How to Enhance Brightness and Clarity with QLED Displays?

QLED Display Evolution

QLED display technology has undergone significant evolution since its inception, marking a series of milestones in the pursuit of enhanced brightness and clarity. The journey began with the introduction of quantum dots in display technology, which revolutionized color reproduction and brightness capabilities. Initially, quantum dots were used as a color conversion layer in LCD displays, improving color gamut and efficiency.

As the technology progressed, researchers and manufacturers focused on refining the quantum dot materials and their application methods. The early generations of QLED displays utilized cadmium-based quantum dots, which offered excellent color performance but raised environmental concerns. This led to the development of cadmium-free quantum dots, a crucial step in making QLED technology more sustainable and widely adoptable.

The next significant advancement came with the integration of quantum dots directly into the LED backlight units. This approach, known as on-chip quantum dots, allowed for better light utilization and further improvements in color accuracy and brightness. The evolution continued with the development of photo-emissive quantum dot displays, where quantum dots are used as the primary light emitters, eliminating the need for a separate backlight and potentially offering OLED-like black levels with superior brightness.

Recent years have seen a focus on enhancing the stability and longevity of quantum dots, addressing earlier issues of degradation under high-energy blue light. This has led to the development of more robust quantum dot materials and protective encapsulation techniques, ensuring longer-lasting and more reliable QLED displays.

The pursuit of higher peak brightness has been a constant theme in QLED evolution. Manufacturers have achieved this through various means, including improved quantum dot efficiency, advanced local dimming techniques, and the use of mini-LED backlights in conjunction with quantum dots. These advancements have pushed the boundaries of HDR performance, allowing for more vivid and lifelike images.

Clarity enhancements have been achieved through improvements in quantum dot uniformity and the development of advanced color management systems. The ability to precisely control the size and composition of quantum dots has led to more accurate and consistent color reproduction across the entire display.

The most recent developments in QLED technology are focusing on self-emissive quantum dot displays, often referred to as QD-OLED or QNED (Quantum Nano Emitting Diode) displays. These technologies aim to combine the color performance of quantum dots with the perfect blacks and wide viewing angles of OLED, potentially offering the best of both worlds in terms of brightness and clarity.

Market Demand Analysis

The market demand for enhanced brightness and clarity in QLED displays has been steadily increasing in recent years, driven by consumer expectations for more immersive viewing experiences and the growing adoption of high-resolution content. As 4K and 8K content becomes more prevalent, there is a corresponding need for displays that can fully showcase these ultra-high-definition visuals with superior brightness and clarity.

In the consumer electronics sector, QLED TVs have gained significant traction, with market research indicating a compound annual growth rate (CAGR) of over 20% for the QLED TV market. This growth is largely attributed to the technology's ability to deliver brighter and more vibrant images compared to traditional LED-LCD displays. The demand is particularly strong in regions with high disposable income, such as North America and Western Europe, where consumers are willing to invest in premium display technologies.

The commercial display market is also showing increased interest in QLED technology, especially in sectors such as digital signage, control rooms, and high-end conference facilities. These applications require displays with high brightness and clarity to ensure visibility in various lighting conditions and to convey detailed information effectively.

The automotive industry represents another growing market for QLED displays. As vehicles become more technologically advanced, there is a rising demand for high-quality in-car displays that can maintain clarity and readability even in bright sunlight. This has led to a surge in interest from automotive manufacturers looking to integrate QLED technology into their infotainment systems and digital dashboards.

Furthermore, the gaming industry has emerged as a significant driver of demand for enhanced QLED displays. Gamers are increasingly seeking displays that can render fast-moving images with exceptional clarity and minimal motion blur, while also providing high brightness for HDR gaming experiences. This has resulted in a growing market for QLED gaming monitors and TVs optimized for gaming performance.

The professional content creation industry, including film and video production, graphic design, and photography, also contributes to the demand for high-brightness, high-clarity displays. These professionals require accurate color reproduction and high dynamic range capabilities that QLED technology can provide.

As the global display market continues to evolve, the demand for enhanced brightness and clarity in QLED displays is expected to grow further. This trend is supported by the increasing availability of HDR content, the push towards higher refresh rates, and the ongoing improvements in color gamut coverage. Manufacturers are likely to focus on developing QLED displays that can meet these evolving market demands while also addressing concerns such as energy efficiency and cost-effectiveness.

Technical Challenges

QLED (Quantum Dot Light Emitting Diode) displays have made significant strides in enhancing brightness and clarity, but they still face several technical challenges. One of the primary obstacles is the efficiency of quantum dot conversion. While quantum dots excel at producing vibrant colors, the process of converting blue light to red and green can result in energy loss, impacting overall brightness and power consumption.

Another challenge lies in the stability and longevity of quantum dots. These nanoparticles are susceptible to degradation over time, particularly when exposed to heat and moisture. This degradation can lead to color shift and reduced brightness, affecting the long-term performance of QLED displays. Manufacturers must develop more robust encapsulation techniques to protect quantum dots from environmental factors and extend their lifespan.

Color volume and gamut present additional hurdles. While QLEDs offer an impressive color range, achieving consistent color accuracy across different brightness levels remains challenging. This is particularly evident in HDR (High Dynamic Range) content, where maintaining color fidelity at both high and low luminance levels is crucial for a superior viewing experience.

The pursuit of higher peak brightness in QLED displays introduces thermal management issues. As displays push for brighter output, they generate more heat, which can negatively impact both the quantum dots and other display components. Developing effective heat dissipation solutions without compromising the display's form factor is a significant engineering challenge.

Uniformity across the display panel is another area of concern. Ensuring consistent brightness and color reproduction from edge to edge on large QLED screens requires precise manufacturing processes and advanced light distribution techniques. Any inconsistencies can result in visible banding or hotspots, detracting from the overall image quality.

The backlight technology used in QLED displays also presents challenges. While mini-LED backlights have improved local dimming capabilities, achieving OLED-like black levels and contrast ratios remains elusive. The trade-off between the number of dimming zones, cost, and power consumption continues to be a balancing act for manufacturers.

Lastly, the production of quantum dots themselves poses challenges. Synthesizing high-quality quantum dots with consistent size and properties at scale is a complex process. Variations in quantum dot quality can lead to inconsistencies in color reproduction and overall display performance. Improving manufacturing processes to ensure uniformity and reduce costs is an ongoing challenge in the QLED industry.

Current Enhancement Methods

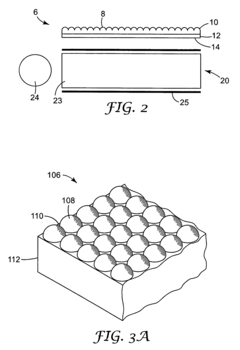

01 Quantum dot enhancement for improved brightness and color

QLED displays utilize quantum dots to enhance brightness and color accuracy. These nanocrystals emit light when excited, producing vibrant and precise colors. The technology allows for a wider color gamut and higher peak brightness compared to traditional LED displays, resulting in improved image quality and clarity.- Quantum dot enhancement for improved brightness and color: QLED displays utilize quantum dots to enhance brightness and color accuracy. These nanocrystals emit light when excited, producing vibrant and precise colors. The technology allows for a wider color gamut and higher peak brightness compared to traditional LED displays, resulting in improved image quality and clarity.

- Advanced backlight and local dimming techniques: QLED displays employ sophisticated backlight systems and local dimming techniques to improve contrast and brightness. These methods allow for precise control of light output across different areas of the screen, enhancing dark scenes while maintaining bright highlights, thus contributing to overall picture clarity and dynamic range.

- Color management and image processing algorithms: Advanced color management systems and image processing algorithms are implemented in QLED displays to optimize brightness and clarity. These technologies work to enhance color accuracy, reduce noise, and improve overall picture quality by adjusting various parameters in real-time based on the content being displayed.

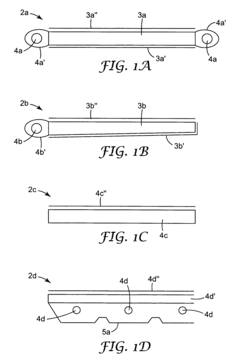

- Panel structure and optical film improvements: Innovations in panel structure and optical film technology contribute to enhanced brightness and clarity in QLED displays. These improvements include advanced light guide plates, diffusion films, and polarizers that work together to maximize light transmission and minimize reflections, resulting in improved overall display performance.

- Driving and control circuitry optimization: Optimized driving and control circuitry play a crucial role in achieving high brightness and clarity in QLED displays. Advanced power management systems, voltage regulation techniques, and timing controllers are employed to ensure efficient operation of quantum dots and precise control of pixel illumination, contributing to improved overall display performance.

02 Advanced backlight and local dimming techniques

QLED displays employ sophisticated backlight systems and local dimming techniques to enhance contrast and brightness. These methods allow for precise control of light output across different areas of the screen, resulting in deeper blacks, brighter highlights, and improved overall picture quality.Expand Specific Solutions03 Color management and image processing algorithms

Advanced color management systems and image processing algorithms are implemented in QLED displays to optimize brightness and clarity. These technologies work to enhance color accuracy, reduce noise, and improve overall image quality, resulting in a more lifelike and immersive viewing experience.Expand Specific Solutions04 Panel structure and optical film improvements

QLED displays incorporate innovative panel structures and optical films to enhance light transmission and reduce reflections. These advancements contribute to improved brightness, contrast, and overall clarity of the displayed image, even in challenging lighting conditions.Expand Specific Solutions05 Power management and heat dissipation techniques

Efficient power management and heat dissipation techniques are employed in QLED displays to maintain optimal performance and longevity. These methods help to preserve brightness and clarity over time by preventing degradation of the quantum dots and other display components due to heat and power-related issues.Expand Specific Solutions

Key Industry Players

The QLED display technology market is in a growth phase, with increasing demand for high-quality, energy-efficient displays. The global QLED market size is projected to expand significantly in the coming years, driven by consumer electronics and commercial applications. Technologically, QLED displays are maturing rapidly, with key players like Samsung Electronics Co., Ltd. and Samsung Display Co., Ltd. leading innovation. Other significant contributors include BOE Technology Group Co., Ltd., TCL China Star Optoelectronics Technology Co., Ltd., and Sony Group Corp. These companies are actively developing advanced QLED technologies to enhance brightness and clarity, focusing on quantum dot efficiency, color gamut expansion, and improved backlight systems. The competitive landscape is intensifying as more players enter the market, spurring further technological advancements and market growth.

Samsung Electronics Co., Ltd.

Samsung Display Co., Ltd.

Core QLED Innovations

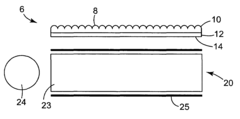

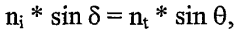

- The use of optical films with a two-dimensional array of closely packed substantially hemispherically-shaped structures on one surface to control the angular distribution of light from backlights, enhancing light efficiency and uniformity by redirecting and recycling light along the viewing axis.

- An optical film with a structured surface featuring a plurality of prismatic structures, where at least one side of each structure is offset with respect to another, is used to control light distribution and enhance brightness by redirecting and recycling light along the viewing axis, thereby providing an optical gain and improving spatial uniformity.

Environmental Impact

The environmental impact of QLED (Quantum Dot Light Emitting Diode) displays is an important consideration in the ongoing efforts to enhance brightness and clarity. As these displays become increasingly prevalent in consumer electronics, their ecological footprint throughout their lifecycle warrants careful examination.

QLED technology offers significant advantages in terms of energy efficiency compared to traditional LCD displays. The quantum dots used in QLED screens are highly efficient at converting electrical energy into light, resulting in reduced power consumption during operation. This energy efficiency not only translates to lower electricity bills for consumers but also contributes to reduced carbon emissions associated with power generation.

However, the production of quantum dots raises environmental concerns. The manufacturing process of these nanoparticles often involves the use of heavy metals, such as cadmium, which can be toxic if released into the environment. While efforts are being made to develop cadmium-free quantum dots, the industry still faces challenges in achieving comparable performance without these materials.

The disposal of QLED displays at the end of their lifecycle presents another environmental challenge. The presence of quantum dots and other specialized materials in these screens necessitates careful recycling processes to prevent the release of potentially harmful substances into ecosystems. Developing efficient and widespread recycling infrastructure for QLED displays is crucial to mitigate their environmental impact.

On the positive side, the enhanced durability and longevity of QLED displays contribute to a reduction in electronic waste. These screens typically have a longer lifespan compared to traditional LCD displays, which means fewer replacements and less frequent disposal of outdated units. This extended product life cycle can significantly reduce the overall environmental burden associated with display technology.

The pursuit of enhanced brightness and clarity in QLED displays also drives innovations in material science and manufacturing processes. Research into more environmentally friendly quantum dot materials and production methods holds promise for reducing the ecological footprint of these displays. Additionally, advancements in display efficiency may lead to further reductions in energy consumption, aligning with global efforts to combat climate change.

As the technology continues to evolve, balancing the quest for superior visual performance with environmental responsibility remains a key challenge for the industry. Manufacturers and researchers must prioritize sustainable practices and materials throughout the QLED display lifecycle, from production to disposal, to ensure that the benefits of enhanced brightness and clarity do not come at an unacceptable environmental cost.

Manufacturing Processes

The manufacturing processes for QLED displays involve several intricate steps that are crucial for enhancing brightness and clarity. The production begins with the creation of quantum dots, typically made from semiconductor materials such as cadmium selenide or indium phosphide. These nanocrystals are synthesized through precise chemical processes, controlling their size and composition to achieve specific color emission properties.

Once the quantum dots are produced, they are incorporated into a film or layer that will be integrated into the display structure. This quantum dot layer is typically sandwiched between other functional layers of the display. The placement and uniformity of this layer are critical for achieving optimal brightness and color performance.

The next stage involves the fabrication of the backlight unit, which is essential for QLED displays as they are fundamentally LCD technology enhanced with quantum dots. The backlight unit consists of LEDs that emit blue light, which is then converted by the quantum dot layer into pure red and green light. The precision in manufacturing this component is vital for ensuring even illumination across the display.

The LCD panel itself is manufactured separately, involving the creation of thin-film transistors (TFTs) on a glass substrate, followed by the assembly of liquid crystal cells. The integration of the quantum dot layer with the LCD panel is a delicate process that requires careful alignment and bonding to maintain the integrity of the display structure.

Color filters are then applied to further refine the color output of the display. These filters work in conjunction with the quantum dot layer to produce a wide color gamut and enhance overall picture quality. The manufacturing process also includes the application of various optical films and polarizers to improve light transmission and viewing angles.

Finally, the display undergoes rigorous quality control and calibration processes. This involves testing for uniformity, color accuracy, and brightness levels across the entire panel. Advanced algorithms and software are often employed to fine-tune the display's performance, ensuring that each unit meets the high standards required for enhanced brightness and clarity in QLED displays.

Throughout the manufacturing process, maintaining a clean and controlled environment is paramount. Dust particles and contaminants can significantly impact the performance and longevity of QLED displays, necessitating stringent cleanroom protocols and advanced filtration systems in production facilities.