How to Navigate Challenges in QLED Display Manufacturing?

JUN 19, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Display Evolution

QLED display technology has undergone significant evolution since its inception, driven by the demand for superior image quality and energy efficiency in display applications. The journey began with the development of quantum dots, nanoscale semiconductor particles that emit light of specific wavelengths when excited. These quantum dots were initially used to enhance the color gamut of traditional LCD displays.

The first generation of QLED displays, introduced in the mid-2010s, utilized quantum dots in a film layer placed in front of the LED backlight. This configuration improved color accuracy and brightness compared to conventional LCDs. However, these early QLEDs still relied on LCD technology for light modulation, limiting their potential for perfect blacks and high contrast ratios.

As research progressed, the focus shifted towards developing self-emissive QLED displays. This next generation aimed to eliminate the need for a separate backlight by using quantum dots as the primary light source. The challenge lay in creating stable, efficient blue quantum dots, as blue light is crucial for producing a full-color spectrum.

Advancements in materials science and nanotechnology led to breakthroughs in quantum dot synthesis and stability. Researchers developed new core-shell structures and surface treatments to enhance the longevity and efficiency of quantum dots, particularly for blue light emission. These improvements paved the way for the creation of prototypes demonstrating the feasibility of self-emissive QLED displays.

Parallel to these developments, efforts were made to improve the manufacturing processes for QLED displays. Innovations in quantum dot deposition techniques, such as inkjet printing and photolithography, enabled more precise and cost-effective production methods. These advancements were crucial in scaling up QLED technology for commercial applications.

The most recent phase of QLED evolution has focused on addressing remaining challenges, such as improving the lifetime of blue quantum dots and enhancing overall display efficiency. Researchers have explored hybrid approaches, combining quantum dots with other emerging technologies like micro-LEDs to leverage the strengths of both systems.

Looking ahead, the QLED display evolution is expected to continue with a focus on achieving higher peak brightness, wider color gamuts, and improved power efficiency. The integration of artificial intelligence for image processing and the development of flexible and transparent QLED displays represent exciting frontiers in this ongoing technological journey.

The first generation of QLED displays, introduced in the mid-2010s, utilized quantum dots in a film layer placed in front of the LED backlight. This configuration improved color accuracy and brightness compared to conventional LCDs. However, these early QLEDs still relied on LCD technology for light modulation, limiting their potential for perfect blacks and high contrast ratios.

As research progressed, the focus shifted towards developing self-emissive QLED displays. This next generation aimed to eliminate the need for a separate backlight by using quantum dots as the primary light source. The challenge lay in creating stable, efficient blue quantum dots, as blue light is crucial for producing a full-color spectrum.

Advancements in materials science and nanotechnology led to breakthroughs in quantum dot synthesis and stability. Researchers developed new core-shell structures and surface treatments to enhance the longevity and efficiency of quantum dots, particularly for blue light emission. These improvements paved the way for the creation of prototypes demonstrating the feasibility of self-emissive QLED displays.

Parallel to these developments, efforts were made to improve the manufacturing processes for QLED displays. Innovations in quantum dot deposition techniques, such as inkjet printing and photolithography, enabled more precise and cost-effective production methods. These advancements were crucial in scaling up QLED technology for commercial applications.

The most recent phase of QLED evolution has focused on addressing remaining challenges, such as improving the lifetime of blue quantum dots and enhancing overall display efficiency. Researchers have explored hybrid approaches, combining quantum dots with other emerging technologies like micro-LEDs to leverage the strengths of both systems.

Looking ahead, the QLED display evolution is expected to continue with a focus on achieving higher peak brightness, wider color gamuts, and improved power efficiency. The integration of artificial intelligence for image processing and the development of flexible and transparent QLED displays represent exciting frontiers in this ongoing technological journey.

QLED Market Dynamics

The QLED display market has experienced significant growth in recent years, driven by increasing demand for high-quality displays in various applications. This technology offers superior color performance, brightness, and energy efficiency compared to traditional LED displays, making it attractive for both consumer electronics and commercial applications.

The global QLED market has been expanding rapidly, with major players like Samsung, TCL, and Hisense leading the charge. Samsung, in particular, has been at the forefront of QLED technology development and commercialization, capturing a substantial market share. The consumer electronics segment, especially high-end televisions, has been the primary driver of QLED adoption.

Market trends indicate a growing preference for larger screen sizes and higher resolutions, which plays to the strengths of QLED technology. The ability to produce vibrant colors and deep blacks while maintaining energy efficiency has positioned QLED as a strong competitor to OLED displays in the premium segment.

The COVID-19 pandemic has had a mixed impact on the QLED market. While initial supply chain disruptions caused temporary setbacks, the increased demand for home entertainment systems during lockdowns has boosted sales of high-end televisions, including QLED models.

In terms of regional dynamics, Asia-Pacific has emerged as the largest market for QLED displays, followed by North America and Europe. China, in particular, has seen rapid growth in both production and consumption of QLED displays, with domestic manufacturers ramping up their capabilities to compete on the global stage.

The automotive sector represents a promising growth area for QLED technology. As vehicles become more technologically advanced, there is increasing demand for high-quality displays for infotainment systems and digital dashboards. QLED's advantages in brightness and color accuracy make it well-suited for automotive applications, where readability in various lighting conditions is crucial.

Despite its growth, the QLED market faces challenges. Competition from other display technologies, particularly OLED, remains intense. Additionally, the high cost of QLED displays compared to conventional LED options limits their penetration in mid-range and budget segments.

Looking ahead, technological advancements are expected to drive further market expansion. Improvements in quantum dot materials, manufacturing processes, and panel designs are likely to enhance performance while reducing costs. This could lead to broader adoption across various price points and applications, potentially expanding QLED's market share in the overall display industry.

The global QLED market has been expanding rapidly, with major players like Samsung, TCL, and Hisense leading the charge. Samsung, in particular, has been at the forefront of QLED technology development and commercialization, capturing a substantial market share. The consumer electronics segment, especially high-end televisions, has been the primary driver of QLED adoption.

Market trends indicate a growing preference for larger screen sizes and higher resolutions, which plays to the strengths of QLED technology. The ability to produce vibrant colors and deep blacks while maintaining energy efficiency has positioned QLED as a strong competitor to OLED displays in the premium segment.

The COVID-19 pandemic has had a mixed impact on the QLED market. While initial supply chain disruptions caused temporary setbacks, the increased demand for home entertainment systems during lockdowns has boosted sales of high-end televisions, including QLED models.

In terms of regional dynamics, Asia-Pacific has emerged as the largest market for QLED displays, followed by North America and Europe. China, in particular, has seen rapid growth in both production and consumption of QLED displays, with domestic manufacturers ramping up their capabilities to compete on the global stage.

The automotive sector represents a promising growth area for QLED technology. As vehicles become more technologically advanced, there is increasing demand for high-quality displays for infotainment systems and digital dashboards. QLED's advantages in brightness and color accuracy make it well-suited for automotive applications, where readability in various lighting conditions is crucial.

Despite its growth, the QLED market faces challenges. Competition from other display technologies, particularly OLED, remains intense. Additionally, the high cost of QLED displays compared to conventional LED options limits their penetration in mid-range and budget segments.

Looking ahead, technological advancements are expected to drive further market expansion. Improvements in quantum dot materials, manufacturing processes, and panel designs are likely to enhance performance while reducing costs. This could lead to broader adoption across various price points and applications, potentially expanding QLED's market share in the overall display industry.

QLED Tech Hurdles

QLED display manufacturing faces several significant technical challenges that need to be addressed to improve production efficiency and product quality. One of the primary hurdles is the precise deposition of quantum dots onto the substrate. The uniformity and accuracy of this process directly impact the display's color performance and overall quality. Current methods often struggle to achieve consistent results across large-scale production, leading to variations in color reproduction and brightness.

Another major challenge lies in the stability and longevity of quantum dots. These nanoparticles are susceptible to degradation when exposed to oxygen, moisture, and high temperatures. This vulnerability can result in reduced color purity and shortened lifespan of QLED displays. Developing effective encapsulation techniques to protect quantum dots from environmental factors remains a critical area of focus for manufacturers.

The integration of quantum dots with other display components presents additional complexities. Ensuring compatibility between quantum dots and the underlying LED backlight, as well as with the color filters and other layers in the display stack, requires precise engineering and material science expertise. Mismatches in these integrations can lead to reduced efficiency and compromised display performance.

Scale-up of production processes from laboratory to industrial levels poses another significant hurdle. Maintaining the quality and consistency of quantum dot synthesis and application across large-scale manufacturing lines is challenging. This includes controlling particle size distribution, preventing agglomeration, and ensuring uniform dispersion within the display matrix.

Furthermore, the cost-effectiveness of QLED manufacturing remains a concern. While QLEDs offer superior color performance compared to traditional LED displays, the production costs are still higher. Reducing these costs while maintaining or improving quality is crucial for wider market adoption. This involves optimizing material usage, improving production yields, and developing more efficient manufacturing processes.

Lastly, environmental and regulatory challenges cannot be overlooked. The use of heavy metals in some quantum dot formulations raises concerns about toxicity and environmental impact. Manufacturers must navigate increasingly stringent regulations while developing alternative, eco-friendly quantum dot materials that maintain the desired optical properties.

Another major challenge lies in the stability and longevity of quantum dots. These nanoparticles are susceptible to degradation when exposed to oxygen, moisture, and high temperatures. This vulnerability can result in reduced color purity and shortened lifespan of QLED displays. Developing effective encapsulation techniques to protect quantum dots from environmental factors remains a critical area of focus for manufacturers.

The integration of quantum dots with other display components presents additional complexities. Ensuring compatibility between quantum dots and the underlying LED backlight, as well as with the color filters and other layers in the display stack, requires precise engineering and material science expertise. Mismatches in these integrations can lead to reduced efficiency and compromised display performance.

Scale-up of production processes from laboratory to industrial levels poses another significant hurdle. Maintaining the quality and consistency of quantum dot synthesis and application across large-scale manufacturing lines is challenging. This includes controlling particle size distribution, preventing agglomeration, and ensuring uniform dispersion within the display matrix.

Furthermore, the cost-effectiveness of QLED manufacturing remains a concern. While QLEDs offer superior color performance compared to traditional LED displays, the production costs are still higher. Reducing these costs while maintaining or improving quality is crucial for wider market adoption. This involves optimizing material usage, improving production yields, and developing more efficient manufacturing processes.

Lastly, environmental and regulatory challenges cannot be overlooked. The use of heavy metals in some quantum dot formulations raises concerns about toxicity and environmental impact. Manufacturers must navigate increasingly stringent regulations while developing alternative, eco-friendly quantum dot materials that maintain the desired optical properties.

QLED Fabrication Tech

01 QLED structure and materials

QLED displays utilize quantum dot technology to enhance color performance. The structure typically includes layers of quantum dots, electron transport layers, and hole transport layers. Advanced materials such as perovskite quantum dots or metal halide quantum dots are being explored to improve efficiency and color purity.- QLED display structure and composition: QLED displays utilize quantum dot technology to enhance color performance and efficiency. The structure typically includes a quantum dot layer, light-emitting diodes, and various optical and electronic components to produce high-quality images with improved brightness and color accuracy.

- Quantum dot materials and synthesis: The development of advanced quantum dot materials is crucial for QLED performance. This includes the synthesis of quantum dots with specific properties, such as improved stability, narrow emission spectra, and high quantum yield. Various methods and compositions are employed to create quantum dots suitable for display applications.

- QLED backlight and color conversion: QLED displays often use quantum dots for color conversion in the backlight system. This involves incorporating quantum dots into films or other structures to convert blue LED light into pure red and green light, resulting in a wider color gamut and improved color accuracy compared to traditional LCD displays.

- QLED panel manufacturing and assembly: The manufacturing process for QLED displays involves several steps, including the deposition of quantum dot layers, integration with other display components, and assembly of the final panel. Techniques such as inkjet printing, photolithography, and roll-to-roll processing are used to create efficient and cost-effective QLED panels.

- QLED display driving and control systems: Advanced driving and control systems are essential for optimizing QLED display performance. This includes developing specialized circuits, algorithms, and software for managing quantum dot emission, color calibration, and overall display operation. These systems aim to enhance image quality, reduce power consumption, and extend the lifespan of QLED displays.

02 Quantum dot synthesis and application methods

Various methods for synthesizing and applying quantum dots in QLED displays are being developed. These include solution-based processes, inkjet printing techniques, and vapor deposition methods. The focus is on achieving uniform quantum dot layers and improving the interface between different functional layers.Expand Specific Solutions03 QLED device architecture optimization

Researchers are exploring different device architectures to enhance QLED performance. This includes developing inverted structures, tandem devices, and hybrid architectures that combine quantum dots with other emissive materials. The goal is to improve efficiency, lifetime, and color quality of QLED displays.Expand Specific Solutions04 QLED backlight and color conversion

QLED technology is being applied in backlight units for LCD displays and as color conversion layers in other display technologies. This involves optimizing quantum dot films or color conversion layers to enhance color gamut and brightness while maintaining energy efficiency.Expand Specific Solutions05 QLED manufacturing and quality control

Advanced manufacturing techniques and quality control processes are being developed for QLED displays. This includes methods for large-scale production, encapsulation techniques to protect quantum dots from environmental degradation, and in-line monitoring systems to ensure consistent display quality.Expand Specific Solutions

QLED Industry Leaders

The QLED display manufacturing landscape is in a growth phase, with increasing market size and technological advancements. The industry is characterized by intense competition among major players like Samsung Display, LG Electronics, and BOE Technology Group. These companies are driving innovation and pushing the boundaries of QLED technology. The market is witnessing rapid expansion due to growing demand for high-quality displays in various applications. While QLED technology has matured significantly, challenges remain in areas such as production efficiency, color accuracy, and cost reduction. Companies like TCL China Star Optoelectronics and Sharp Corp. are also making strides in QLED development, contributing to the overall technological progress in the field.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced QLED manufacturing techniques, including their proprietary "printing" method for quantum dot deposition. This process involves precisely depositing quantum dots onto a substrate using inkjet-like technology, allowing for more accurate placement and reduced material waste. BOE has also implemented AI-driven quality control systems to detect defects in real-time during production, significantly improving yield rates. Additionally, they've developed a unique encapsulation technology to protect quantum dots from environmental degradation, enhancing the longevity and stability of their QLED displays.

Strengths: Innovative printing method reduces production costs and improves efficiency. AI-driven quality control enhances product reliability. Advanced encapsulation technology improves display longevity. Weaknesses: Relatively new to QLED technology compared to some competitors. May face challenges in scaling up production to meet global demand.

LG Electronics, Inc.

Technical Solution: LG has developed a proprietary "NanoCell" technology for their QLED displays, which uses nanoparticles to absorb unwanted light wavelengths, enhancing color purity and viewing angles. They've also implemented an advanced color calibration system that uses AI to optimize color accuracy across different content types. LG's manufacturing process incorporates a unique quantum dot film application method that ensures uniform distribution of quantum dots, resulting in consistent brightness and color across the entire display. Furthermore, they've developed a heat management system specifically designed for QLED panels to prevent quantum dot degradation and extend the lifespan of their displays.

Strengths: NanoCell technology provides superior color accuracy and wider viewing angles. AI-driven color calibration enhances user experience. Advanced heat management system improves display longevity. Weaknesses: Higher production costs due to proprietary technologies may impact pricing competitiveness.

QLED Patent Landscape

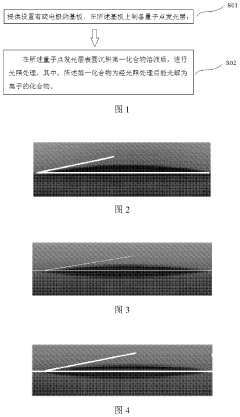

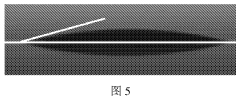

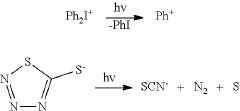

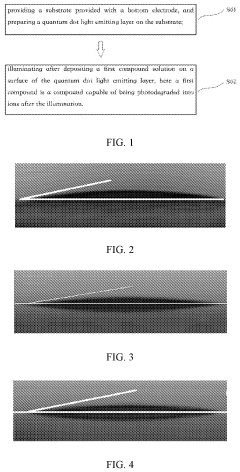

QLED and manufacturing method thereof

PatentActiveUS20220081313A1

Innovation

- A QLED manufacturing method involving the use of a first compound solution that photodegrades into ions under illumination, applied to the quantum dot light emitting layer, which reduces the contact angle and improves the compatibility between layers, enhancing the flatness and luminous efficiency of the QLED.

QLED and manufacturing method thereof

PatentActiveUS11965124B2

Innovation

- A QLED manufacturing method involving the use of a first compound solution that photodegrades into ions upon illumination, applied to the quantum dot light emitting layer, which reduces the contact angle and improves the compatibility between layers, enhancing the flatness and luminous efficiency of the QLED device.

QLED Supply Chain

The QLED supply chain plays a crucial role in the manufacturing and distribution of Quantum Dot Light-Emitting Diode (QLED) displays. This complex network involves multiple stakeholders, from raw material suppliers to end-product manufacturers, each contributing to the production of high-quality QLED displays.

At the foundation of the QLED supply chain are the suppliers of quantum dots, the key component that gives QLED displays their superior color performance. These nanocrystal semiconductors are typically produced by specialized chemical companies or dedicated quantum dot manufacturers. The production of quantum dots requires precise control over particle size and composition, making it a highly specialized process.

Moving up the chain, we find the manufacturers of QLED films and components. These companies integrate quantum dots into films or other structures that can be incorporated into display panels. This step is critical in ensuring the uniform distribution of quantum dots and maintaining their optical properties in the final product.

Panel manufacturers form the next crucial link in the QLED supply chain. These companies assemble the various components, including the QLED films, backlight units, and other necessary elements, to create the complete display panel. This stage requires significant technological expertise and manufacturing capabilities to ensure high yield rates and consistent quality.

The supply chain also includes providers of other essential components such as backlights, color filters, and electronic drivers. These components work in concert with the quantum dot layer to produce the final display output. The integration of these elements requires close collaboration between suppliers and panel manufacturers to optimize performance and reduce production costs.

Display module assemblers represent another important segment of the QLED supply chain. These companies take the completed panels and integrate them with additional components such as frames, control boards, and interfaces to create finished display modules ready for integration into consumer electronics.

At the end of the supply chain are the consumer electronics brands that incorporate QLED displays into their products. These companies work closely with suppliers throughout the chain to ensure that the displays meet their specific requirements for performance, quality, and cost.

The QLED supply chain is characterized by its global nature, with different stages of production often occurring in various countries. This international distribution can introduce challenges related to logistics, quality control, and supply chain resilience. Managing these complexities requires sophisticated supply chain management strategies and close coordination among all participants.

At the foundation of the QLED supply chain are the suppliers of quantum dots, the key component that gives QLED displays their superior color performance. These nanocrystal semiconductors are typically produced by specialized chemical companies or dedicated quantum dot manufacturers. The production of quantum dots requires precise control over particle size and composition, making it a highly specialized process.

Moving up the chain, we find the manufacturers of QLED films and components. These companies integrate quantum dots into films or other structures that can be incorporated into display panels. This step is critical in ensuring the uniform distribution of quantum dots and maintaining their optical properties in the final product.

Panel manufacturers form the next crucial link in the QLED supply chain. These companies assemble the various components, including the QLED films, backlight units, and other necessary elements, to create the complete display panel. This stage requires significant technological expertise and manufacturing capabilities to ensure high yield rates and consistent quality.

The supply chain also includes providers of other essential components such as backlights, color filters, and electronic drivers. These components work in concert with the quantum dot layer to produce the final display output. The integration of these elements requires close collaboration between suppliers and panel manufacturers to optimize performance and reduce production costs.

Display module assemblers represent another important segment of the QLED supply chain. These companies take the completed panels and integrate them with additional components such as frames, control boards, and interfaces to create finished display modules ready for integration into consumer electronics.

At the end of the supply chain are the consumer electronics brands that incorporate QLED displays into their products. These companies work closely with suppliers throughout the chain to ensure that the displays meet their specific requirements for performance, quality, and cost.

The QLED supply chain is characterized by its global nature, with different stages of production often occurring in various countries. This international distribution can introduce challenges related to logistics, quality control, and supply chain resilience. Managing these complexities requires sophisticated supply chain management strategies and close coordination among all participants.

QLED Sustainability

Sustainability in QLED display manufacturing is becoming increasingly crucial as the industry expands and environmental concerns grow. The production of QLED displays involves several processes that can have significant environmental impacts, including the use of rare earth materials, energy-intensive manufacturing techniques, and potential waste generation.

One of the primary sustainability challenges in QLED manufacturing is the sourcing of materials. Quantum dots, the key components of QLED displays, often contain heavy metals such as cadmium, which can be toxic if not properly managed. Industry leaders are actively researching alternative materials that offer similar performance without the environmental risks. For instance, indium phosphide-based quantum dots have shown promise as a more environmentally friendly option.

Energy consumption during the manufacturing process is another area of concern. QLED production requires precise temperature control and clean room environments, both of which are energy-intensive. To address this, manufacturers are investing in more efficient equipment and exploring ways to optimize production processes. Some facilities have begun implementing renewable energy sources, such as solar panels, to offset their carbon footprint.

Waste reduction and management are also critical aspects of QLED sustainability. The production of quantum dots and other components can generate hazardous waste that requires careful handling and disposal. Advanced recycling techniques are being developed to recover valuable materials from manufacturing waste and end-of-life products, promoting a more circular economy approach in the industry.

Water usage is another sustainability factor that manufacturers are addressing. QLED production requires ultra-pure water for cleaning and processing. Implementing water recycling systems and more efficient cleaning technologies can significantly reduce water consumption and wastewater generation.

As consumer awareness of environmental issues grows, QLED manufacturers are also focusing on the sustainability of their end products. This includes designing displays for longer lifespans, improved energy efficiency during use, and easier disassembly for recycling at the end of their life cycle. Some companies are exploring modular designs that allow for component upgrades rather than full device replacement.

The industry is also seeing a push towards more transparent supply chains and sustainability reporting. Many QLED manufacturers are now publishing detailed environmental impact assessments and setting ambitious targets for reducing their carbon footprint and improving overall sustainability. This transparency not only helps in meeting regulatory requirements but also builds consumer trust and brand value.

One of the primary sustainability challenges in QLED manufacturing is the sourcing of materials. Quantum dots, the key components of QLED displays, often contain heavy metals such as cadmium, which can be toxic if not properly managed. Industry leaders are actively researching alternative materials that offer similar performance without the environmental risks. For instance, indium phosphide-based quantum dots have shown promise as a more environmentally friendly option.

Energy consumption during the manufacturing process is another area of concern. QLED production requires precise temperature control and clean room environments, both of which are energy-intensive. To address this, manufacturers are investing in more efficient equipment and exploring ways to optimize production processes. Some facilities have begun implementing renewable energy sources, such as solar panels, to offset their carbon footprint.

Waste reduction and management are also critical aspects of QLED sustainability. The production of quantum dots and other components can generate hazardous waste that requires careful handling and disposal. Advanced recycling techniques are being developed to recover valuable materials from manufacturing waste and end-of-life products, promoting a more circular economy approach in the industry.

Water usage is another sustainability factor that manufacturers are addressing. QLED production requires ultra-pure water for cleaning and processing. Implementing water recycling systems and more efficient cleaning technologies can significantly reduce water consumption and wastewater generation.

As consumer awareness of environmental issues grows, QLED manufacturers are also focusing on the sustainability of their end products. This includes designing displays for longer lifespans, improved energy efficiency during use, and easier disassembly for recycling at the end of their life cycle. Some companies are exploring modular designs that allow for component upgrades rather than full device replacement.

The industry is also seeing a push towards more transparent supply chains and sustainability reporting. Many QLED manufacturers are now publishing detailed environmental impact assessments and setting ambitious targets for reducing their carbon footprint and improving overall sustainability. This transparency not only helps in meeting regulatory requirements but also builds consumer trust and brand value.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!