliability standards. Technologically, the field shows moderate maturity with ongoing innovation in conformal coating interactions, moisture management, and rework processes. Leading players like Senju Metal Industry, Nihon Superior, and DUKSAN HI METAL are advancing specialized solder materials, while Panasonic, Texas Instruments, and Samsung SDI focus on application-specific reliability solutions. Research institutions such as Beihang University collaborate with industrial partners like Bosch and TSMC to address emerging challenges in moisture trapping and coating compatibility, particularly for automotive and aerospace applications.

Senju Metal Industry Co., Ltd.

Technical Solution: Senju Metal Industry has pioneered innovative approaches to solder joint reliability with specific focus on conformal coating compatibility. Their technology centers on specialized lead-free solder alloys with optimized surface tension properties that minimize flux residue spreading, a common cause of coating adhesion failures. Senju's M705-GRN series incorporates proprietary flux chemistry that leaves minimal ionic residues after reflow, significantly reducing the risk of electrochemical migration under conformal coatings. Their research has demonstrated that controlling the microstructure of the intermetallic compounds at the solder interface can improve resistance to moisture-induced degradation by up to 40% compared to conventional alloys. For addressing moisture traps, Senju has developed a two-stage reflow profile that effectively removes entrapped moisture before coating application. Their rework solution includes specially formulated low-temperature alloys that minimize thermal stress during repair operations, allowing up to four rework cycles while maintaining joint integrity. The company's comprehensive approach also includes post-soldering cleaning protocols specifically designed to prepare surfaces for optimal coating adhesion.

Strengths: Advanced lead-free alloys with superior moisture resistance and minimal ionic residue generation. Their solutions allow for multiple rework cycles without compromising reliability. Weaknesses: Specialized alloys may come at premium pricing, and the required process controls for optimal performance may be challenging to implement in high-volume manufacturing environments.

Robert Bosch GmbH

Technical Solution: Robert Bosch has developed a comprehensive approach to solder joint reliability focusing on automotive and industrial applications where harsh environments demand exceptional performance. Their technology integrates material science and process engineering to address conformal coating interactions. Bosch's approach begins with specialized flux formulations that leave minimal residues compatible with their proprietary coating systems. Their research has identified optimal surface energy parameters that prevent coating delamination while maintaining moisture resistance. Bosch employs a multi-layer coating strategy where the first layer is specifically designed to interact with any remaining flux residues, while subsequent layers provide environmental protection. For moisture trap prevention, they've developed vacuum-assisted coating processes that eliminate air pockets around complex solder joint geometries. Their data shows this reduces moisture-related failures by approximately 65% in high-humidity testing. Regarding rework limits, Bosch has established precise thermal profiles that maintain the mechanical integrity of the board and components through multiple rework cycles. Their process includes controlled local heating techniques that limit thermal exposure to adjacent components, allowing up to three rework cycles while maintaining reliability standards for automotive-grade electronics.

Strengths: Highly engineered solutions specifically designed for harsh environment applications with proven field reliability. Their vacuum-assisted coating process effectively eliminates moisture traps in complex geometries. Weaknesses: Solutions may be overengineered for consumer electronics applications, potentially increasing costs. Their approach often requires specialized equipment that may not be accessible to smaller manufacturers.

Critical Patents in Solder Joint Protection Methods

Solder joint reliability in microelectronic packaging

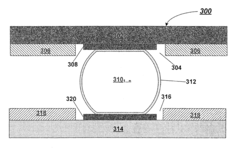

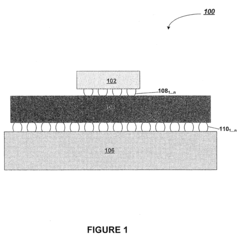

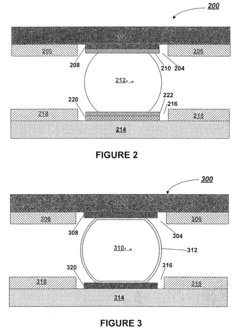

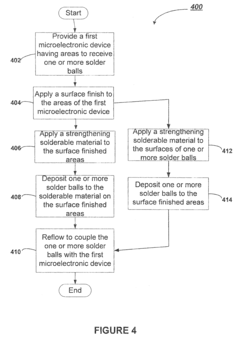

PatentActiveUS8436470B2

Innovation

- Local strengthening of solder joints by applying a solder material containing copper (Cu) or nickel (Ni) at the interface between microelectronic devices and solder balls, reducing the thickness of defect-rich layers and intermetallic compounds that weaken the joints, while allowing the use of traditional bulk solder alloys.

Joining structure

PatentInactiveJP2012020331A

Innovation

- Prevention of direct contact between copper material and Sn-Zn based lead-free solder alloy by forming an intermetallic compound at the solder joining interface to improve joining characteristics.

- Addition of elements with antioxidant effects (such as Mn) to the Sn-Zn based lead-free solder alloy to suppress oxidation of the solder surface.

- Structure design that prevents dissimilar metal contact corrosion among the constituting metals of the Sn-Zn based lead-free solder alloy and the joined material.

Environmental Impact of Conformal Coating Materials

The environmental impact of conformal coating materials has become increasingly significant as electronic manufacturing faces stricter regulatory requirements and growing sustainability concerns. Traditional conformal coatings often contain volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that contribute to air pollution and pose health risks to workers during application and curing processes. Solvent-based acrylic and polyurethane coatings, while effective for solder joint protection, typically release substantial VOCs during evaporation phases.

Recent environmental regulations, including RoHS, REACH, and various regional clean air acts, have accelerated the development of eco-friendly alternatives. Water-based conformal coatings have emerged as lower-VOC options, though they often present challenges regarding moisture trapping around solder joints, potentially compromising reliability through increased corrosion risk and reduced thermal cycling performance.

UV-curable conformal coatings represent another environmentally conscious alternative, offering near-zero VOC emissions and reduced energy consumption during curing. However, their interaction with solder joints differs from traditional coatings, sometimes creating higher mechanical stress during thermal cycling due to their rigid nature after curing.

Life cycle assessment (LCA) studies indicate that while eco-friendly coatings may have lower environmental impact during application, their durability and rework characteristics can affect overall sustainability. Less durable coatings require more frequent replacement, generating additional electronic waste. Furthermore, many environmentally friendly formulations present significant challenges during rework processes, often requiring stronger solvents or mechanical removal methods that may damage solder joints.

Biodegradable conformal coating materials represent the newest frontier, incorporating bio-based polymers that reduce dependence on petrochemicals. Early testing shows promising results for environmental metrics but raises questions about long-term reliability protection for solder joints, particularly in high-humidity environments where moisture interaction becomes critical.

Waste management considerations also factor into environmental impact assessments. Coating removal during rework generates hazardous waste that requires specialized disposal procedures. Newer coating technologies designed with end-of-life considerations incorporate chemistries that break down more completely during recycling processes, reducing contamination of recovered metals from solder joints.

The electronics industry continues to balance environmental responsibility with technical performance requirements. The ideal conformal coating would offer robust protection for solder joints while minimizing environmental impact throughout its lifecycle—from raw material sourcing through application, service life, and eventual disposal or recycling.

Recent environmental regulations, including RoHS, REACH, and various regional clean air acts, have accelerated the development of eco-friendly alternatives. Water-based conformal coatings have emerged as lower-VOC options, though they often present challenges regarding moisture trapping around solder joints, potentially compromising reliability through increased corrosion risk and reduced thermal cycling performance.

UV-curable conformal coatings represent another environmentally conscious alternative, offering near-zero VOC emissions and reduced energy consumption during curing. However, their interaction with solder joints differs from traditional coatings, sometimes creating higher mechanical stress during thermal cycling due to their rigid nature after curing.

Life cycle assessment (LCA) studies indicate that while eco-friendly coatings may have lower environmental impact during application, their durability and rework characteristics can affect overall sustainability. Less durable coatings require more frequent replacement, generating additional electronic waste. Furthermore, many environmentally friendly formulations present significant challenges during rework processes, often requiring stronger solvents or mechanical removal methods that may damage solder joints.

Biodegradable conformal coating materials represent the newest frontier, incorporating bio-based polymers that reduce dependence on petrochemicals. Early testing shows promising results for environmental metrics but raises questions about long-term reliability protection for solder joints, particularly in high-humidity environments where moisture interaction becomes critical.

Waste management considerations also factor into environmental impact assessments. Coating removal during rework generates hazardous waste that requires specialized disposal procedures. Newer coating technologies designed with end-of-life considerations incorporate chemistries that break down more completely during recycling processes, reducing contamination of recovered metals from solder joints.

The electronics industry continues to balance environmental responsibility with technical performance requirements. The ideal conformal coating would offer robust protection for solder joints while minimizing environmental impact throughout its lifecycle—from raw material sourcing through application, service life, and eventual disposal or recycling.

Reliability Testing Standards and Certification Requirements

Reliability testing standards and certification requirements play a crucial role in ensuring solder joint reliability, particularly when considering conformal coating interactions, moisture traps, and rework limits. The electronics industry has established comprehensive frameworks to validate the performance and durability of electronic assemblies under various environmental conditions.

IPC-CC-830 serves as the primary standard for qualifying conformal coatings, detailing specific testing methodologies to evaluate coating performance characteristics including moisture resistance, chemical resistance, and thermal shock resilience. This standard provides essential guidelines for manufacturers to ensure their conformal coating applications meet industry requirements for protecting solder joints from environmental stressors.

JEDEC standards, particularly JESD22-A104 and JESD22-A101, outline temperature cycling and humidity testing protocols that are instrumental in assessing how solder joints perform when subjected to thermal stress and moisture exposure. These standards define precise testing parameters including temperature ranges, ramp rates, and dwell times that simulate real-world operating conditions.

IPC-9701 specifically addresses the performance test methods and qualification requirements for surface mount solder attachments. This standard provides detailed procedures for reliability testing of solder joints, including guidelines for evaluating the impact of conformal coatings on joint integrity and the effects of moisture entrapment.

The IEC 60068 series encompasses environmental testing procedures for electronic equipment, with specific sections dedicated to temperature cycling, humidity, and combined environmental stresses. These standards are particularly relevant when evaluating how conformal coatings interact with solder joints under varying environmental conditions.

For military and aerospace applications, MIL-STD-810 defines environmental test methods that are more rigorous than commercial standards. These include specific protocols for evaluating conformal coating performance in extreme environments and assessing the reliability of reworked solder joints.

UL 746E certification requirements focus on the industrial laminate and coating materials used in electronic devices, providing guidelines for testing the dielectric properties and flame resistance of conformal coatings. This certification is essential for ensuring that coatings maintain their protective properties without compromising solder joint reliability.

The J-STD-001 standard specifically addresses requirements for soldered electrical and electronic assemblies, including sections on rework limitations and acceptance criteria. This standard provides critical guidance on the number of rework cycles permitted before solder joint reliability is compromised, particularly when conformal coatings are present.

IPC-CC-830 serves as the primary standard for qualifying conformal coatings, detailing specific testing methodologies to evaluate coating performance characteristics including moisture resistance, chemical resistance, and thermal shock resilience. This standard provides essential guidelines for manufacturers to ensure their conformal coating applications meet industry requirements for protecting solder joints from environmental stressors.

JEDEC standards, particularly JESD22-A104 and JESD22-A101, outline temperature cycling and humidity testing protocols that are instrumental in assessing how solder joints perform when subjected to thermal stress and moisture exposure. These standards define precise testing parameters including temperature ranges, ramp rates, and dwell times that simulate real-world operating conditions.

IPC-9701 specifically addresses the performance test methods and qualification requirements for surface mount solder attachments. This standard provides detailed procedures for reliability testing of solder joints, including guidelines for evaluating the impact of conformal coatings on joint integrity and the effects of moisture entrapment.

The IEC 60068 series encompasses environmental testing procedures for electronic equipment, with specific sections dedicated to temperature cycling, humidity, and combined environmental stresses. These standards are particularly relevant when evaluating how conformal coatings interact with solder joints under varying environmental conditions.

For military and aerospace applications, MIL-STD-810 defines environmental test methods that are more rigorous than commercial standards. These include specific protocols for evaluating conformal coating performance in extreme environments and assessing the reliability of reworked solder joints.

UL 746E certification requirements focus on the industrial laminate and coating materials used in electronic devices, providing guidelines for testing the dielectric properties and flame resistance of conformal coatings. This certification is essential for ensuring that coatings maintain their protective properties without compromising solder joint reliability.

The J-STD-001 standard specifically addresses requirements for soldered electrical and electronic assemblies, including sections on rework limitations and acceptance criteria. This standard provides critical guidance on the number of rework cycles permitted before solder joint reliability is compromised, particularly when conformal coatings are present.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!