How to Develop Cutting‑Edge Solutions with QLED?

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Technology Evolution and Objectives

Quantum Dot Light-Emitting Diode (QLED) technology has emerged as a revolutionary advancement in display technology, offering superior color performance and energy efficiency compared to traditional LED displays. The evolution of QLED technology can be traced back to the discovery of quantum dots in the 1980s, but it wasn't until the early 2000s that researchers began exploring their potential in display applications.

The primary objective of QLED technology development is to create displays with enhanced color accuracy, brightness, and energy efficiency while maintaining cost-effectiveness and scalability for mass production. As the technology progresses, researchers and manufacturers aim to overcome challenges such as improving quantum dot stability, enhancing blue QLED performance, and reducing production costs.

QLED technology has undergone several key evolutionary stages. Initially, quantum dots were used as color converters in LED backlights, improving color gamut and accuracy in LCD displays. This approach, known as photo-emissive QLED, is currently the most widely commercialized form of QLED technology. The next stage involves the development of electro-emissive QLED, where quantum dots are directly excited by electrical current, potentially offering even better performance and efficiency.

Recent advancements in QLED technology include the development of cadmium-free quantum dots, addressing environmental concerns and regulatory requirements. Researchers are also exploring new quantum dot materials and structures, such as perovskite quantum dots, to further enhance performance and reduce costs.

The future objectives of QLED technology development include achieving 100% color volume coverage of the Rec. 2020 color space, improving the lifetime and stability of blue QLEDs, and reducing power consumption. Additionally, there is a focus on developing flexible and transparent QLED displays for emerging applications in wearable devices and augmented reality.

To develop cutting-edge solutions with QLED technology, researchers and manufacturers are pursuing several key strategies. These include optimizing quantum dot synthesis and deposition methods, improving charge transport layers, and developing novel device architectures. There is also a growing emphasis on integrating QLED technology with other emerging technologies, such as micro-LED displays and advanced backplane technologies, to create hybrid solutions that leverage the strengths of multiple approaches.

As QLED technology continues to evolve, it is expected to play a crucial role in next-generation display applications, ranging from high-end televisions and monitors to automotive displays and mobile devices. The ongoing research and development efforts aim to push the boundaries of display performance, opening up new possibilities for immersive visual experiences and energy-efficient display solutions.

The primary objective of QLED technology development is to create displays with enhanced color accuracy, brightness, and energy efficiency while maintaining cost-effectiveness and scalability for mass production. As the technology progresses, researchers and manufacturers aim to overcome challenges such as improving quantum dot stability, enhancing blue QLED performance, and reducing production costs.

QLED technology has undergone several key evolutionary stages. Initially, quantum dots were used as color converters in LED backlights, improving color gamut and accuracy in LCD displays. This approach, known as photo-emissive QLED, is currently the most widely commercialized form of QLED technology. The next stage involves the development of electro-emissive QLED, where quantum dots are directly excited by electrical current, potentially offering even better performance and efficiency.

Recent advancements in QLED technology include the development of cadmium-free quantum dots, addressing environmental concerns and regulatory requirements. Researchers are also exploring new quantum dot materials and structures, such as perovskite quantum dots, to further enhance performance and reduce costs.

The future objectives of QLED technology development include achieving 100% color volume coverage of the Rec. 2020 color space, improving the lifetime and stability of blue QLEDs, and reducing power consumption. Additionally, there is a focus on developing flexible and transparent QLED displays for emerging applications in wearable devices and augmented reality.

To develop cutting-edge solutions with QLED technology, researchers and manufacturers are pursuing several key strategies. These include optimizing quantum dot synthesis and deposition methods, improving charge transport layers, and developing novel device architectures. There is also a growing emphasis on integrating QLED technology with other emerging technologies, such as micro-LED displays and advanced backplane technologies, to create hybrid solutions that leverage the strengths of multiple approaches.

As QLED technology continues to evolve, it is expected to play a crucial role in next-generation display applications, ranging from high-end televisions and monitors to automotive displays and mobile devices. The ongoing research and development efforts aim to push the boundaries of display performance, opening up new possibilities for immersive visual experiences and energy-efficient display solutions.

QLED Market Demand Analysis

The QLED (Quantum Dot Light-Emitting Diode) technology has been gaining significant traction in the display market, driven by its superior color performance, brightness, and energy efficiency compared to traditional LED and OLED technologies. The market demand for QLED displays has been steadily increasing across various sectors, including consumer electronics, automotive, and commercial applications.

In the consumer electronics segment, QLED televisions have emerged as a popular choice for high-end home entertainment systems. The technology's ability to deliver vibrant colors, deep blacks, and high brightness levels has resonated well with consumers seeking premium viewing experiences. This has led to a growing market share for QLED TVs, particularly in the large-screen and ultra-high-definition segments.

The automotive industry has also shown increasing interest in QLED technology for in-vehicle displays. As vehicles become more connected and autonomous, the demand for high-quality, durable, and energy-efficient displays for infotainment systems and digital dashboards has surged. QLED's advantages in brightness and color accuracy make it well-suited for automotive applications, where readability under various lighting conditions is crucial.

Commercial applications, such as digital signage and professional monitors, represent another growing market for QLED technology. The need for eye-catching, high-resolution displays in retail environments, airports, and other public spaces has driven the adoption of QLED solutions. Additionally, the technology's potential for flexible and transparent displays opens up new possibilities for innovative advertising and information display applications.

The global QLED market is expected to experience robust growth in the coming years. Factors contributing to this growth include increasing consumer demand for high-quality visual experiences, technological advancements in quantum dot materials, and the expanding application areas for QLED displays. The market is also benefiting from ongoing research and development efforts aimed at improving QLED performance and reducing production costs.

However, the QLED market faces competition from other display technologies, particularly OLED. While QLED offers advantages in brightness and longevity, OLED still holds an edge in certain aspects like contrast ratio and viewing angles. This competition is driving further innovation in both technologies, ultimately benefiting consumers with improved display options.

As the demand for high-performance displays continues to grow across various industries, QLED technology is well-positioned to capture a significant share of the market. The ongoing development of cutting-edge solutions in QLED technology will be crucial in meeting evolving consumer expectations and expanding into new application areas, ensuring sustained market growth and technological advancement in the display industry.

In the consumer electronics segment, QLED televisions have emerged as a popular choice for high-end home entertainment systems. The technology's ability to deliver vibrant colors, deep blacks, and high brightness levels has resonated well with consumers seeking premium viewing experiences. This has led to a growing market share for QLED TVs, particularly in the large-screen and ultra-high-definition segments.

The automotive industry has also shown increasing interest in QLED technology for in-vehicle displays. As vehicles become more connected and autonomous, the demand for high-quality, durable, and energy-efficient displays for infotainment systems and digital dashboards has surged. QLED's advantages in brightness and color accuracy make it well-suited for automotive applications, where readability under various lighting conditions is crucial.

Commercial applications, such as digital signage and professional monitors, represent another growing market for QLED technology. The need for eye-catching, high-resolution displays in retail environments, airports, and other public spaces has driven the adoption of QLED solutions. Additionally, the technology's potential for flexible and transparent displays opens up new possibilities for innovative advertising and information display applications.

The global QLED market is expected to experience robust growth in the coming years. Factors contributing to this growth include increasing consumer demand for high-quality visual experiences, technological advancements in quantum dot materials, and the expanding application areas for QLED displays. The market is also benefiting from ongoing research and development efforts aimed at improving QLED performance and reducing production costs.

However, the QLED market faces competition from other display technologies, particularly OLED. While QLED offers advantages in brightness and longevity, OLED still holds an edge in certain aspects like contrast ratio and viewing angles. This competition is driving further innovation in both technologies, ultimately benefiting consumers with improved display options.

As the demand for high-performance displays continues to grow across various industries, QLED technology is well-positioned to capture a significant share of the market. The ongoing development of cutting-edge solutions in QLED technology will be crucial in meeting evolving consumer expectations and expanding into new application areas, ensuring sustained market growth and technological advancement in the display industry.

QLED Technical Challenges and Limitations

QLED technology, while promising, faces several technical challenges and limitations that hinder its widespread adoption and performance optimization. One of the primary issues is the stability of quantum dots, particularly blue quantum dots, which tend to degrade faster than their red and green counterparts. This instability affects the overall lifespan and color accuracy of QLED displays over time.

Another significant challenge lies in the efficiency of quantum dot light emission. Despite improvements, the quantum yield of quantum dots still falls short of ideal levels, resulting in energy loss and reduced brightness. This inefficiency not only impacts display quality but also increases power consumption, a critical factor in portable devices.

Color purity and gamut remain areas of concern for QLED technology. While quantum dots offer superior color reproduction compared to traditional LED displays, achieving consistent and accurate colors across the entire spectrum proves challenging. This is particularly evident in maintaining color accuracy at different brightness levels and viewing angles.

The manufacturing process for QLED displays presents its own set of hurdles. Ensuring uniform distribution of quantum dots and preventing aggregation during the production process is crucial for display quality but technically demanding. Additionally, the integration of quantum dots into existing display architectures without compromising their optical properties requires sophisticated engineering solutions.

Thermal management is another critical limitation in QLED technology. Quantum dots are sensitive to temperature fluctuations, which can affect their emission properties and longevity. Developing effective heat dissipation mechanisms without increasing device bulk or complexity remains a significant challenge for manufacturers.

The environmental impact and potential toxicity of certain quantum dot materials, particularly those containing heavy metals, raise concerns about long-term sustainability and regulatory compliance. This necessitates research into alternative, eco-friendly quantum dot compositions that maintain high performance standards.

Lastly, the cost of production for high-quality QLED displays remains relatively high compared to other display technologies. Scaling up production while maintaining quality and reducing costs is essential for QLED to compete effectively in the consumer electronics market. Overcoming these technical challenges and limitations is crucial for the continued development and widespread adoption of cutting-edge QLED solutions.

Another significant challenge lies in the efficiency of quantum dot light emission. Despite improvements, the quantum yield of quantum dots still falls short of ideal levels, resulting in energy loss and reduced brightness. This inefficiency not only impacts display quality but also increases power consumption, a critical factor in portable devices.

Color purity and gamut remain areas of concern for QLED technology. While quantum dots offer superior color reproduction compared to traditional LED displays, achieving consistent and accurate colors across the entire spectrum proves challenging. This is particularly evident in maintaining color accuracy at different brightness levels and viewing angles.

The manufacturing process for QLED displays presents its own set of hurdles. Ensuring uniform distribution of quantum dots and preventing aggregation during the production process is crucial for display quality but technically demanding. Additionally, the integration of quantum dots into existing display architectures without compromising their optical properties requires sophisticated engineering solutions.

Thermal management is another critical limitation in QLED technology. Quantum dots are sensitive to temperature fluctuations, which can affect their emission properties and longevity. Developing effective heat dissipation mechanisms without increasing device bulk or complexity remains a significant challenge for manufacturers.

The environmental impact and potential toxicity of certain quantum dot materials, particularly those containing heavy metals, raise concerns about long-term sustainability and regulatory compliance. This necessitates research into alternative, eco-friendly quantum dot compositions that maintain high performance standards.

Lastly, the cost of production for high-quality QLED displays remains relatively high compared to other display technologies. Scaling up production while maintaining quality and reducing costs is essential for QLED to compete effectively in the consumer electronics market. Overcoming these technical challenges and limitations is crucial for the continued development and widespread adoption of cutting-edge QLED solutions.

Current QLED Solutions Overview

01 QLED structure and composition

QLED (Quantum Dot Light Emitting Diode) technology involves the use of quantum dots as light-emitting materials. The structure typically includes layers of quantum dots sandwiched between electron and hole transport layers. The composition and arrangement of these layers are crucial for optimizing the device's performance, including color purity, brightness, and efficiency.- QLED structure and composition: QLED (Quantum Dot Light Emitting Diode) technology involves the use of quantum dots as light-emitting materials. The structure typically includes layers of quantum dots sandwiched between electron and hole transport layers. The composition and arrangement of these layers are crucial for optimizing the device's performance, including color purity, brightness, and efficiency.

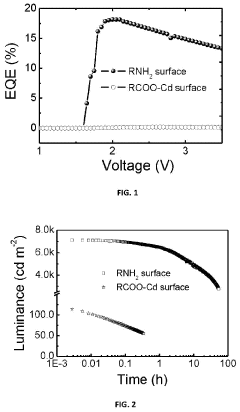

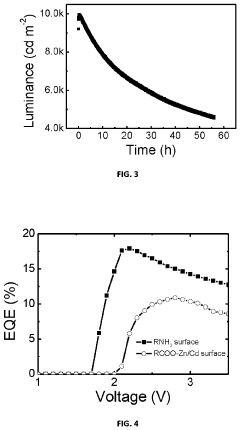

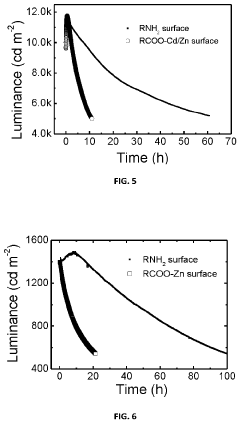

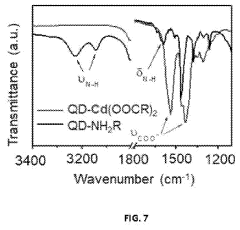

- Quantum dot synthesis and modification: The synthesis and modification of quantum dots play a vital role in QLED performance. This includes developing methods to control the size, shape, and surface properties of quantum dots. Techniques such as core-shell structures, surface ligand engineering, and doping are employed to enhance the optical and electronic properties of quantum dots for QLED applications.

- QLED device fabrication techniques: Various fabrication techniques are employed to manufacture QLED devices. These include solution processing methods such as spin-coating, inkjet printing, and transfer printing. Advanced deposition techniques like thermal evaporation and atomic layer deposition are also used to create high-quality, uniform layers. The choice of fabrication method impacts device performance and scalability.

- QLED color tuning and optimization: Color tuning and optimization in QLEDs involve manipulating the emission properties of quantum dots to achieve desired color output. This includes strategies for enhancing color purity, expanding the color gamut, and improving color stability. Techniques such as mixing different quantum dot populations and using color conversion layers are employed to achieve optimal color performance in QLED displays.

- QLED efficiency and lifetime improvement: Improving the efficiency and lifetime of QLED devices is a key focus area. This involves developing strategies to enhance charge injection and transport, reduce non-radiative recombination, and mitigate degradation mechanisms. Approaches include optimizing device architecture, developing new charge transport materials, and implementing encapsulation techniques to protect quantum dots from environmental factors.

02 Quantum dot synthesis and modification

The synthesis and modification of quantum dots play a vital role in QLED performance. This includes developing methods to control the size, shape, and surface properties of quantum dots. Techniques such as core-shell structures and surface ligand engineering are employed to enhance the optical and electrical properties of the quantum dots, leading to improved QLED devices.Expand Specific Solutions03 QLED manufacturing processes

Advancements in QLED manufacturing processes focus on improving production efficiency and device quality. This includes developing new deposition techniques for quantum dot layers, optimizing the fabrication of multi-layer structures, and implementing quality control measures. Innovations in this area aim to enable large-scale production of high-performance QLED displays and lighting devices.Expand Specific Solutions04 QLED color tuning and enhancement

Techniques for tuning and enhancing the color output of QLED devices are crucial for display applications. This involves manipulating the quantum dot composition, size distribution, and arrangement to achieve precise color control. Additionally, methods for improving color gamut, color purity, and color stability over time are developed to meet the demands of high-quality display technologies.Expand Specific Solutions05 QLED device efficiency and lifetime improvement

Enhancing the efficiency and extending the lifetime of QLED devices are ongoing challenges. Research in this area focuses on reducing energy consumption, improving quantum yield, and developing strategies to mitigate degradation mechanisms. This includes optimizing charge injection and transport, reducing non-radiative recombination, and implementing protective measures against environmental factors that can affect device performance over time.Expand Specific Solutions

Key QLED Industry Players

The development of cutting-edge QLED solutions is currently in a dynamic growth phase, with the market expanding rapidly due to increasing demand for high-quality displays. The global QLED market is projected to reach significant scale in the coming years, driven by advancements in display technology. In terms of technological maturity, companies like BOE Technology Group Co., Ltd. and Sharp Corp. are leading the way with innovative QLED solutions. Other players such as Hefei Visionox Technology Co., Ltd. and Shenzhen China Star Optoelectronics Semicon Display Tech Co. are also making substantial contributions to QLED development. Academic institutions like Zhejiang University and The Hong Kong University of Science & Technology are conducting crucial research to further enhance QLED technology, indicating a collaborative ecosystem between industry and academia.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced QLED technology using quantum dot materials to enhance color performance and energy efficiency. Their solution involves a hybrid structure combining quantum dots with traditional LED backlights. This approach allows for precise control of light emission, resulting in wider color gamut and improved brightness. BOE's QLED panels utilize a unique quantum dot film that converts blue light from LEDs into pure red and green light, achieving more accurate and vibrant color reproduction.

Strengths: Superior color performance, energy efficiency, and potential for flexible displays. Weaknesses: Higher production costs and potential issues with long-term stability of quantum dot materials.

Hefei Visionox Technology Co., Ltd.

Technical Solution: Visionox has developed a proprietary QLED solution that focuses on improving the quantum yield of quantum dots and enhancing the overall efficiency of the display. Their approach involves using specially engineered quantum dot materials with optimized size distribution and surface chemistry. This results in improved light emission and color purity. Visionox's QLED panels also incorporate advanced light management techniques, such as micro-lens arrays, to enhance light extraction and reduce energy consumption.

Strengths: High quantum yield, improved energy efficiency, and potential for high-resolution displays. Weaknesses: Challenges in scaling up production and potential color shift over time.

QLED Core Patents and Innovations

QLED and Method for Manufacturing Quantum Dot

PatentActiveUS20210380878A1

Innovation

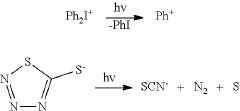

- The use of electrochemically inert ligands, such as amine, alkylphosphine, and metal carboxylate ligands, which have a reduction potential greater than the quantum dot's conduction band and an oxidation potential less than its valence band, accounting for at least 80% of the surface ligands, to prevent carrier consumption and ligand detachment under electrical excitation, thereby enhancing stability and efficiency.

QLED and manufacturing method thereof

PatentActiveUS20220081313A1

Innovation

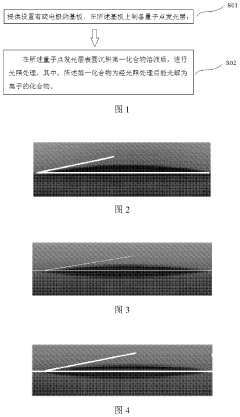

- A QLED manufacturing method involving the use of a first compound solution that photodegrades into ions under illumination, applied to the quantum dot light emitting layer, which reduces the contact angle and improves the compatibility between layers, enhancing the flatness and luminous efficiency of the QLED.

QLED Manufacturing Processes

QLED manufacturing processes have evolved significantly over the years, incorporating advanced technologies to enhance efficiency and product quality. The process begins with the preparation of quantum dots, typically using colloidal synthesis methods. These nanocrystals are carefully engineered to emit specific colors when excited by light, forming the foundation of QLED technology.

The next crucial step involves the deposition of quantum dots onto a substrate. This is often achieved through solution-based techniques such as inkjet printing or spin coating. These methods allow for precise control over the thickness and uniformity of the quantum dot layer, which is critical for optimal performance. Advanced manufacturing processes may also employ photolithography techniques to create patterned quantum dot arrays, enabling higher resolution displays.

Following quantum dot deposition, multiple layers are added to complete the QLED structure. These typically include electron transport layers, hole transport layers, and electrode materials. Each layer is deposited using specialized techniques such as thermal evaporation, sputtering, or chemical vapor deposition. The exact sequence and composition of these layers can vary depending on the specific QLED design and intended application.

Quality control is a crucial aspect of QLED manufacturing. Advanced imaging and spectroscopic techniques are employed to assess the uniformity and performance of the quantum dot layers. Automated inspection systems using machine vision and artificial intelligence algorithms help identify defects and ensure consistency across large-scale production.

Encapsulation is another critical step in QLED manufacturing, protecting the sensitive quantum dot layers from environmental factors such as moisture and oxygen. This often involves the application of barrier films or the use of hermetic sealing techniques. Recent advancements in encapsulation technology have significantly improved the longevity and stability of QLED devices.

As QLED technology continues to advance, manufacturing processes are evolving to accommodate new materials and device architectures. For instance, the development of cadmium-free quantum dots has necessitated adjustments in synthesis and deposition techniques. Similarly, the integration of QLED technology with flexible substrates is driving innovations in roll-to-roll manufacturing processes, potentially enabling the production of bendable and foldable displays.

The next crucial step involves the deposition of quantum dots onto a substrate. This is often achieved through solution-based techniques such as inkjet printing or spin coating. These methods allow for precise control over the thickness and uniformity of the quantum dot layer, which is critical for optimal performance. Advanced manufacturing processes may also employ photolithography techniques to create patterned quantum dot arrays, enabling higher resolution displays.

Following quantum dot deposition, multiple layers are added to complete the QLED structure. These typically include electron transport layers, hole transport layers, and electrode materials. Each layer is deposited using specialized techniques such as thermal evaporation, sputtering, or chemical vapor deposition. The exact sequence and composition of these layers can vary depending on the specific QLED design and intended application.

Quality control is a crucial aspect of QLED manufacturing. Advanced imaging and spectroscopic techniques are employed to assess the uniformity and performance of the quantum dot layers. Automated inspection systems using machine vision and artificial intelligence algorithms help identify defects and ensure consistency across large-scale production.

Encapsulation is another critical step in QLED manufacturing, protecting the sensitive quantum dot layers from environmental factors such as moisture and oxygen. This often involves the application of barrier films or the use of hermetic sealing techniques. Recent advancements in encapsulation technology have significantly improved the longevity and stability of QLED devices.

As QLED technology continues to advance, manufacturing processes are evolving to accommodate new materials and device architectures. For instance, the development of cadmium-free quantum dots has necessitated adjustments in synthesis and deposition techniques. Similarly, the integration of QLED technology with flexible substrates is driving innovations in roll-to-roll manufacturing processes, potentially enabling the production of bendable and foldable displays.

QLED Environmental Impact Assessment

The environmental impact of Quantum Dot Light-Emitting Diode (QLED) technology is a crucial consideration in its development and implementation. As QLED displays gain popularity in consumer electronics, it is essential to assess their ecological footprint throughout their lifecycle.

QLED technology offers several environmental advantages over traditional display technologies. The manufacturing process of QLED displays typically requires fewer materials and less energy compared to OLED or LCD production. This reduction in resource consumption contributes to a lower carbon footprint during the manufacturing phase. Additionally, QLED displays are known for their energy efficiency during operation, consuming less power than many alternative display technologies, which translates to reduced energy consumption and lower greenhouse gas emissions over the product's lifespan.

However, the environmental impact of QLED technology is not without challenges. The production of quantum dots often involves the use of heavy metals, such as cadmium, which can pose environmental risks if not properly managed. While efforts are being made to develop cadmium-free quantum dots, the industry must continue to address concerns related to the potential release of toxic materials during manufacturing, use, and disposal.

The longevity of QLED displays is another factor that influences their environmental impact. These displays generally have a longer lifespan compared to some other display technologies, which can reduce electronic waste generation. However, the eventual disposal of QLED devices presents challenges due to the presence of quantum dots and other specialized materials that may require specific recycling processes.

Water usage and pollution are additional environmental considerations in QLED production. The manufacturing of quantum dots and display components may involve water-intensive processes and the potential release of pollutants. Implementing advanced water treatment and recycling systems in production facilities is crucial to mitigate these impacts.

As the QLED industry evolves, there is a growing focus on developing more sustainable production methods and materials. Research into bio-based quantum dots and environmentally friendly synthesis techniques shows promise for reducing the ecological footprint of QLED technology. Furthermore, advancements in recycling technologies specific to QLED displays are essential for establishing a circular economy approach to electronic waste management.

To fully assess and improve the environmental impact of QLED technology, a comprehensive life cycle analysis is necessary. This analysis should consider raw material extraction, manufacturing processes, energy consumption during use, and end-of-life disposal or recycling. By identifying key areas for improvement, the industry can work towards developing more sustainable QLED solutions that balance technological advancement with environmental responsibility.

QLED technology offers several environmental advantages over traditional display technologies. The manufacturing process of QLED displays typically requires fewer materials and less energy compared to OLED or LCD production. This reduction in resource consumption contributes to a lower carbon footprint during the manufacturing phase. Additionally, QLED displays are known for their energy efficiency during operation, consuming less power than many alternative display technologies, which translates to reduced energy consumption and lower greenhouse gas emissions over the product's lifespan.

However, the environmental impact of QLED technology is not without challenges. The production of quantum dots often involves the use of heavy metals, such as cadmium, which can pose environmental risks if not properly managed. While efforts are being made to develop cadmium-free quantum dots, the industry must continue to address concerns related to the potential release of toxic materials during manufacturing, use, and disposal.

The longevity of QLED displays is another factor that influences their environmental impact. These displays generally have a longer lifespan compared to some other display technologies, which can reduce electronic waste generation. However, the eventual disposal of QLED devices presents challenges due to the presence of quantum dots and other specialized materials that may require specific recycling processes.

Water usage and pollution are additional environmental considerations in QLED production. The manufacturing of quantum dots and display components may involve water-intensive processes and the potential release of pollutants. Implementing advanced water treatment and recycling systems in production facilities is crucial to mitigate these impacts.

As the QLED industry evolves, there is a growing focus on developing more sustainable production methods and materials. Research into bio-based quantum dots and environmentally friendly synthesis techniques shows promise for reducing the ecological footprint of QLED technology. Furthermore, advancements in recycling technologies specific to QLED displays are essential for establishing a circular economy approach to electronic waste management.

To fully assess and improve the environmental impact of QLED technology, a comprehensive life cycle analysis is necessary. This analysis should consider raw material extraction, manufacturing processes, energy consumption during use, and end-of-life disposal or recycling. By identifying key areas for improvement, the industry can work towards developing more sustainable QLED solutions that balance technological advancement with environmental responsibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!