How to Achieve Color Accuracy with QLED Displays?

QLED Color Accuracy Background and Objectives

Quantum Dot Light Emitting Diode (QLED) technology has emerged as a significant advancement in display technology, offering enhanced color accuracy and brightness compared to traditional LED displays. The pursuit of color accuracy in QLED displays is driven by the increasing demand for high-quality visual experiences across various applications, from consumer electronics to professional imaging systems.

The development of QLED technology can be traced back to the early 2000s, with significant progress made in the last decade. The core principle behind QLED displays is the use of quantum dots, nanoscale semiconductor particles that emit light of specific wavelengths when excited by an electric current. This property allows for precise control over the colors produced, potentially leading to more accurate and vibrant displays.

As the technology has evolved, the focus has shifted from merely achieving brighter and more colorful displays to ensuring that the colors reproduced are as close as possible to real-world colors. This shift aligns with the growing emphasis on color fidelity in industries such as film production, photography, and graphic design, where accurate color representation is crucial.

The primary objective in achieving color accuracy with QLED displays is to overcome the limitations of traditional display technologies. These limitations include color gamut restrictions, inconsistent color reproduction across different viewing angles, and degradation of color accuracy over time. By addressing these challenges, QLED technology aims to provide displays that can reproduce a wider range of colors with greater precision and consistency.

Another key goal is to improve the energy efficiency of displays while maintaining high color accuracy. QLED technology has the potential to offer superior color performance without significantly increasing power consumption, making it an attractive option for both large-scale displays and portable devices.

The pursuit of color accuracy in QLED displays also involves developing standardized methods for measuring and calibrating color performance. This includes creating industry-wide benchmarks and testing procedures to ensure consistency across different manufacturers and display models.

As the technology continues to advance, researchers and engineers are exploring ways to further enhance the color-rendering capabilities of QLED displays. This includes investigating new quantum dot materials, improving manufacturing processes, and developing more sophisticated color management systems. The ultimate aim is to create displays that can faithfully reproduce the full spectrum of visible colors, providing viewers with an unparalleled visual experience that closely mimics real-world color perception.

Market Demand for High-Fidelity QLED Displays

The demand for high-fidelity QLED displays has been steadily increasing in recent years, driven by the growing consumer appetite for superior visual experiences across various applications. This trend is particularly evident in the premium television market, where QLED technology has gained significant traction due to its ability to deliver vibrant colors, deep blacks, and high contrast ratios.

In the consumer electronics sector, there is a notable shift towards larger screen sizes and higher resolutions, with 4K and 8K displays becoming increasingly popular. This trend has created a substantial market for QLED displays, as they can effectively showcase the enhanced detail and color depth of high-resolution content. The gaming industry has also emerged as a key driver for high-fidelity QLED displays, with gamers seeking immersive experiences that require accurate color reproduction and fast response times.

The professional market segment, including graphic design, video editing, and digital content creation, has shown a growing demand for color-accurate displays. QLED technology's ability to reproduce a wide color gamut with high accuracy makes it an attractive option for professionals who require precise color representation in their work.

The automotive industry is another sector where the demand for high-fidelity displays is on the rise. As vehicles become more technologically advanced, there is an increasing need for high-quality displays for infotainment systems, digital dashboards, and heads-up displays. QLED technology's ability to maintain color accuracy and visibility in varying lighting conditions makes it well-suited for automotive applications.

Market research indicates that the global QLED display market is expected to grow significantly in the coming years. This growth is attributed to factors such as increasing disposable income, technological advancements, and the expanding application areas for QLED displays. The Asia-Pacific region, particularly countries like China and South Korea, is anticipated to be a major contributor to this market growth due to the presence of key manufacturers and a large consumer base.

Despite the positive market outlook, there are challenges that need to be addressed to fully capitalize on the demand for high-fidelity QLED displays. These include reducing production costs to make the technology more accessible to a broader consumer base and improving energy efficiency to meet increasingly stringent environmental regulations.

In conclusion, the market demand for high-fidelity QLED displays is robust and diverse, spanning multiple industries and applications. As technology continues to advance and consumer expectations for visual quality rise, the importance of achieving and maintaining color accuracy in QLED displays becomes increasingly critical for manufacturers to remain competitive in this growing market.

Current QLED Color Accuracy Challenges

QLED displays, while offering significant advancements in color reproduction, still face several challenges in achieving optimal color accuracy. One of the primary issues is color shift, which occurs when viewing angles change. As viewers move off-axis, the perceived colors can alter significantly, leading to inconsistent experiences across different viewing positions. This phenomenon is particularly noticeable in large-format displays or in multi-viewer scenarios.

Another challenge lies in the quantum dot layer's sensitivity to temperature fluctuations. As QLED displays operate, heat generation can affect the quantum dots' emission properties, potentially leading to color drift over time. This thermal instability can result in inconsistent color reproduction across the display panel and may require sophisticated thermal management systems to mitigate.

Color volume and gamut mapping present additional hurdles. While QLEDs can produce a wide color gamut, accurately mapping content to this expanded color space without oversaturation or loss of detail remains complex. Balancing the vibrant colors QLEDs can produce with the need for natural, lifelike representation is an ongoing challenge for display engineers and content creators alike.

The pursuit of perfect black levels also impacts color accuracy. Although QLEDs offer improved contrast ratios compared to traditional LED-LCD displays, they still struggle to achieve the deep blacks of OLED technology. This limitation can affect the overall perceived color accuracy, especially in high-contrast scenes or dark environments.

Calibration and uniformity across the display panel pose significant challenges as well. Ensuring consistent color reproduction from edge to edge on large QLED panels requires precise manufacturing processes and advanced calibration techniques. Even minor variations in the quantum dot layer or backlight uniformity can lead to noticeable color inconsistencies across the display.

Lastly, the interaction between the quantum dot layer and the color filters used in QLED displays can introduce complexities in color management. Optimizing this interaction to achieve both wide color gamut and accurate color reproduction demands sophisticated algorithms and fine-tuning of display components. As QLED technology continues to evolve, addressing these challenges remains crucial for delivering displays that can faithfully reproduce colors across a wide range of content and viewing conditions.

Existing QLED Color Calibration Techniques

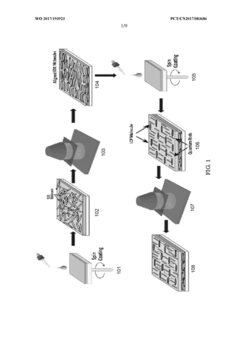

01 Quantum dot enhancement for color accuracy

QLED displays utilize quantum dots to enhance color accuracy. These nanocrystals emit precise wavelengths of light when excited, resulting in more vibrant and accurate colors. The size and composition of quantum dots can be tailored to produce specific colors, allowing for a wider color gamut and improved color reproduction in QLED displays.- Quantum dot enhancement for color accuracy: QLED displays utilize quantum dots to enhance color accuracy. These nanocrystals emit precise wavelengths of light when excited, resulting in more vibrant and accurate colors. The size and composition of quantum dots can be tailored to produce specific colors, allowing for a wider color gamut and improved color reproduction in QLED displays.

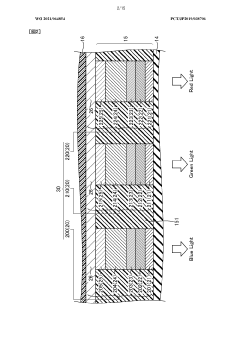

- Color filter optimization: Improving color accuracy in QLED displays involves optimizing color filters. Advanced color filter designs and materials are used to selectively transmit specific wavelengths of light, enhancing color purity and reducing color crosstalk. This results in more accurate color representation and improved overall display performance.

- Backlight and local dimming technology: QLED displays employ advanced backlight and local dimming technologies to improve color accuracy. Precise control of LED backlights and implementation of local dimming algorithms allow for better contrast ratios and more accurate color reproduction across different areas of the display, resulting in enhanced overall image quality.

- Color calibration and compensation techniques: To achieve high color accuracy, QLED displays incorporate sophisticated color calibration and compensation techniques. These methods involve measuring and adjusting color output, compensating for variations in quantum dot performance, and implementing color management systems to ensure consistent and accurate color reproduction across different content and viewing conditions.

- Quantum dot material improvements: Ongoing research focuses on improving quantum dot materials to enhance color accuracy in QLED displays. This includes developing new quantum dot compositions, improving stability and efficiency, and exploring novel synthesis methods. These advancements aim to produce quantum dots with more precise emission spectra and better long-term performance, ultimately leading to improved color accuracy in QLED displays.

02 Color filter optimization

Improving color accuracy in QLED displays involves optimizing color filters. Advanced color filter designs and materials are used to selectively transmit specific wavelengths of light, enhancing color purity and reducing color crosstalk. This results in more accurate color representation and improved overall display performance.Expand Specific Solutions03 Backlight and local dimming techniques

QLED displays employ sophisticated backlight and local dimming techniques to improve color accuracy. By precisely controlling the intensity and distribution of light across the display, these methods enhance contrast ratios and color reproduction. Advanced algorithms are used to optimize backlight control, resulting in more accurate and vibrant colors.Expand Specific Solutions04 Color calibration and compensation algorithms

To achieve high color accuracy, QLED displays utilize advanced color calibration and compensation algorithms. These algorithms analyze and adjust color output in real-time, compensating for variations in manufacturing processes and environmental factors. This ensures consistent and accurate color reproduction across different display units and viewing conditions.Expand Specific Solutions05 Quantum dot film structure optimization

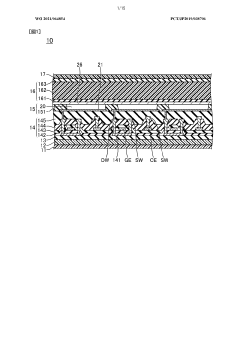

The structure and composition of quantum dot films play a crucial role in color accuracy. Optimizing the quantum dot film structure, including its thickness, density, and arrangement, can significantly improve color purity and accuracy. Advanced manufacturing techniques are employed to create uniform and stable quantum dot films, resulting in more consistent and accurate color reproduction in QLED displays.Expand Specific Solutions

Key QLED Display Manufacturers

The QLED display market is in a growth phase, driven by increasing demand for high-quality visual experiences. The global QLED market size is projected to expand significantly, with key players like Samsung Electronics, TCL, and BOE Technology Group leading the competition. Technologically, QLED displays are maturing rapidly, with companies such as Samsung Display and Nanosys making significant advancements in color accuracy and quantum dot technology. Research institutions like MIT and HKUST are contributing to further innovations. The industry is seeing a convergence of efforts from display manufacturers, quantum dot developers, and color management specialists like X-Rite, all working towards achieving superior color accuracy in QLED displays.

TCL China Star Optoelectronics Technology Co., Ltd.

Samsung Electronics Co., Ltd.

Innovative Color Management Algorithms

- A light emitting element with a first light emitting layer composed of quantum dots made from compounds containing Zn, Se, and Te, where the average particle diameter and composition ratio are optimized to achieve a peak wavelength between 394 nm and 474 nm, allowing for a wider color gamut in display devices.

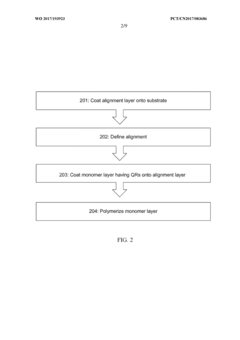

- Utilizing quantum rods (QRs) with aspect ratios above 1 to emit polarized light, potentially increasing the efficiency of LCD polarizers.

- Tuning QRs to emit light at specific wavelengths by adjusting their size during fabrication, resulting in improved color purity and gamut.

- Implementing field sequential color display concept to reduce or eliminate losses associated with color filters in LCDs.

QLED Display Industry Standards

Industry standards play a crucial role in ensuring color accuracy and consistency across QLED displays. These standards provide a framework for manufacturers, content creators, and consumers to achieve reliable and high-quality color reproduction.

One of the most important standards in the QLED display industry is the International Electrotechnical Commission (IEC) 62087-7:2018. This standard defines the measurement methods for the optical characteristics of quantum dot enhancement film (QDEF) used in QLED displays. It establishes guidelines for measuring color gamut, luminance, and other optical properties, ensuring consistency across different manufacturers and models.

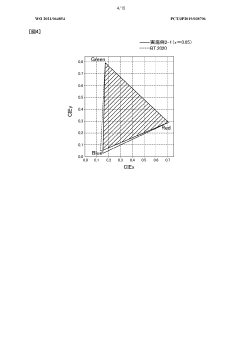

The International Commission on Illumination (CIE) has developed several color space standards that are widely used in the QLED industry. The CIE 1931 color space and its derivatives, such as CIE 1976 (L*a*b*), provide a standardized way to represent and communicate colors. These standards are essential for accurate color mapping and reproduction in QLED displays.

The Video Electronics Standards Association (VESA) has introduced the DisplayHDR standard, which includes specific requirements for color accuracy in high dynamic range displays. This standard defines different tiers of HDR performance, including color gamut coverage and bit depth, which are particularly relevant for QLED displays aiming to achieve superior color accuracy.

The Digital Cinema Initiatives (DCI) has established the DCI-P3 color space, which has become a benchmark for wide color gamut displays, including QLEDs. Many QLED manufacturers strive to meet or exceed the DCI-P3 color space coverage, as it represents a significant improvement over the traditional sRGB color space.

The International Telecommunication Union (ITU) has developed the ITU-R BT.2020 standard, also known as Rec. 2020. This standard defines an even wider color gamut than DCI-P3 and is increasingly being adopted as a target for high-end QLED displays. It sets ambitious goals for color reproduction, pushing the boundaries of what QLED technology can achieve.

To ensure compliance with these standards, the QLED display industry relies on various calibration and measurement tools. The Portrait Displays CalMAN software, for example, has become an industry standard for display calibration and verification. It incorporates many of the aforementioned standards and provides a comprehensive suite of tools for achieving and maintaining color accuracy in QLED displays.

As the QLED technology continues to evolve, industry standards are also adapting to keep pace. Organizations like the Ultra HD Alliance are working on developing new standards that specifically address the unique capabilities of quantum dot displays, ensuring that future QLED products can be accurately evaluated and compared across different manufacturers and models.

Environmental Impact of QLED Manufacturing

The manufacturing process of QLED displays has significant environmental implications that warrant careful consideration. The production of quantum dots, the key component in QLED technology, involves the use of heavy metals such as cadmium and indium, which can pose environmental risks if not properly managed. These materials require specialized handling and disposal procedures to prevent contamination of soil and water resources.

The energy-intensive nature of QLED manufacturing is another environmental concern. The production of quantum dots and the assembly of QLED panels require high-temperature processes and clean room environments, leading to substantial energy consumption. This increased energy demand contributes to higher carbon emissions, particularly in regions where the energy grid relies heavily on fossil fuels.

Water usage in QLED manufacturing is also a critical environmental factor. The production process requires large volumes of ultra-pure water for cleaning and cooling purposes. The treatment and disposal of this water, which may contain trace amounts of chemicals and heavy metals, present additional environmental challenges and potential risks to local ecosystems.

Electronic waste (e-waste) generation is a growing concern as QLED displays become more prevalent in the market. The relatively short lifespan of consumer electronics, coupled with the difficulty in recycling quantum dot materials, contributes to the accumulation of e-waste. Proper recycling and disposal methods for QLED displays are still in development, highlighting the need for improved end-of-life management strategies.

The supply chain for QLED components also has environmental implications. The extraction and processing of rare earth elements and other materials used in QLED production can lead to habitat destruction, soil erosion, and water pollution in mining regions. Additionally, the global transportation of materials and finished products contributes to the carbon footprint of QLED displays.

Despite these challenges, ongoing research and development efforts are focused on improving the environmental sustainability of QLED technology. Innovations in quantum dot synthesis, such as the development of cadmium-free alternatives, aim to reduce the use of toxic materials. Advancements in manufacturing processes are also being pursued to enhance energy efficiency and reduce water consumption.

As the QLED industry continues to grow, it is crucial for manufacturers to adopt more sustainable practices and invest in cleaner production technologies. Implementing circular economy principles, improving recycling capabilities, and exploring bio-based materials for quantum dot production are potential avenues for reducing the environmental impact of QLED manufacturing.