How to Maximize QLED Lifespan in Everyday Use?

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Lifespan Fundamentals

QLED (Quantum Dot Light Emitting Diode) technology has revolutionized the display industry with its superior color reproduction and energy efficiency. Understanding the fundamentals of QLED lifespan is crucial for maximizing its longevity in everyday use. At its core, QLED displays utilize quantum dots, which are semiconductor nanocrystals that emit light when excited by an electric current.

The lifespan of a QLED display is primarily determined by the stability and durability of these quantum dots. Over time, quantum dots can degrade due to various factors, including exposure to heat, moisture, and oxygen. This degradation process, known as photo-oxidation, can lead to a decrease in luminescence efficiency and color shift, ultimately affecting the overall display quality and lifespan.

One of the key factors influencing QLED lifespan is the operating temperature. Higher temperatures accelerate the degradation of quantum dots, reducing their light-emitting efficiency. Therefore, maintaining optimal thermal management is essential for prolonging QLED lifespan. This involves efficient heat dissipation mechanisms and proper ventilation in the display design.

Another critical aspect is the encapsulation of quantum dots. Effective encapsulation protects the quantum dots from environmental factors such as moisture and oxygen, which can cause oxidation and degradation. Advanced encapsulation techniques, including the use of barrier films and hermetic sealing, play a vital role in extending QLED lifespan.

The driving current and voltage applied to the quantum dots also significantly impact their longevity. Excessive current can lead to accelerated degradation and reduced lifespan. Implementing intelligent power management systems and optimizing driving parameters are crucial strategies for maximizing QLED lifespan in everyday use.

Furthermore, the composition and structure of quantum dots themselves influence their stability and durability. Research into more stable quantum dot materials, such as perovskite quantum dots or core-shell structures, has shown promising results in enhancing QLED lifespan. These advancements aim to mitigate the effects of photo-oxidation and improve overall stability.

Understanding these fundamental aspects of QLED lifespan provides a foundation for developing strategies to maximize their longevity in everyday use. By addressing factors such as thermal management, encapsulation, driving parameters, and quantum dot composition, manufacturers and users can work towards extending the lifespan of QLED displays, ensuring sustained performance and visual quality over time.

The lifespan of a QLED display is primarily determined by the stability and durability of these quantum dots. Over time, quantum dots can degrade due to various factors, including exposure to heat, moisture, and oxygen. This degradation process, known as photo-oxidation, can lead to a decrease in luminescence efficiency and color shift, ultimately affecting the overall display quality and lifespan.

One of the key factors influencing QLED lifespan is the operating temperature. Higher temperatures accelerate the degradation of quantum dots, reducing their light-emitting efficiency. Therefore, maintaining optimal thermal management is essential for prolonging QLED lifespan. This involves efficient heat dissipation mechanisms and proper ventilation in the display design.

Another critical aspect is the encapsulation of quantum dots. Effective encapsulation protects the quantum dots from environmental factors such as moisture and oxygen, which can cause oxidation and degradation. Advanced encapsulation techniques, including the use of barrier films and hermetic sealing, play a vital role in extending QLED lifespan.

The driving current and voltage applied to the quantum dots also significantly impact their longevity. Excessive current can lead to accelerated degradation and reduced lifespan. Implementing intelligent power management systems and optimizing driving parameters are crucial strategies for maximizing QLED lifespan in everyday use.

Furthermore, the composition and structure of quantum dots themselves influence their stability and durability. Research into more stable quantum dot materials, such as perovskite quantum dots or core-shell structures, has shown promising results in enhancing QLED lifespan. These advancements aim to mitigate the effects of photo-oxidation and improve overall stability.

Understanding these fundamental aspects of QLED lifespan provides a foundation for developing strategies to maximize their longevity in everyday use. By addressing factors such as thermal management, encapsulation, driving parameters, and quantum dot composition, manufacturers and users can work towards extending the lifespan of QLED displays, ensuring sustained performance and visual quality over time.

Market Trends in QLED Longevity

The QLED (Quantum Dot Light Emitting Diode) display market has been experiencing significant growth in recent years, with a particular focus on improving the longevity of these devices. As consumers become more aware of the importance of product lifespan, manufacturers are increasingly prioritizing the development of QLED technologies that offer extended durability and performance.

One of the key market trends in QLED longevity is the shift towards more efficient and stable quantum dot materials. Manufacturers are investing heavily in research and development to create quantum dots that are less susceptible to degradation over time, resulting in displays that maintain their color accuracy and brightness for longer periods. This trend is driven by consumer demand for high-quality displays that retain their performance characteristics throughout the product's lifetime.

Another notable trend is the integration of advanced thermal management systems in QLED displays. As heat is a major factor in the degradation of quantum dots, manufacturers are developing innovative cooling solutions to regulate temperature and extend the lifespan of QLED panels. This includes the use of advanced heat-dissipating materials and improved ventilation designs, which are becoming standard features in premium QLED products.

The market is also witnessing a growing emphasis on software-based solutions to enhance QLED longevity. Manufacturers are implementing sophisticated algorithms and AI-driven technologies to optimize display performance and reduce wear on the quantum dot layer. These software solutions can dynamically adjust brightness, contrast, and color settings based on usage patterns and environmental conditions, effectively prolonging the lifespan of QLED displays.

Consumer awareness and demand for longer-lasting displays are driving market competition, with manufacturers highlighting longevity as a key selling point. This has led to the introduction of extended warranty programs and lifespan guarantees for QLED products, reflecting the industry's confidence in the improved durability of these displays.

The commercial sector is also influencing market trends in QLED longevity. Businesses, particularly in sectors such as digital signage and control rooms, are seeking QLED displays with extended lifespans to reduce total cost of ownership and minimize downtime. This demand is pushing manufacturers to develop specialized QLED solutions that can withstand continuous operation in challenging environments.

As sustainability becomes an increasingly important factor for consumers and businesses alike, the market is seeing a trend towards more environmentally friendly QLED technologies. Manufacturers are exploring ways to improve the recyclability of QLED components and reduce the environmental impact of production processes, aligning with the growing demand for sustainable and long-lasting electronic products.

One of the key market trends in QLED longevity is the shift towards more efficient and stable quantum dot materials. Manufacturers are investing heavily in research and development to create quantum dots that are less susceptible to degradation over time, resulting in displays that maintain their color accuracy and brightness for longer periods. This trend is driven by consumer demand for high-quality displays that retain their performance characteristics throughout the product's lifetime.

Another notable trend is the integration of advanced thermal management systems in QLED displays. As heat is a major factor in the degradation of quantum dots, manufacturers are developing innovative cooling solutions to regulate temperature and extend the lifespan of QLED panels. This includes the use of advanced heat-dissipating materials and improved ventilation designs, which are becoming standard features in premium QLED products.

The market is also witnessing a growing emphasis on software-based solutions to enhance QLED longevity. Manufacturers are implementing sophisticated algorithms and AI-driven technologies to optimize display performance and reduce wear on the quantum dot layer. These software solutions can dynamically adjust brightness, contrast, and color settings based on usage patterns and environmental conditions, effectively prolonging the lifespan of QLED displays.

Consumer awareness and demand for longer-lasting displays are driving market competition, with manufacturers highlighting longevity as a key selling point. This has led to the introduction of extended warranty programs and lifespan guarantees for QLED products, reflecting the industry's confidence in the improved durability of these displays.

The commercial sector is also influencing market trends in QLED longevity. Businesses, particularly in sectors such as digital signage and control rooms, are seeking QLED displays with extended lifespans to reduce total cost of ownership and minimize downtime. This demand is pushing manufacturers to develop specialized QLED solutions that can withstand continuous operation in challenging environments.

As sustainability becomes an increasingly important factor for consumers and businesses alike, the market is seeing a trend towards more environmentally friendly QLED technologies. Manufacturers are exploring ways to improve the recyclability of QLED components and reduce the environmental impact of production processes, aligning with the growing demand for sustainable and long-lasting electronic products.

QLED Degradation Factors

QLED displays, while offering superior color performance and energy efficiency, are subject to various degradation factors that can significantly impact their lifespan. One of the primary culprits is heat generation during operation. As QLEDs function, they produce heat, which can lead to accelerated degradation of the quantum dots, particularly in high-brightness settings or prolonged usage scenarios.

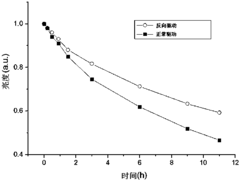

Light exposure, ironically, is another major factor contributing to QLED degradation. Continuous exposure to light, especially high-intensity or UV light, can cause photooxidation of the quantum dots, leading to a gradual decrease in their light-emitting efficiency. This phenomenon is particularly pronounced in outdoor or brightly lit environments where displays may be exposed to direct sunlight.

Moisture and oxygen are also significant threats to QLED longevity. The quantum dots used in QLED displays are highly sensitive to these elements, which can cause oxidation and degradation of the nanocrystals. This sensitivity necessitates robust encapsulation techniques to protect the quantum dots from environmental factors, but even small amounts of moisture or oxygen ingress over time can lead to performance deterioration.

Electrical stress is another crucial factor affecting QLED lifespan. The constant flow of electrical current through the quantum dots can cause gradual degradation, particularly at higher voltages or currents. This stress can lead to changes in the quantum dot structure or composition, affecting their light-emitting properties over time.

Material instability is an inherent challenge in QLED technology. The quantum dots themselves can undergo structural changes or agglomeration over time, leading to shifts in color output and reduced efficiency. This instability is often exacerbated by other degradation factors, creating a compounding effect on display performance.

Usage patterns also play a significant role in QLED degradation. Displaying static images for extended periods can lead to image retention or burn-in, where certain areas of the display degrade faster than others. Similarly, frequent on-off cycling can stress the display components, potentially shortening their lifespan.

Understanding these degradation factors is crucial for developing strategies to maximize QLED lifespan. By addressing these issues through improved materials, better encapsulation techniques, advanced thermal management, and intelligent power management systems, manufacturers can significantly enhance the longevity and reliability of QLED displays in everyday use scenarios.

Light exposure, ironically, is another major factor contributing to QLED degradation. Continuous exposure to light, especially high-intensity or UV light, can cause photooxidation of the quantum dots, leading to a gradual decrease in their light-emitting efficiency. This phenomenon is particularly pronounced in outdoor or brightly lit environments where displays may be exposed to direct sunlight.

Moisture and oxygen are also significant threats to QLED longevity. The quantum dots used in QLED displays are highly sensitive to these elements, which can cause oxidation and degradation of the nanocrystals. This sensitivity necessitates robust encapsulation techniques to protect the quantum dots from environmental factors, but even small amounts of moisture or oxygen ingress over time can lead to performance deterioration.

Electrical stress is another crucial factor affecting QLED lifespan. The constant flow of electrical current through the quantum dots can cause gradual degradation, particularly at higher voltages or currents. This stress can lead to changes in the quantum dot structure or composition, affecting their light-emitting properties over time.

Material instability is an inherent challenge in QLED technology. The quantum dots themselves can undergo structural changes or agglomeration over time, leading to shifts in color output and reduced efficiency. This instability is often exacerbated by other degradation factors, creating a compounding effect on display performance.

Usage patterns also play a significant role in QLED degradation. Displaying static images for extended periods can lead to image retention or burn-in, where certain areas of the display degrade faster than others. Similarly, frequent on-off cycling can stress the display components, potentially shortening their lifespan.

Understanding these degradation factors is crucial for developing strategies to maximize QLED lifespan. By addressing these issues through improved materials, better encapsulation techniques, advanced thermal management, and intelligent power management systems, manufacturers can significantly enhance the longevity and reliability of QLED displays in everyday use scenarios.

Current Lifespan Extension Techniques

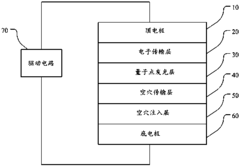

01 QLED device structure optimization

Improving the structure of QLED devices can enhance their lifespan. This includes optimizing the quantum dot layer, electron transport layer, and hole transport layer. Advanced materials and novel architectures can reduce degradation and increase operational stability.- QLED device structure optimization: Improving the structure of QLED devices can enhance their lifespan. This includes optimizing the layers of the device, such as the electron transport layer, hole transport layer, and emissive layer. By carefully designing these components, the efficiency and stability of the QLED can be increased, leading to a longer operational life.

- Quantum dot material enhancement: Developing and utilizing improved quantum dot materials is crucial for extending QLED lifespan. This involves creating more stable and efficient quantum dots that are less prone to degradation over time. Techniques such as core-shell structures and surface passivation can be employed to protect the quantum dots and maintain their performance for longer periods.

- Thermal management strategies: Implementing effective thermal management strategies is essential for prolonging QLED lifespan. This includes designing heat dissipation mechanisms, using thermally conductive materials, and optimizing the overall device architecture to reduce heat buildup. Proper thermal management helps prevent premature degradation of the quantum dots and other components, thereby extending the operational life of the QLED.

- Encapsulation and barrier technologies: Developing advanced encapsulation and barrier technologies is crucial for protecting QLED components from environmental factors. This involves creating effective moisture and oxygen barriers to prevent degradation of the quantum dots and other sensitive materials. Improved encapsulation techniques can significantly extend the lifespan of QLED devices by shielding them from external contaminants.

- Driving and control mechanisms: Optimizing driving and control mechanisms can contribute to extending QLED lifespan. This includes developing intelligent driving schemes, implementing adaptive brightness control, and utilizing advanced power management techniques. By carefully controlling the operation of the QLED device, it is possible to reduce stress on the components and maintain performance over a longer period.

02 Encapsulation techniques

Effective encapsulation methods protect QLED components from environmental factors like moisture and oxygen, significantly extending their lifespan. Advanced barrier films and sealing technologies are employed to prevent degradation of quantum dots and other sensitive materials.Expand Specific Solutions03 Quantum dot material engineering

Developing more stable and efficient quantum dot materials is crucial for extending QLED lifespan. This includes improving core-shell structures, surface treatments, and composition to enhance photostability and reduce degradation under operational conditions.Expand Specific Solutions04 Thermal management solutions

Implementing effective thermal management strategies helps maintain optimal operating temperatures for QLEDs, preventing premature aging and degradation. This includes advanced heat dissipation designs and materials to prolong device lifespan.Expand Specific Solutions05 Driving circuit and power management

Optimizing driving circuits and power management systems can reduce stress on QLED components, extending their operational life. This includes developing intelligent control algorithms, efficient power supply designs, and adaptive brightness control mechanisms.Expand Specific Solutions

Key QLED Manufacturers

The QLED lifespan maximization market is in a growth phase, with increasing demand for longer-lasting display technologies. The market size is expanding as QLED technology gains popularity in consumer electronics. Technologically, QLED is maturing, with companies like BOE Technology Group, TCL China Star Optoelectronics, and Sharp Corp. leading innovation. These firms are developing advanced quantum dot materials and manufacturing processes to enhance QLED durability. Research institutions such as Zhejiang University and Soochow University are contributing to fundamental advancements, while companies like Huawei Technologies are integrating QLED into diverse product lines, driving market growth and technological refinement.

Nanoco Technologies Ltd.

Technical Solution: Nanoco has developed a cadmium-free quantum dot technology called CFQD® (Cadmium Free Quantum Dots) that addresses both performance and environmental concerns. Their approach to maximizing QLED lifespan involves a proprietary "Shell Engineering" technique that creates multiple protective layers around the quantum dot core, significantly enhancing stability. Nanoco has also implemented a "Quantum Dot Dispersion" technology that ensures uniform distribution of quantum dots within the film, reducing hotspots and improving overall lifespan. Furthermore, they've developed an "Adaptive Emission Control" system that dynamically adjusts the quantum dot excitation based on the displayed content, optimizing energy usage and reducing unnecessary stress on the nanocrystals.

Strengths: Environmentally friendly cadmium-free technology. Advanced shell engineering for enhanced stability. Weaknesses: Cadmium-free quantum dots may have slightly lower efficiency compared to cadmium-based alternatives.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive QLED lifespan maximization strategy. Their approach includes advanced quantum dot synthesis techniques to create more stable and durable nanocrystals. They've also implemented a multi-layer encapsulation technology that effectively shields the quantum dots from moisture and oxygen, two primary factors in QLED degradation. Additionally, BOE has developed an intelligent power management system that optimizes the current flow to each pixel, reducing stress on the quantum dots and extending their lifespan. Their QLED panels also incorporate a heat dissipation layer to manage temperature, which is crucial for maintaining quantum dot stability over time.

Strengths: Comprehensive approach addressing multiple factors affecting QLED lifespan. Advanced encapsulation technology provides superior protection. Weaknesses: May increase production costs, potentially affecting market competitiveness.

Innovative QLED Preservation Methods

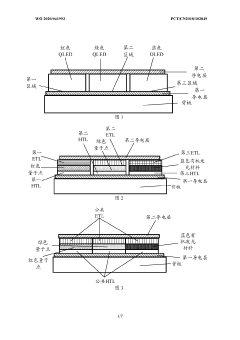

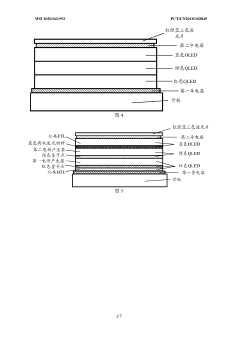

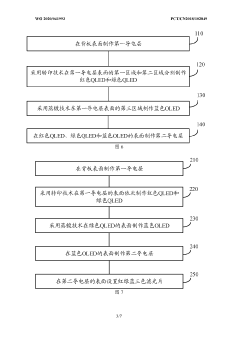

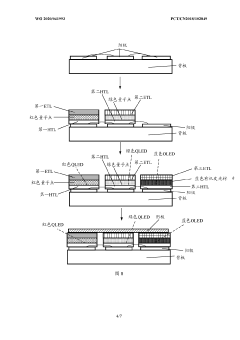

Display screen using hybrid light-emitting diode and manufacturing method therefor

PatentWO2020041993A1

Innovation

- Using a hybrid light-emitting diode structure, combining red quantum dot light-emitting diodes (QLED) and green quantum dot light-emitting diodes (QLED) with blue organic light-emitting diodes (OLED), by designing the structures and structures of red QLED, green QLED and blue OLED respectively. Materials to improve the color gamut range and lifespan of the display screen.

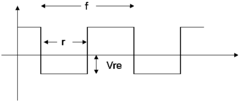

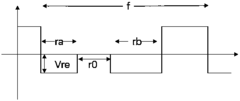

Electromagnetic wave-based QLED driving method

PatentActiveCN108934097A

Innovation

- Using a driving method based on electromagnetic waves, a driving circuit is set up in the QLED to output a reverse driving signal, such as a reverse voltage or a reverse current, to change the potential barrier of the defect well, eliminate the accumulated charge, and reduce the density of the limited charge.

Environmental Impact of QLED Durability

The environmental impact of QLED durability is a crucial aspect to consider when evaluating the long-term sustainability of this display technology. QLED (Quantum Dot Light Emitting Diode) displays have gained popularity due to their superior color reproduction and energy efficiency compared to traditional LED displays. However, their environmental footprint extends beyond just energy consumption during use.

One of the primary environmental benefits of QLED durability is the reduction of electronic waste. As QLEDs typically have a longer lifespan than conventional displays, they contribute to a decrease in the frequency of device replacements. This longevity translates to fewer discarded displays entering landfills or requiring resource-intensive recycling processes. The extended lifespan of QLEDs also means a reduction in the overall demand for raw materials used in display manufacturing, potentially alleviating pressure on natural resources.

However, the production of quantum dots, the key component in QLED technology, involves the use of rare earth elements and heavy metals. The mining and processing of these materials can have significant environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions. As QLED technology becomes more widespread, the demand for these materials may increase, potentially exacerbating these environmental issues.

The durability of QLEDs also has implications for energy consumption over the product lifecycle. While QLEDs are generally more energy-efficient than their predecessors, their extended lifespan means they will consume energy over a longer period. This highlights the importance of continuous improvements in energy efficiency to ensure that the cumulative energy consumption remains low throughout the product's life.

End-of-life considerations for QLEDs present both challenges and opportunities. The complex composition of QLED displays, including the quantum dot layer, makes recycling more challenging than for traditional displays. However, their durability provides an opportunity for refurbishment and reuse, potentially extending the useful life of the display beyond its original intended lifespan.

The environmental impact of QLED durability also extends to the manufacturing process. The production of more durable displays may require additional resources or energy-intensive processes. However, this initial investment in durability can be offset by the reduced need for replacement products, potentially resulting in a net positive environmental impact over time.

In conclusion, while the durability of QLED displays offers several environmental benefits, particularly in terms of waste reduction and resource conservation, it also presents challenges related to material sourcing and end-of-life management. As the technology continues to evolve, addressing these environmental considerations will be crucial for ensuring the sustainable development and adoption of QLED displays.

One of the primary environmental benefits of QLED durability is the reduction of electronic waste. As QLEDs typically have a longer lifespan than conventional displays, they contribute to a decrease in the frequency of device replacements. This longevity translates to fewer discarded displays entering landfills or requiring resource-intensive recycling processes. The extended lifespan of QLEDs also means a reduction in the overall demand for raw materials used in display manufacturing, potentially alleviating pressure on natural resources.

However, the production of quantum dots, the key component in QLED technology, involves the use of rare earth elements and heavy metals. The mining and processing of these materials can have significant environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions. As QLED technology becomes more widespread, the demand for these materials may increase, potentially exacerbating these environmental issues.

The durability of QLEDs also has implications for energy consumption over the product lifecycle. While QLEDs are generally more energy-efficient than their predecessors, their extended lifespan means they will consume energy over a longer period. This highlights the importance of continuous improvements in energy efficiency to ensure that the cumulative energy consumption remains low throughout the product's life.

End-of-life considerations for QLEDs present both challenges and opportunities. The complex composition of QLED displays, including the quantum dot layer, makes recycling more challenging than for traditional displays. However, their durability provides an opportunity for refurbishment and reuse, potentially extending the useful life of the display beyond its original intended lifespan.

The environmental impact of QLED durability also extends to the manufacturing process. The production of more durable displays may require additional resources or energy-intensive processes. However, this initial investment in durability can be offset by the reduced need for replacement products, potentially resulting in a net positive environmental impact over time.

In conclusion, while the durability of QLED displays offers several environmental benefits, particularly in terms of waste reduction and resource conservation, it also presents challenges related to material sourcing and end-of-life management. As the technology continues to evolve, addressing these environmental considerations will be crucial for ensuring the sustainable development and adoption of QLED displays.

Consumer Education on QLED Care

Consumer education plays a crucial role in maximizing the lifespan of QLED displays in everyday use. By providing users with comprehensive knowledge and practical guidelines, manufacturers and retailers can empower consumers to make informed decisions and adopt proper care practices for their QLED devices.

One of the primary aspects of consumer education is raising awareness about the optimal viewing conditions for QLED displays. Users should be informed about the importance of maintaining appropriate ambient lighting levels to prevent unnecessary strain on the display and preserve its color accuracy. Additionally, educating consumers about the benefits of adjusting brightness and contrast settings according to their viewing environment can significantly contribute to extending the display's lifespan.

Another key area of focus should be on proper cleaning and maintenance techniques. Consumers need to be educated about the delicate nature of QLED screens and the potential damage that can be caused by using harsh chemicals or abrasive materials. Clear instructions on using microfiber cloths and specialized cleaning solutions can help prevent accidental damage and maintain the display's pristine condition.

Temperature management is another critical factor in QLED longevity. Educating users about the importance of proper ventilation and avoiding exposure to extreme temperatures can prevent overheating and potential damage to the display components. This information should be coupled with guidelines on optimal placement within living spaces to ensure adequate airflow and minimize environmental stressors.

Consumer education should also address the impact of static images and screen burn-in. While QLED technology is less susceptible to burn-in compared to OLED, users should still be aware of the potential risks associated with displaying static content for extended periods. Providing information on screen savers, pixel shifting technologies, and the benefits of varied content consumption can help mitigate these risks.

Furthermore, educating consumers about the energy-saving features of their QLED displays can not only reduce electricity costs but also contribute to prolonging the device's lifespan. Instructions on utilizing power-saving modes, automatic brightness adjustment, and sleep timers can encourage users to adopt energy-efficient practices without compromising their viewing experience.

Lastly, consumer education should emphasize the importance of software updates and regular maintenance checks. Keeping the display's firmware up-to-date can improve performance, address potential issues, and introduce new features that may contribute to longevity. Encouraging users to perform periodic self-diagnostics and seek professional assistance when necessary can help identify and address potential problems before they escalate.

One of the primary aspects of consumer education is raising awareness about the optimal viewing conditions for QLED displays. Users should be informed about the importance of maintaining appropriate ambient lighting levels to prevent unnecessary strain on the display and preserve its color accuracy. Additionally, educating consumers about the benefits of adjusting brightness and contrast settings according to their viewing environment can significantly contribute to extending the display's lifespan.

Another key area of focus should be on proper cleaning and maintenance techniques. Consumers need to be educated about the delicate nature of QLED screens and the potential damage that can be caused by using harsh chemicals or abrasive materials. Clear instructions on using microfiber cloths and specialized cleaning solutions can help prevent accidental damage and maintain the display's pristine condition.

Temperature management is another critical factor in QLED longevity. Educating users about the importance of proper ventilation and avoiding exposure to extreme temperatures can prevent overheating and potential damage to the display components. This information should be coupled with guidelines on optimal placement within living spaces to ensure adequate airflow and minimize environmental stressors.

Consumer education should also address the impact of static images and screen burn-in. While QLED technology is less susceptible to burn-in compared to OLED, users should still be aware of the potential risks associated with displaying static content for extended periods. Providing information on screen savers, pixel shifting technologies, and the benefits of varied content consumption can help mitigate these risks.

Furthermore, educating consumers about the energy-saving features of their QLED displays can not only reduce electricity costs but also contribute to prolonging the device's lifespan. Instructions on utilizing power-saving modes, automatic brightness adjustment, and sleep timers can encourage users to adopt energy-efficient practices without compromising their viewing experience.

Lastly, consumer education should emphasize the importance of software updates and regular maintenance checks. Keeping the display's firmware up-to-date can improve performance, address potential issues, and introduce new features that may contribute to longevity. Encouraging users to perform periodic self-diagnostics and seek professional assistance when necessary can help identify and address potential problems before they escalate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!