Best Practices for QLED Maintenance and Care

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Technology Evolution

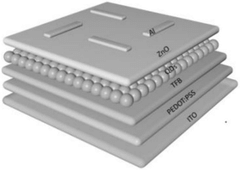

QLED technology has undergone significant evolution since its inception, driven by continuous research and development efforts to enhance display performance and efficiency. The journey began with the introduction of quantum dots in display technology, initially used to improve color gamut and brightness in LCD panels. As the technology matured, researchers focused on developing direct-emissive quantum dot light-emitting diodes (QLEDs), aiming to rival and surpass OLED technology.

The early stages of QLED evolution centered on refining quantum dot synthesis and deposition techniques. Scientists worked on improving the uniformity and stability of quantum dot layers, crucial for achieving consistent color reproduction and longevity. Concurrently, efforts were made to enhance the quantum yield of these nanoparticles, directly impacting the energy efficiency and brightness of QLED displays.

A significant milestone in QLED development was the transition from photo-emissive to electro-emissive quantum dots. This shift allowed for direct current-driven emission, paving the way for self-emissive QLED displays with improved contrast ratios and viewing angles. The challenge of creating stable and efficient blue quantum dots, essential for a complete RGB color gamut, became a focal point of research, driving innovations in material science and quantum confinement techniques.

The evolution of QLED technology also saw advancements in manufacturing processes. Researchers explored various deposition methods, including inkjet printing and photolithography, to achieve precise quantum dot patterning. These efforts aimed to improve production scalability and reduce costs, making QLED displays more commercially viable.

Recent years have witnessed a push towards enhancing the durability and lifespan of QLED displays. This includes developing more robust encapsulation techniques to protect quantum dots from environmental factors and improving the stability of charge transport layers. Additionally, research into reducing the impact of heat on quantum dot performance has led to innovations in thermal management within QLED structures.

The ongoing evolution of QLED technology continues to focus on increasing energy efficiency, expanding color gamut, and improving brightness levels. Researchers are exploring new quantum dot materials and structures, such as perovskite quantum dots, to overcome current limitations. The integration of artificial intelligence and machine learning algorithms for color management and image processing is also emerging as a promising direction in QLED development.

As QLED technology evolves, maintenance and care practices have adapted to ensure optimal performance and longevity of these advanced displays. This evolution in maintenance strategies parallels the technological advancements, emphasizing the importance of proper handling, cleaning, and environmental control to preserve the unique qualities of QLED displays.

The early stages of QLED evolution centered on refining quantum dot synthesis and deposition techniques. Scientists worked on improving the uniformity and stability of quantum dot layers, crucial for achieving consistent color reproduction and longevity. Concurrently, efforts were made to enhance the quantum yield of these nanoparticles, directly impacting the energy efficiency and brightness of QLED displays.

A significant milestone in QLED development was the transition from photo-emissive to electro-emissive quantum dots. This shift allowed for direct current-driven emission, paving the way for self-emissive QLED displays with improved contrast ratios and viewing angles. The challenge of creating stable and efficient blue quantum dots, essential for a complete RGB color gamut, became a focal point of research, driving innovations in material science and quantum confinement techniques.

The evolution of QLED technology also saw advancements in manufacturing processes. Researchers explored various deposition methods, including inkjet printing and photolithography, to achieve precise quantum dot patterning. These efforts aimed to improve production scalability and reduce costs, making QLED displays more commercially viable.

Recent years have witnessed a push towards enhancing the durability and lifespan of QLED displays. This includes developing more robust encapsulation techniques to protect quantum dots from environmental factors and improving the stability of charge transport layers. Additionally, research into reducing the impact of heat on quantum dot performance has led to innovations in thermal management within QLED structures.

The ongoing evolution of QLED technology continues to focus on increasing energy efficiency, expanding color gamut, and improving brightness levels. Researchers are exploring new quantum dot materials and structures, such as perovskite quantum dots, to overcome current limitations. The integration of artificial intelligence and machine learning algorithms for color management and image processing is also emerging as a promising direction in QLED development.

As QLED technology evolves, maintenance and care practices have adapted to ensure optimal performance and longevity of these advanced displays. This evolution in maintenance strategies parallels the technological advancements, emphasizing the importance of proper handling, cleaning, and environmental control to preserve the unique qualities of QLED displays.

QLED Market Demand Analysis

The QLED (Quantum Dot Light Emitting Diode) market has experienced significant growth in recent years, driven by increasing consumer demand for high-quality display technologies. As consumers seek more immersive viewing experiences, QLED technology has emerged as a popular choice due to its superior color reproduction, brightness, and energy efficiency compared to traditional LED displays.

The global QLED market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily fueled by the rising adoption of QLED technology in various applications, including televisions, monitors, smartphones, and automotive displays.

In the television segment, QLED has gained substantial market share, particularly in the premium and ultra-premium categories. Consumers are increasingly willing to invest in high-end displays that offer enhanced picture quality and larger screen sizes. This trend has been further accelerated by the growing popularity of streaming services and the demand for home entertainment systems during the global pandemic.

The monitor market has also seen a surge in demand for QLED displays, especially in the gaming and professional sectors. Gamers appreciate the technology's ability to deliver vibrant colors and high refresh rates, while professionals value the accurate color reproduction and wide color gamut for tasks such as photo and video editing.

In the smartphone industry, QLED technology is gradually making inroads, with several manufacturers incorporating it into their flagship devices. The improved color accuracy and energy efficiency of QLED displays are particularly appealing for mobile applications, where battery life is a critical factor.

The automotive sector represents a growing market for QLED technology, with an increasing number of vehicle manufacturers integrating QLED displays into their infotainment systems and digital dashboards. The technology's ability to maintain visibility in bright sunlight and its durability make it well-suited for automotive applications.

As the QLED market expands, there is a corresponding increase in demand for maintenance and care services. Consumers are seeking ways to protect their investment and ensure the longevity of their QLED devices. This has created opportunities for specialized cleaning and maintenance products, as well as professional services tailored to QLED displays.

The market demand for QLED technology is also driving innovation in related fields, such as quantum dot manufacturing and display panel production. As a result, there is growing interest in developing more efficient and cost-effective production methods to meet the rising demand while potentially reducing consumer prices in the long term.

The global QLED market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily fueled by the rising adoption of QLED technology in various applications, including televisions, monitors, smartphones, and automotive displays.

In the television segment, QLED has gained substantial market share, particularly in the premium and ultra-premium categories. Consumers are increasingly willing to invest in high-end displays that offer enhanced picture quality and larger screen sizes. This trend has been further accelerated by the growing popularity of streaming services and the demand for home entertainment systems during the global pandemic.

The monitor market has also seen a surge in demand for QLED displays, especially in the gaming and professional sectors. Gamers appreciate the technology's ability to deliver vibrant colors and high refresh rates, while professionals value the accurate color reproduction and wide color gamut for tasks such as photo and video editing.

In the smartphone industry, QLED technology is gradually making inroads, with several manufacturers incorporating it into their flagship devices. The improved color accuracy and energy efficiency of QLED displays are particularly appealing for mobile applications, where battery life is a critical factor.

The automotive sector represents a growing market for QLED technology, with an increasing number of vehicle manufacturers integrating QLED displays into their infotainment systems and digital dashboards. The technology's ability to maintain visibility in bright sunlight and its durability make it well-suited for automotive applications.

As the QLED market expands, there is a corresponding increase in demand for maintenance and care services. Consumers are seeking ways to protect their investment and ensure the longevity of their QLED devices. This has created opportunities for specialized cleaning and maintenance products, as well as professional services tailored to QLED displays.

The market demand for QLED technology is also driving innovation in related fields, such as quantum dot manufacturing and display panel production. As a result, there is growing interest in developing more efficient and cost-effective production methods to meet the rising demand while potentially reducing consumer prices in the long term.

QLED Maintenance Challenges

QLED (Quantum Dot Light Emitting Diode) technology has revolutionized the display industry with its superior color performance and energy efficiency. However, maintaining these advanced displays presents unique challenges that require careful attention and specialized care practices.

One of the primary maintenance challenges for QLED displays is the prevention of image retention or burn-in. Although QLEDs are less susceptible to this issue compared to OLED displays, prolonged static image display can still lead to temporary or permanent image ghosting. This necessitates the implementation of pixel-shifting technologies and screen savers to mitigate the risk of burn-in, especially in commercial settings where displays may operate continuously.

Another significant challenge is the sensitivity of quantum dots to environmental factors. Exposure to excessive heat, humidity, or direct sunlight can degrade the quantum dot material, leading to color shift and reduced display performance over time. This requires careful consideration of display placement and the implementation of advanced thermal management systems to maintain optimal operating conditions.

The delicate nature of the QLED panel surface poses additional maintenance hurdles. Unlike traditional LCD screens, QLED displays often feature ultra-thin designs and sensitive anti-reflective coatings. This makes them more susceptible to physical damage and requires specialized cleaning procedures to avoid scratching or damaging the display surface during routine maintenance.

Dust accumulation is a persistent issue for QLED displays, particularly in the narrow gaps between the quantum dot layer and other display components. Over time, this can affect display brightness and color accuracy. Developing effective dust-proofing measures and establishing regular, yet gentle cleaning protocols is crucial for maintaining optimal display performance.

The complexity of QLED technology also presents challenges in diagnosing and addressing performance issues. The interplay between quantum dots, backlighting systems, and color filters requires sophisticated diagnostic tools and expertise to accurately identify and resolve problems. This complexity often necessitates professional servicing, which can be costly and time-consuming for end-users.

Lastly, the long-term stability of quantum dot materials remains a concern. While significant improvements have been made, ensuring consistent color performance over the lifespan of the display requires ongoing research into more stable quantum dot formulations and encapsulation techniques. This challenge extends to the development of effective end-of-life recycling processes for QLED displays, considering the unique materials used in their construction.

One of the primary maintenance challenges for QLED displays is the prevention of image retention or burn-in. Although QLEDs are less susceptible to this issue compared to OLED displays, prolonged static image display can still lead to temporary or permanent image ghosting. This necessitates the implementation of pixel-shifting technologies and screen savers to mitigate the risk of burn-in, especially in commercial settings where displays may operate continuously.

Another significant challenge is the sensitivity of quantum dots to environmental factors. Exposure to excessive heat, humidity, or direct sunlight can degrade the quantum dot material, leading to color shift and reduced display performance over time. This requires careful consideration of display placement and the implementation of advanced thermal management systems to maintain optimal operating conditions.

The delicate nature of the QLED panel surface poses additional maintenance hurdles. Unlike traditional LCD screens, QLED displays often feature ultra-thin designs and sensitive anti-reflective coatings. This makes them more susceptible to physical damage and requires specialized cleaning procedures to avoid scratching or damaging the display surface during routine maintenance.

Dust accumulation is a persistent issue for QLED displays, particularly in the narrow gaps between the quantum dot layer and other display components. Over time, this can affect display brightness and color accuracy. Developing effective dust-proofing measures and establishing regular, yet gentle cleaning protocols is crucial for maintaining optimal display performance.

The complexity of QLED technology also presents challenges in diagnosing and addressing performance issues. The interplay between quantum dots, backlighting systems, and color filters requires sophisticated diagnostic tools and expertise to accurately identify and resolve problems. This complexity often necessitates professional servicing, which can be costly and time-consuming for end-users.

Lastly, the long-term stability of quantum dot materials remains a concern. While significant improvements have been made, ensuring consistent color performance over the lifespan of the display requires ongoing research into more stable quantum dot formulations and encapsulation techniques. This challenge extends to the development of effective end-of-life recycling processes for QLED displays, considering the unique materials used in their construction.

Current QLED Maintenance Methods

01 Protective coatings for QLED displays

Application of specialized protective coatings to QLED displays can enhance durability and longevity. These coatings may include anti-reflective, anti-scratch, or hydrophobic layers that protect the display surface from environmental factors and daily wear. Regular reapplication or maintenance of these coatings may be necessary for optimal performance.- Cleaning and protection methods: Various techniques for cleaning and protecting QLED displays are employed to maintain their performance and longevity. These methods may include using specialized cleaning solutions, microfiber cloths, and protective coatings to prevent dust accumulation and damage from external factors.

- Temperature and humidity control: Maintaining optimal temperature and humidity levels is crucial for QLED display care. Implementing climate control systems and monitoring devices helps prevent issues related to extreme temperatures or moisture, which can affect display performance and lifespan.

- Pixel maintenance and calibration: Regular pixel maintenance and calibration procedures are essential for QLED displays. This includes software-based pixel refreshing, color calibration, and addressing issues like image retention or burn-in to ensure consistent image quality over time.

- Power management and energy efficiency: Implementing effective power management strategies and enhancing energy efficiency are important aspects of QLED display maintenance. This involves optimizing power consumption, using energy-saving modes, and employing advanced circuit designs to prolong the display's lifespan and reduce operational costs.

- Protective enclosures and mounting solutions: Designing and utilizing protective enclosures and mounting solutions can significantly contribute to the care and maintenance of QLED displays. These may include anti-glare screens, shock-absorbing frames, and secure mounting systems to protect the display from physical damage and environmental factors.

02 Cleaning methods and solutions for QLED screens

Proper cleaning techniques and solutions are crucial for maintaining QLED displays. This includes using gentle, non-abrasive cleaning agents specifically designed for sensitive electronic screens. Microfiber cloths are often recommended to avoid scratching. Regular cleaning helps prevent buildup of dust and fingerprints, which can affect display quality.Expand Specific Solutions03 Temperature and humidity control

Maintaining optimal environmental conditions is essential for QLED display longevity. This involves controlling temperature and humidity levels in the display's surroundings to prevent damage from heat, cold, or moisture. Proper ventilation and climate control systems may be necessary in certain installations.Expand Specific Solutions04 Pixel refresh and burn-in prevention

QLED displays may benefit from periodic pixel refresh procedures to prevent image retention or burn-in. This can include running built-in refresh cycles or using specialized software. Additionally, avoiding static images for prolonged periods and using screen savers can help maintain display quality over time.Expand Specific Solutions05 Power management and energy efficiency

Implementing effective power management strategies can extend the life of QLED displays and improve energy efficiency. This may involve using auto-brightness features, scheduled power-off times, and energy-saving modes. Proper power cycling and surge protection can also prevent damage from electrical issues.Expand Specific Solutions

Key QLED Manufacturers

The QLED maintenance and care market is in a growth phase, driven by increasing adoption of QLED displays in consumer electronics and commercial applications. The market size is expanding, with major players like BOE Technology Group, Sharp Corp., and Huawei Technologies investing in research and development. Technological maturity varies among companies, with established firms like BOE and Sharp leading in innovation, while emerging players such as Wuxi Jishi Technology and Najing Technology are rapidly advancing. Universities and research institutions, including Zhejiang University and Chinese Academy of Science Guanzhou Energy Research Institute, contribute to the field's development through collaborative research and knowledge transfer, enhancing overall industry expertise in QLED maintenance practices.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive QLED maintenance and care system that includes advanced panel cleaning techniques, color calibration software, and intelligent brightness adjustment algorithms. Their approach focuses on preserving color accuracy and extending panel lifespan through a combination of hardware and software solutions. BOE's system utilizes AI-driven diagnostics to detect early signs of panel degradation and automatically adjusts settings to compensate, ensuring consistent image quality over time.

Strengths: Integrated hardware-software approach, AI-driven diagnostics. Weaknesses: May require specialized training for maintenance personnel.

Sharp Corp.

Technical Solution: Sharp's QLED maintenance strategy emphasizes preventive care through their "Eco-Shield" technology. This system incorporates a nano-coating on the QLED panel surface that repels dust and reduces the need for frequent cleaning. Additionally, Sharp has developed a proprietary "Quantum Color Refresh" process that periodically recalibrates the quantum dot layer to maintain optimal color performance. Their maintenance protocol also includes a remote monitoring system that alerts users to potential issues before they become visible problems.

Strengths: Innovative nano-coating technology, proactive maintenance approach. Weaknesses: May increase initial product cost.

Innovative QLED Care Solutions

Method for optimizing performance of QLED device

PatentPendingCN119677364A

Innovation

- By placing the packaged QLED device in a supercritical reactor, using a combined treatment of supercritical carbon dioxide or supercritical carbon dioxide and trace amounts of water, the pressure and temperature are controlled for supercritical treatment, affecting the zinc oxide layer to reduce electron transport capacity and balance carrier injection.

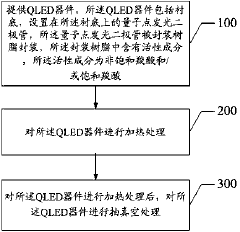

After-treatment method for QLED device

PatentActiveCN109935738A

Innovation

- Use post-processing methods of heating and vacuuming to remove residual active ingredients, including adding unsaturated carboxylic acid or saturated carboxylic acid to the encapsulation resin, and heating at 50-90°C for 1-48 hours, followed by 10-5~10 Carry out vacuum treatment at a vacuum degree of -1 Pa.

Environmental Impact of QLED Care

The environmental impact of QLED care practices is an important consideration in the overall sustainability of this display technology. QLED (Quantum Dot Light Emitting Diode) displays have gained popularity due to their superior color performance and energy efficiency. However, the maintenance and care of these devices can have significant environmental implications.

One of the primary environmental concerns related to QLED care is the disposal of cleaning materials. Many QLED manufacturers recommend using specialized cleaning solutions and microfiber cloths for optimal maintenance. These products often contain chemicals that can be harmful to the environment if not disposed of properly. Additionally, the frequent replacement of cleaning materials contributes to increased waste generation.

Energy consumption during the cleaning process is another factor to consider. While QLEDs are generally energy-efficient during operation, the use of electronic cleaning devices or prolonged use of lighting for inspection during maintenance can lead to increased energy consumption. This indirectly contributes to carbon emissions, especially in regions where electricity generation relies heavily on fossil fuels.

The longevity of QLED displays is closely tied to proper care and maintenance. Effective care practices can significantly extend the lifespan of these devices, reducing the frequency of replacements and, consequently, the environmental impact associated with manufacturing and disposing of new units. However, improper care techniques may lead to premature degradation, necessitating more frequent replacements and increasing electronic waste.

Water usage is another environmental aspect to consider in QLED care. While most cleaning procedures for QLEDs do not require large amounts of water, the cumulative effect of regular cleaning across millions of devices globally can be substantial. This is particularly relevant in water-stressed regions where conservation is crucial.

The production of specialized QLED care products also has environmental implications. Manufacturing cleaning solutions, microfiber cloths, and other maintenance tools requires resources and energy, contributing to the overall environmental footprint of QLED technology. The packaging and distribution of these products further add to this impact through increased plastic usage and transportation-related emissions.

Lastly, the potential release of harmful substances during the cleaning process is a concern. Some cleaning agents may contain volatile organic compounds (VOCs) or other chemicals that can negatively impact indoor air quality and, when released into the environment, contribute to air and water pollution. Proper ventilation during cleaning and the use of eco-friendly cleaning products can help mitigate these risks.

One of the primary environmental concerns related to QLED care is the disposal of cleaning materials. Many QLED manufacturers recommend using specialized cleaning solutions and microfiber cloths for optimal maintenance. These products often contain chemicals that can be harmful to the environment if not disposed of properly. Additionally, the frequent replacement of cleaning materials contributes to increased waste generation.

Energy consumption during the cleaning process is another factor to consider. While QLEDs are generally energy-efficient during operation, the use of electronic cleaning devices or prolonged use of lighting for inspection during maintenance can lead to increased energy consumption. This indirectly contributes to carbon emissions, especially in regions where electricity generation relies heavily on fossil fuels.

The longevity of QLED displays is closely tied to proper care and maintenance. Effective care practices can significantly extend the lifespan of these devices, reducing the frequency of replacements and, consequently, the environmental impact associated with manufacturing and disposing of new units. However, improper care techniques may lead to premature degradation, necessitating more frequent replacements and increasing electronic waste.

Water usage is another environmental aspect to consider in QLED care. While most cleaning procedures for QLEDs do not require large amounts of water, the cumulative effect of regular cleaning across millions of devices globally can be substantial. This is particularly relevant in water-stressed regions where conservation is crucial.

The production of specialized QLED care products also has environmental implications. Manufacturing cleaning solutions, microfiber cloths, and other maintenance tools requires resources and energy, contributing to the overall environmental footprint of QLED technology. The packaging and distribution of these products further add to this impact through increased plastic usage and transportation-related emissions.

Lastly, the potential release of harmful substances during the cleaning process is a concern. Some cleaning agents may contain volatile organic compounds (VOCs) or other chemicals that can negatively impact indoor air quality and, when released into the environment, contribute to air and water pollution. Proper ventilation during cleaning and the use of eco-friendly cleaning products can help mitigate these risks.

QLED Longevity Factors

QLED (Quantum Dot Light Emitting Diode) displays have gained significant popularity in recent years due to their superior color reproduction and brightness. However, like all electronic devices, their longevity depends on various factors and proper maintenance practices. Several key elements contribute to the lifespan of QLED displays.

One crucial factor is the operating environment. QLED displays perform optimally and last longer when used in controlled temperature and humidity conditions. Excessive heat can accelerate the degradation of quantum dots, while high humidity may lead to moisture-related issues. It is recommended to maintain room temperature between 20-25°C (68-77°F) and relative humidity below 60% for optimal performance and longevity.

Power management plays a vital role in extending QLED lifespan. Implementing proper power cycling practices, such as turning off the display when not in use for extended periods, can prevent unnecessary stress on the components. Additionally, using surge protectors and stable power sources helps protect the display from voltage fluctuations that could potentially damage sensitive electronic components.

Image retention and burn-in prevention are essential considerations for QLED longevity. Although QLEDs are less susceptible to burn-in compared to OLED displays, it is still advisable to avoid displaying static images for prolonged periods. Utilizing screen savers, enabling pixel shift technology, and varying content can help mitigate the risk of image retention and extend the display's lifespan.

Regular cleaning and maintenance contribute significantly to QLED longevity. Dust accumulation can affect heat dissipation and potentially lead to overheating. Gentle cleaning with a soft, lint-free cloth and approved cleaning solutions helps maintain the display's clarity and prevents damage to the screen surface. It is crucial to avoid using abrasive materials or harsh chemicals that could harm the display's protective layers.

Software updates and calibration are often overlooked but play a crucial role in maintaining QLED performance over time. Keeping the display's firmware up to date ensures optimal functionality and may include improvements in power management and image processing algorithms. Periodic color calibration helps maintain accurate color reproduction and compensates for any slight shifts that may occur over time.

Lastly, proper handling and installation significantly impact QLED longevity. Ensuring the display is securely mounted or placed on a stable surface reduces the risk of physical damage. When moving or transporting the display, following manufacturer guidelines for packaging and handling is essential to prevent stress on the panel and internal components.

One crucial factor is the operating environment. QLED displays perform optimally and last longer when used in controlled temperature and humidity conditions. Excessive heat can accelerate the degradation of quantum dots, while high humidity may lead to moisture-related issues. It is recommended to maintain room temperature between 20-25°C (68-77°F) and relative humidity below 60% for optimal performance and longevity.

Power management plays a vital role in extending QLED lifespan. Implementing proper power cycling practices, such as turning off the display when not in use for extended periods, can prevent unnecessary stress on the components. Additionally, using surge protectors and stable power sources helps protect the display from voltage fluctuations that could potentially damage sensitive electronic components.

Image retention and burn-in prevention are essential considerations for QLED longevity. Although QLEDs are less susceptible to burn-in compared to OLED displays, it is still advisable to avoid displaying static images for prolonged periods. Utilizing screen savers, enabling pixel shift technology, and varying content can help mitigate the risk of image retention and extend the display's lifespan.

Regular cleaning and maintenance contribute significantly to QLED longevity. Dust accumulation can affect heat dissipation and potentially lead to overheating. Gentle cleaning with a soft, lint-free cloth and approved cleaning solutions helps maintain the display's clarity and prevents damage to the screen surface. It is crucial to avoid using abrasive materials or harsh chemicals that could harm the display's protective layers.

Software updates and calibration are often overlooked but play a crucial role in maintaining QLED performance over time. Keeping the display's firmware up to date ensures optimal functionality and may include improvements in power management and image processing algorithms. Periodic color calibration helps maintain accurate color reproduction and compensates for any slight shifts that may occur over time.

Lastly, proper handling and installation significantly impact QLED longevity. Ensuring the display is securely mounted or placed on a stable surface reduces the risk of physical damage. When moving or transporting the display, following manufacturer guidelines for packaging and handling is essential to prevent stress on the panel and internal components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!