How to Maintain Image Integrity in QLED Display Units?

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Display Evolution

The evolution of QLED (Quantum Dot Light Emitting Diode) display technology represents a significant advancement in the field of visual display systems. This technology has its roots in the early 2000s when researchers first began exploring the potential of quantum dots for display applications. The journey from concept to commercial reality has been marked by several key milestones and technological breakthroughs.

In the initial stages, QLED technology faced challenges in achieving stable and efficient light emission from quantum dots. Researchers focused on improving the quantum yield and color purity of these nanoscale semiconductors. By the mid-2000s, significant progress had been made in synthesizing high-quality quantum dots with narrow emission spectra, laying the foundation for their use in displays.

The next phase of QLED evolution saw the integration of quantum dots into existing display technologies. Around 2013, the first QLED TVs were introduced to the market, utilizing quantum dots in combination with traditional LED backlighting. These early models demonstrated enhanced color gamut and brightness compared to conventional LED-LCD displays, but still relied on liquid crystal technology for image formation.

A major leap forward came with the development of electroluminescent quantum dot displays. This approach aimed to use quantum dots as the primary light-emitting elements, similar to OLED technology. Researchers worked on overcoming challenges such as charge injection and quantum dot stability under electrical excitation. By the late 2010s, prototypes of true QLED displays began to emerge, promising improved efficiency and color performance.

Recent years have seen a focus on refining QLED technology to address image integrity issues. Efforts have been directed towards enhancing the stability of quantum dots, reducing degradation over time, and improving color consistency across the display. Advanced manufacturing techniques, such as photolithography patterning of quantum dots, have been developed to achieve higher pixel densities and better image quality.

The ongoing evolution of QLED displays also involves addressing challenges related to blue light emission, which has traditionally been a weak point for quantum dot technology. Research into new materials and structures, such as perovskite quantum dots, shows promise in overcoming this limitation and further improving display performance.

As QLED technology continues to mature, the focus is shifting towards large-scale production and cost-effective manufacturing processes. This includes developing methods for precise deposition of quantum dots and integrating them with existing display manufacturing infrastructure. The goal is to make QLED displays commercially viable across a wide range of applications, from smartphones to large-format displays.

In the initial stages, QLED technology faced challenges in achieving stable and efficient light emission from quantum dots. Researchers focused on improving the quantum yield and color purity of these nanoscale semiconductors. By the mid-2000s, significant progress had been made in synthesizing high-quality quantum dots with narrow emission spectra, laying the foundation for their use in displays.

The next phase of QLED evolution saw the integration of quantum dots into existing display technologies. Around 2013, the first QLED TVs were introduced to the market, utilizing quantum dots in combination with traditional LED backlighting. These early models demonstrated enhanced color gamut and brightness compared to conventional LED-LCD displays, but still relied on liquid crystal technology for image formation.

A major leap forward came with the development of electroluminescent quantum dot displays. This approach aimed to use quantum dots as the primary light-emitting elements, similar to OLED technology. Researchers worked on overcoming challenges such as charge injection and quantum dot stability under electrical excitation. By the late 2010s, prototypes of true QLED displays began to emerge, promising improved efficiency and color performance.

Recent years have seen a focus on refining QLED technology to address image integrity issues. Efforts have been directed towards enhancing the stability of quantum dots, reducing degradation over time, and improving color consistency across the display. Advanced manufacturing techniques, such as photolithography patterning of quantum dots, have been developed to achieve higher pixel densities and better image quality.

The ongoing evolution of QLED displays also involves addressing challenges related to blue light emission, which has traditionally been a weak point for quantum dot technology. Research into new materials and structures, such as perovskite quantum dots, shows promise in overcoming this limitation and further improving display performance.

As QLED technology continues to mature, the focus is shifting towards large-scale production and cost-effective manufacturing processes. This includes developing methods for precise deposition of quantum dots and integrating them with existing display manufacturing infrastructure. The goal is to make QLED displays commercially viable across a wide range of applications, from smartphones to large-format displays.

Market Demand Analysis

The market demand for QLED display units with high image integrity continues to grow rapidly across various sectors. Consumer electronics, particularly high-end televisions and monitors, represent the largest market segment. As consumers increasingly seek immersive viewing experiences, the demand for QLED displays offering superior color accuracy, brightness, and contrast has surged. This trend is further amplified by the rising popularity of 4K and 8K content, which requires displays capable of maintaining image integrity at higher resolutions.

In the professional sector, industries such as graphic design, video editing, and medical imaging are driving demand for QLED displays with exceptional image integrity. These fields require displays that can accurately reproduce colors and maintain image quality over extended periods, making QLED technology particularly attractive. The gaming industry also contributes significantly to market growth, with gamers demanding displays that can deliver high refresh rates and vibrant colors without compromising image integrity.

The automotive industry is emerging as a promising market for QLED displays. As vehicles become more technologically advanced, there is an increasing need for high-quality displays in infotainment systems and digital dashboards. QLED technology's ability to maintain image integrity under varying lighting conditions makes it well-suited for in-vehicle applications.

Market analysts project the global QLED display market to expand at a compound annual growth rate of over 20% in the coming years. This growth is attributed to technological advancements, increasing disposable income in developing economies, and the growing adoption of QLED technology in various applications.

However, the market faces challenges that could impact demand. The high cost of QLED displays compared to traditional LED and OLED alternatives remains a barrier to widespread adoption, particularly in price-sensitive markets. Additionally, concerns about the long-term durability and potential for image retention in QLED displays may influence consumer purchasing decisions.

Despite these challenges, the overall market outlook remains positive. Manufacturers are investing heavily in research and development to address issues related to image integrity, focusing on areas such as quantum dot stability, color accuracy, and longevity. As these improvements are realized and production costs decrease, the demand for QLED displays with superior image integrity is expected to accelerate across both consumer and professional markets.

In the professional sector, industries such as graphic design, video editing, and medical imaging are driving demand for QLED displays with exceptional image integrity. These fields require displays that can accurately reproduce colors and maintain image quality over extended periods, making QLED technology particularly attractive. The gaming industry also contributes significantly to market growth, with gamers demanding displays that can deliver high refresh rates and vibrant colors without compromising image integrity.

The automotive industry is emerging as a promising market for QLED displays. As vehicles become more technologically advanced, there is an increasing need for high-quality displays in infotainment systems and digital dashboards. QLED technology's ability to maintain image integrity under varying lighting conditions makes it well-suited for in-vehicle applications.

Market analysts project the global QLED display market to expand at a compound annual growth rate of over 20% in the coming years. This growth is attributed to technological advancements, increasing disposable income in developing economies, and the growing adoption of QLED technology in various applications.

However, the market faces challenges that could impact demand. The high cost of QLED displays compared to traditional LED and OLED alternatives remains a barrier to widespread adoption, particularly in price-sensitive markets. Additionally, concerns about the long-term durability and potential for image retention in QLED displays may influence consumer purchasing decisions.

Despite these challenges, the overall market outlook remains positive. Manufacturers are investing heavily in research and development to address issues related to image integrity, focusing on areas such as quantum dot stability, color accuracy, and longevity. As these improvements are realized and production costs decrease, the demand for QLED displays with superior image integrity is expected to accelerate across both consumer and professional markets.

Technical Challenges

QLED (Quantum Dot Light Emitting Diode) display technology has made significant strides in recent years, offering enhanced color accuracy and brightness. However, maintaining image integrity in QLED display units presents several technical challenges that researchers and manufacturers must address.

One of the primary challenges is the degradation of quantum dots over time. Quantum dots, the core component of QLED displays, are susceptible to oxidation and photo-bleaching, which can lead to a decrease in luminescence efficiency and color shift. This degradation affects the long-term stability of image quality, potentially resulting in reduced brightness and color accuracy as the display ages.

Another significant challenge is the uniformity of quantum dot distribution across the display panel. Achieving consistent quantum dot deposition during the manufacturing process is crucial for maintaining uniform color and brightness across the entire screen. Variations in quantum dot density can lead to visible inconsistencies in image quality, particularly in large-format displays.

Temperature sensitivity poses an additional hurdle for QLED technology. Quantum dots exhibit temperature-dependent behavior, with their emission characteristics changing as the operating temperature fluctuates. This can result in color shifts and brightness variations, especially in environments with unstable temperature conditions or during extended use periods when the display generates heat.

The integration of quantum dots with other display components, such as color filters and light-guiding structures, presents its own set of challenges. Optimizing the interaction between these elements is crucial for maximizing color gamut and maintaining image integrity across different viewing angles. Achieving perfect alignment and minimizing light loss at interfaces remains an ongoing technical challenge.

Electrical stability is another critical factor in maintaining image integrity. QLED displays require precise control of current flow to individual pixels to ensure accurate color reproduction and prevent issues such as image retention or burn-in. Developing robust driving circuits and addressing potential current leakage problems are essential for long-term image quality preservation.

Furthermore, the encapsulation of quantum dots to protect them from environmental factors such as moisture and oxygen presents a significant challenge. Effective encapsulation is crucial for preventing degradation and ensuring the longevity of the display, but it must be achieved without compromising optical performance or increasing manufacturing complexity excessively.

Lastly, the challenge of scaling up production while maintaining consistent quality cannot be overlooked. As QLED technology moves towards mass production, ensuring uniformity and reliability across large volumes of displays becomes increasingly difficult. Developing robust quality control measures and refining manufacturing processes to minimize variability are ongoing challenges in the industry.

One of the primary challenges is the degradation of quantum dots over time. Quantum dots, the core component of QLED displays, are susceptible to oxidation and photo-bleaching, which can lead to a decrease in luminescence efficiency and color shift. This degradation affects the long-term stability of image quality, potentially resulting in reduced brightness and color accuracy as the display ages.

Another significant challenge is the uniformity of quantum dot distribution across the display panel. Achieving consistent quantum dot deposition during the manufacturing process is crucial for maintaining uniform color and brightness across the entire screen. Variations in quantum dot density can lead to visible inconsistencies in image quality, particularly in large-format displays.

Temperature sensitivity poses an additional hurdle for QLED technology. Quantum dots exhibit temperature-dependent behavior, with their emission characteristics changing as the operating temperature fluctuates. This can result in color shifts and brightness variations, especially in environments with unstable temperature conditions or during extended use periods when the display generates heat.

The integration of quantum dots with other display components, such as color filters and light-guiding structures, presents its own set of challenges. Optimizing the interaction between these elements is crucial for maximizing color gamut and maintaining image integrity across different viewing angles. Achieving perfect alignment and minimizing light loss at interfaces remains an ongoing technical challenge.

Electrical stability is another critical factor in maintaining image integrity. QLED displays require precise control of current flow to individual pixels to ensure accurate color reproduction and prevent issues such as image retention or burn-in. Developing robust driving circuits and addressing potential current leakage problems are essential for long-term image quality preservation.

Furthermore, the encapsulation of quantum dots to protect them from environmental factors such as moisture and oxygen presents a significant challenge. Effective encapsulation is crucial for preventing degradation and ensuring the longevity of the display, but it must be achieved without compromising optical performance or increasing manufacturing complexity excessively.

Lastly, the challenge of scaling up production while maintaining consistent quality cannot be overlooked. As QLED technology moves towards mass production, ensuring uniformity and reliability across large volumes of displays becomes increasingly difficult. Developing robust quality control measures and refining manufacturing processes to minimize variability are ongoing challenges in the industry.

Current Image Integrity Solutions

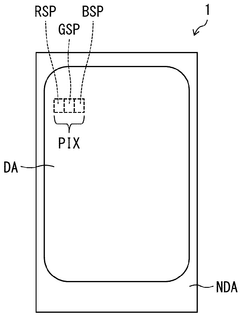

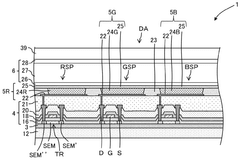

01 QLED display structure optimization

Improving the structure of QLED displays to enhance image integrity. This includes optimizing quantum dot layers, electrode configurations, and light-emitting components to achieve better color accuracy, brightness uniformity, and overall image quality.- QLED display structure and materials: QLED displays utilize quantum dot technology to enhance color accuracy and brightness. The structure typically includes layers of quantum dots, electron transport layers, and hole transport layers. Advanced materials and fabrication techniques are employed to improve the overall performance and image integrity of QLED displays.

- Image processing and enhancement techniques: Various image processing algorithms and techniques are implemented to improve the image integrity of QLED displays. These may include color correction, contrast enhancement, and noise reduction methods. Advanced signal processing and AI-based techniques are also utilized to optimize image quality and maintain integrity across different content types.

- Driving and control systems for QLED displays: Specialized driving circuits and control systems are developed to ensure optimal performance of QLED display units. These systems manage factors such as voltage distribution, current control, and timing to maintain image integrity. Advanced control algorithms may be implemented to compensate for potential issues like non-uniformity or aging effects.

- Optical designs for improved image quality: Various optical designs and components are incorporated into QLED displays to enhance image integrity. These may include specialized lenses, filters, and light management structures. Optical designs aim to improve factors such as viewing angle, color uniformity, and contrast ratio, contributing to overall image quality.

- Calibration and quality control methods: Advanced calibration techniques and quality control methods are employed to ensure consistent image integrity across QLED display units. These may include automated testing systems, in-line calibration processes, and feedback mechanisms to adjust display parameters. Such methods help maintain color accuracy, brightness uniformity, and overall image quality throughout the production and lifecycle of QLED displays.

02 Image processing algorithms for QLED displays

Developing advanced image processing algorithms specifically tailored for QLED technology. These algorithms focus on enhancing color reproduction, reducing motion blur, and improving contrast ratios to maintain image integrity across various content types and viewing conditions.Expand Specific Solutions03 Quantum dot material advancements

Researching and developing new quantum dot materials or improving existing ones to enhance the overall performance of QLED displays. This includes efforts to increase quantum yield, improve color purity, and enhance stability for maintaining image integrity over extended periods.Expand Specific Solutions04 Driving and control systems for QLED displays

Innovating driving circuits and control systems specifically designed for QLED displays. These systems aim to optimize power distribution, pixel addressing, and refresh rates to ensure consistent image quality and integrity across the entire display panel.Expand Specific Solutions05 QLED display calibration and compensation techniques

Developing advanced calibration and compensation techniques to maintain image integrity in QLED displays. This includes methods for real-time adjustment of color balance, brightness levels, and gamma curves to compensate for variations in manufacturing processes and aging effects.Expand Specific Solutions

Key Industry Players

The QLED display market is in a growth phase, with increasing demand for high-quality, energy-efficient displays. The global QLED market size is projected to expand significantly in the coming years. Technologically, QLED displays are maturing, with key players like Samsung Display, LG Display, and BOE Technology Group leading innovation. These companies are focusing on improving image integrity through enhanced color accuracy, brightness, and longevity. Other significant contributors include Sharp, Sony, and Japan Display, who are investing in R&D to overcome challenges such as color shift and burn-in issues. The competition is intense, with companies like LG Electronics and Kyocera also making strides in QLED technology, driving continuous improvements in image quality and display performance.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a proprietary QLED technology called ART (Advanced Reflective Technology). This technology incorporates a specially designed optical film that enhances light utilization efficiency and reduces reflection, thereby improving image integrity in various lighting conditions. BOE's QLED displays also feature a quantum dot color filter that provides a wider color gamut and better color accuracy. They have implemented an advanced local dimming technology to improve contrast ratios and maintain image quality in dark scenes.

Strengths: Excellent performance in bright environments, wide color gamut, and good energy efficiency. Weaknesses: Slightly lower peak brightness compared to some competitors.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed advanced QLED technology that utilizes quantum dots to enhance color accuracy and brightness. Their approach involves encapsulating quantum dots in a protective shell to prevent oxidation and degradation, which is crucial for maintaining image integrity over time. They have also implemented a color volume 100% technique, which ensures consistent color representation across different brightness levels. Additionally, Samsung has introduced a metal quantum dot material that improves energy efficiency and longevity of the display.

Strengths: Superior color accuracy, high brightness, and long-lasting performance. Weaknesses: Higher production costs and potential for blue light emission.

Core QLED Innovations

Display device and composite-type display device

PatentWO2021261191A1

Innovation

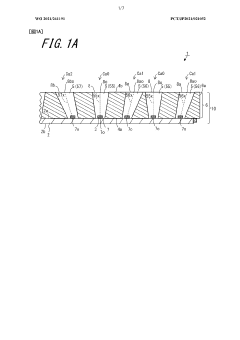

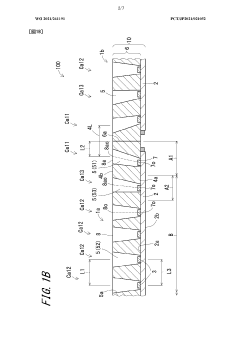

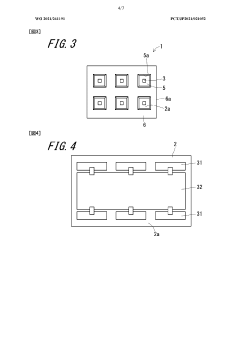

- The display device incorporates a cavity structure with inclined cavities and through holes, where light emitting elements are positioned to radiate light obliquely, covering the joint edges and maintaining uniformity in pixel pitch, and using a combination of light emitting elements with different wavelengths to ensure consistent viewing angles and visibility.

Light-emitting element, display device, and method for forming light-emitting layer

PatentWO2024218932A1

Innovation

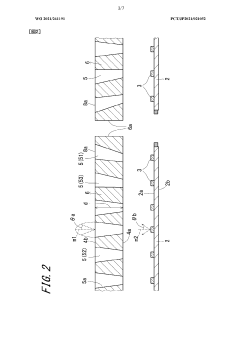

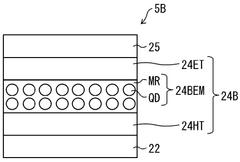

- A light-emitting element and display device with a light-emitting layer comprising multiple quantum dots and a medium containing an inorganic oxide with a metal element or metalloid element and a metal sulfide, where the medium is formed by applying a mixed solution of quantum dots, an inorganic oxide precursor, and a metal sulfide precursor, followed by heat treatment.

Environmental Impact

The environmental impact of QLED display units, particularly in relation to maintaining image integrity, is a crucial consideration in the development and deployment of this technology. QLED displays, while offering superior image quality and energy efficiency compared to traditional LED displays, still present several environmental challenges throughout their lifecycle.

Manufacturing processes for QLED displays involve the use of quantum dots, which are typically made from heavy metals such as cadmium or indium. These materials, if not properly managed, can pose significant environmental risks. The production of quantum dots requires precise control over particle size and composition, often involving energy-intensive processes and potentially hazardous chemicals. This raises concerns about resource depletion and the release of toxic substances into the environment.

During the operational phase, QLED displays consume less energy than their predecessors, contributing to reduced carbon emissions. However, the long-term stability of quantum dots remains a challenge. As these nanoparticles degrade over time, they may release toxic elements, potentially contaminating the environment if not properly contained or disposed of. This degradation also affects image integrity, necessitating more frequent replacements and contributing to electronic waste.

End-of-life management of QLED displays presents another significant environmental challenge. The complex composition of these devices, including the quantum dot layer, makes recycling difficult. Improper disposal can lead to the leaching of hazardous materials into soil and water systems. Developing effective recycling techniques for QLED displays is crucial to mitigate these environmental risks and promote a circular economy approach.

The pursuit of maintaining image integrity in QLED displays often involves trade-offs between performance and environmental impact. For instance, enhancing the stability of quantum dots may require additional protective layers or materials, potentially increasing the overall environmental footprint of the device. Balancing these factors necessitates innovative approaches in materials science and manufacturing processes.

Research into more environmentally friendly quantum dot materials, such as carbon dots or perovskite quantum dots, shows promise in reducing the reliance on heavy metals. These alternatives could potentially offer similar performance characteristics while minimizing environmental risks. Additionally, advancements in encapsulation technologies aim to extend the lifespan of QLED displays, reducing the frequency of replacements and associated electronic waste.

In conclusion, maintaining image integrity in QLED display units while minimizing environmental impact requires a holistic approach. This includes optimizing manufacturing processes, developing more stable and eco-friendly quantum dot materials, improving energy efficiency during operation, and establishing effective recycling and disposal methods. As the technology continues to evolve, addressing these environmental concerns will be crucial for the sustainable growth and adoption of QLED display technology.

Manufacturing processes for QLED displays involve the use of quantum dots, which are typically made from heavy metals such as cadmium or indium. These materials, if not properly managed, can pose significant environmental risks. The production of quantum dots requires precise control over particle size and composition, often involving energy-intensive processes and potentially hazardous chemicals. This raises concerns about resource depletion and the release of toxic substances into the environment.

During the operational phase, QLED displays consume less energy than their predecessors, contributing to reduced carbon emissions. However, the long-term stability of quantum dots remains a challenge. As these nanoparticles degrade over time, they may release toxic elements, potentially contaminating the environment if not properly contained or disposed of. This degradation also affects image integrity, necessitating more frequent replacements and contributing to electronic waste.

End-of-life management of QLED displays presents another significant environmental challenge. The complex composition of these devices, including the quantum dot layer, makes recycling difficult. Improper disposal can lead to the leaching of hazardous materials into soil and water systems. Developing effective recycling techniques for QLED displays is crucial to mitigate these environmental risks and promote a circular economy approach.

The pursuit of maintaining image integrity in QLED displays often involves trade-offs between performance and environmental impact. For instance, enhancing the stability of quantum dots may require additional protective layers or materials, potentially increasing the overall environmental footprint of the device. Balancing these factors necessitates innovative approaches in materials science and manufacturing processes.

Research into more environmentally friendly quantum dot materials, such as carbon dots or perovskite quantum dots, shows promise in reducing the reliance on heavy metals. These alternatives could potentially offer similar performance characteristics while minimizing environmental risks. Additionally, advancements in encapsulation technologies aim to extend the lifespan of QLED displays, reducing the frequency of replacements and associated electronic waste.

In conclusion, maintaining image integrity in QLED display units while minimizing environmental impact requires a holistic approach. This includes optimizing manufacturing processes, developing more stable and eco-friendly quantum dot materials, improving energy efficiency during operation, and establishing effective recycling and disposal methods. As the technology continues to evolve, addressing these environmental concerns will be crucial for the sustainable growth and adoption of QLED display technology.

Quantum Dot Stability

Quantum dot stability is a critical factor in maintaining image integrity in QLED display units. The inherent instability of quantum dots poses significant challenges to the long-term performance and reliability of QLED displays. This instability primarily manifests as degradation of the quantum dots over time, leading to reduced luminescence efficiency and color shift.

One of the main causes of quantum dot instability is photo-oxidation. When exposed to light and oxygen, quantum dots can undergo chemical changes that alter their optical properties. This process is particularly problematic in display applications, where quantum dots are constantly subjected to light exposure. To address this issue, researchers have developed various encapsulation techniques to protect quantum dots from environmental factors.

Another factor affecting quantum dot stability is thermal degradation. High temperatures can cause structural changes in quantum dots, leading to decreased performance. This is especially relevant in display units, where heat generation is inevitable during operation. Thermal management strategies, such as improved heat dissipation and the use of thermally stable materials, are essential for maintaining quantum dot stability.

The choice of quantum dot material also plays a crucial role in stability. Cadmium-based quantum dots, while highly efficient, have raised environmental and health concerns. As a result, there has been a shift towards cadmium-free alternatives, such as indium phosphide-based quantum dots. These materials offer improved stability and reduced toxicity, albeit with some trade-offs in performance.

Surface engineering of quantum dots has emerged as a promising approach to enhance stability. By modifying the surface of quantum dots with protective ligands or shells, researchers can improve their resistance to degradation. Multi-shell structures, for instance, have shown significant improvements in both photo and thermal stability.

Recent advancements in quantum dot synthesis have led to the development of perovskite quantum dots. These materials exhibit exceptional color purity and brightness, along with improved stability compared to traditional semiconductor quantum dots. However, challenges remain in terms of their long-term stability and scalability for commercial applications.

To further improve quantum dot stability in QLED displays, ongoing research focuses on developing novel materials and encapsulation techniques. This includes the exploration of hybrid organic-inorganic structures and the use of advanced barrier films to protect quantum dots from moisture and oxygen. Additionally, the integration of quantum dots into more stable host materials is being investigated as a means to enhance overall device stability.

One of the main causes of quantum dot instability is photo-oxidation. When exposed to light and oxygen, quantum dots can undergo chemical changes that alter their optical properties. This process is particularly problematic in display applications, where quantum dots are constantly subjected to light exposure. To address this issue, researchers have developed various encapsulation techniques to protect quantum dots from environmental factors.

Another factor affecting quantum dot stability is thermal degradation. High temperatures can cause structural changes in quantum dots, leading to decreased performance. This is especially relevant in display units, where heat generation is inevitable during operation. Thermal management strategies, such as improved heat dissipation and the use of thermally stable materials, are essential for maintaining quantum dot stability.

The choice of quantum dot material also plays a crucial role in stability. Cadmium-based quantum dots, while highly efficient, have raised environmental and health concerns. As a result, there has been a shift towards cadmium-free alternatives, such as indium phosphide-based quantum dots. These materials offer improved stability and reduced toxicity, albeit with some trade-offs in performance.

Surface engineering of quantum dots has emerged as a promising approach to enhance stability. By modifying the surface of quantum dots with protective ligands or shells, researchers can improve their resistance to degradation. Multi-shell structures, for instance, have shown significant improvements in both photo and thermal stability.

Recent advancements in quantum dot synthesis have led to the development of perovskite quantum dots. These materials exhibit exceptional color purity and brightness, along with improved stability compared to traditional semiconductor quantum dots. However, challenges remain in terms of their long-term stability and scalability for commercial applications.

To further improve quantum dot stability in QLED displays, ongoing research focuses on developing novel materials and encapsulation techniques. This includes the exploration of hybrid organic-inorganic structures and the use of advanced barrier films to protect quantum dots from moisture and oxygen. Additionally, the integration of quantum dots into more stable host materials is being investigated as a means to enhance overall device stability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!