Understanding Quantum Dot Technology in QLED Displays

JUN 19, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Evolution

Quantum dot technology has undergone significant evolution since its inception in the 1980s. The journey began with the discovery of semiconductor nanocrystals, which exhibited unique optical properties due to quantum confinement effects. Early research focused on understanding and controlling the synthesis of these nanoparticles, with a primary emphasis on cadmium-based materials.

The 1990s saw a surge in quantum dot research, with scientists exploring various compositions and structures to enhance their optical properties. This period marked the development of core-shell quantum dots, which improved stability and quantum yield. Concurrently, efforts to integrate quantum dots into display technologies began, albeit with limited success due to challenges in manufacturing and stability.

The early 2000s brought about a paradigm shift in quantum dot technology. Researchers made significant strides in synthesizing high-quality, monodisperse quantum dots with precise control over size and composition. This advancement paved the way for the first practical applications of quantum dots in biological imaging and sensing.

By the mid-2000s, the focus shifted towards developing quantum dots for display applications. The potential for quantum dots to enhance color gamut and energy efficiency in displays became apparent, leading to increased investment from major electronics manufacturers. This period saw the emergence of quantum dot-enhanced LCD displays, where a quantum dot film was used to improve color reproduction.

The 2010s marked a turning point for quantum dot technology in displays. The introduction of cadmium-free quantum dots addressed environmental concerns and regulatory challenges, accelerating commercial adoption. Quantum dot-enhanced LCD TVs hit the market, offering superior color performance compared to traditional LCD displays.

Recent years have witnessed the evolution of quantum dot technology towards electroluminescent applications, particularly in QLED (Quantum Dot Light-Emitting Diode) displays. This shift represents a significant leap forward, as it allows quantum dots to be used as direct light emitters rather than just color converters. QLED technology promises improved energy efficiency, better color accuracy, and potentially lower manufacturing costs compared to OLED displays.

The ongoing evolution of quantum dot technology continues to focus on improving efficiency, stability, and color purity. Research efforts are directed towards developing new materials, optimizing quantum dot structures, and refining manufacturing processes. The integration of quantum dots with other emerging technologies, such as perovskites and 2D materials, is also being explored to push the boundaries of display performance.

The 1990s saw a surge in quantum dot research, with scientists exploring various compositions and structures to enhance their optical properties. This period marked the development of core-shell quantum dots, which improved stability and quantum yield. Concurrently, efforts to integrate quantum dots into display technologies began, albeit with limited success due to challenges in manufacturing and stability.

The early 2000s brought about a paradigm shift in quantum dot technology. Researchers made significant strides in synthesizing high-quality, monodisperse quantum dots with precise control over size and composition. This advancement paved the way for the first practical applications of quantum dots in biological imaging and sensing.

By the mid-2000s, the focus shifted towards developing quantum dots for display applications. The potential for quantum dots to enhance color gamut and energy efficiency in displays became apparent, leading to increased investment from major electronics manufacturers. This period saw the emergence of quantum dot-enhanced LCD displays, where a quantum dot film was used to improve color reproduction.

The 2010s marked a turning point for quantum dot technology in displays. The introduction of cadmium-free quantum dots addressed environmental concerns and regulatory challenges, accelerating commercial adoption. Quantum dot-enhanced LCD TVs hit the market, offering superior color performance compared to traditional LCD displays.

Recent years have witnessed the evolution of quantum dot technology towards electroluminescent applications, particularly in QLED (Quantum Dot Light-Emitting Diode) displays. This shift represents a significant leap forward, as it allows quantum dots to be used as direct light emitters rather than just color converters. QLED technology promises improved energy efficiency, better color accuracy, and potentially lower manufacturing costs compared to OLED displays.

The ongoing evolution of quantum dot technology continues to focus on improving efficiency, stability, and color purity. Research efforts are directed towards developing new materials, optimizing quantum dot structures, and refining manufacturing processes. The integration of quantum dots with other emerging technologies, such as perovskites and 2D materials, is also being explored to push the boundaries of display performance.

QLED Market Analysis

The QLED display market has experienced significant growth in recent years, driven by the increasing demand for high-quality visual experiences in various applications. As consumers seek superior picture quality, energy efficiency, and longer lifespan in their display devices, QLED technology has emerged as a compelling solution.

The global QLED market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 20% over the next five years. This growth is primarily fueled by the rising adoption of QLED displays in televisions, smartphones, and other consumer electronics. The television segment currently dominates the QLED market, accounting for the largest share of revenue.

Geographically, Asia-Pacific leads the QLED market, with South Korea and China being the major contributors. This dominance is attributed to the presence of key manufacturers and the region's strong consumer electronics industry. North America and Europe follow closely, driven by the increasing demand for premium display technologies in these regions.

The automotive sector presents a promising growth opportunity for QLED displays. As vehicle manufacturers focus on enhancing in-car infotainment systems and dashboard displays, the adoption of QLED technology in this sector is expected to rise significantly in the coming years.

Despite the positive outlook, the QLED market faces certain challenges. The high cost of QLED displays compared to conventional LED displays remains a barrier to widespread adoption, particularly in price-sensitive markets. Additionally, competition from other emerging display technologies, such as microLED, poses a potential threat to QLED market growth.

Key players in the QLED market include Samsung Electronics, TCL Technology, and LG Electronics. These companies are investing heavily in research and development to improve QLED technology and expand its applications. Strategic partnerships and collaborations within the industry are also shaping the competitive landscape.

The COVID-19 pandemic has had a mixed impact on the QLED market. While it initially disrupted supply chains and manufacturing processes, the increased demand for home entertainment systems during lockdowns has subsequently boosted sales of QLED televisions.

Looking ahead, technological advancements in quantum dot materials and manufacturing processes are expected to drive down production costs and improve the performance of QLED displays. This, coupled with the growing demand for high-resolution, energy-efficient displays across various industries, is likely to sustain the strong growth trajectory of the QLED market in the foreseeable future.

The global QLED market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 20% over the next five years. This growth is primarily fueled by the rising adoption of QLED displays in televisions, smartphones, and other consumer electronics. The television segment currently dominates the QLED market, accounting for the largest share of revenue.

Geographically, Asia-Pacific leads the QLED market, with South Korea and China being the major contributors. This dominance is attributed to the presence of key manufacturers and the region's strong consumer electronics industry. North America and Europe follow closely, driven by the increasing demand for premium display technologies in these regions.

The automotive sector presents a promising growth opportunity for QLED displays. As vehicle manufacturers focus on enhancing in-car infotainment systems and dashboard displays, the adoption of QLED technology in this sector is expected to rise significantly in the coming years.

Despite the positive outlook, the QLED market faces certain challenges. The high cost of QLED displays compared to conventional LED displays remains a barrier to widespread adoption, particularly in price-sensitive markets. Additionally, competition from other emerging display technologies, such as microLED, poses a potential threat to QLED market growth.

Key players in the QLED market include Samsung Electronics, TCL Technology, and LG Electronics. These companies are investing heavily in research and development to improve QLED technology and expand its applications. Strategic partnerships and collaborations within the industry are also shaping the competitive landscape.

The COVID-19 pandemic has had a mixed impact on the QLED market. While it initially disrupted supply chains and manufacturing processes, the increased demand for home entertainment systems during lockdowns has subsequently boosted sales of QLED televisions.

Looking ahead, technological advancements in quantum dot materials and manufacturing processes are expected to drive down production costs and improve the performance of QLED displays. This, coupled with the growing demand for high-resolution, energy-efficient displays across various industries, is likely to sustain the strong growth trajectory of the QLED market in the foreseeable future.

QLED Tech Challenges

QLED displays, while offering significant advancements in display technology, face several technical challenges that researchers and manufacturers are actively working to overcome. One of the primary issues is the stability of quantum dots, particularly blue quantum dots, which tend to degrade faster than their red and green counterparts. This instability can lead to color shifts and reduced lifespan of the display, impacting long-term performance and consumer satisfaction.

Another significant challenge lies in the manufacturing process of QLED displays. The precise deposition of quantum dots onto the display substrate requires highly controlled conditions and advanced equipment. Achieving uniform distribution of quantum dots across large display areas while maintaining consistent performance is a complex task that demands continuous refinement of production techniques.

The efficiency of quantum dot light emission is another area of concern. While QLEDs have shown improvements in energy efficiency compared to some other display technologies, there is still room for enhancement. Researchers are exploring ways to increase the quantum yield of quantum dots and reduce energy loss during the light emission process, which could lead to even more energy-efficient displays.

Color accuracy and gamut representation present ongoing challenges. Although QLEDs are capable of producing a wide color gamut, ensuring precise color reproduction across different viewing angles and maintaining color consistency over time remains a technical hurdle. This is particularly important for professional applications that require high color fidelity.

Heat management is a critical issue in QLED displays. Quantum dots can be sensitive to temperature fluctuations, which can affect their performance and longevity. Developing effective thermal management solutions that can dissipate heat without compromising the display's form factor or increasing production costs is an ongoing challenge for manufacturers.

The environmental impact and potential toxicity of certain quantum dot materials, particularly those containing heavy metals like cadmium, have raised concerns. While progress has been made in developing cadmium-free quantum dots, ensuring comparable performance and stability with these alternative materials remains a challenge. Balancing environmental considerations with display performance is a key focus for the industry.

Lastly, the integration of quantum dot technology with other emerging display technologies, such as micro-LED or OLED, presents both opportunities and challenges. Combining these technologies could potentially leverage the strengths of each, but requires overcoming compatibility issues and developing new manufacturing processes.

Another significant challenge lies in the manufacturing process of QLED displays. The precise deposition of quantum dots onto the display substrate requires highly controlled conditions and advanced equipment. Achieving uniform distribution of quantum dots across large display areas while maintaining consistent performance is a complex task that demands continuous refinement of production techniques.

The efficiency of quantum dot light emission is another area of concern. While QLEDs have shown improvements in energy efficiency compared to some other display technologies, there is still room for enhancement. Researchers are exploring ways to increase the quantum yield of quantum dots and reduce energy loss during the light emission process, which could lead to even more energy-efficient displays.

Color accuracy and gamut representation present ongoing challenges. Although QLEDs are capable of producing a wide color gamut, ensuring precise color reproduction across different viewing angles and maintaining color consistency over time remains a technical hurdle. This is particularly important for professional applications that require high color fidelity.

Heat management is a critical issue in QLED displays. Quantum dots can be sensitive to temperature fluctuations, which can affect their performance and longevity. Developing effective thermal management solutions that can dissipate heat without compromising the display's form factor or increasing production costs is an ongoing challenge for manufacturers.

The environmental impact and potential toxicity of certain quantum dot materials, particularly those containing heavy metals like cadmium, have raised concerns. While progress has been made in developing cadmium-free quantum dots, ensuring comparable performance and stability with these alternative materials remains a challenge. Balancing environmental considerations with display performance is a key focus for the industry.

Lastly, the integration of quantum dot technology with other emerging display technologies, such as micro-LED or OLED, presents both opportunities and challenges. Combining these technologies could potentially leverage the strengths of each, but requires overcoming compatibility issues and developing new manufacturing processes.

Current QLED Solutions

01 Quantum dot composition and structure

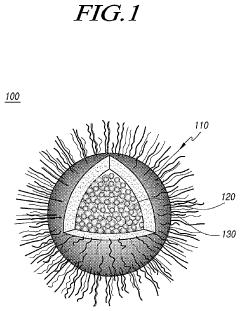

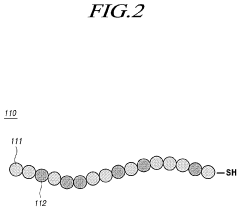

Advancements in quantum dot composition and structure are crucial for improving display quality. This includes developing new materials, optimizing the size and shape of quantum dots, and enhancing their stability. These improvements lead to better color purity, brightness, and overall display performance.- Quantum dot composition and structure: Advancements in quantum dot composition and structure have led to improved display quality. This includes optimizing the size, shape, and material of quantum dots to enhance color purity, brightness, and efficiency. Innovations in core-shell structures and surface treatments have also contributed to better stability and performance of quantum dot displays.

- Quantum dot light-emitting diodes (QLEDs): Development of quantum dot light-emitting diodes (QLEDs) has significantly improved display quality. These devices utilize quantum dots as the emissive layer, offering superior color gamut, high brightness, and energy efficiency compared to traditional LED displays. Innovations in QLED architecture and manufacturing processes have led to enhanced performance and durability.

- Quantum dot color conversion layers: Integration of quantum dot color conversion layers in displays has enhanced color accuracy and vibrancy. These layers convert blue or UV light from LEDs into precise red and green wavelengths, resulting in a wider color gamut and improved color reproduction. Advancements in layer deposition techniques and materials have further improved display quality.

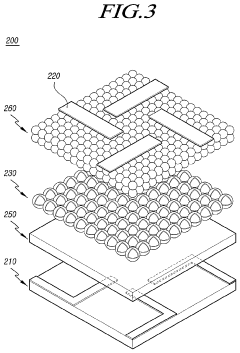

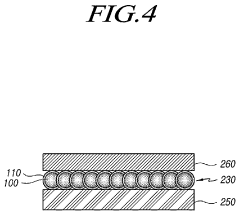

- Quantum dot backlight technology: Quantum dot backlight technology has revolutionized LCD displays by enhancing color accuracy and brightness. By incorporating quantum dots into the backlight unit, displays achieve a wider color gamut and improved energy efficiency. Innovations in quantum dot films and light guide plates have further optimized backlight performance.

- Quantum dot display manufacturing and quality control: Advancements in manufacturing processes and quality control techniques have significantly improved quantum dot display quality. This includes innovations in quantum dot synthesis, deposition methods, and encapsulation technologies. Development of advanced testing and characterization methods has also contributed to more consistent and reliable quantum dot displays.

02 Quantum dot light-emitting diodes (QLEDs)

QLEDs utilize quantum dots as the light-emitting material, offering superior color gamut and energy efficiency compared to traditional display technologies. Research focuses on improving QLED efficiency, longevity, and manufacturing processes to enhance display quality and reduce production costs.Expand Specific Solutions03 Quantum dot color conversion layers

Implementing quantum dot color conversion layers in displays enhances color accuracy and brightness. These layers convert blue or UV light from LEDs into precise red and green wavelengths, resulting in a wider color gamut and improved display quality. Research aims to optimize layer thickness, quantum dot distribution, and light extraction efficiency.Expand Specific Solutions04 Quantum dot backlight technology

Quantum dot backlight technology improves LCD display performance by enhancing color accuracy and brightness. This involves incorporating quantum dots into the backlight unit, either as a film or directly in LED packages. Ongoing research focuses on increasing quantum yield, thermal stability, and reducing light scattering for better display quality.Expand Specific Solutions05 Quantum dot display manufacturing and integration

Advancements in manufacturing processes and integration techniques are essential for improving quantum dot display quality. This includes developing new deposition methods, enhancing quantum dot film uniformity, and optimizing the integration of quantum dot components with existing display technologies. These improvements lead to better yield, consistency, and overall display performance.Expand Specific Solutions

QLED Industry Leaders

The quantum dot technology in QLED displays is in a growth phase, with increasing market adoption and expanding applications. The global QLED market is projected to grow significantly, driven by demand for high-quality displays in various sectors. Technologically, quantum dots are advancing rapidly, with companies like Samsung Electronics, LG Display, and BOE Technology Group leading innovation. These firms are improving color accuracy, brightness, and energy efficiency. Emerging players such as Nanosys and Hansol Chemical are also contributing to the technology's maturation. While QLED displays are becoming more prevalent, ongoing research at institutions like Korea University and Zhejiang University suggests there's still room for substantial technological advancements in this field.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has been actively developing quantum dot technology for their display products. Their approach focuses on integrating quantum dots into both LCD and OLED panels. For LCD-based QLED displays, BOE uses a quantum dot enhancement film (QDEF) to improve color performance and efficiency. They have also been researching the application of quantum dots in electroluminescent (EL) QLEDs, where quantum dots are used as the light-emitting material. BOE has made progress in developing inkjet-printed QLED displays, which could potentially lead to more cost-effective manufacturing processes for large-screen QLED TVs.

Strengths: Strong manufacturing capabilities, potential for cost-effective production methods. Weaknesses: Relatively new entrant in the QLED market compared to some competitors, still establishing brand recognition in premium display segments.

Apple, Inc.

Technical Solution: While Apple has not publicly released QLED displays, they have been actively researching and developing quantum dot technology. Apple's approach focuses on integrating quantum dots with their existing display technologies to enhance color accuracy and energy efficiency. They have filed several patents related to quantum dot-enhanced displays, including methods for improving quantum dot stability and incorporating quantum dots into OLED displays. Apple is also exploring the use of quantum dots in micro-LED displays, which could potentially lead to extremely high-resolution, energy-efficient displays for future devices.

Strengths: Strong research and development capabilities, potential for integration with other proprietary technologies. Weaknesses: No commercially available QLED products yet, potential challenges in scaling up production.

Key QD Innovations

Quantum dots, display apparatus including the same, and method for manufacturing the display apparatus

PatentPendingUS20240114709A1

Innovation

- A quantum dot with a ligand that includes a copolymer having hole transporting and photocrosslinkable functional groups, allowing for the formation of a light emitting layer through photolithography, which enhances reliability, reduces process time, and enables high-resolution display apparatus production.

QLED and preparation method thereof

PatentPendingUS20240083764A1

Innovation

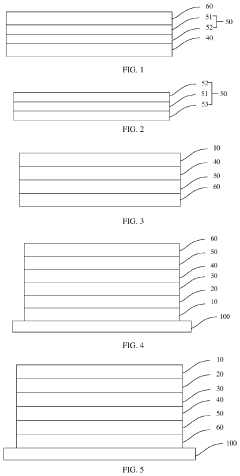

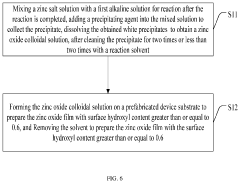

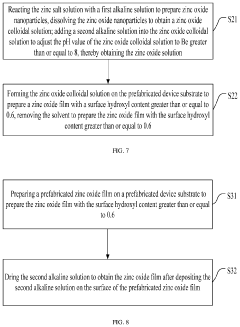

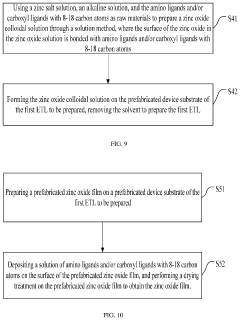

- A QLED device structure utilizing a zinc oxide electron transport layer with a surface hydroxyl content greater than or equal to 0.6 or modified with amino ligands and carboxyl ligands, which reduces electron mobility and injection efficiency, achieving carrier balance without the need for additional barrier layers.

QD Material Safety

Quantum dot (QD) technology in QLED displays has revolutionized the display industry, offering enhanced color performance and energy efficiency. However, the safety of QD materials remains a critical concern that requires thorough examination and ongoing research.

The primary safety concern with QD materials stems from their composition, which often includes heavy metals such as cadmium, lead, or indium. These elements can pose significant health and environmental risks if not properly managed throughout the product lifecycle. Cadmium, in particular, has been a focus of regulatory scrutiny due to its known toxicity.

To address these safety concerns, manufacturers have been developing cadmium-free QDs using alternative materials like indium phosphide. While these alternatives reduce the risks associated with cadmium, they still require careful handling and disposal procedures to minimize potential environmental impact.

The production process of QDs also presents safety challenges. The synthesis of QDs often involves the use of toxic precursors and solvents, necessitating stringent safety protocols in manufacturing facilities. Proper ventilation, personal protective equipment, and waste management systems are essential to protect workers and prevent environmental contamination.

In the context of consumer products, the encapsulation of QDs within display components is crucial for safety. Effective encapsulation prevents the leaching of potentially harmful materials during the use and disposal of QLED devices. Manufacturers must ensure that their encapsulation methods can withstand various environmental conditions and degradation over time.

End-of-life management of QLED displays is another critical aspect of QD material safety. Proper recycling and disposal procedures are necessary to prevent the release of toxic materials into the environment. This requires the development of specialized recycling technologies and infrastructure capable of handling QD-containing devices.

Regulatory bodies worldwide are increasingly focusing on the safety aspects of QD technology. The European Union's Restriction of Hazardous Substances (RoHS) directive, for instance, has set strict limits on the use of cadmium in electronic devices, prompting manufacturers to invest in safer alternatives.

Ongoing research in QD material safety is exploring several avenues, including the development of inherently safer QD compositions, improved encapsulation techniques, and more efficient recycling methods. Additionally, long-term studies on the potential health and environmental impacts of QD materials are crucial for informing future safety regulations and industry practices.

As QLED technology continues to evolve, the balance between performance enhancement and material safety remains a key challenge for the industry. Addressing these safety concerns is essential not only for regulatory compliance but also for ensuring consumer trust and the long-term sustainability of QD technology in display applications.

The primary safety concern with QD materials stems from their composition, which often includes heavy metals such as cadmium, lead, or indium. These elements can pose significant health and environmental risks if not properly managed throughout the product lifecycle. Cadmium, in particular, has been a focus of regulatory scrutiny due to its known toxicity.

To address these safety concerns, manufacturers have been developing cadmium-free QDs using alternative materials like indium phosphide. While these alternatives reduce the risks associated with cadmium, they still require careful handling and disposal procedures to minimize potential environmental impact.

The production process of QDs also presents safety challenges. The synthesis of QDs often involves the use of toxic precursors and solvents, necessitating stringent safety protocols in manufacturing facilities. Proper ventilation, personal protective equipment, and waste management systems are essential to protect workers and prevent environmental contamination.

In the context of consumer products, the encapsulation of QDs within display components is crucial for safety. Effective encapsulation prevents the leaching of potentially harmful materials during the use and disposal of QLED devices. Manufacturers must ensure that their encapsulation methods can withstand various environmental conditions and degradation over time.

End-of-life management of QLED displays is another critical aspect of QD material safety. Proper recycling and disposal procedures are necessary to prevent the release of toxic materials into the environment. This requires the development of specialized recycling technologies and infrastructure capable of handling QD-containing devices.

Regulatory bodies worldwide are increasingly focusing on the safety aspects of QD technology. The European Union's Restriction of Hazardous Substances (RoHS) directive, for instance, has set strict limits on the use of cadmium in electronic devices, prompting manufacturers to invest in safer alternatives.

Ongoing research in QD material safety is exploring several avenues, including the development of inherently safer QD compositions, improved encapsulation techniques, and more efficient recycling methods. Additionally, long-term studies on the potential health and environmental impacts of QD materials are crucial for informing future safety regulations and industry practices.

As QLED technology continues to evolve, the balance between performance enhancement and material safety remains a key challenge for the industry. Addressing these safety concerns is essential not only for regulatory compliance but also for ensuring consumer trust and the long-term sustainability of QD technology in display applications.

QLED vs OLED Comparison

QLED (Quantum Dot Light Emitting Diode) and OLED (Organic Light Emitting Diode) are two leading display technologies in the current market. Both offer superior picture quality compared to traditional LCD displays, but they achieve this through different mechanisms.

QLED displays utilize quantum dots, which are semiconductor nanocrystals that emit light when excited by an electric current. These quantum dots are typically made of materials like cadmium selenide or indium phosphide. In QLED displays, a layer of quantum dots is placed in front of a blue LED backlight. When the blue light passes through the quantum dots, they emit red and green light, creating a full-color spectrum.

OLED displays, on the other hand, use organic compounds that emit light when an electric current is applied. Each pixel in an OLED display is made up of red, green, and blue OLEDs, which can be individually controlled to produce a wide range of colors.

One of the key advantages of QLED displays is their brightness. The quantum dot layer can produce very intense and pure colors, resulting in a brighter overall image. This makes QLED displays particularly well-suited for use in bright environments. Additionally, QLED displays tend to have a longer lifespan than OLED displays, as they are less susceptible to burn-in.

OLED displays, however, have the advantage of producing perfect blacks. Since each pixel can be turned off completely, OLED displays can achieve infinite contrast ratios. This results in deeper, richer colors and better performance in dark scenes. OLED displays also offer wider viewing angles and faster response times compared to QLED.

In terms of energy efficiency, OLED displays generally have the edge. Since they don't require a backlight and can turn off individual pixels, they consume less power, especially when displaying darker content. QLED displays, while more energy-efficient than traditional LCD displays, still require a constant backlight.

Both technologies continue to evolve, with manufacturers working to address their respective weaknesses. For QLED, this includes improving viewing angles and black levels, while OLED development focuses on increasing brightness and longevity. As these technologies advance, the choice between QLED and OLED will likely come down to specific use cases and personal preferences.

QLED displays utilize quantum dots, which are semiconductor nanocrystals that emit light when excited by an electric current. These quantum dots are typically made of materials like cadmium selenide or indium phosphide. In QLED displays, a layer of quantum dots is placed in front of a blue LED backlight. When the blue light passes through the quantum dots, they emit red and green light, creating a full-color spectrum.

OLED displays, on the other hand, use organic compounds that emit light when an electric current is applied. Each pixel in an OLED display is made up of red, green, and blue OLEDs, which can be individually controlled to produce a wide range of colors.

One of the key advantages of QLED displays is their brightness. The quantum dot layer can produce very intense and pure colors, resulting in a brighter overall image. This makes QLED displays particularly well-suited for use in bright environments. Additionally, QLED displays tend to have a longer lifespan than OLED displays, as they are less susceptible to burn-in.

OLED displays, however, have the advantage of producing perfect blacks. Since each pixel can be turned off completely, OLED displays can achieve infinite contrast ratios. This results in deeper, richer colors and better performance in dark scenes. OLED displays also offer wider viewing angles and faster response times compared to QLED.

In terms of energy efficiency, OLED displays generally have the edge. Since they don't require a backlight and can turn off individual pixels, they consume less power, especially when displaying darker content. QLED displays, while more energy-efficient than traditional LCD displays, still require a constant backlight.

Both technologies continue to evolve, with manufacturers working to address their respective weaknesses. For QLED, this includes improving viewing angles and black levels, while OLED development focuses on increasing brightness and longevity. As these technologies advance, the choice between QLED and OLED will likely come down to specific use cases and personal preferences.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!