Solder Joint Reliability: SAC Alloy Selection, Ag/Cu Content And IMC Brittleness

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SAC Alloy Evolution and Reliability Objectives

Solder alloys have undergone significant evolution since the transition from traditional tin-lead (SnPb) solders to lead-free alternatives, primarily driven by environmental regulations such as the European Union's Restriction of Hazardous Substances (RoHS) directive implemented in 2006. Among lead-free alternatives, tin-silver-copper (SAC) alloys have emerged as the industry standard, with SAC305 (Sn-3.0Ag-0.5Cu) being widely adopted across electronics manufacturing sectors.

The historical development of SAC alloys reveals a continuous refinement process aimed at balancing mechanical properties, thermal performance, and cost considerations. Initial formulations focused primarily on replicating the melting characteristics of SnPb solders, but subsequent generations have increasingly prioritized reliability under diverse operating conditions. This evolution reflects the growing complexity of electronic devices and their deployment in increasingly demanding environments.

Current reliability objectives for SAC alloys center on addressing several critical performance parameters. Thermal cycling resistance has become paramount as electronic devices face wider temperature fluctuations, particularly in automotive and aerospace applications where temperature ranges can span from -40°C to 150°C. Mechanical shock and drop resistance have gained importance with the proliferation of portable electronics, where impact events represent a primary failure mode.

Creep resistance at elevated temperatures presents another significant reliability challenge, particularly as miniaturization trends increase power density and operating temperatures in modern electronics. The formation and growth characteristics of intermetallic compounds (IMCs) at the solder-substrate interface critically influence long-term reliability, with excessive IMC growth often leading to brittle fracture points.

Recent research has focused on optimizing silver and copper content within SAC alloys to achieve an optimal balance of properties. Higher silver content (3-4%) typically improves thermal fatigue resistance but increases both cost and brittleness. Lower silver formulations (≤1%) offer enhanced mechanical shock resistance and cost advantages but may sacrifice thermal cycling performance. Copper content modulation primarily affects melting temperature and IMC formation dynamics.

The electronics industry increasingly demands alloys tailored to specific application requirements rather than one-size-fits-all solutions. This has led to the development of specialized SAC variants incorporating dopants such as nickel, bismuth, antimony, and rare earth elements to enhance specific performance attributes. These modifications aim to address the inherent trade-offs between different reliability factors in standard SAC formulations.

Future reliability objectives will likely focus on developing alloys capable of withstanding the extreme miniaturization in advanced packaging technologies, higher operating temperatures in power electronics, and the unique stress profiles of flexible and wearable electronics.

The historical development of SAC alloys reveals a continuous refinement process aimed at balancing mechanical properties, thermal performance, and cost considerations. Initial formulations focused primarily on replicating the melting characteristics of SnPb solders, but subsequent generations have increasingly prioritized reliability under diverse operating conditions. This evolution reflects the growing complexity of electronic devices and their deployment in increasingly demanding environments.

Current reliability objectives for SAC alloys center on addressing several critical performance parameters. Thermal cycling resistance has become paramount as electronic devices face wider temperature fluctuations, particularly in automotive and aerospace applications where temperature ranges can span from -40°C to 150°C. Mechanical shock and drop resistance have gained importance with the proliferation of portable electronics, where impact events represent a primary failure mode.

Creep resistance at elevated temperatures presents another significant reliability challenge, particularly as miniaturization trends increase power density and operating temperatures in modern electronics. The formation and growth characteristics of intermetallic compounds (IMCs) at the solder-substrate interface critically influence long-term reliability, with excessive IMC growth often leading to brittle fracture points.

Recent research has focused on optimizing silver and copper content within SAC alloys to achieve an optimal balance of properties. Higher silver content (3-4%) typically improves thermal fatigue resistance but increases both cost and brittleness. Lower silver formulations (≤1%) offer enhanced mechanical shock resistance and cost advantages but may sacrifice thermal cycling performance. Copper content modulation primarily affects melting temperature and IMC formation dynamics.

The electronics industry increasingly demands alloys tailored to specific application requirements rather than one-size-fits-all solutions. This has led to the development of specialized SAC variants incorporating dopants such as nickel, bismuth, antimony, and rare earth elements to enhance specific performance attributes. These modifications aim to address the inherent trade-offs between different reliability factors in standard SAC formulations.

Future reliability objectives will likely focus on developing alloys capable of withstanding the extreme miniaturization in advanced packaging technologies, higher operating temperatures in power electronics, and the unique stress profiles of flexible and wearable electronics.

Market Demand Analysis for High-Reliability Solder Solutions

The global market for high-reliability solder solutions has experienced significant growth in recent years, driven primarily by the increasing complexity and miniaturization of electronic devices. The demand for SAC (Tin-Silver-Copper) alloys has been particularly strong, with the market value reaching $3.2 billion in 2022 and projected to grow at a CAGR of 4.7% through 2028.

The automotive electronics sector represents one of the largest demand segments, accounting for approximately 28% of the high-reliability solder market. This is attributed to the stringent reliability requirements for electronic components in vehicles, which must withstand extreme temperature fluctuations, vibration, and long service life expectations of 10-15 years. The transition to electric vehicles has further accelerated this demand, as EVs contain significantly more electronic components than traditional vehicles.

Aerospace and defense applications constitute another critical market segment, valued at $780 million in 2022. These applications demand solder joints capable of withstanding harsh environmental conditions, including extreme temperatures, radiation, and mechanical stress. The long lifecycle requirements in these sectors, often exceeding 20 years, necessitate solder solutions with exceptional reliability and minimal degradation over time.

Consumer electronics manufacturers are increasingly seeking high-reliability solder solutions as devices become more compact and feature-rich. The trend toward wearable technology and IoT devices has created demand for solder joints that can maintain integrity despite frequent thermal cycling and potential physical impacts. This segment grew by 5.8% in 2022, outpacing the overall market growth.

Regional analysis reveals that Asia-Pacific dominates the market with a 52% share, led by manufacturing hubs in China, Taiwan, and South Korea. North America follows with 24% market share, driven by aerospace, defense, and medical device manufacturing. Europe accounts for 19% of the market, with particular strength in automotive electronics and industrial applications.

Industry surveys indicate that 73% of electronics manufacturers consider solder joint reliability as a critical factor in their component selection process. Furthermore, 62% of manufacturers report willingness to pay premium prices for solder solutions that demonstrate superior reliability characteristics and reduced intermetallic compound (IMC) brittleness.

The market is also witnessing a shift toward lead-free solder solutions with optimized Ag/Cu content ratios that balance cost considerations with performance requirements. SAC305 (3.0% Ag, 0.5% Cu) remains the industry standard, but specialized formulations with modified silver and copper content are gaining traction in applications with specific thermal cycling or mechanical shock requirements.

The automotive electronics sector represents one of the largest demand segments, accounting for approximately 28% of the high-reliability solder market. This is attributed to the stringent reliability requirements for electronic components in vehicles, which must withstand extreme temperature fluctuations, vibration, and long service life expectations of 10-15 years. The transition to electric vehicles has further accelerated this demand, as EVs contain significantly more electronic components than traditional vehicles.

Aerospace and defense applications constitute another critical market segment, valued at $780 million in 2022. These applications demand solder joints capable of withstanding harsh environmental conditions, including extreme temperatures, radiation, and mechanical stress. The long lifecycle requirements in these sectors, often exceeding 20 years, necessitate solder solutions with exceptional reliability and minimal degradation over time.

Consumer electronics manufacturers are increasingly seeking high-reliability solder solutions as devices become more compact and feature-rich. The trend toward wearable technology and IoT devices has created demand for solder joints that can maintain integrity despite frequent thermal cycling and potential physical impacts. This segment grew by 5.8% in 2022, outpacing the overall market growth.

Regional analysis reveals that Asia-Pacific dominates the market with a 52% share, led by manufacturing hubs in China, Taiwan, and South Korea. North America follows with 24% market share, driven by aerospace, defense, and medical device manufacturing. Europe accounts for 19% of the market, with particular strength in automotive electronics and industrial applications.

Industry surveys indicate that 73% of electronics manufacturers consider solder joint reliability as a critical factor in their component selection process. Furthermore, 62% of manufacturers report willingness to pay premium prices for solder solutions that demonstrate superior reliability characteristics and reduced intermetallic compound (IMC) brittleness.

The market is also witnessing a shift toward lead-free solder solutions with optimized Ag/Cu content ratios that balance cost considerations with performance requirements. SAC305 (3.0% Ag, 0.5% Cu) remains the industry standard, but specialized formulations with modified silver and copper content are gaining traction in applications with specific thermal cycling or mechanical shock requirements.

Current Challenges in SAC Alloy Performance

Despite significant advancements in lead-free solder technology, SAC (Tin-Silver-Copper) alloys continue to face several critical performance challenges that impact their reliability in electronic assemblies. The primary concern remains thermal cycling performance, where SAC alloys exhibit inconsistent behavior across different temperature ranges. Under harsh conditions involving extreme temperature fluctuations, these alloys often develop microcracks at the intermetallic compound (IMC) interface, compromising joint integrity over time.

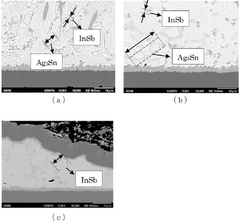

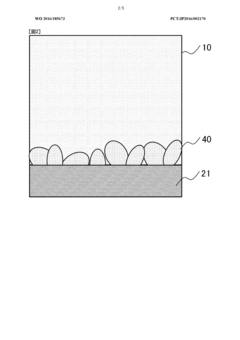

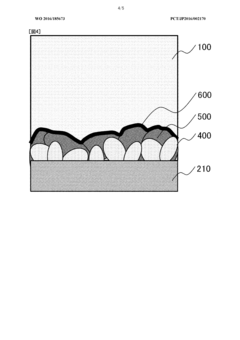

The formation and growth of brittle IMCs represent another significant challenge. The reaction between SAC alloys and substrate metallization produces Cu6Sn5 and Ag3Sn intermetallic compounds that, while initially beneficial for joint strength, become problematic as they thicken during thermal aging. These brittle phases create stress concentration points that serve as crack initiation sites, particularly under mechanical shock or vibration conditions.

Drop test performance remains suboptimal for many SAC formulations, especially those with higher silver content. The inherent brittleness of high-Ag SAC alloys (>3% Ag) makes them vulnerable to failure under impact conditions, limiting their application in portable electronic devices that require enhanced mechanical reliability. This challenge has driven the industry toward lower-Ag compositions, which introduces trade-offs in other performance characteristics.

Whisker growth susceptibility continues to be a concern for SAC alloys, though to a lesser extent than pure tin. The propensity for tin whisker formation under compressive stress, humidity, or electrical bias conditions presents long-term reliability risks, especially in high-reliability applications where electrical shorts could have catastrophic consequences.

Voiding behavior during the reflow process presents manufacturing challenges, with SAC alloys often exhibiting higher void content compared to traditional lead-based solders. These voids reduce the effective cross-sectional area of solder joints, potentially compromising both electrical and mechanical performance. The void formation mechanism is complex, involving flux chemistry interactions, reflow profiles, and alloy composition variables.

Microstructural stability under elevated operating temperatures remains problematic, with SAC alloys showing accelerated coarsening of the microstructure that leads to mechanical property degradation. This is particularly evident in automotive and industrial applications where components may operate continuously at elevated temperatures, causing premature joint fatigue.

Cost considerations also present challenges, particularly for high-silver content formulations. The significant price volatility of silver has driven manufacturers to seek lower-Ag alternatives, which must be carefully balanced against performance requirements. This economic pressure has fragmented the market with numerous proprietary formulations, complicating standardization efforts and reliability predictions across the industry.

The formation and growth of brittle IMCs represent another significant challenge. The reaction between SAC alloys and substrate metallization produces Cu6Sn5 and Ag3Sn intermetallic compounds that, while initially beneficial for joint strength, become problematic as they thicken during thermal aging. These brittle phases create stress concentration points that serve as crack initiation sites, particularly under mechanical shock or vibration conditions.

Drop test performance remains suboptimal for many SAC formulations, especially those with higher silver content. The inherent brittleness of high-Ag SAC alloys (>3% Ag) makes them vulnerable to failure under impact conditions, limiting their application in portable electronic devices that require enhanced mechanical reliability. This challenge has driven the industry toward lower-Ag compositions, which introduces trade-offs in other performance characteristics.

Whisker growth susceptibility continues to be a concern for SAC alloys, though to a lesser extent than pure tin. The propensity for tin whisker formation under compressive stress, humidity, or electrical bias conditions presents long-term reliability risks, especially in high-reliability applications where electrical shorts could have catastrophic consequences.

Voiding behavior during the reflow process presents manufacturing challenges, with SAC alloys often exhibiting higher void content compared to traditional lead-based solders. These voids reduce the effective cross-sectional area of solder joints, potentially compromising both electrical and mechanical performance. The void formation mechanism is complex, involving flux chemistry interactions, reflow profiles, and alloy composition variables.

Microstructural stability under elevated operating temperatures remains problematic, with SAC alloys showing accelerated coarsening of the microstructure that leads to mechanical property degradation. This is particularly evident in automotive and industrial applications where components may operate continuously at elevated temperatures, causing premature joint fatigue.

Cost considerations also present challenges, particularly for high-silver content formulations. The significant price volatility of silver has driven manufacturers to seek lower-Ag alternatives, which must be carefully balanced against performance requirements. This economic pressure has fragmented the market with numerous proprietary formulations, complicating standardization efforts and reliability predictions across the industry.

Current SAC Composition Optimization Approaches

01 Composition optimization of SAC alloys for improved reliability

Optimizing the composition of SAC (Tin-Silver-Copper) solder alloys can significantly improve their reliability and reduce IMC brittleness. By adjusting the percentages of tin, silver, and copper, or by adding small amounts of other elements such as bismuth, indium, or nickel, the mechanical properties and thermal cycling performance of the solder joints can be enhanced. These modifications can lead to finer grain structures, improved creep resistance, and reduced intermetallic compound growth rates, all contributing to more reliable solder connections in electronic assemblies.- Composition optimization of SAC alloys to improve reliability: Optimizing the composition of Tin-Silver-Copper (SAC) solder alloys can significantly improve their reliability and reduce intermetallic compound (IMC) brittleness. By adjusting the percentages of tin, silver, and copper, or by adding small amounts of other elements such as bismuth, indium, or nickel, the mechanical properties and thermal cycling performance of the solder joints can be enhanced. These modifications can control IMC growth, improve ductility, and increase resistance to thermal fatigue.

- IMC growth control methods for SAC solder joints: Various methods can be employed to control the growth of intermetallic compounds in SAC solder joints, thereby reducing brittleness and improving reliability. These methods include thermal treatment processes, application of specific surface finishes, controlled cooling rates during soldering, and the use of barrier layers. By controlling IMC thickness and morphology, the mechanical integrity of solder joints can be maintained over longer periods, even under thermal cycling and mechanical stress conditions.

- Doping and alloying strategies to reduce IMC brittleness: Adding micro-alloying elements or dopants to SAC solder alloys can effectively reduce IMC brittleness and enhance joint reliability. Elements such as nickel, cobalt, manganese, titanium, or rare earth elements can refine the microstructure of the IMC layer, improve its mechanical properties, and slow down its growth rate. These additives can create more stable interfaces between the solder and substrate, resulting in improved thermal cycling performance and longer service life of electronic assemblies.

- Surface finish impact on SAC solder joint reliability: The type of surface finish used on PCB pads and component terminations significantly affects the formation and growth of IMCs in SAC solder joints. Surface finishes such as ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservative), HASL (Hot Air Solder Leveling), and immersion silver or tin each interact differently with SAC alloys, resulting in varying IMC compositions, thicknesses, and morphologies. Selecting the appropriate surface finish can help control IMC brittleness and improve the overall reliability of solder connections.

- Thermal cycling and aging effects on SAC solder joint reliability: Thermal cycling and aging significantly impact the reliability of SAC solder joints through their effects on IMC growth and properties. During thermal cycling and long-term aging, IMCs continue to grow and change in morphology, potentially increasing brittleness and reducing joint strength. Understanding these effects is crucial for predicting solder joint lifetime and reliability. Various testing methodologies and acceleration factors can be used to evaluate the long-term performance of SAC solder joints under different operating conditions.

02 Intermetallic compound (IMC) formation control techniques

Various techniques can be employed to control the formation and growth of intermetallic compounds in SAC solder joints, thereby reducing brittleness issues. These techniques include thermal profile optimization during soldering, surface finish selection, application of diffusion barriers, and post-soldering heat treatments. Controlling the cooling rate during solidification is particularly important as it affects the IMC morphology and thickness. Thinner and more uniform IMC layers generally result in improved mechanical properties and joint reliability, while excessive IMC growth can lead to brittle fractures at the interface between the solder and substrate.Expand Specific Solutions03 Dopants and micro-alloying elements to enhance SAC reliability

The addition of small amounts of dopants or micro-alloying elements to SAC solder alloys can significantly improve their reliability by modifying the microstructure and IMC characteristics. Elements such as nickel, antimony, manganese, titanium, and rare earth elements have been shown to refine grain structure, strengthen the solder matrix, and inhibit excessive IMC growth. These additives can improve thermal cycling performance, reduce creep deformation, enhance drop test reliability, and mitigate the brittle nature of intermetallic compounds, resulting in more robust solder joints for electronic applications.Expand Specific Solutions04 Surface finish and substrate material effects on IMC formation

The choice of surface finish and substrate material significantly impacts the formation and characteristics of intermetallic compounds in SAC solder joints. Different surface finishes such as ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservative), immersion silver, or immersion tin interact differently with SAC alloys, resulting in varying IMC compositions, morphologies, and growth rates. The substrate material (copper, nickel, etc.) also plays a crucial role in determining the type of IMC formed and its growth behavior. Proper selection of these materials can help control IMC brittleness and improve the overall reliability of solder connections.Expand Specific Solutions05 Thermal aging and cycling effects on SAC solder joint reliability

Thermal aging and cycling have significant impacts on the reliability of SAC solder joints due to their effects on IMC growth and mechanical properties. During thermal aging, IMCs continue to grow at the solder-substrate interface, potentially increasing brittleness and reducing joint strength. Thermal cycling induces repeated expansion and contraction, creating stress at the interface that can lead to crack initiation and propagation, particularly through brittle IMC layers. Understanding these effects is crucial for predicting long-term reliability of SAC solder joints in electronic assemblies, especially for applications subjected to temperature fluctuations or elevated operating temperatures.Expand Specific Solutions

Key Industry Players in Lead-Free Solder Manufacturing

The solder joint reliability market is currently in a growth phase, driven by increasing demand for high-performance electronics across automotive, aerospace, and consumer sectors. The global market for lead-free solder materials is projected to expand significantly, with SAC (Tin-Silver-Copper) alloys dominating due to their superior mechanical properties. Key players like Indium Corporation, Senju Metal, and Nihon Superior are leading innovation in optimizing Ag/Cu content ratios to address intermetallic compound (IMC) brittleness challenges. Companies including Alpha Assembly Solutions and Koki are developing next-generation SAC formulations with micro-alloying elements to enhance thermal cycling performance. The technology is approaching maturity for standard applications, but research continues at institutions like Iowa State University Research Foundation and Hunan University to improve reliability under extreme conditions, particularly focusing on reducing IMC brittleness through controlled solidification processes.

Senju Metal Industry Co., Ltd.

Technical Solution: Senju Metal Industry has developed the M705 and ECO SOLDER series focusing on optimized SAC alloy compositions for enhanced solder joint reliability. Their approach centers on controlling Ag content between 0.3-3.0% and Cu at 0.5-0.7% depending on the specific application requirements. Senju's research has demonstrated that their low-silver formulations (0.3-1.0% Ag) provide superior drop shock resistance while maintaining acceptable thermal cycling performance for consumer electronics. For automotive and industrial applications, their higher silver content alloys (2.5-3.0% Ag) with proprietary dopants show excellent resistance to thermal fatigue. Their technology includes micro-alloying with elements such as nickel, germanium, and indium to control IMC growth and morphology. Senju's extensive reliability testing has shown that their doped SAC alloys exhibit up to 35% reduction in IMC thickness after 1000 hours at 150°C compared to standard SAC305. The company has also developed specialized flux systems that promote formation of more ductile Cu-Sn intermetallics with refined grain structures, reducing the propensity for brittle fracture along IMC interfaces during thermal cycling or mechanical shock events.

Strengths: Wide portfolio of application-specific alloys with proven performance in various electronic assembly scenarios. Their products demonstrate excellent wetting characteristics and controlled IMC formation. Weaknesses: Some of their specialized formulations may require tighter process control parameters, and their premium alloys command higher prices than standard SAC compositions.

The Indium Corporation of America

Technical Solution: Indium Corporation has developed advanced SAC (Tin-Silver-Copper) alloy formulations with optimized Ag/Cu content ratios to address solder joint reliability challenges. Their Durafuse™ LT technology combines a low-melting-point alloy with a high-reliability alloy to create a novel solution that provides both excellent drop shock performance and thermal cycling reliability. The company's research has demonstrated that controlling Ag content between 1.0-3.0% and Cu between 0.5-0.7% creates an optimal balance for various electronic applications. Their proprietary dopant additions to SAC alloys help mitigate the formation of brittle intermetallic compounds (IMCs) at the solder-substrate interface, particularly limiting the growth of Cu6Sn5 and Cu3Sn phases during thermal aging. Indium's materials engineering approach includes nano-particle reinforcement of SAC alloys to improve mechanical properties and reduce IMC brittleness under thermal cycling conditions. Their extensive reliability testing has shown up to 40% improvement in thermal cycling performance compared to standard SAC305 alloys.

Strengths: Industry-leading expertise in specialized alloy formulations with proprietary dopants that effectively control IMC growth. Their materials show superior performance in both high-temperature and drop-shock conditions. Weaknesses: Premium pricing compared to standard SAC alloys, and some formulations may require specific process adjustments in manufacturing environments.

Critical IMC Formation Mechanisms and Control Methods

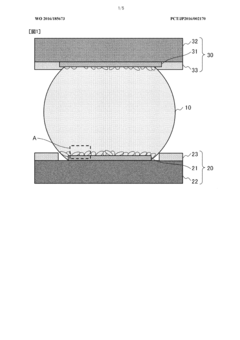

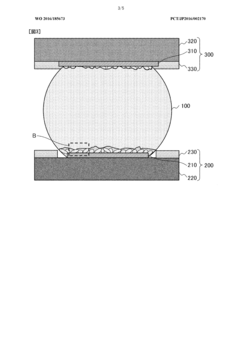

Solder alloy, solder ball, solder preform, solder paste, and solder joint

PatentWO2023054629A1

Innovation

- A solder alloy composition with specific ranges of Ag, Cu, Sb, In, Ni, and optional elements like Co and Bi, optimized to improve wettability and mechanical strength by controlling phase transformations and intermetallic compound formation, which alleviates stress and enhances bonding interface refinement.

Solder alloy

PatentWO2016185673A1

Innovation

- A solder alloy composition of 2.0 to 4.0% Ag, 0.5 to 1.0% Cu, and 0.1 to 0.5% of either calcium (Ca) or manganese (Mn) added to tin (Sn), which improves mechanical strength and elongation while preventing additive element segregation at the interface.

Thermal Cycling Performance Assessment Methods

Thermal cycling testing represents the cornerstone methodology for evaluating solder joint reliability in electronic assemblies. This assessment approach simulates the real-world temperature fluctuations that electronic components experience during operational cycles. The industry has established several standardized thermal cycling test protocols, including JEDEC JESD22-A104, IPC-9701, and MIL-STD-883, each specifying different temperature ranges, dwell times, and ramp rates tailored to specific application environments.

For SAC (Tin-Silver-Copper) alloys, thermal cycling performance assessment typically involves subjecting test vehicles to temperature extremes ranging from -40°C to +125°C, with controlled transition rates between 10-15°C/minute. The number of cycles to failure serves as the primary metric, with statistical analysis methods such as Weibull distribution commonly employed to interpret reliability data and predict failure rates.

Accelerated thermal cycling (ATC) tests are particularly valuable for comparing different SAC alloy compositions. These tests compress time scales by increasing cycling frequency and temperature differentials, allowing researchers to evaluate months or years of operational stress within weeks. When assessing SAC alloys with varying Ag/Cu content, researchers typically monitor changes in electrical resistance, as sudden increases often indicate crack formation or propagation within the solder joint.

Advanced assessment techniques incorporate in-situ monitoring capabilities, including real-time resistance measurement and strain gauging. These approaches provide valuable insights into failure progression mechanisms rather than simply identifying the point of complete failure. Cross-sectional analysis using scanning electron microscopy (SEM) complements these methods by enabling detailed examination of intermetallic compound (IMC) layer growth and crack propagation patterns after thermal cycling.

Finite element modeling (FEM) has emerged as a powerful complementary tool to physical testing. These computational models simulate thermal-mechanical stresses within solder joints during temperature cycling, allowing engineers to predict failure modes and optimize designs before physical prototyping. For SAC alloys, constitutive models incorporating creep behavior, plastic deformation, and microstructural evolution have demonstrated increasing accuracy in predicting thermal cycling performance.

The correlation between thermal cycling results and field reliability remains a critical consideration. Acceleration factors must be carefully calculated to translate accelerated test results into real-world reliability predictions. For SAC alloys, these factors typically account for the activation energy of failure mechanisms, which varies significantly based on silver and copper content percentages.

For SAC (Tin-Silver-Copper) alloys, thermal cycling performance assessment typically involves subjecting test vehicles to temperature extremes ranging from -40°C to +125°C, with controlled transition rates between 10-15°C/minute. The number of cycles to failure serves as the primary metric, with statistical analysis methods such as Weibull distribution commonly employed to interpret reliability data and predict failure rates.

Accelerated thermal cycling (ATC) tests are particularly valuable for comparing different SAC alloy compositions. These tests compress time scales by increasing cycling frequency and temperature differentials, allowing researchers to evaluate months or years of operational stress within weeks. When assessing SAC alloys with varying Ag/Cu content, researchers typically monitor changes in electrical resistance, as sudden increases often indicate crack formation or propagation within the solder joint.

Advanced assessment techniques incorporate in-situ monitoring capabilities, including real-time resistance measurement and strain gauging. These approaches provide valuable insights into failure progression mechanisms rather than simply identifying the point of complete failure. Cross-sectional analysis using scanning electron microscopy (SEM) complements these methods by enabling detailed examination of intermetallic compound (IMC) layer growth and crack propagation patterns after thermal cycling.

Finite element modeling (FEM) has emerged as a powerful complementary tool to physical testing. These computational models simulate thermal-mechanical stresses within solder joints during temperature cycling, allowing engineers to predict failure modes and optimize designs before physical prototyping. For SAC alloys, constitutive models incorporating creep behavior, plastic deformation, and microstructural evolution have demonstrated increasing accuracy in predicting thermal cycling performance.

The correlation between thermal cycling results and field reliability remains a critical consideration. Acceleration factors must be carefully calculated to translate accelerated test results into real-world reliability predictions. For SAC alloys, these factors typically account for the activation energy of failure mechanisms, which varies significantly based on silver and copper content percentages.

Environmental Impact of SAC Alloy Compositions

The environmental impact of SAC (Tin-Silver-Copper) alloy compositions has become increasingly significant as electronics manufacturing faces greater scrutiny regarding sustainability. Different SAC formulations, varying in silver and copper content, present distinct environmental footprints throughout their lifecycle from raw material extraction to end-of-life disposal.

Mining activities for silver and copper contribute significantly to the environmental burden of SAC alloys. Higher silver content alloys (SAC305, SAC405) require more extensive mining operations, resulting in greater land disturbance, water usage, and energy consumption. Studies indicate that reducing silver content by just 1% can decrease the associated carbon footprint by approximately 8-12% during the extraction phase.

Manufacturing processes for SAC alloys with higher metal content typically demand higher melting temperatures, consequently increasing energy consumption. SAC305 (3% Ag, 0.5% Cu) requires approximately 217-220°C for reflow, while lower silver content alternatives like SAC0307 (0.3% Ag, 0.7% Cu) can function at slightly lower temperatures, potentially reducing energy usage by 3-5% in high-volume manufacturing environments.

The intermetallic compound (IMC) formation characteristics of different SAC compositions also influence product lifespan and consequently environmental impact. Alloys with optimized Ag/Cu ratios that form more stable IMCs contribute to longer-lasting solder joints, reducing the frequency of electronic waste generation. Research indicates that properly balanced SAC alloys can extend product lifespans by 15-30% compared to poorly formulated alternatives.

Recycling considerations vary significantly across SAC formulations. Higher silver content alloys present greater economic incentives for recycling but may require more complex separation processes due to the formation of brittle IMCs during thermal aging. The recovery efficiency for silver from SAC305 averages 87-92%, while copper recovery rates typically range from 60-75%, depending on recycling technology employed.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of solder materials. The European Union's RoHS and REACH regulations, along with similar initiatives in Asia and North America, are driving manufacturers toward SAC compositions with reduced environmental impacts. This regulatory landscape has accelerated research into SAC alloys with lower precious metal content while maintaining reliability standards.

Life cycle assessment (LCA) studies comparing various SAC formulations reveal that optimizing silver content presents the most significant opportunity for environmental improvement. A comprehensive LCA conducted across multiple electronics manufacturing facilities demonstrated that transitioning from SAC305 to SAC0307 could reduce the overall carbon footprint by 7-11% while maintaining acceptable reliability metrics in many consumer electronics applications.

Mining activities for silver and copper contribute significantly to the environmental burden of SAC alloys. Higher silver content alloys (SAC305, SAC405) require more extensive mining operations, resulting in greater land disturbance, water usage, and energy consumption. Studies indicate that reducing silver content by just 1% can decrease the associated carbon footprint by approximately 8-12% during the extraction phase.

Manufacturing processes for SAC alloys with higher metal content typically demand higher melting temperatures, consequently increasing energy consumption. SAC305 (3% Ag, 0.5% Cu) requires approximately 217-220°C for reflow, while lower silver content alternatives like SAC0307 (0.3% Ag, 0.7% Cu) can function at slightly lower temperatures, potentially reducing energy usage by 3-5% in high-volume manufacturing environments.

The intermetallic compound (IMC) formation characteristics of different SAC compositions also influence product lifespan and consequently environmental impact. Alloys with optimized Ag/Cu ratios that form more stable IMCs contribute to longer-lasting solder joints, reducing the frequency of electronic waste generation. Research indicates that properly balanced SAC alloys can extend product lifespans by 15-30% compared to poorly formulated alternatives.

Recycling considerations vary significantly across SAC formulations. Higher silver content alloys present greater economic incentives for recycling but may require more complex separation processes due to the formation of brittle IMCs during thermal aging. The recovery efficiency for silver from SAC305 averages 87-92%, while copper recovery rates typically range from 60-75%, depending on recycling technology employed.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of solder materials. The European Union's RoHS and REACH regulations, along with similar initiatives in Asia and North America, are driving manufacturers toward SAC compositions with reduced environmental impacts. This regulatory landscape has accelerated research into SAC alloys with lower precious metal content while maintaining reliability standards.

Life cycle assessment (LCA) studies comparing various SAC formulations reveal that optimizing silver content presents the most significant opportunity for environmental improvement. A comprehensive LCA conducted across multiple electronics manufacturing facilities demonstrated that transitioning from SAC305 to SAC0307 could reduce the overall carbon footprint by 7-11% while maintaining acceptable reliability metrics in many consumer electronics applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!