How to Implement Cost‑Effective QLED Solutions?

QLED Technology Evolution and Objectives

Quantum Dot Light-Emitting Diode (QLED) technology has emerged as a promising advancement in display technology, offering superior color performance and energy efficiency compared to traditional LED displays. The evolution of QLED technology can be traced back to the early 2000s when researchers first began exploring the potential of quantum dots in light-emitting applications.

Initially, the focus was on developing stable and efficient quantum dot materials that could produce pure, saturated colors. As the technology progressed, efforts shifted towards integrating these quantum dots into display structures. The first QLED prototypes demonstrated in the mid-2000s showed the potential for improved color gamut and brightness, but faced challenges in terms of stability and manufacturing scalability.

Over the past decade, significant advancements have been made in quantum dot synthesis, encapsulation techniques, and device architectures. These improvements have led to enhanced stability, longer lifetimes, and improved efficiency of QLED displays. The introduction of cadmium-free quantum dots has also addressed environmental concerns, paving the way for wider adoption of the technology.

The current objectives in QLED technology development are multifaceted, with a primary focus on cost-effective implementation. Researchers and industry players are working towards reducing manufacturing costs while maintaining or improving display performance. This includes developing more efficient production methods for quantum dots, optimizing device structures to minimize material usage, and exploring new materials that offer similar performance at lower costs.

Another key objective is to enhance the overall efficiency of QLED displays. This involves improving the quantum yield of the quantum dots, optimizing charge injection and transport layers, and developing more effective light extraction techniques. By increasing efficiency, QLED displays can offer better brightness and lower power consumption, making them more competitive in the market.

Durability and longevity remain critical objectives in QLED technology development. Efforts are being made to improve the stability of quantum dots under various operating conditions, enhance encapsulation techniques to protect against environmental factors, and develop more robust device architectures that can withstand long-term use.

As the display industry moves towards more diverse form factors, flexibility and scalability have become important objectives for QLED technology. Researchers are exploring ways to integrate quantum dots into flexible substrates and develop manufacturing processes that can accommodate various screen sizes and shapes.

Looking ahead, the evolution of QLED technology is expected to continue with a focus on achieving cost-effective solutions that can compete with established display technologies in terms of performance, efficiency, and manufacturability. The ultimate goal is to position QLED as a viable and attractive option for a wide range of display applications, from consumer electronics to professional and industrial use cases.

QLED Market Demand Analysis

The QLED (Quantum Dot Light-Emitting Diode) market has been experiencing significant growth and demand in recent years, driven by the increasing adoption of high-quality display technologies across various industries. The global QLED market is expected to expand rapidly, with a compound annual growth rate (CAGR) projected to be in the double digits over the next five years.

Consumer electronics, particularly televisions and smartphones, represent the largest segment of QLED market demand. As consumers seek improved picture quality, higher contrast ratios, and more vibrant colors, QLED technology has emerged as a compelling alternative to traditional LED and OLED displays. The automotive industry is also showing increased interest in QLED technology for in-vehicle displays and infotainment systems, driven by the trend towards connected and autonomous vehicles.

The commercial display sector, including digital signage and large-format displays for advertising and information dissemination, is another key driver of QLED market demand. These applications benefit from QLED's high brightness, wide color gamut, and energy efficiency, making them ideal for use in various lighting conditions.

Geographically, Asia-Pacific leads the QLED market demand, with countries like China, South Korea, and Japan at the forefront of both production and consumption. North America and Europe follow closely, with growing adoption rates in both consumer and commercial sectors.

Despite the positive market outlook, cost remains a significant factor influencing QLED adoption. While QLED displays offer superior performance in many aspects, they are generally more expensive than conventional LED displays. This price premium has limited widespread adoption, particularly in price-sensitive markets and applications.

To address this challenge, there is a growing demand for cost-effective QLED solutions that can maintain the technology's performance advantages while reducing overall production costs. This includes innovations in materials science, manufacturing processes, and supply chain optimization. The industry is actively seeking ways to scale up production, improve yield rates, and develop more efficient quantum dot synthesis methods to drive down costs.

Furthermore, there is an increasing focus on sustainability and environmental considerations in the QLED market. Consumers and regulators are demanding more eco-friendly display technologies, creating a need for QLED solutions that minimize the use of heavy metals and improve recyclability. This trend is shaping research and development efforts towards greener QLED materials and manufacturing processes.

QLED Technical Challenges

QLED technology, while promising, faces several significant technical challenges that need to be addressed for widespread adoption and cost-effective implementation. One of the primary hurdles is the stability and longevity of quantum dots. These nanocrystals are prone to degradation when exposed to air, moisture, and high temperatures, which can lead to a decrease in luminescence efficiency and color purity over time. This instability not only affects the overall performance of QLED displays but also impacts their long-term reliability, a crucial factor for consumer electronics.

Another major challenge lies in the development of efficient and stable blue quantum dots. While red and green quantum dots have achieved relatively high efficiency and stability, blue quantum dots lag behind in terms of both performance and durability. This disparity creates an imbalance in the color gamut and affects the overall display quality. The search for high-performance blue emitters remains a key focus area for researchers and manufacturers alike.

The manufacturing process for QLEDs also presents significant challenges. Current production methods often involve complex and costly procedures, making it difficult to achieve economies of scale. The precise control required for quantum dot synthesis, size distribution, and uniform deposition in display panels adds to the manufacturing complexity. Additionally, the integration of quantum dots with existing display technologies, such as OLED backplanes, requires careful engineering to ensure optimal performance and compatibility.

Environmental concerns and regulatory compliance pose another set of challenges for QLED technology. Many quantum dots contain heavy metals like cadmium, which are subject to strict regulations in various countries. While cadmium-free alternatives are being developed, they often fall short in terms of performance compared to their cadmium-based counterparts. Balancing environmental sustainability with performance requirements remains a significant hurdle for the industry.

Lastly, the optimization of quantum dot excitation mechanisms presents a technical challenge. Current QLED designs often rely on blue LEDs to excite quantum dots, which can lead to energy losses and reduced efficiency. Developing more efficient excitation methods, such as direct electrical excitation of quantum dots, could significantly improve the overall energy efficiency of QLED displays. However, achieving stable and uniform electrical excitation across large display areas remains a complex engineering problem.

Addressing these technical challenges is crucial for the successful implementation of cost-effective QLED solutions. Overcoming these hurdles will require continued research and development efforts, innovative manufacturing techniques, and collaborative approaches across the industry. As progress is made in these areas, QLED technology has the potential to offer significant advantages in display performance, energy efficiency, and cost-effectiveness.

Current Cost-Effective QLED Solutions

01 Improved manufacturing processes for cost reduction

Advanced manufacturing techniques and processes are being developed to reduce the production costs of QLED displays. These include optimized deposition methods, improved material utilization, and streamlined assembly processes. By enhancing manufacturing efficiency, the overall cost-effectiveness of QLED technology can be significantly improved.- Improved manufacturing processes for cost reduction: Advanced manufacturing techniques and processes are being developed to reduce the production costs of QLED displays. These include optimized deposition methods, improved material utilization, and streamlined assembly processes. Such advancements contribute to making QLED technology more cost-effective and competitive in the display market.

- Enhanced quantum dot efficiency: Research is focused on improving the efficiency of quantum dots used in QLED displays. This includes developing new quantum dot materials, optimizing their size and composition, and enhancing their light-emitting properties. Higher efficiency quantum dots can lead to reduced power consumption and potentially lower production costs.

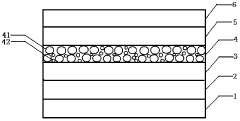

- Simplified device structure: Efforts are being made to simplify the structure of QLED devices while maintaining or improving their performance. This includes reducing the number of layers, developing multifunctional materials, and optimizing the overall device architecture. A simpler structure can lead to reduced material costs and streamlined manufacturing processes.

- Integration of quantum dots with existing display technologies: Researchers are exploring ways to integrate quantum dots with established display technologies, such as LCD and OLED. This approach aims to leverage existing manufacturing infrastructure while enhancing display performance, potentially offering a cost-effective pathway to market adoption of quantum dot technology.

- Large-scale production and economies of scale: As QLED technology matures, efforts are being made to scale up production and achieve economies of scale. This includes developing high-volume manufacturing techniques, improving supply chain efficiency, and optimizing resource allocation. Large-scale production can significantly reduce per-unit costs, making QLED displays more cost-competitive in the market.

02 Novel quantum dot materials for enhanced performance

Research is focused on developing new quantum dot materials that offer improved efficiency, color purity, and stability. These advancements can lead to better performance of QLED displays while potentially reducing material costs, thus enhancing the overall cost-effectiveness of the technology.Expand Specific Solutions03 Simplified device structures for cost reduction

Efforts are being made to simplify QLED device structures without compromising performance. This includes reducing the number of layers, using alternative materials, and optimizing the overall architecture of QLED displays. Simplified structures can lead to reduced material and manufacturing costs.Expand Specific Solutions04 Integration of quantum dots with existing display technologies

Researchers are exploring ways to integrate quantum dots with existing display technologies, such as LCD and OLED. This approach can leverage established manufacturing infrastructure while enhancing display performance, potentially offering a cost-effective path to market adoption.Expand Specific Solutions05 Scalable production methods for quantum dots

Development of scalable production methods for quantum dots is crucial for improving the cost-effectiveness of QLED technology. This includes continuous flow synthesis, large-scale batch production, and automated manufacturing processes that can increase yield and reduce production costs.Expand Specific Solutions

Key QLED Industry Players

The QLED market is in a growth phase, with increasing demand for high-quality displays driving innovation and competition. Major players like BOE Technology, TCL China Star, and Samsung Display are investing heavily in R&D to develop cost-effective QLED solutions. The market size is expanding rapidly, fueled by applications in TVs, smartphones, and automotive displays. Technological maturity varies, with established companies like Sharp and emerging players such as Yiwu QingYue Optoelectronics pushing boundaries. Universities and research institutions, including Zhejiang University and The Hong Kong University of Science & Technology, are contributing to advancements in QLED technology, focusing on improving efficiency and reducing production costs. The competitive landscape is dynamic, with collaborations between industry and academia driving progress towards more affordable QLED implementations.

BOE Technology Group Co., Ltd.

TCL China Star Optoelectronics Technology Co., Ltd.

QLED Core Patents and Innovations

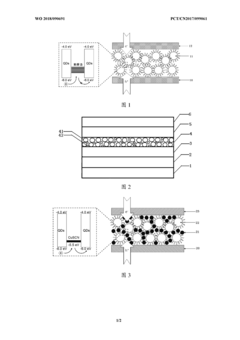

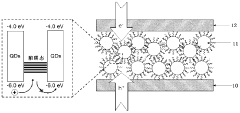

- A blend of quantum dots and CuSCN nanoparticles is used to form a film as the quantum dot light-emitting layer. Through the excellent hole transport ability and abundant material sources of CuSCN nanoparticles, the hole defect state on the surface of the quantum dot is passivated and the hole transport effect is improved. , to achieve the balance of carrier injection.

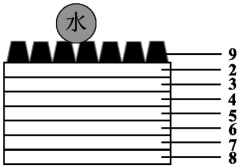

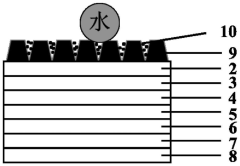

- Using a superhydrophobic surface based on a graded refractive index, the refractive index is controlled to enhance the light extraction efficiency through a superhydrophobic surface composed of polymers and nanoparticles, combined with a transparent substrate, a conductive layer, a hole injection layer, and a hole transport layer , the structure of the quantum dot luminescent layer and electrode, and the superhydrophobic surface with micro-nano structure is prepared using the sol-gel method, soft transfer technology and spraying method.

QLED Manufacturing Process Optimization

QLED manufacturing process optimization is crucial for implementing cost-effective QLED solutions. The current manufacturing process involves several key steps, including the synthesis of quantum dots, the deposition of quantum dot layers, and the integration of these layers into the display structure. To optimize this process, manufacturers are focusing on improving yield rates, reducing material waste, and enhancing production efficiency.

One of the primary areas for optimization is the quantum dot synthesis process. Advanced techniques such as continuous flow synthesis and microfluidic reactors are being explored to produce more uniform quantum dots with higher efficiency. These methods allow for better control over particle size and composition, resulting in improved color purity and reduced material consumption.

The deposition of quantum dot layers is another critical area for improvement. Traditional methods like spin coating and inkjet printing are being refined to achieve more precise and uniform layer thicknesses. Emerging techniques such as roll-to-roll printing and photolithography are being investigated for their potential to increase throughput and reduce production costs.

Integration of quantum dot layers into the display structure presents opportunities for process optimization. Advanced encapsulation techniques are being developed to protect quantum dots from environmental factors, extending the lifespan of QLED displays. Additionally, novel electrode designs and materials are being explored to enhance charge injection and improve overall device efficiency.

Automation and Industry 4.0 principles are being applied to QLED manufacturing processes. Smart factory concepts, including real-time monitoring, predictive maintenance, and data-driven quality control, are being implemented to reduce downtime, minimize defects, and optimize resource utilization.

Material innovations play a significant role in process optimization. Research is ongoing to develop more stable and efficient quantum dot materials, as well as improved barrier and encapsulation materials. These advancements aim to enhance device performance while reducing material costs and simplifying manufacturing processes.

By focusing on these key areas of process optimization, manufacturers can significantly reduce production costs, improve yield rates, and enhance the overall quality of QLED displays. This, in turn, will contribute to the implementation of more cost-effective QLED solutions, making this technology more accessible and competitive in the display market.

Environmental Impact of QLED Production

The environmental impact of QLED production is a critical consideration in the implementation of cost-effective QLED solutions. As the demand for QLED displays continues to grow, it is essential to assess and mitigate the potential environmental consequences associated with their manufacturing processes.

One of the primary environmental concerns in QLED production is the use of heavy metals, particularly cadmium, in the quantum dot materials. While cadmium-based quantum dots offer superior color performance, they pose significant environmental and health risks if not properly managed. Recent advancements in cadmium-free quantum dot technologies have shown promise in reducing these risks, but their widespread adoption is still in progress.

The production of QLED displays also involves energy-intensive processes, contributing to greenhouse gas emissions. The high-temperature synthesis of quantum dots and the vacuum deposition techniques used in display manufacturing require substantial energy inputs. Improving energy efficiency in these processes is crucial for reducing the carbon footprint of QLED production.

Water consumption and wastewater management are additional environmental challenges in QLED manufacturing. The production of quantum dots and the cleaning processes involved in display fabrication can lead to significant water usage and potential contamination. Implementing water recycling systems and developing more efficient cleaning methods can help mitigate these impacts.

The use of organic solvents in QLED production raises concerns about volatile organic compound (VOC) emissions. These emissions can contribute to air pollution and pose health risks to workers and surrounding communities. Developing alternative, environmentally friendly solvents or improving solvent recovery systems is essential for addressing this issue.

Electronic waste (e-waste) management is another critical aspect of the environmental impact of QLED technology. As QLED displays become more prevalent, ensuring proper recycling and disposal of end-of-life products is crucial to prevent the release of hazardous materials into the environment. Designing displays for easier disassembly and recyclability can significantly improve their end-of-life management.

The sourcing of raw materials for QLED production, including rare earth elements, also has environmental implications. Mining and processing these materials can lead to habitat destruction, soil erosion, and water pollution. Developing sustainable sourcing practices and exploring alternative materials can help reduce the environmental footprint of the supply chain.

In conclusion, addressing the environmental impact of QLED production is essential for implementing truly cost-effective solutions. By focusing on sustainable manufacturing processes, reducing hazardous material usage, improving energy efficiency, and implementing effective waste management strategies, the QLED industry can minimize its environmental footprint while delivering high-performance display technologies.