Advances in QLED Technologies for Diverse Applications

JUN 19, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Tech Evolution

Quantum dot light-emitting diode (QLED) technology has undergone significant evolution since its inception in the early 1990s. The journey of QLED development can be traced through several key stages, each marked by crucial technological advancements and breakthroughs.

In the initial phase, researchers focused on understanding the fundamental properties of quantum dots and their potential for light emission. The first QLEDs were fabricated using CdSe nanocrystals, demonstrating the feasibility of using quantum dots for electroluminescence. However, these early devices suffered from low efficiency and poor stability.

The next major milestone came in the mid-2000s with the introduction of core-shell quantum dots. This innovation significantly improved the quantum yield and stability of the emitters, leading to enhanced device performance. Researchers also began exploring different quantum dot materials, such as InP and ZnSe, to address toxicity concerns associated with cadmium-based quantum dots.

The late 2000s and early 2010s saw a focus on optimizing device architectures. Multi-layer structures were developed to improve charge injection and transport, resulting in higher efficiencies and longer device lifetimes. The introduction of solution-processed charge transport layers further simplified manufacturing processes and reduced costs.

A significant breakthrough occurred in the mid-2010s with the development of quantum dot color converters for LCD backlights. This technology, which combines blue LEDs with red and green quantum dots, marked the first widespread commercial application of quantum dots in displays.

Recent years have witnessed rapid advancements in QLED performance. The introduction of perovskite quantum dots has opened new possibilities for high-efficiency, wide color gamut displays. Researchers have also made progress in developing blue QLEDs, which have traditionally lagged behind their red and green counterparts in terms of efficiency and stability.

The latest frontier in QLED evolution is the development of electrically-driven quantum dot displays. While most commercial QLED displays still rely on LCD technology with quantum dot color conversion, true electroluminescent QLEDs promise even better color performance and energy efficiency. Major display manufacturers are investing heavily in this technology, with prototypes already demonstrated and commercial products on the horizon.

Looking ahead, the QLED technology roadmap includes further improvements in efficiency, color purity, and stability. Research is ongoing into new quantum dot materials, advanced manufacturing techniques, and novel device architectures. The integration of QLEDs with flexible and transparent substrates is also an area of active development, paving the way for innovative display applications beyond traditional flat panels.

In the initial phase, researchers focused on understanding the fundamental properties of quantum dots and their potential for light emission. The first QLEDs were fabricated using CdSe nanocrystals, demonstrating the feasibility of using quantum dots for electroluminescence. However, these early devices suffered from low efficiency and poor stability.

The next major milestone came in the mid-2000s with the introduction of core-shell quantum dots. This innovation significantly improved the quantum yield and stability of the emitters, leading to enhanced device performance. Researchers also began exploring different quantum dot materials, such as InP and ZnSe, to address toxicity concerns associated with cadmium-based quantum dots.

The late 2000s and early 2010s saw a focus on optimizing device architectures. Multi-layer structures were developed to improve charge injection and transport, resulting in higher efficiencies and longer device lifetimes. The introduction of solution-processed charge transport layers further simplified manufacturing processes and reduced costs.

A significant breakthrough occurred in the mid-2010s with the development of quantum dot color converters for LCD backlights. This technology, which combines blue LEDs with red and green quantum dots, marked the first widespread commercial application of quantum dots in displays.

Recent years have witnessed rapid advancements in QLED performance. The introduction of perovskite quantum dots has opened new possibilities for high-efficiency, wide color gamut displays. Researchers have also made progress in developing blue QLEDs, which have traditionally lagged behind their red and green counterparts in terms of efficiency and stability.

The latest frontier in QLED evolution is the development of electrically-driven quantum dot displays. While most commercial QLED displays still rely on LCD technology with quantum dot color conversion, true electroluminescent QLEDs promise even better color performance and energy efficiency. Major display manufacturers are investing heavily in this technology, with prototypes already demonstrated and commercial products on the horizon.

Looking ahead, the QLED technology roadmap includes further improvements in efficiency, color purity, and stability. Research is ongoing into new quantum dot materials, advanced manufacturing techniques, and novel device architectures. The integration of QLEDs with flexible and transparent substrates is also an area of active development, paving the way for innovative display applications beyond traditional flat panels.

QLED Market Dynamics

The QLED market has experienced significant growth in recent years, driven by increasing demand for high-quality displays in various applications. The global QLED market size was valued at approximately $8.5 billion in 2020 and is projected to reach $15.7 billion by 2026, growing at a CAGR of 10.8% during the forecast period. This robust growth is attributed to the superior performance characteristics of QLED technology, including enhanced color gamut, brightness, and energy efficiency compared to traditional LED and OLED displays.

The consumer electronics sector, particularly the television industry, has been the primary driver of QLED market expansion. Major manufacturers such as Samsung, TCL, and Hisense have heavily invested in QLED technology, leading to a wider range of QLED TV models across different price points. This has contributed to increased consumer adoption and market penetration. The automotive industry has also emerged as a significant growth area for QLED technology, with applications in advanced infotainment systems and heads-up displays.

In terms of regional dynamics, Asia-Pacific dominates the QLED market, accounting for over 40% of the global market share. This is largely due to the presence of major display manufacturers and a strong consumer electronics industry in countries like South Korea, China, and Japan. North America and Europe follow as key markets, driven by high consumer spending on premium display technologies and increasing adoption in commercial applications.

The QLED market is characterized by intense competition among key players, with Samsung Electronics holding the largest market share. Other significant players include LG Display, BOE Technology, and AUO Corporation. These companies are continuously investing in research and development to improve QLED technology and expand its applications beyond traditional display markets.

Emerging trends in the QLED market include the development of micro-LED and mini-LED technologies, which promise even higher contrast ratios and energy efficiency. Additionally, there is growing interest in flexible and transparent QLED displays, opening up new possibilities for innovative product designs and applications in sectors such as wearable technology and smart home devices.

Despite the positive growth outlook, the QLED market faces challenges such as high manufacturing costs and competition from other display technologies, particularly OLED. However, ongoing technological advancements and economies of scale are expected to gradually address these issues, further solidifying QLED's position in the display technology landscape.

The consumer electronics sector, particularly the television industry, has been the primary driver of QLED market expansion. Major manufacturers such as Samsung, TCL, and Hisense have heavily invested in QLED technology, leading to a wider range of QLED TV models across different price points. This has contributed to increased consumer adoption and market penetration. The automotive industry has also emerged as a significant growth area for QLED technology, with applications in advanced infotainment systems and heads-up displays.

In terms of regional dynamics, Asia-Pacific dominates the QLED market, accounting for over 40% of the global market share. This is largely due to the presence of major display manufacturers and a strong consumer electronics industry in countries like South Korea, China, and Japan. North America and Europe follow as key markets, driven by high consumer spending on premium display technologies and increasing adoption in commercial applications.

The QLED market is characterized by intense competition among key players, with Samsung Electronics holding the largest market share. Other significant players include LG Display, BOE Technology, and AUO Corporation. These companies are continuously investing in research and development to improve QLED technology and expand its applications beyond traditional display markets.

Emerging trends in the QLED market include the development of micro-LED and mini-LED technologies, which promise even higher contrast ratios and energy efficiency. Additionally, there is growing interest in flexible and transparent QLED displays, opening up new possibilities for innovative product designs and applications in sectors such as wearable technology and smart home devices.

Despite the positive growth outlook, the QLED market faces challenges such as high manufacturing costs and competition from other display technologies, particularly OLED. However, ongoing technological advancements and economies of scale are expected to gradually address these issues, further solidifying QLED's position in the display technology landscape.

QLED Tech Challenges

QLED (Quantum Dot Light-Emitting Diode) technology has made significant strides in recent years, but it still faces several technical challenges that need to be addressed for wider adoption and improved performance across diverse applications. One of the primary challenges is the stability and longevity of quantum dots, particularly in blue-emitting QLEDs. The blue quantum dots tend to degrade faster than their red and green counterparts, leading to color shift and reduced lifespan of QLED displays.

Another significant challenge is the efficiency of charge injection and transport within QLED devices. The interface between the quantum dot layer and the charge transport layers often suffers from energy level mismatches, resulting in reduced quantum efficiency and increased power consumption. Improving the charge balance and minimizing non-radiative recombination at these interfaces remains a critical area of research.

The manufacturing process for QLEDs also presents challenges, particularly in achieving uniform and precise deposition of quantum dot layers at scale. Current methods, such as inkjet printing and photolithography, struggle to maintain consistent quantum dot distribution and thickness across large areas, which can lead to variations in color and brightness in QLED displays.

Environmental stability is another concern for QLED technology. Quantum dots are sensitive to oxygen and moisture, which can cause degradation and loss of optical properties over time. Developing effective encapsulation techniques to protect quantum dots from environmental factors without compromising device performance is crucial for long-term reliability.

In the realm of flexible and stretchable electronics, integrating QLEDs into deformable substrates while maintaining their optical and electrical properties poses significant challenges. The rigid nature of traditional QLED structures conflicts with the requirements for flexibility, necessitating innovative approaches to materials and device architectures.

The toxicity of certain quantum dot materials, particularly those containing heavy metals like cadmium, raises environmental and health concerns. While progress has been made in developing cadmium-free quantum dots, these alternatives often fall short in terms of efficiency and color purity compared to their cadmium-based counterparts.

Lastly, the cost of QLED production remains a barrier to widespread adoption, especially in consumer electronics. The complex manufacturing processes and high-purity materials required for QLED fabrication contribute to elevated production costs. Developing more cost-effective production methods and materials without sacrificing performance is essential for the technology's commercial viability across diverse applications.

Another significant challenge is the efficiency of charge injection and transport within QLED devices. The interface between the quantum dot layer and the charge transport layers often suffers from energy level mismatches, resulting in reduced quantum efficiency and increased power consumption. Improving the charge balance and minimizing non-radiative recombination at these interfaces remains a critical area of research.

The manufacturing process for QLEDs also presents challenges, particularly in achieving uniform and precise deposition of quantum dot layers at scale. Current methods, such as inkjet printing and photolithography, struggle to maintain consistent quantum dot distribution and thickness across large areas, which can lead to variations in color and brightness in QLED displays.

Environmental stability is another concern for QLED technology. Quantum dots are sensitive to oxygen and moisture, which can cause degradation and loss of optical properties over time. Developing effective encapsulation techniques to protect quantum dots from environmental factors without compromising device performance is crucial for long-term reliability.

In the realm of flexible and stretchable electronics, integrating QLEDs into deformable substrates while maintaining their optical and electrical properties poses significant challenges. The rigid nature of traditional QLED structures conflicts with the requirements for flexibility, necessitating innovative approaches to materials and device architectures.

The toxicity of certain quantum dot materials, particularly those containing heavy metals like cadmium, raises environmental and health concerns. While progress has been made in developing cadmium-free quantum dots, these alternatives often fall short in terms of efficiency and color purity compared to their cadmium-based counterparts.

Lastly, the cost of QLED production remains a barrier to widespread adoption, especially in consumer electronics. The complex manufacturing processes and high-purity materials required for QLED fabrication contribute to elevated production costs. Developing more cost-effective production methods and materials without sacrificing performance is essential for the technology's commercial viability across diverse applications.

Current QLED Solutions

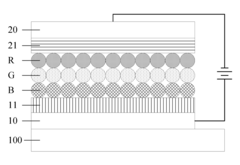

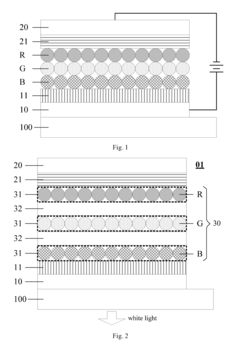

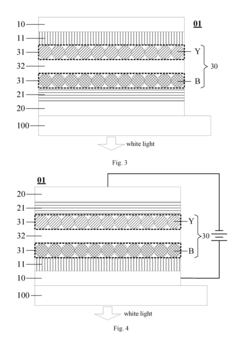

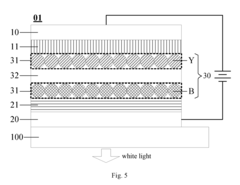

01 QLED structure and materials

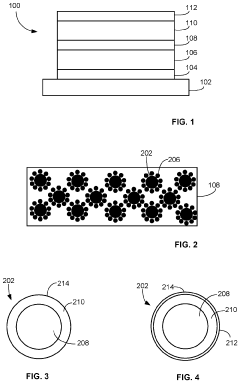

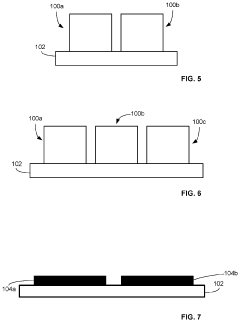

QLED technology involves the use of quantum dots as light-emitting materials. The structure typically includes layers of quantum dots sandwiched between electron and hole transport layers. Various materials and compositions are used to optimize the performance of QLEDs, including different types of quantum dots and charge transport materials.- QLED structure and materials: QLED technology involves the use of quantum dots as light-emitting materials. The structure typically includes layers of quantum dots sandwiched between electron and hole transport layers. Various materials and compositions are used to optimize the performance of these layers, including the quantum dot emissive layer, charge transport layers, and electrodes.

- Quantum dot synthesis and processing: The synthesis and processing of quantum dots are crucial for QLED performance. This includes methods for producing quantum dots with specific sizes, compositions, and surface treatments. Techniques for incorporating quantum dots into device structures, such as solution processing or transfer printing, are also important aspects of QLED technology.

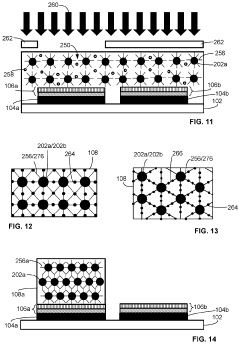

- Color conversion and light management: QLED technology often involves color conversion, where blue or UV light is converted to other colors using quantum dots. This includes the development of color filters, light management structures, and optimization of quantum dot placement to achieve desired color output and efficiency.

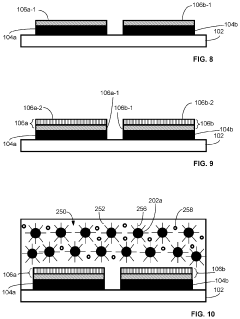

- Device architecture and fabrication: Innovations in QLED device architecture and fabrication processes are key to improving performance and manufacturability. This includes the development of novel electrode structures, encapsulation methods, and integration with other display technologies such as OLEDs or micro-LEDs.

- Efficiency and stability enhancement: Improving the efficiency and stability of QLED devices is a major focus of research. This includes developing new materials and structures to enhance charge injection and transport, reduce non-radiative recombination, and improve the longevity of devices under operational conditions.

02 Quantum dot synthesis and processing

The synthesis and processing of quantum dots are crucial for QLED performance. This includes methods for producing quantum dots with specific sizes, compositions, and surface properties. Techniques for incorporating quantum dots into device structures, such as solution processing or transfer printing, are also important aspects of QLED technology.Expand Specific Solutions03 QLED device architecture and optimization

QLED device architecture plays a significant role in determining performance. This includes the design of multilayer structures, electrode configurations, and light extraction techniques. Optimization of layer thicknesses, material interfaces, and charge balance are key factors in improving QLED efficiency and lifetime.Expand Specific Solutions04 Color tuning and white light emission

QLED technology allows for precise color tuning through control of quantum dot size and composition. Methods for achieving white light emission using combinations of different color quantum dots or hybrid approaches with other emissive materials are important for lighting applications. Color conversion layers using quantum dots are also explored for display technologies.Expand Specific Solutions05 QLED manufacturing and scalability

Developing scalable manufacturing processes for QLEDs is crucial for commercialization. This includes methods for large-area deposition of quantum dot layers, integration with existing display manufacturing techniques, and approaches to improve yield and reduce costs. Innovations in patterning techniques and encapsulation methods are also important for QLED production.Expand Specific Solutions

QLED Industry Leaders

The QLED technology market is experiencing rapid growth and innovation, driven by increasing demand for high-quality displays across various applications. The industry is in a phase of intense competition and technological advancement, with major players like Samsung Electronics, BOE Technology Group, and TCL China Star Optoelectronics Technology leading the charge. The market size is expanding significantly, fueled by applications in consumer electronics, automotive displays, and large-scale signage. Technological maturity varies among companies, with Samsung at the forefront, while others like Apple and Huawei are making strategic investments. Universities such as Zhejiang University and The Hong Kong University of Science & Technology are contributing to research and development, pushing the boundaries of QLED technology.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced QLED technology using quantum dot materials to enhance color performance and energy efficiency. Their QLED displays utilize a blue LED backlight combined with red and green quantum dots to produce a wide color gamut. BOE has also implemented quantum dot color filter technology, where quantum dots are directly patterned onto the color filter, improving light efficiency and reducing power consumption. Additionally, they have explored the use of perovskite quantum dots to further enhance color purity and stability.

Strengths: Wide color gamut, high brightness, and energy efficiency. Weaknesses: Potential for burn-in and shorter lifespan compared to some other display technologies.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed a proprietary QLED technology called "Q-cell" that combines quantum dot material with mini-LED backlighting. This approach allows for precise local dimming, enhancing contrast and HDR performance. They have also implemented a quantum dot color conversion layer that improves color accuracy and expands the color gamut. TCL CSOT's QLED displays feature advanced thermal management systems to maintain quantum dot stability and longevity. Furthermore, they have explored the integration of QLED technology with flexible substrates for curved and foldable display applications.

Strengths: High contrast ratio, excellent HDR performance, and potential for flexible displays. Weaknesses: Higher production costs compared to traditional LED-LCD displays.

QLED Core Innovations

Light emitting device and fabricating method thereof, display device

PatentActiveUS20180054872A1

Innovation

- Incorporating a transparent insulating layer between neighboring QD light-emitting layers of different colors in a light-emitting device, which blocks high-energy exciton transfer and acts as a buffer to maintain light balance and prevent electric leakage.

Photo-patterned emissive layer containing passivated quantum dots, arrangement of light-emitting devices including same, and method of making same

PatentActiveUS20210043862A1

Innovation

- The use of compact ligands, such as short-chain organic, inorganic molecular, or inorganic ion ligands, is introduced to improve passivation and charge transport by replacing conventional long-chain ligands through a process involving cross-linkable and exchangeable ligands, followed by UV lithography and ligand exchange to form a denser emissive layer with enhanced packing and reduced defects.

QLED Eco-Friendliness

QLED technology has made significant strides in eco-friendliness, positioning itself as a more sustainable alternative in the display industry. One of the key advantages of QLEDs is their energy efficiency. These displays consume less power compared to traditional LED and OLED technologies, resulting in reduced energy consumption over their lifetime. This not only translates to lower electricity bills for consumers but also contributes to overall energy conservation efforts.

The manufacturing process of QLEDs has also seen improvements in terms of environmental impact. Unlike some other display technologies, QLED production does not require the use of rare earth elements, which are often associated with environmentally damaging mining practices. This reduces the ecological footprint of QLED manufacturing and helps preserve natural resources.

Furthermore, QLEDs have demonstrated excellent longevity, with many models boasting lifespans of up to 100,000 hours. This extended durability means fewer replacements are needed over time, reducing electronic waste and the environmental burden associated with disposal. The materials used in QLED displays are also generally more recyclable compared to other display technologies, facilitating easier end-of-life management.

Recent advancements in QLED technology have focused on further improving their eco-credentials. Researchers are exploring ways to enhance the quantum yield of quantum dots, which could lead to even greater energy efficiency. Additionally, efforts are being made to develop quantum dots from more environmentally friendly materials, moving away from potentially harmful heavy metals like cadmium.

The eco-friendliness of QLEDs extends beyond the displays themselves. The technology's high brightness and color accuracy allow for more efficient use in outdoor signage and advertising, potentially reducing the overall number of displays needed and their associated energy consumption. In automotive applications, QLED displays can contribute to lighter, more fuel-efficient vehicles due to their thin and flexible nature.

As sustainability becomes an increasingly important factor in consumer and industrial decision-making, the eco-friendly aspects of QLED technology are likely to drive its adoption across various sectors. This trend is expected to spur further research and development into making QLEDs even more environmentally friendly, potentially setting new standards for sustainable display technologies in the future.

The manufacturing process of QLEDs has also seen improvements in terms of environmental impact. Unlike some other display technologies, QLED production does not require the use of rare earth elements, which are often associated with environmentally damaging mining practices. This reduces the ecological footprint of QLED manufacturing and helps preserve natural resources.

Furthermore, QLEDs have demonstrated excellent longevity, with many models boasting lifespans of up to 100,000 hours. This extended durability means fewer replacements are needed over time, reducing electronic waste and the environmental burden associated with disposal. The materials used in QLED displays are also generally more recyclable compared to other display technologies, facilitating easier end-of-life management.

Recent advancements in QLED technology have focused on further improving their eco-credentials. Researchers are exploring ways to enhance the quantum yield of quantum dots, which could lead to even greater energy efficiency. Additionally, efforts are being made to develop quantum dots from more environmentally friendly materials, moving away from potentially harmful heavy metals like cadmium.

The eco-friendliness of QLEDs extends beyond the displays themselves. The technology's high brightness and color accuracy allow for more efficient use in outdoor signage and advertising, potentially reducing the overall number of displays needed and their associated energy consumption. In automotive applications, QLED displays can contribute to lighter, more fuel-efficient vehicles due to their thin and flexible nature.

As sustainability becomes an increasingly important factor in consumer and industrial decision-making, the eco-friendly aspects of QLED technology are likely to drive its adoption across various sectors. This trend is expected to spur further research and development into making QLEDs even more environmentally friendly, potentially setting new standards for sustainable display technologies in the future.

QLED Standardization

The standardization of QLED technologies is a critical aspect of their advancement and widespread adoption across diverse applications. As the field of quantum dot light-emitting diodes continues to evolve, establishing uniform standards becomes increasingly important for ensuring consistency, reliability, and interoperability among different manufacturers and applications.

One of the primary areas of focus in QLED standardization is the development of common measurement and characterization techniques. This includes standardized methods for assessing key performance parameters such as luminance, color gamut, efficiency, and lifetime. By establishing these uniform measurement protocols, researchers and manufacturers can more accurately compare and evaluate different QLED technologies, facilitating innovation and quality control.

Another crucial aspect of QLED standardization is the establishment of safety and environmental regulations. As quantum dot materials often contain heavy metals, it is essential to develop guidelines for their safe handling, disposal, and potential environmental impact. This includes standardizing toxicity assessments and setting limits on the use of certain materials in QLED production.

Standardization efforts also extend to the manufacturing processes of QLEDs. This involves developing best practices for quantum dot synthesis, deposition techniques, and device fabrication. By establishing these standards, the industry can improve consistency in production and potentially reduce costs through streamlined processes.

Interoperability standards are becoming increasingly important as QLEDs find applications in various devices and systems. These standards ensure that QLED displays and lighting solutions can seamlessly integrate with other technologies and platforms, promoting wider adoption across different industries.

The development of QLED standards is a collaborative effort involving industry leaders, research institutions, and regulatory bodies. Organizations such as the International Electrotechnical Commission (IEC) and the Society for Information Display (SID) play crucial roles in facilitating discussions and establishing consensus on QLED standards.

As QLED technology continues to advance, standardization efforts must evolve to keep pace with new developments. This includes addressing emerging applications such as flexible and transparent displays, as well as integrating QLEDs with other technologies like augmented reality and Internet of Things devices.

One of the primary areas of focus in QLED standardization is the development of common measurement and characterization techniques. This includes standardized methods for assessing key performance parameters such as luminance, color gamut, efficiency, and lifetime. By establishing these uniform measurement protocols, researchers and manufacturers can more accurately compare and evaluate different QLED technologies, facilitating innovation and quality control.

Another crucial aspect of QLED standardization is the establishment of safety and environmental regulations. As quantum dot materials often contain heavy metals, it is essential to develop guidelines for their safe handling, disposal, and potential environmental impact. This includes standardizing toxicity assessments and setting limits on the use of certain materials in QLED production.

Standardization efforts also extend to the manufacturing processes of QLEDs. This involves developing best practices for quantum dot synthesis, deposition techniques, and device fabrication. By establishing these standards, the industry can improve consistency in production and potentially reduce costs through streamlined processes.

Interoperability standards are becoming increasingly important as QLEDs find applications in various devices and systems. These standards ensure that QLED displays and lighting solutions can seamlessly integrate with other technologies and platforms, promoting wider adoption across different industries.

The development of QLED standards is a collaborative effort involving industry leaders, research institutions, and regulatory bodies. Organizations such as the International Electrotechnical Commission (IEC) and the Society for Information Display (SID) play crucial roles in facilitating discussions and establishing consensus on QLED standards.

As QLED technology continues to advance, standardization efforts must evolve to keep pace with new developments. This includes addressing emerging applications such as flexible and transparent displays, as well as integrating QLEDs with other technologies like augmented reality and Internet of Things devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!