How to Harness Quantum Dot Technology in QLED?

Quantum Dot Evolution and QLED Objectives

Quantum dot technology has undergone significant evolution since its discovery in the 1980s, revolutionizing various fields, particularly in display technology. The journey of quantum dots from laboratory curiosities to commercial applications has been marked by continuous improvements in synthesis methods, stability, and performance. Initially, quantum dots were primarily used in biological imaging and sensing applications due to their unique optical properties. However, as research progressed, their potential in display technology became increasingly apparent.

The development of quantum dot-enhanced LED (QLED) displays represents a major milestone in this evolution. QLEDs leverage the exceptional color purity and efficiency of quantum dots to create displays with superior color gamut, brightness, and energy efficiency compared to traditional LED and OLED technologies. The objectives of QLED technology are multifaceted, focusing on enhancing display performance while addressing challenges in manufacturing scalability and long-term stability.

One primary objective is to further improve color accuracy and expand the color gamut. Quantum dots' narrow emission spectra allow for more precise color control, potentially enabling displays to reproduce colors beyond the current standards. Researchers aim to fine-tune quantum dot compositions and structures to achieve even narrower emission peaks and more stable performance across different operating conditions.

Another critical goal is to increase the overall efficiency of QLED displays. This involves optimizing the quantum yield of quantum dots, improving light extraction from the device, and enhancing the energy transfer between the excitation source and the quantum dots. By boosting efficiency, QLED technology can offer brighter displays with lower power consumption, making it particularly attractive for mobile devices and large-format displays.

Longevity and stability remain key challenges in QLED development. Objectives in this area include improving the photostability of quantum dots to prevent degradation under prolonged exposure to light and heat. Researchers are exploring various encapsulation techniques and materials to protect quantum dots from environmental factors that can affect their performance over time.

Manufacturing scalability is another crucial objective. As QLED technology moves towards mass production, there is a need for more efficient and cost-effective manufacturing processes. This includes developing methods for large-scale quantum dot synthesis with consistent quality, as well as integrating quantum dots into display panels using techniques compatible with existing manufacturing infrastructure.

The future evolution of quantum dot technology in QLEDs is likely to focus on expanding its applications beyond traditional displays. Potential areas of development include flexible and transparent displays, as well as integration with other emerging technologies such as microLED. The ultimate objective is to establish QLED as a dominant display technology, offering unparalleled visual quality, energy efficiency, and versatility across a wide range of applications.

QLED Market Demand Analysis

The QLED (Quantum Dot Light-Emitting Diode) market has been experiencing significant growth and is poised for further expansion in the coming years. This surge in demand is primarily driven by the increasing adoption of QLED technology in various display applications, particularly in the consumer electronics sector.

The global QLED market has shown remarkable growth, with a compound annual growth rate (CAGR) projected to remain strong through the next decade. This growth is attributed to several factors, including the superior color performance, energy efficiency, and longer lifespan of QLED displays compared to traditional LED and OLED technologies.

Consumer electronics, especially high-end televisions, represent the largest segment of the QLED market. The demand for larger screen sizes with higher resolutions and improved color accuracy has been a key driver for QLED adoption. Major television manufacturers have been increasingly incorporating quantum dot technology into their premium product lines, offering consumers enhanced viewing experiences.

Beyond televisions, the QLED market is expanding into other consumer electronics segments such as smartphones, tablets, and monitors. The improved color gamut and brightness offered by QLED technology make it particularly attractive for mobile devices and computer displays, where visual quality is a key differentiator.

The automotive industry is emerging as another significant market for QLED technology. As vehicles become more technologically advanced, there is a growing demand for high-quality displays in dashboards, infotainment systems, and heads-up displays. QLED's ability to deliver vibrant colors and high brightness even in challenging lighting conditions makes it well-suited for automotive applications.

Commercial and industrial sectors are also contributing to the growth of the QLED market. Digital signage, control room displays, and medical imaging equipment are increasingly adopting QLED technology due to its superior image quality and reliability.

Geographically, Asia-Pacific leads the QLED market, with countries like South Korea, China, and Japan at the forefront of both production and consumption. North America and Europe follow closely, driven by high consumer demand for premium display technologies.

The market demand for QLED technology is also influenced by ongoing research and development efforts. Advancements in quantum dot materials, manufacturing processes, and integration techniques are expected to further improve performance and reduce costs, potentially expanding the market to more price-sensitive segments.

However, challenges remain in the QLED market. Competition from other display technologies, particularly OLED, continues to be significant. Additionally, concerns about the environmental impact of certain quantum dot materials and the need for more sustainable production methods are factors that could influence market dynamics in the future.

QLED Tech Status and Challenges

Quantum dot light-emitting diode (QLED) technology has made significant strides in recent years, offering promising advancements in display technology. However, the current state of QLED technology faces several challenges that need to be addressed for wider adoption and improved performance.

One of the primary challenges in QLED technology is the stability and longevity of quantum dots. While quantum dots exhibit excellent color purity and brightness, they are susceptible to degradation over time, particularly when exposed to heat and oxygen. This degradation can lead to color shifts and reduced overall display performance. Researchers are actively working on developing more stable quantum dot materials and protective encapsulation techniques to mitigate these issues.

Another significant challenge is the efficiency of blue quantum dots. While red and green quantum dots have achieved high efficiency levels, blue quantum dots lag behind in terms of both efficiency and stability. This imbalance affects the overall color gamut and power consumption of QLED displays. Improving the efficiency and stability of blue quantum dots remains a key focus area for researchers and manufacturers.

The manufacturing process for QLED displays also presents challenges. Current methods for depositing quantum dots onto substrates, such as inkjet printing or photolithography, can be complex and costly. Achieving uniform quantum dot distribution and precise control over layer thickness are critical factors that impact display quality. Developing more efficient and scalable manufacturing processes is essential for reducing production costs and improving yield rates.

In terms of market adoption, QLED technology faces competition from other display technologies, particularly OLED. While QLED offers advantages in brightness and color volume, OLED still holds an edge in contrast ratio and viewing angles. Overcoming these limitations and demonstrating clear superiority in key performance metrics is crucial for QLED to gain wider market acceptance.

Environmental concerns also pose challenges for QLED technology. Many quantum dots contain heavy metals, such as cadmium, which raise toxicity and disposal issues. Developing cadmium-free quantum dots with comparable performance characteristics is an ongoing research focus to address these environmental concerns and comply with stringent regulations.

The integration of quantum dots with other emerging technologies, such as micro-LED, presents both opportunities and challenges. While such combinations could potentially offer superior display performance, they also introduce additional complexity in terms of manufacturing and cost considerations.

Lastly, the optimization of quantum dot size and composition for specific color emission wavelengths remains an active area of research. Achieving precise control over these parameters is crucial for maximizing color purity and efficiency across the entire visible spectrum.

Current QLED Implementation Approaches

01 Quantum dot synthesis and composition

This category focuses on the methods and materials used to synthesize quantum dots, including their chemical composition and structural properties. It covers techniques for controlling size, shape, and surface characteristics of quantum dots to optimize their optical and electronic properties for various applications.- Quantum dot synthesis and composition: This category focuses on the methods and materials used to synthesize quantum dots, including their chemical composition and structural properties. It covers techniques for controlling size, shape, and surface characteristics of quantum dots to optimize their optical and electronic properties for various applications.

- Quantum dot-based display technologies: This area involves the integration of quantum dots into display technologies, such as LED and OLED screens. It includes methods for enhancing color gamut, brightness, and energy efficiency in displays using quantum dot materials, as well as techniques for incorporating quantum dots into display manufacturing processes.

- Quantum dot photovoltaic applications: This category covers the use of quantum dots in solar cell and photovoltaic technologies. It includes methods for improving light absorption, charge separation, and overall efficiency of solar cells using quantum dot materials, as well as techniques for integrating quantum dots into various solar cell architectures.

- Quantum dot-based sensors and detectors: This area focuses on the development of sensors and detectors utilizing quantum dot technology. It includes applications in chemical and biological sensing, as well as in imaging and spectroscopy. The category covers methods for enhancing sensitivity, selectivity, and response time of quantum dot-based sensing systems.

- Quantum dot integration in electronic devices: This category encompasses the incorporation of quantum dots into various electronic devices and components. It includes methods for integrating quantum dots into transistors, memory devices, and other semiconductor applications to enhance performance, reduce power consumption, or enable new functionalities.

02 Quantum dot-based display technologies

This area involves the integration of quantum dots into display technologies, such as LED and OLED screens. It includes methods for enhancing color gamut, brightness, and energy efficiency in displays using quantum dot materials, as well as techniques for incorporating quantum dots into display manufacturing processes.Expand Specific Solutions03 Quantum dot photovoltaic applications

This category covers the use of quantum dots in solar cell and photovoltaic technologies. It includes methods for improving light absorption, charge separation, and overall efficiency of solar cells using quantum dot materials, as well as techniques for integrating quantum dots into various solar cell architectures.Expand Specific Solutions04 Quantum dot-based sensors and detectors

This area focuses on the development of sensors and detectors utilizing quantum dot technology. It includes applications in chemical and biological sensing, as well as in imaging and spectroscopy. The category covers methods for enhancing sensitivity, selectivity, and response time of quantum dot-based sensing systems.Expand Specific Solutions05 Quantum dot integration in electronic devices

This category involves the incorporation of quantum dots into various electronic devices and components. It includes methods for integrating quantum dots into transistors, memory devices, and other semiconductor applications to enhance performance, reduce power consumption, or enable new functionalities.Expand Specific Solutions

QLED Industry Key Players

The quantum dot technology in QLED displays is currently in a growth phase, with increasing market adoption and technological advancements. The global QLED market is expanding rapidly, driven by demand for high-quality displays in various applications. Technologically, quantum dots are maturing, but there's still room for innovation. Companies like BOE Technology Group, TCL China Star Optoelectronics, and LG Display are leading in commercialization, while research institutions such as The Hong Kong University of Science & Technology and Zhejiang University are pushing boundaries in quantum dot efficiency and stability. Nanosys and Dow Global Technologies are key players in quantum dot material development, contributing to the overall advancement of QLED technology.

BOE Technology Group Co., Ltd.

TCL China Star Optoelectronics Technology Co., Ltd.

Core QLED Innovations and Patents

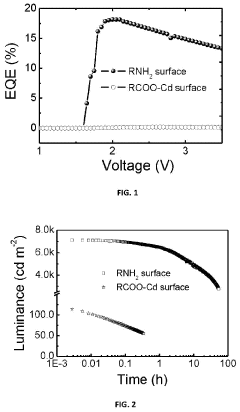

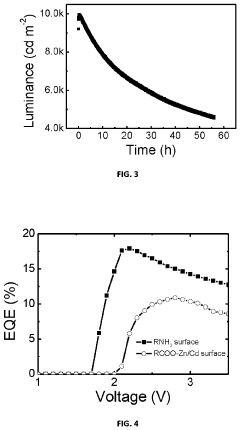

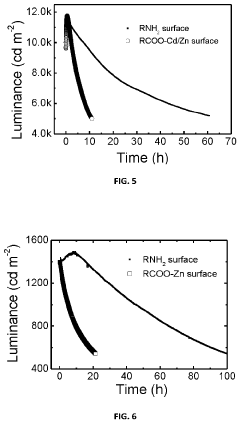

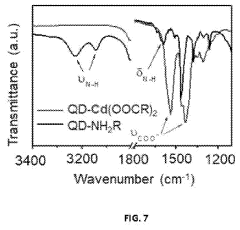

- The use of electrochemically inert ligands, such as amine, alkylphosphine, and metal carboxylate ligands, which have a reduction potential greater than the quantum dot's conduction band and an oxidation potential less than its valence band, accounting for at least 80% of the surface ligands, to prevent carrier consumption and ligand detachment under electrical excitation, thereby enhancing stability and efficiency.

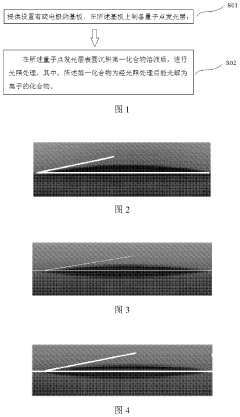

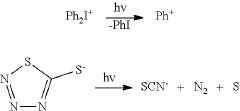

- A QLED manufacturing method involving the use of a first compound solution that photodegrades into ions under illumination, applied to the quantum dot light emitting layer, which reduces the contact angle and improves the compatibility between layers, enhancing the flatness and luminous efficiency of the QLED.

QLED Manufacturing Processes

The manufacturing processes for QLED (Quantum Dot Light Emitting Diode) displays involve several intricate steps that leverage the unique properties of quantum dots. These nanoscale semiconductor particles are at the heart of QLED technology, offering superior color performance and energy efficiency compared to traditional display technologies.

The process begins with the synthesis of quantum dots, typically using colloidal synthesis methods. This involves carefully controlling the growth of nanocrystals in solution, with precise temperature and time parameters to achieve the desired size and composition. The size of quantum dots directly correlates to the wavelength of light they emit, allowing manufacturers to fine-tune the color output.

Once synthesized, the quantum dots undergo a purification process to remove excess reactants and ensure uniformity. This is followed by a surface modification step, where ligands are attached to the quantum dots to improve their stability and compatibility with subsequent manufacturing processes.

The next critical stage is the deposition of quantum dots onto a substrate. This is often achieved through solution-based methods such as inkjet printing or spin coating. These techniques allow for precise control over the thickness and uniformity of the quantum dot layer, which is crucial for display performance.

Following deposition, the quantum dot layer is typically encapsulated to protect it from environmental factors such as moisture and oxygen, which can degrade performance over time. This encapsulation process may involve the application of barrier films or the use of advanced packaging techniques.

The integration of the quantum dot layer with other components of the display, such as the backlight unit and color filters, is a complex process that requires careful alignment and bonding. In some QLED designs, quantum dots are incorporated directly into the LED backlight, while in others, they form a separate layer in front of the backlight.

Quality control is paramount throughout the manufacturing process. Advanced imaging and spectroscopic techniques are employed to assess the uniformity of quantum dot distribution, layer thickness, and color performance. Any defects or inconsistencies must be identified and addressed to ensure the final product meets stringent display standards.

The final stages of QLED manufacturing involve the assembly of the display panel, including the addition of electronic components, drivers, and the outer casing. Rigorous testing is conducted to verify the display's performance, including color accuracy, brightness, and longevity.

Environmental Impact of QLED Production

The production of Quantum Light-Emitting Diode (QLED) displays, which harness quantum dot technology, has significant environmental implications that warrant careful consideration. The manufacturing process of QLEDs involves the use of various materials and chemicals, some of which can pose environmental risks if not properly managed.

One of the primary environmental concerns is the use of heavy metals in quantum dots, particularly cadmium. While cadmium-based quantum dots offer superior color performance, they are toxic and can potentially leach into the environment if not properly contained or disposed of. This has led to increased research into cadmium-free alternatives, such as indium phosphide-based quantum dots, which show promise in reducing the environmental impact of QLED production.

The synthesis of quantum dots also requires the use of organic solvents and high-temperature processes, which can contribute to air and water pollution if emissions are not adequately controlled. Additionally, the production of QLED displays involves multiple layers of materials, including plastics and metals, which can create challenges for recycling and end-of-life management.

Energy consumption during the manufacturing process is another significant environmental factor. The production of quantum dots and the assembly of QLED displays require substantial energy inputs, potentially contributing to greenhouse gas emissions depending on the energy sources used. However, it's worth noting that QLEDs are generally more energy-efficient in operation compared to traditional LED displays, which may offset some of the environmental costs of production over the product lifecycle.

Water usage in QLED manufacturing is also a concern, particularly in regions where water scarcity is an issue. The production process requires ultra-pure water for cleaning and processing, and the resulting wastewater must be carefully treated to remove contaminants before release.

To address these environmental challenges, many manufacturers are adopting more sustainable practices. These include implementing closed-loop production systems to minimize waste, investing in more efficient energy and water management technologies, and exploring bio-based materials for quantum dot production. Additionally, there is a growing focus on designing QLEDs for easier disassembly and recycling at the end of their useful life.

As QLED technology continues to evolve, ongoing research is crucial to further reduce its environmental footprint. This includes developing more eco-friendly quantum dot materials, improving production efficiencies, and enhancing recycling technologies specific to QLED components. By addressing these environmental concerns, the QLED industry can work towards more sustainable production practices while continuing to advance display technology.