The Science Behind Quantum Efficiency in QLED

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Quantum Efficiency Evolution and Objectives

Quantum Light-Emitting Diodes (QLEDs) have emerged as a promising technology in the field of display and lighting applications. The evolution of QLED quantum efficiency has been a journey of continuous improvement and innovation. Initially, QLEDs faced significant challenges in achieving high quantum efficiency, with early devices exhibiting external quantum efficiencies (EQEs) of less than 1%. However, through persistent research and development efforts, remarkable progress has been made over the past decade.

The primary objective in QLED quantum efficiency research has been to maximize the conversion of electrical energy into light output. This involves optimizing several key factors, including charge injection, exciton formation, and light extraction. Researchers have focused on enhancing the quantum yield of the quantum dots themselves, as well as improving the overall device architecture to minimize energy losses.

One of the major milestones in QLED efficiency was the development of core-shell quantum dot structures. These structures helped to passivate surface defects and reduce non-radiative recombination, leading to significant improvements in internal quantum efficiency. Subsequently, the introduction of advanced hole and electron transport layers further enhanced charge injection and confinement, pushing EQEs beyond 20% for some color ranges.

Recent advancements have centered on tackling the issue of efficiency roll-off at high current densities, a critical factor for practical applications. Strategies such as graded quantum dot layers and engineered interfacial energy levels have shown promise in mitigating this problem. Additionally, the exploration of perovskite quantum dots has opened new avenues for achieving even higher efficiencies, with some reports suggesting the potential for near-unity internal quantum efficiency.

Looking forward, the objectives for QLED quantum efficiency are ambitious yet achievable. Researchers aim to push EQEs beyond 30% across all color ranges while maintaining high efficiency at practical operating conditions. This involves not only improving the quantum dots themselves but also optimizing the entire device stack for better charge balance and reduced quenching effects.

Another key goal is to enhance the stability of high-efficiency QLEDs, ensuring that the impressive quantum efficiencies achieved in laboratory settings can be maintained over extended operational lifetimes. This requires a multifaceted approach, including the development of more robust quantum dot materials, improved encapsulation techniques, and innovative device architectures that minimize degradation mechanisms.

In conclusion, the evolution of QLED quantum efficiency has been marked by significant progress, driven by a deep understanding of the underlying physics and innovative engineering solutions. As research continues, the objectives remain focused on pushing the boundaries of efficiency, stability, and practical applicability, paving the way for QLEDs to potentially surpass current display technologies in terms of performance and energy efficiency.

The primary objective in QLED quantum efficiency research has been to maximize the conversion of electrical energy into light output. This involves optimizing several key factors, including charge injection, exciton formation, and light extraction. Researchers have focused on enhancing the quantum yield of the quantum dots themselves, as well as improving the overall device architecture to minimize energy losses.

One of the major milestones in QLED efficiency was the development of core-shell quantum dot structures. These structures helped to passivate surface defects and reduce non-radiative recombination, leading to significant improvements in internal quantum efficiency. Subsequently, the introduction of advanced hole and electron transport layers further enhanced charge injection and confinement, pushing EQEs beyond 20% for some color ranges.

Recent advancements have centered on tackling the issue of efficiency roll-off at high current densities, a critical factor for practical applications. Strategies such as graded quantum dot layers and engineered interfacial energy levels have shown promise in mitigating this problem. Additionally, the exploration of perovskite quantum dots has opened new avenues for achieving even higher efficiencies, with some reports suggesting the potential for near-unity internal quantum efficiency.

Looking forward, the objectives for QLED quantum efficiency are ambitious yet achievable. Researchers aim to push EQEs beyond 30% across all color ranges while maintaining high efficiency at practical operating conditions. This involves not only improving the quantum dots themselves but also optimizing the entire device stack for better charge balance and reduced quenching effects.

Another key goal is to enhance the stability of high-efficiency QLEDs, ensuring that the impressive quantum efficiencies achieved in laboratory settings can be maintained over extended operational lifetimes. This requires a multifaceted approach, including the development of more robust quantum dot materials, improved encapsulation techniques, and innovative device architectures that minimize degradation mechanisms.

In conclusion, the evolution of QLED quantum efficiency has been marked by significant progress, driven by a deep understanding of the underlying physics and innovative engineering solutions. As research continues, the objectives remain focused on pushing the boundaries of efficiency, stability, and practical applicability, paving the way for QLEDs to potentially surpass current display technologies in terms of performance and energy efficiency.

QLED Market Demand Analysis

The QLED (Quantum Dot Light Emitting Diode) market has experienced significant growth in recent years, driven by increasing demand for high-quality displays in various consumer electronics and professional applications. The global QLED market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to exceed 20% over the next five years.

Consumer electronics, particularly televisions, remain the primary driver of QLED market demand. As consumers seek enhanced visual experiences, QLED technology offers superior color accuracy, brightness, and energy efficiency compared to traditional LED displays. The growing popularity of 4K and 8K resolution content has further accelerated the adoption of QLED displays in the premium TV segment.

Beyond televisions, QLED technology is gaining traction in other consumer electronics sectors. Smartphones, tablets, and laptops are increasingly incorporating QLED displays to provide users with vibrant, high-contrast screens. This trend is expected to continue as manufacturers strive to differentiate their products in competitive markets.

The automotive industry represents another significant growth area for QLED technology. As vehicles become more technologically advanced, there is a rising demand for high-quality displays in infotainment systems, digital dashboards, and heads-up displays. QLED's ability to deliver bright, clear images even in challenging lighting conditions makes it particularly well-suited for automotive applications.

In the professional and commercial sectors, QLED displays are finding applications in digital signage, control rooms, and medical imaging. The technology's wide color gamut and high brightness capabilities make it ideal for these demanding environments where image quality and visibility are crucial.

The market demand for QLED technology is also being driven by increasing awareness of energy efficiency and environmental concerns. QLED displays typically consume less power than their OLED counterparts, making them an attractive option for environmentally conscious consumers and businesses looking to reduce their carbon footprint.

As the technology continues to mature, we can expect to see further innovations in QLED displays, such as improved quantum efficiency, enhanced color accuracy, and reduced production costs. These advancements are likely to expand the market potential of QLED technology, opening up new applications and market segments.

However, challenges remain in the QLED market. Competition from other display technologies, particularly OLED, continues to be fierce. Additionally, the high cost of premium QLED displays may limit adoption in price-sensitive markets. Overcoming these challenges will be crucial for the continued growth and widespread adoption of QLED technology across various industries and applications.

Consumer electronics, particularly televisions, remain the primary driver of QLED market demand. As consumers seek enhanced visual experiences, QLED technology offers superior color accuracy, brightness, and energy efficiency compared to traditional LED displays. The growing popularity of 4K and 8K resolution content has further accelerated the adoption of QLED displays in the premium TV segment.

Beyond televisions, QLED technology is gaining traction in other consumer electronics sectors. Smartphones, tablets, and laptops are increasingly incorporating QLED displays to provide users with vibrant, high-contrast screens. This trend is expected to continue as manufacturers strive to differentiate their products in competitive markets.

The automotive industry represents another significant growth area for QLED technology. As vehicles become more technologically advanced, there is a rising demand for high-quality displays in infotainment systems, digital dashboards, and heads-up displays. QLED's ability to deliver bright, clear images even in challenging lighting conditions makes it particularly well-suited for automotive applications.

In the professional and commercial sectors, QLED displays are finding applications in digital signage, control rooms, and medical imaging. The technology's wide color gamut and high brightness capabilities make it ideal for these demanding environments where image quality and visibility are crucial.

The market demand for QLED technology is also being driven by increasing awareness of energy efficiency and environmental concerns. QLED displays typically consume less power than their OLED counterparts, making them an attractive option for environmentally conscious consumers and businesses looking to reduce their carbon footprint.

As the technology continues to mature, we can expect to see further innovations in QLED displays, such as improved quantum efficiency, enhanced color accuracy, and reduced production costs. These advancements are likely to expand the market potential of QLED technology, opening up new applications and market segments.

However, challenges remain in the QLED market. Competition from other display technologies, particularly OLED, continues to be fierce. Additionally, the high cost of premium QLED displays may limit adoption in price-sensitive markets. Overcoming these challenges will be crucial for the continued growth and widespread adoption of QLED technology across various industries and applications.

Current QLED Quantum Efficiency Challenges

Quantum efficiency remains a critical challenge in the development and optimization of Quantum Dot Light-Emitting Diodes (QLEDs). Despite significant advancements in recent years, several hurdles persist in achieving optimal quantum efficiency for these devices.

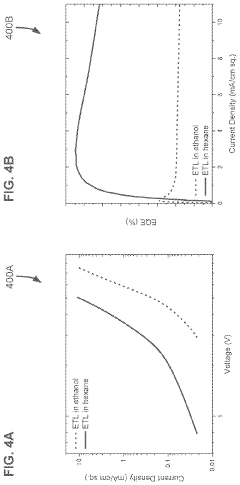

One of the primary challenges is the issue of charge injection and transport within the QLED structure. The efficiency of electron and hole injection from the respective electrodes into the emissive quantum dot layer significantly impacts the overall quantum efficiency. Imbalanced charge injection can lead to charge accumulation, resulting in non-radiative recombination and reduced efficiency.

Another major obstacle is the presence of surface defects and trap states in quantum dots. These imperfections can act as non-radiative recombination centers, diminishing the quantum efficiency by providing alternative pathways for exciton decay. Addressing this issue requires advanced surface passivation techniques and precise control over quantum dot synthesis.

The phenomenon of Auger recombination poses a significant challenge, particularly at high current densities. This non-radiative process becomes more pronounced as the excitation level increases, leading to efficiency droop in QLEDs. Mitigating Auger recombination without compromising other performance aspects remains a complex task for researchers.

Energy transfer between quantum dots is another factor affecting quantum efficiency. In densely packed quantum dot films, exciton energy can be transferred from smaller to larger dots, potentially leading to red-shifted emission and reduced overall efficiency. Controlling inter-dot spacing and energy transfer dynamics is crucial for optimizing device performance.

The stability of quantum dots under operational conditions is a persistent challenge. Degradation of quantum dots due to environmental factors, such as heat and moisture, can lead to a decrease in quantum efficiency over time. Enhancing the robustness of quantum dots while maintaining their optical properties is essential for long-term device stability.

Furthermore, the interface between the quantum dot layer and adjacent charge transport layers plays a critical role in determining quantum efficiency. Poor interface quality can lead to increased non-radiative recombination and reduced charge injection efficiency. Developing strategies to optimize these interfaces without disrupting the quantum dot properties is an ongoing area of research.

Lastly, achieving high color purity while maintaining high quantum efficiency across different color emissions (red, green, and blue) remains challenging. Each color requires specific optimization strategies, and balancing the performance across the entire visible spectrum is crucial for display applications.

One of the primary challenges is the issue of charge injection and transport within the QLED structure. The efficiency of electron and hole injection from the respective electrodes into the emissive quantum dot layer significantly impacts the overall quantum efficiency. Imbalanced charge injection can lead to charge accumulation, resulting in non-radiative recombination and reduced efficiency.

Another major obstacle is the presence of surface defects and trap states in quantum dots. These imperfections can act as non-radiative recombination centers, diminishing the quantum efficiency by providing alternative pathways for exciton decay. Addressing this issue requires advanced surface passivation techniques and precise control over quantum dot synthesis.

The phenomenon of Auger recombination poses a significant challenge, particularly at high current densities. This non-radiative process becomes more pronounced as the excitation level increases, leading to efficiency droop in QLEDs. Mitigating Auger recombination without compromising other performance aspects remains a complex task for researchers.

Energy transfer between quantum dots is another factor affecting quantum efficiency. In densely packed quantum dot films, exciton energy can be transferred from smaller to larger dots, potentially leading to red-shifted emission and reduced overall efficiency. Controlling inter-dot spacing and energy transfer dynamics is crucial for optimizing device performance.

The stability of quantum dots under operational conditions is a persistent challenge. Degradation of quantum dots due to environmental factors, such as heat and moisture, can lead to a decrease in quantum efficiency over time. Enhancing the robustness of quantum dots while maintaining their optical properties is essential for long-term device stability.

Furthermore, the interface between the quantum dot layer and adjacent charge transport layers plays a critical role in determining quantum efficiency. Poor interface quality can lead to increased non-radiative recombination and reduced charge injection efficiency. Developing strategies to optimize these interfaces without disrupting the quantum dot properties is an ongoing area of research.

Lastly, achieving high color purity while maintaining high quantum efficiency across different color emissions (red, green, and blue) remains challenging. Each color requires specific optimization strategies, and balancing the performance across the entire visible spectrum is crucial for display applications.

Quantum Efficiency Enhancement Strategies

01 Quantum dot composition and structure

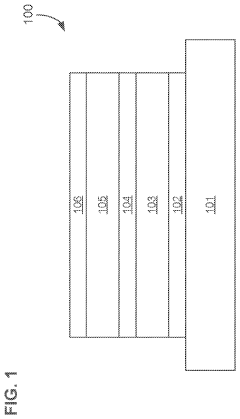

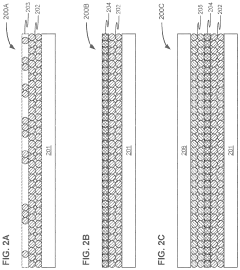

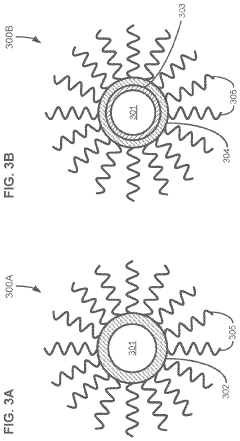

The composition and structure of quantum dots play a crucial role in QLED quantum efficiency. Optimizing the core-shell structure, size distribution, and material composition of quantum dots can significantly enhance their light-emitting properties and overall device performance.- Quantum dot composition and structure: The composition and structure of quantum dots play a crucial role in QLED quantum efficiency. Researchers focus on optimizing the core-shell structure, size distribution, and material selection of quantum dots to enhance their optical properties and stability. This includes developing novel synthesis methods and exploring different semiconductor materials to achieve higher quantum yields and improved color purity.

- Charge transport layers and interfaces: Improving charge transport layers and interfaces between different components of QLEDs is essential for enhancing quantum efficiency. This involves designing and optimizing electron and hole transport layers, as well as developing novel interface materials to facilitate efficient charge injection and reduce energy barriers. Researchers also focus on minimizing non-radiative recombination at interfaces to improve overall device performance.

- Light extraction and outcoupling techniques: Enhancing light extraction and outcoupling is crucial for improving QLED quantum efficiency. Various techniques are explored, including the use of nanostructured surfaces, microlens arrays, and photonic crystals to reduce total internal reflection and increase light output. Researchers also investigate novel substrate materials and device architectures to optimize light extraction efficiency.

- Quantum dot surface modification and passivation: Surface modification and passivation of quantum dots are essential for improving their stability and quantum yield. Researchers develop various surface ligands and passivation techniques to reduce surface defects, minimize non-radiative recombination, and enhance the overall quantum efficiency of QLEDs. This includes exploring organic and inorganic passivation methods to protect quantum dots from degradation and maintain their optical properties.

- Device architecture and fabrication processes: Optimizing device architecture and fabrication processes is crucial for achieving high quantum efficiency in QLEDs. Researchers investigate various device structures, including inverted and tandem configurations, to improve charge balance and light emission. Advanced fabrication techniques, such as solution processing and roll-to-roll manufacturing, are explored to enhance device performance and scalability while maintaining high quantum efficiency.

02 Charge transport layers

Efficient charge transport layers are essential for improving QLED quantum efficiency. These layers facilitate the movement of electrons and holes to the quantum dot emissive layer, enhancing charge injection and recombination efficiency. Optimizing the materials and structure of these layers can significantly boost device performance.Expand Specific Solutions03 Surface modification and passivation

Surface modification and passivation techniques are employed to reduce non-radiative recombination and improve quantum dot stability. These methods can involve the use of organic ligands or inorganic shells to passivate surface defects and enhance the quantum efficiency of QLEDs.Expand Specific Solutions04 Device architecture optimization

Optimizing the overall device architecture of QLEDs can lead to improved quantum efficiency. This includes fine-tuning the thickness and arrangement of various layers, incorporating light outcoupling structures, and designing efficient electrode configurations to enhance charge injection and light extraction.Expand Specific Solutions05 Doping and energy transfer mechanisms

Exploring doping strategies and energy transfer mechanisms can enhance QLED quantum efficiency. This involves incorporating dopants or additional emissive materials to facilitate energy transfer, reduce efficiency roll-off at high current densities, and improve overall device performance.Expand Specific Solutions

Key QLED Industry Players

The quantum efficiency in QLED technology is at a critical juncture, with the market rapidly expanding and attracting significant investment. The industry is in a growth phase, with major players like BOE Technology Group, TCL China Star Optoelectronics, and Nanosys leading the charge. The market size is projected to increase substantially, driven by demand for high-performance displays. Technologically, QLED is maturing, with companies like Sharp Corp. and Guangdong Juhua Printing Display Technology making strides in improving quantum efficiency. Research institutions such as The Hong Kong University of Science & Technology and Zhejiang University are contributing to advancements, pushing the boundaries of QLED performance and efficiency.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has been actively researching and developing QLED technology, focusing on improving quantum efficiency through advanced material design and manufacturing processes. Their approach involves optimizing the structure of quantum dots and the surrounding matrix to enhance light emission and reduce energy loss. BOE has also been working on integrating quantum dots into their existing display manufacturing lines, aiming to produce large-scale QLED displays with high color accuracy and brightness.

Strengths: Large-scale manufacturing capabilities and integration with existing production lines. Weaknesses: Relatively new to QLED technology compared to some competitors.

The Hong Kong University of Science & Technology

Technical Solution: HKUST has been conducting cutting-edge research on quantum dot materials and their application in QLED displays. Their work focuses on understanding and improving the fundamental physics behind quantum efficiency in these systems. This includes studying the effects of quantum dot size, shape, and composition on light emission properties, as well as investigating novel methods to enhance energy transfer and reduce non-radiative recombination processes. HKUST researchers are also exploring the use of perovskite quantum dots and other advanced materials to further improve QLED performance.

Strengths: Strong fundamental research capabilities and potential for breakthrough innovations. Weaknesses: May face challenges in translating research findings into commercial products.

Breakthrough QLED Quantum Efficiency Patents

QLED and Method for Manufacturing Quantum Dot

PatentActiveUS20210380878A1

Innovation

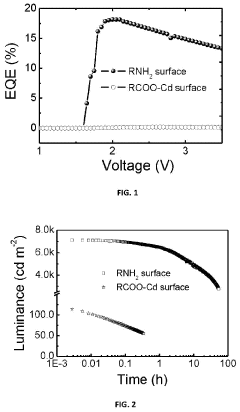

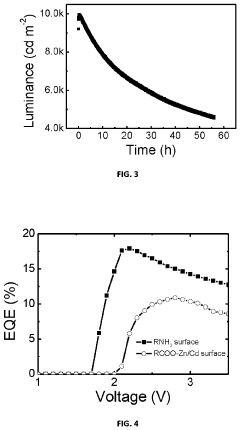

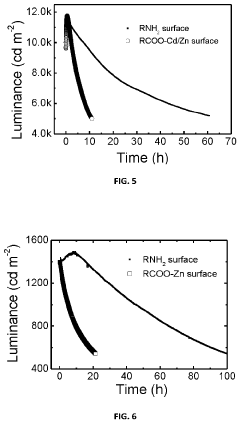

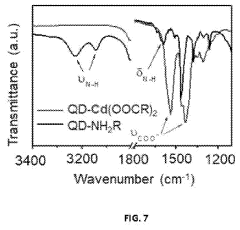

- The use of electrochemically inert ligands, such as amine, alkylphosphine, and metal carboxylate ligands, which have a reduction potential greater than the quantum dot's conduction band and an oxidation potential less than its valence band, accounting for at least 80% of the surface ligands, to prevent carrier consumption and ligand detachment under electrical excitation, thereby enhancing stability and efficiency.

Light-emitting apparatus with improved charge transport layer

PatentPendingUS20240138178A1

Innovation

- Incorporating a metal-oxide nanoparticle-based electron transport layer with specific solvent polarity and size characteristics, which improves charge balance and injection efficiency by depositing nanoparticles in a multi-layer structure with varying sizes and polarities, potentially matching or exceeding the size of quantum dots.

QLED Manufacturing Process Optimization

The optimization of QLED manufacturing processes is crucial for enhancing quantum efficiency and overall device performance. A key focus in this area is the precise control of quantum dot synthesis and deposition. Advanced colloidal synthesis techniques have been developed to produce highly uniform quantum dots with narrow size distributions, which is essential for achieving high color purity and efficiency in QLEDs.

One significant advancement in the manufacturing process is the implementation of automated, high-throughput production lines. These systems utilize robotic handling and precise environmental controls to maintain consistency in quantum dot production. The integration of in-line quality control measures, such as real-time spectroscopic analysis, ensures that each batch of quantum dots meets stringent specifications for size, shape, and composition.

The deposition of quantum dots onto the device substrate is another critical step that has seen substantial improvements. Techniques such as inkjet printing and photolithography have been refined to allow for precise patterning of quantum dots, minimizing waste and improving pixel definition. Additionally, the development of transfer printing methods has enabled the creation of flexible QLED displays, expanding the potential applications of this technology.

Surface treatment and encapsulation processes have also been optimized to enhance the stability and longevity of QLEDs. Advanced passivation techniques, using materials such as zinc oxide or aluminum oxide, have been shown to reduce surface defects and prevent oxidation of the quantum dots. This results in improved quantum yield and device lifetime.

The integration of quantum dots into the emissive layer has been further refined through the development of hybrid organic-inorganic structures. These composite materials combine the high efficiency of quantum dots with the charge transport properties of organic semiconductors, leading to enhanced overall device performance.

Efforts to scale up production while maintaining high quality have led to the adoption of continuous flow reactors for quantum dot synthesis. This approach allows for better control over reaction conditions and enables the production of larger quantities of uniform quantum dots. Furthermore, the implementation of machine learning algorithms in process control has facilitated real-time adjustments to manufacturing parameters, ensuring optimal output quality.

One significant advancement in the manufacturing process is the implementation of automated, high-throughput production lines. These systems utilize robotic handling and precise environmental controls to maintain consistency in quantum dot production. The integration of in-line quality control measures, such as real-time spectroscopic analysis, ensures that each batch of quantum dots meets stringent specifications for size, shape, and composition.

The deposition of quantum dots onto the device substrate is another critical step that has seen substantial improvements. Techniques such as inkjet printing and photolithography have been refined to allow for precise patterning of quantum dots, minimizing waste and improving pixel definition. Additionally, the development of transfer printing methods has enabled the creation of flexible QLED displays, expanding the potential applications of this technology.

Surface treatment and encapsulation processes have also been optimized to enhance the stability and longevity of QLEDs. Advanced passivation techniques, using materials such as zinc oxide or aluminum oxide, have been shown to reduce surface defects and prevent oxidation of the quantum dots. This results in improved quantum yield and device lifetime.

The integration of quantum dots into the emissive layer has been further refined through the development of hybrid organic-inorganic structures. These composite materials combine the high efficiency of quantum dots with the charge transport properties of organic semiconductors, leading to enhanced overall device performance.

Efforts to scale up production while maintaining high quality have led to the adoption of continuous flow reactors for quantum dot synthesis. This approach allows for better control over reaction conditions and enables the production of larger quantities of uniform quantum dots. Furthermore, the implementation of machine learning algorithms in process control has facilitated real-time adjustments to manufacturing parameters, ensuring optimal output quality.

Environmental Impact of QLED Production

The production of Quantum Light-Emitting Diodes (QLEDs) has significant environmental implications that warrant careful consideration. The manufacturing process involves the use of various materials and chemicals, some of which can have adverse effects on the environment if not properly managed.

One of the primary environmental concerns in QLED production is the use of heavy metals, particularly cadmium, which is a key component in many quantum dot formulations. Cadmium is known for its toxicity and potential to accumulate in ecosystems. While efforts are being made to develop cadmium-free alternatives, the current reliance on this element poses risks to soil and water quality if not properly contained and disposed of during the manufacturing process.

The synthesis of quantum dots also requires the use of organic solvents and other chemicals that can contribute to air and water pollution if released into the environment. Proper handling, storage, and disposal of these substances are crucial to minimizing their environmental impact. Additionally, the energy-intensive nature of QLED production contributes to greenhouse gas emissions, particularly in regions where electricity generation relies heavily on fossil fuels.

However, it's important to note that QLEDs offer potential environmental benefits in their application. The high efficiency of QLED displays can lead to reduced energy consumption compared to traditional display technologies, potentially offsetting some of the environmental costs associated with their production over the lifetime of the devices.

The manufacturing of QLED components also generates electronic waste, which presents challenges for recycling and disposal. The complex nature of these devices, with their mix of organic and inorganic materials, makes them difficult to recycle using conventional methods. This necessitates the development of specialized recycling processes to recover valuable materials and minimize landfill waste.

Water usage in QLED production is another environmental consideration. The manufacturing process requires significant amounts of ultra-pure water, which can strain local water resources, especially in water-scarce regions. Implementing water recycling and conservation measures in production facilities is crucial for sustainable manufacturing practices.

As the QLED industry continues to grow, there is an increasing focus on developing more environmentally friendly production methods. This includes research into green chemistry approaches for quantum dot synthesis, the use of less toxic materials, and the implementation of closed-loop manufacturing systems to minimize waste and emissions. These efforts aim to improve the overall environmental profile of QLED technology, balancing its potential benefits with responsible production practices.

One of the primary environmental concerns in QLED production is the use of heavy metals, particularly cadmium, which is a key component in many quantum dot formulations. Cadmium is known for its toxicity and potential to accumulate in ecosystems. While efforts are being made to develop cadmium-free alternatives, the current reliance on this element poses risks to soil and water quality if not properly contained and disposed of during the manufacturing process.

The synthesis of quantum dots also requires the use of organic solvents and other chemicals that can contribute to air and water pollution if released into the environment. Proper handling, storage, and disposal of these substances are crucial to minimizing their environmental impact. Additionally, the energy-intensive nature of QLED production contributes to greenhouse gas emissions, particularly in regions where electricity generation relies heavily on fossil fuels.

However, it's important to note that QLEDs offer potential environmental benefits in their application. The high efficiency of QLED displays can lead to reduced energy consumption compared to traditional display technologies, potentially offsetting some of the environmental costs associated with their production over the lifetime of the devices.

The manufacturing of QLED components also generates electronic waste, which presents challenges for recycling and disposal. The complex nature of these devices, with their mix of organic and inorganic materials, makes them difficult to recycle using conventional methods. This necessitates the development of specialized recycling processes to recover valuable materials and minimize landfill waste.

Water usage in QLED production is another environmental consideration. The manufacturing process requires significant amounts of ultra-pure water, which can strain local water resources, especially in water-scarce regions. Implementing water recycling and conservation measures in production facilities is crucial for sustainable manufacturing practices.

As the QLED industry continues to grow, there is an increasing focus on developing more environmentally friendly production methods. This includes research into green chemistry approaches for quantum dot synthesis, the use of less toxic materials, and the implementation of closed-loop manufacturing systems to minimize waste and emissions. These efforts aim to improve the overall environmental profile of QLED technology, balancing its potential benefits with responsible production practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!