How to Ensure Quantum Dot Stability in QLED Displays?

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QD Stability Challenges

Quantum dot (QD) stability remains a critical challenge in the development and commercialization of QLED displays. The primary issues stem from the inherent sensitivity of quantum dots to environmental factors, which can significantly impact their optical and electronic properties. One of the most pressing concerns is photo-oxidation, where exposure to light and oxygen leads to degradation of the QD structure, resulting in reduced luminescence efficiency and color shift over time.

Thermal stability is another major hurdle for QD technology in displays. High temperatures, often generated during device operation, can cause structural changes in the quantum dots, leading to decreased performance and shortened lifespan of the display. This thermal instability is particularly problematic in high-brightness applications, where increased current flow generates more heat.

Chemical stability poses an additional challenge, as quantum dots can be susceptible to reactions with surrounding materials in the device structure. This includes interactions with encapsulation materials, electrode components, and even other layers within the QLED architecture. Such chemical reactions can alter the surface properties of the QDs, affecting their emission characteristics and overall device efficiency.

The size and composition uniformity of quantum dots also play a crucial role in their stability. Variations in size and composition can lead to inconsistent performance across the display, resulting in non-uniform aging and color reproduction issues. Maintaining precise control over QD synthesis and deposition processes is essential to mitigate these challenges.

Electrical stability is yet another concern, particularly in electroluminescent QLED devices. The passage of current through the quantum dot layer can lead to charge trapping, ion migration, and other phenomena that degrade the QDs over time. This electrical stress can manifest as reduced brightness, color shifts, and ultimately, device failure.

Addressing these stability challenges requires a multifaceted approach. Researchers are exploring various strategies, including core-shell structures to protect the QD core, surface ligand engineering to enhance stability and compatibility with host materials, and advanced encapsulation techniques to shield QDs from environmental factors. Additionally, the development of more robust QD materials, such as perovskite quantum dots, shows promise in overcoming some of these stability issues.

The quest for improved QD stability also extends to the manufacturing processes. Optimizing deposition methods, refining encapsulation techniques, and developing more effective barrier materials are all critical areas of focus. Furthermore, the integration of QDs into novel device architectures, such as those employing tandem structures or hybrid organic-inorganic designs, may offer pathways to enhanced stability while maintaining or improving display performance.

Thermal stability is another major hurdle for QD technology in displays. High temperatures, often generated during device operation, can cause structural changes in the quantum dots, leading to decreased performance and shortened lifespan of the display. This thermal instability is particularly problematic in high-brightness applications, where increased current flow generates more heat.

Chemical stability poses an additional challenge, as quantum dots can be susceptible to reactions with surrounding materials in the device structure. This includes interactions with encapsulation materials, electrode components, and even other layers within the QLED architecture. Such chemical reactions can alter the surface properties of the QDs, affecting their emission characteristics and overall device efficiency.

The size and composition uniformity of quantum dots also play a crucial role in their stability. Variations in size and composition can lead to inconsistent performance across the display, resulting in non-uniform aging and color reproduction issues. Maintaining precise control over QD synthesis and deposition processes is essential to mitigate these challenges.

Electrical stability is yet another concern, particularly in electroluminescent QLED devices. The passage of current through the quantum dot layer can lead to charge trapping, ion migration, and other phenomena that degrade the QDs over time. This electrical stress can manifest as reduced brightness, color shifts, and ultimately, device failure.

Addressing these stability challenges requires a multifaceted approach. Researchers are exploring various strategies, including core-shell structures to protect the QD core, surface ligand engineering to enhance stability and compatibility with host materials, and advanced encapsulation techniques to shield QDs from environmental factors. Additionally, the development of more robust QD materials, such as perovskite quantum dots, shows promise in overcoming some of these stability issues.

The quest for improved QD stability also extends to the manufacturing processes. Optimizing deposition methods, refining encapsulation techniques, and developing more effective barrier materials are all critical areas of focus. Furthermore, the integration of QDs into novel device architectures, such as those employing tandem structures or hybrid organic-inorganic designs, may offer pathways to enhanced stability while maintaining or improving display performance.

QLED Market Dynamics

The QLED display market has experienced significant growth in recent years, driven by the increasing demand for high-quality, energy-efficient displays across various sectors. This market segment is characterized by its rapid technological advancements and evolving consumer preferences, particularly in the areas of consumer electronics, automotive displays, and large-format signage.

The global QLED market size was valued at approximately $7.5 billion in 2020 and is projected to reach $15.4 billion by 2026, growing at a CAGR of 12.8% during the forecast period. This robust growth is primarily attributed to the superior color gamut, brightness, and energy efficiency offered by QLED technology compared to traditional LED and OLED displays.

Consumer electronics, particularly televisions, remain the dominant application segment for QLED displays. Major manufacturers such as Samsung, TCL, and Hisense have been aggressively promoting QLED TVs, capitalizing on their ability to deliver vibrant colors and high contrast ratios. The increasing adoption of 4K and 8K resolution displays has further bolstered the demand for QLED technology in the premium TV segment.

The automotive industry is emerging as a significant growth driver for QLED displays. As vehicles become more connected and autonomous, there is a growing need for high-quality, durable displays for infotainment systems, digital cockpits, and heads-up displays. QLED technology's ability to maintain color accuracy and brightness in varying light conditions makes it particularly suitable for automotive applications.

Geographically, Asia-Pacific dominates the QLED market, with China and South Korea leading in both production and consumption. North America and Europe follow closely, driven by the high adoption rates of premium consumer electronics and the presence of key automotive manufacturers.

Despite its growth, the QLED market faces challenges, primarily from competing technologies such as OLED and MicroLED. OLED displays, in particular, have gained significant market share in high-end smartphones and premium TVs, posing a threat to QLED's expansion in these segments. Additionally, the high cost of quantum dot materials and the complexity of manufacturing processes remain barriers to wider adoption, especially in price-sensitive markets.

The stability of quantum dots in QLED displays is a critical factor influencing market dynamics. Improvements in quantum dot stability can lead to longer device lifetimes, better color accuracy over time, and reduced production costs. As research progresses in this area, it is expected to drive further market growth and potentially open up new application areas for QLED technology.

The global QLED market size was valued at approximately $7.5 billion in 2020 and is projected to reach $15.4 billion by 2026, growing at a CAGR of 12.8% during the forecast period. This robust growth is primarily attributed to the superior color gamut, brightness, and energy efficiency offered by QLED technology compared to traditional LED and OLED displays.

Consumer electronics, particularly televisions, remain the dominant application segment for QLED displays. Major manufacturers such as Samsung, TCL, and Hisense have been aggressively promoting QLED TVs, capitalizing on their ability to deliver vibrant colors and high contrast ratios. The increasing adoption of 4K and 8K resolution displays has further bolstered the demand for QLED technology in the premium TV segment.

The automotive industry is emerging as a significant growth driver for QLED displays. As vehicles become more connected and autonomous, there is a growing need for high-quality, durable displays for infotainment systems, digital cockpits, and heads-up displays. QLED technology's ability to maintain color accuracy and brightness in varying light conditions makes it particularly suitable for automotive applications.

Geographically, Asia-Pacific dominates the QLED market, with China and South Korea leading in both production and consumption. North America and Europe follow closely, driven by the high adoption rates of premium consumer electronics and the presence of key automotive manufacturers.

Despite its growth, the QLED market faces challenges, primarily from competing technologies such as OLED and MicroLED. OLED displays, in particular, have gained significant market share in high-end smartphones and premium TVs, posing a threat to QLED's expansion in these segments. Additionally, the high cost of quantum dot materials and the complexity of manufacturing processes remain barriers to wider adoption, especially in price-sensitive markets.

The stability of quantum dots in QLED displays is a critical factor influencing market dynamics. Improvements in quantum dot stability can lead to longer device lifetimes, better color accuracy over time, and reduced production costs. As research progresses in this area, it is expected to drive further market growth and potentially open up new application areas for QLED technology.

QD Degradation Factors

Quantum dot (QD) stability is a critical factor in the performance and longevity of QLED displays. Several key factors contribute to the degradation of quantum dots, impacting their optical properties and overall device efficiency. One of the primary degradation mechanisms is photo-oxidation, which occurs when QDs are exposed to oxygen and light simultaneously. This process leads to the formation of surface defects and the alteration of the QD's electronic structure, resulting in reduced quantum yield and color shift.

Thermal degradation is another significant factor affecting QD stability. High temperatures can cause the diffusion of core atoms to the QD surface, leading to changes in size and shape. This phenomenon, known as Ostwald ripening, can result in broadened emission spectra and decreased color purity. Additionally, elevated temperatures may cause the decomposition of the QD's organic ligands, compromising the colloidal stability and increasing the likelihood of aggregation.

Chemical instability is a crucial aspect of QD degradation. The interaction between QDs and the surrounding matrix material, such as polymers or metal oxides, can lead to surface reactions that alter the QD's properties. These reactions may include ligand exchange, surface etching, or the formation of new chemical species at the QD-matrix interface. Such interactions can significantly impact the QD's emission efficiency and spectral characteristics.

Moisture is another detrimental factor for QD stability. Water molecules can penetrate the QD's protective layers, leading to hydrolysis of the surface atoms and the formation of trap states. This process not only reduces the quantum yield but also accelerates other degradation mechanisms by facilitating the diffusion of oxygen and other reactive species to the QD core.

Electrical stress is a unique degradation factor in QLED displays. The continuous flow of charge carriers through the QD layer can lead to charging effects, Auger recombination, and even physical damage to the QDs. These phenomena can result in decreased luminescence efficiency and altered emission characteristics over time.

The presence of impurities or contaminants in the QD layer can also contribute to degradation. These impurities may act as catalysts for undesired reactions or create local inhomogeneities that affect the overall performance of the QLED device. Careful purification and quality control during the manufacturing process are essential to mitigate this factor.

Lastly, mechanical stress can play a role in QD degradation, particularly in flexible or stretchable QLED displays. Bending, stretching, or compression of the device can lead to physical deformation of the QD layer, potentially causing cracks, delamination, or changes in the QD distribution. These mechanical effects can result in non-uniform emission and reduced device lifetime.

Thermal degradation is another significant factor affecting QD stability. High temperatures can cause the diffusion of core atoms to the QD surface, leading to changes in size and shape. This phenomenon, known as Ostwald ripening, can result in broadened emission spectra and decreased color purity. Additionally, elevated temperatures may cause the decomposition of the QD's organic ligands, compromising the colloidal stability and increasing the likelihood of aggregation.

Chemical instability is a crucial aspect of QD degradation. The interaction between QDs and the surrounding matrix material, such as polymers or metal oxides, can lead to surface reactions that alter the QD's properties. These reactions may include ligand exchange, surface etching, or the formation of new chemical species at the QD-matrix interface. Such interactions can significantly impact the QD's emission efficiency and spectral characteristics.

Moisture is another detrimental factor for QD stability. Water molecules can penetrate the QD's protective layers, leading to hydrolysis of the surface atoms and the formation of trap states. This process not only reduces the quantum yield but also accelerates other degradation mechanisms by facilitating the diffusion of oxygen and other reactive species to the QD core.

Electrical stress is a unique degradation factor in QLED displays. The continuous flow of charge carriers through the QD layer can lead to charging effects, Auger recombination, and even physical damage to the QDs. These phenomena can result in decreased luminescence efficiency and altered emission characteristics over time.

The presence of impurities or contaminants in the QD layer can also contribute to degradation. These impurities may act as catalysts for undesired reactions or create local inhomogeneities that affect the overall performance of the QLED device. Careful purification and quality control during the manufacturing process are essential to mitigate this factor.

Lastly, mechanical stress can play a role in QD degradation, particularly in flexible or stretchable QLED displays. Bending, stretching, or compression of the device can lead to physical deformation of the QD layer, potentially causing cracks, delamination, or changes in the QD distribution. These mechanical effects can result in non-uniform emission and reduced device lifetime.

Current QD Stabilization

01 Surface modification for enhanced stability

Quantum dots can be stabilized through surface modification techniques. This involves coating the quantum dots with protective layers or ligands that prevent degradation and improve their overall stability. These modifications can enhance the durability of quantum dots in various environments and applications.- Surface modification for enhanced stability: Quantum dots can be stabilized through surface modification techniques. This involves coating the quantum dots with protective layers or ligands that prevent degradation and improve their overall stability. These modifications can enhance the durability of quantum dots in various environments and applications.

- Core-shell structures for improved stability: The stability of quantum dots can be significantly improved by creating core-shell structures. This involves encapsulating the core quantum dot with one or more layers of semiconductor materials, which can protect the core from environmental factors and enhance its optical and electronic properties.

- Polymer encapsulation for quantum dot stability: Encapsulating quantum dots within polymer matrices can greatly enhance their stability. This method protects the quantum dots from external factors such as oxygen and moisture, while also improving their compatibility with various solvents and materials used in different applications.

- Ligand exchange for improved stability: Ligand exchange processes can be employed to replace the original surface ligands of quantum dots with more stable alternatives. This technique can enhance the chemical and colloidal stability of quantum dots, making them more suitable for integration into various devices and applications.

- Environmental control for quantum dot stability: Controlling the environment in which quantum dots are synthesized, stored, and utilized can significantly impact their stability. This includes regulating factors such as temperature, humidity, and exposure to light or oxygen. Proper environmental control can extend the lifetime and maintain the performance of quantum dots in various applications.

02 Core-shell structures for improved stability

Implementing core-shell structures in quantum dots can significantly improve their stability. By encapsulating the core quantum dot with a shell of a different material, the overall stability and optical properties can be enhanced. This approach helps to protect the core from environmental factors and reduces surface defects.Expand Specific Solutions03 Stabilization through matrix encapsulation

Encapsulating quantum dots within a suitable matrix material can improve their stability. This method involves dispersing quantum dots in a host material, such as polymers or inorganic matrices, which provides physical protection and prevents aggregation. Matrix encapsulation can enhance the long-term stability of quantum dots in various applications.Expand Specific Solutions04 Chemical composition optimization

Optimizing the chemical composition of quantum dots can lead to improved stability. This involves carefully selecting and adjusting the materials used in the quantum dot synthesis process to create more stable structures. Tailoring the composition can enhance resistance to degradation and improve overall performance.Expand Specific Solutions05 Environmental control for stability

Controlling the environment in which quantum dots are stored or used can significantly impact their stability. This includes managing factors such as temperature, humidity, and exposure to light or oxygen. Proper environmental control can help maintain the structural integrity and optical properties of quantum dots over extended periods.Expand Specific Solutions

QLED Industry Leaders

The quantum dot stability in QLED displays market is in a growth phase, with increasing demand for high-quality displays driving innovation. The market size is expanding rapidly, projected to reach billions of dollars in the coming years. Technologically, quantum dot stability is advancing, but challenges remain. Companies like Samsung SDI, BOE Technology, and TCL China Star Optoelectronics are at the forefront, investing heavily in R&D. Other players such as Najing Technology, 3M, and Merck Patent GmbH are also contributing significantly to technological advancements. The competition is intense, with both established electronics giants and specialized materials companies vying for market share and technological breakthroughs in quantum dot stability.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a novel approach to QD stability in QLED displays through their "QD-in-Glass" technology. This method involves dispersing quantum dots in a glass matrix, which is then integrated into the display structure. The glass encapsulation provides a robust barrier against environmental factors that can degrade QDs. BOE also utilizes a proprietary surface treatment process for the QDs to enhance their compatibility with the glass matrix and improve overall stability. Additionally, they have implemented an advanced thermal management system within their QLED panels to regulate temperature and prevent heat-induced degradation of the quantum dots.

Strengths: Enhanced QD protection from environmental factors. Improved thermal stability. Potential for longer display lifespan. Weaknesses: May limit flexibility in display design. Possible reduction in quantum yield due to glass matrix.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a proprietary quantum dot (QD) encapsulation technology called "QD-on-Glass" for QLED displays. This method involves depositing QDs directly onto a glass substrate and sealing them with a protective layer. The QDs are precisely patterned using photolithography techniques, allowing for high-resolution displays. To enhance stability, Samsung employs a multi-layer encapsulation process that includes inorganic barrier films and organic planarization layers. This structure effectively protects QDs from moisture and oxygen, significantly improving their longevity and performance in displays.

Strengths: Excellent color purity and wide color gamut. Highly scalable for large displays. Improved QD stability due to advanced encapsulation. Weaknesses: Potentially higher production costs. Complexity in manufacturing process.

QD Encapsulation Tech

Core-shell quantum dot, quantum dot light-emitting device, display apparatus and manufacturing method

PatentPendingUS20250145883A1

Innovation

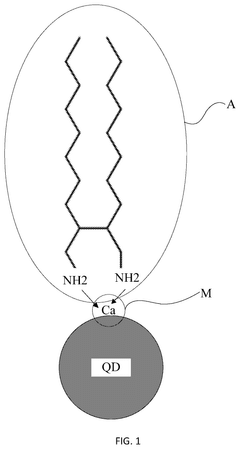

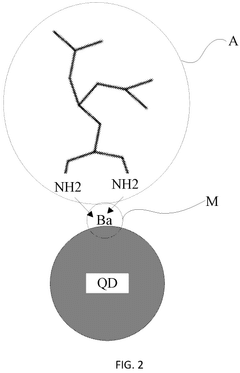

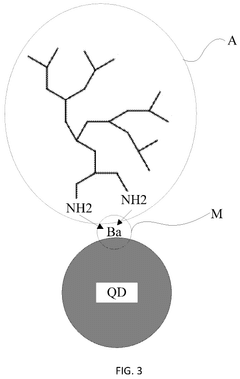

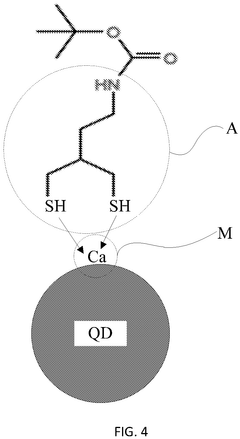

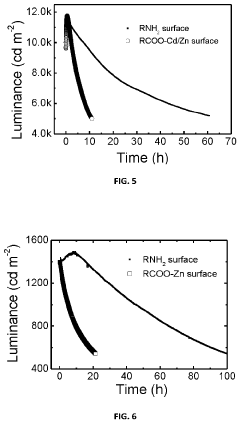

- The development of core-shell quantum dots with a shell layer containing metal ions and a chelating ligand that forms a stable closed ring structure, enhancing ligand adsorption and preventing detachment during patterning and device operation.

QLED and Method for Manufacturing Quantum Dot

PatentActiveUS20210380878A1

Innovation

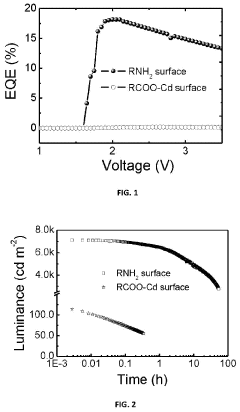

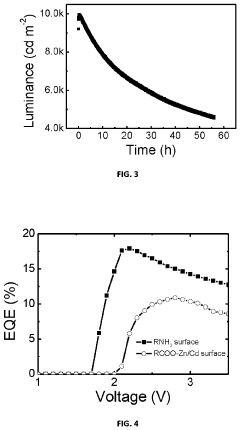

- The use of electrochemically inert ligands, such as amine, alkylphosphine, and metal carboxylate ligands, which have a reduction potential greater than the quantum dot's conduction band and an oxidation potential less than its valence band, accounting for at least 80% of the surface ligands, to prevent carrier consumption and ligand detachment under electrical excitation, thereby enhancing stability and efficiency.

Environmental Impact

The environmental impact of quantum dot light-emitting diode (QLED) displays is a critical consideration in the development and adoption of this technology. As quantum dots become increasingly prevalent in display applications, their potential effects on the environment throughout their lifecycle must be carefully evaluated and mitigated.

One of the primary environmental concerns associated with quantum dots is the use of heavy metals in their composition. Many quantum dots contain cadmium, lead, or other toxic elements that can pose risks to ecosystems and human health if not properly managed. While efforts are being made to develop cadmium-free quantum dots, the environmental implications of alternative materials must also be thoroughly assessed.

The manufacturing process of quantum dots and QLED displays also contributes to their environmental footprint. The production of these materials often involves energy-intensive processes and the use of potentially hazardous chemicals. Improving the efficiency of manufacturing techniques and implementing cleaner production methods can help reduce the environmental impact of QLED technology.

End-of-life disposal and recycling of QLED displays present another significant environmental challenge. The complex nature of these devices, combined with the presence of quantum dots, makes proper recycling and disposal crucial to prevent the release of harmful substances into the environment. Developing effective recycling processes and establishing robust e-waste management systems are essential steps in mitigating the long-term environmental impact of QLED technology.

Energy efficiency is a positive aspect of QLED displays from an environmental perspective. These displays typically consume less power compared to traditional LED or OLED technologies, potentially reducing overall energy consumption and associated carbon emissions. However, the increased brightness and color capabilities of QLED displays may lead to higher energy usage in some applications, necessitating careful consideration of power management strategies.

The durability and lifespan of QLED displays also play a role in their environmental impact. Enhancing the stability and longevity of quantum dots can lead to longer-lasting displays, reducing the frequency of replacement and, consequently, the amount of electronic waste generated. This highlights the importance of research into quantum dot stability not only for performance reasons but also for environmental sustainability.

As QLED technology continues to evolve, it is crucial to prioritize eco-friendly design principles and sustainable practices throughout the entire product lifecycle. This includes exploring bio-based or recyclable materials for quantum dot synthesis, optimizing manufacturing processes to minimize resource consumption and waste generation, and developing innovative recycling technologies specifically tailored for QLED displays.

One of the primary environmental concerns associated with quantum dots is the use of heavy metals in their composition. Many quantum dots contain cadmium, lead, or other toxic elements that can pose risks to ecosystems and human health if not properly managed. While efforts are being made to develop cadmium-free quantum dots, the environmental implications of alternative materials must also be thoroughly assessed.

The manufacturing process of quantum dots and QLED displays also contributes to their environmental footprint. The production of these materials often involves energy-intensive processes and the use of potentially hazardous chemicals. Improving the efficiency of manufacturing techniques and implementing cleaner production methods can help reduce the environmental impact of QLED technology.

End-of-life disposal and recycling of QLED displays present another significant environmental challenge. The complex nature of these devices, combined with the presence of quantum dots, makes proper recycling and disposal crucial to prevent the release of harmful substances into the environment. Developing effective recycling processes and establishing robust e-waste management systems are essential steps in mitigating the long-term environmental impact of QLED technology.

Energy efficiency is a positive aspect of QLED displays from an environmental perspective. These displays typically consume less power compared to traditional LED or OLED technologies, potentially reducing overall energy consumption and associated carbon emissions. However, the increased brightness and color capabilities of QLED displays may lead to higher energy usage in some applications, necessitating careful consideration of power management strategies.

The durability and lifespan of QLED displays also play a role in their environmental impact. Enhancing the stability and longevity of quantum dots can lead to longer-lasting displays, reducing the frequency of replacement and, consequently, the amount of electronic waste generated. This highlights the importance of research into quantum dot stability not only for performance reasons but also for environmental sustainability.

As QLED technology continues to evolve, it is crucial to prioritize eco-friendly design principles and sustainable practices throughout the entire product lifecycle. This includes exploring bio-based or recyclable materials for quantum dot synthesis, optimizing manufacturing processes to minimize resource consumption and waste generation, and developing innovative recycling technologies specifically tailored for QLED displays.

QD Manufacturing Process

The manufacturing process of quantum dots (QDs) for QLED displays is a critical factor in ensuring their stability and performance. The process typically begins with the synthesis of QDs, which involves carefully controlled chemical reactions to produce nanocrystals with specific size and composition. Precursor materials, such as cadmium selenide or indium phosphide, are combined in a high-temperature environment to form the QD core. This is followed by the growth of a shell layer, often made of zinc sulfide, to enhance the optical properties and stability of the QDs.

Once synthesized, the QDs undergo a purification process to remove excess reactants and byproducts. This step is crucial for maintaining the quality and uniformity of the QDs. Centrifugation and selective precipitation techniques are commonly employed to separate the desired QDs from impurities. The purified QDs are then subjected to a surface modification process, where ligands are attached to the QD surface to improve their compatibility with the host matrix and prevent aggregation.

The next stage involves the incorporation of QDs into the display structure. This can be achieved through various methods, including photolithography, inkjet printing, or transfer printing. The choice of method depends on the specific requirements of the display and the desired QD pattern. In some cases, QDs are dispersed in a polymer matrix to form a QD-polymer composite, which can be applied as a thin film onto the display substrate.

Quality control measures are implemented throughout the manufacturing process to ensure consistency and reliability. Advanced characterization techniques, such as transmission electron microscopy and spectroscopy, are used to assess the size distribution, crystal structure, and optical properties of the QDs. Rigorous testing of the QD films is conducted to evaluate their stability under various environmental conditions, including temperature, humidity, and light exposure.

To enhance the stability of QDs in QLED displays, several strategies are employed during the manufacturing process. These include the development of core-shell structures with multiple layers to protect the QD core, the use of inorganic matrices to encapsulate QDs, and the incorporation of additives to mitigate degradation mechanisms. Additionally, advanced packaging techniques are utilized to create a hermetic seal around the QD layer, protecting it from moisture and oxygen.

The optimization of the QD manufacturing process is an ongoing effort, with researchers and manufacturers continually exploring new materials and techniques to improve QD stability and performance. This includes the development of heavy-metal-free QDs, the refinement of surface passivation methods, and the integration of QDs with emerging display technologies.

Once synthesized, the QDs undergo a purification process to remove excess reactants and byproducts. This step is crucial for maintaining the quality and uniformity of the QDs. Centrifugation and selective precipitation techniques are commonly employed to separate the desired QDs from impurities. The purified QDs are then subjected to a surface modification process, where ligands are attached to the QD surface to improve their compatibility with the host matrix and prevent aggregation.

The next stage involves the incorporation of QDs into the display structure. This can be achieved through various methods, including photolithography, inkjet printing, or transfer printing. The choice of method depends on the specific requirements of the display and the desired QD pattern. In some cases, QDs are dispersed in a polymer matrix to form a QD-polymer composite, which can be applied as a thin film onto the display substrate.

Quality control measures are implemented throughout the manufacturing process to ensure consistency and reliability. Advanced characterization techniques, such as transmission electron microscopy and spectroscopy, are used to assess the size distribution, crystal structure, and optical properties of the QDs. Rigorous testing of the QD films is conducted to evaluate their stability under various environmental conditions, including temperature, humidity, and light exposure.

To enhance the stability of QDs in QLED displays, several strategies are employed during the manufacturing process. These include the development of core-shell structures with multiple layers to protect the QD core, the use of inorganic matrices to encapsulate QDs, and the incorporation of additives to mitigate degradation mechanisms. Additionally, advanced packaging techniques are utilized to create a hermetic seal around the QD layer, protecting it from moisture and oxygen.

The optimization of the QD manufacturing process is an ongoing effort, with researchers and manufacturers continually exploring new materials and techniques to improve QD stability and performance. This includes the development of heavy-metal-free QDs, the refinement of surface passivation methods, and the integration of QDs with emerging display technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!