How to Advance Graphene Oxide in Hydrophobic Coatings?

Graphene Oxide Coating Evolution and Objectives

Graphene oxide (GO) has emerged as a revolutionary material in the field of hydrophobic coatings, marking a significant milestone in the evolution of surface protection technologies. The journey of GO in this domain began with the discovery of graphene's exceptional properties, which led researchers to explore its oxidized form for various applications. The development of GO-based hydrophobic coatings has been driven by the increasing demand for more durable, efficient, and environmentally friendly surface protection solutions across multiple industries.

The evolution of GO in hydrophobic coatings has been characterized by several key advancements. Initially, researchers focused on understanding the fundamental properties of GO and its interaction with water molecules. This led to the development of simple GO-based coatings with moderate hydrophobic properties. As the field progressed, scientists began to explore methods to enhance the hydrophobicity of GO coatings, such as chemical functionalization and the incorporation of other nanomaterials.

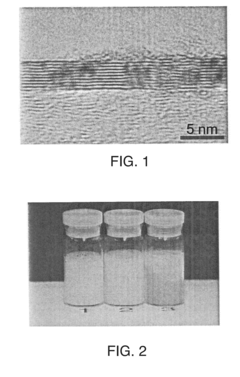

A significant breakthrough came with the development of reduced graphene oxide (rGO), which exhibited improved hydrophobic properties compared to its oxidized counterpart. This discovery opened up new avenues for creating highly water-repellent coatings with enhanced durability and performance. Subsequent research efforts focused on optimizing the reduction process and exploring various reduction methods to fine-tune the hydrophobic properties of rGO-based coatings.

The objectives of advancing GO in hydrophobic coatings are multifaceted and ambitious. Primarily, researchers aim to develop coatings with superhydrophobic properties, characterized by water contact angles exceeding 150 degrees and low sliding angles. This would enable the creation of self-cleaning surfaces with exceptional water-repellent capabilities. Another key objective is to enhance the durability and longevity of GO-based hydrophobic coatings, ensuring they maintain their performance under harsh environmental conditions and prolonged use.

Furthermore, there is a strong focus on improving the scalability and cost-effectiveness of GO-based hydrophobic coating production. This involves developing more efficient synthesis methods for GO and rGO, as well as optimizing coating application techniques for large-scale industrial use. Researchers are also exploring ways to combine GO with other materials to create multifunctional coatings that offer additional properties such as corrosion resistance, thermal insulation, or antimicrobial activity.

Environmental sustainability is another crucial objective in the advancement of GO-based hydrophobic coatings. Scientists are working on developing eco-friendly production methods and exploring the use of green reducing agents for rGO synthesis. Additionally, there is growing interest in creating biodegradable GO-based coatings that can offer temporary protection without long-term environmental impact.

Market Analysis for Hydrophobic Coatings

The hydrophobic coatings market has been experiencing significant growth in recent years, driven by increasing demand across various industries such as automotive, construction, electronics, and aerospace. The global market for hydrophobic coatings was valued at approximately $1.8 billion in 2020 and is projected to reach $2.5 billion by 2025, growing at a CAGR of 6.8% during the forecast period.

The automotive sector represents one of the largest application areas for hydrophobic coatings, with a growing emphasis on improving vehicle aesthetics and durability. The construction industry is another major consumer, utilizing these coatings for self-cleaning surfaces and moisture protection in buildings. Additionally, the electronics industry is adopting hydrophobic coatings to enhance the water resistance of electronic devices.

Geographically, Asia-Pacific dominates the hydrophobic coatings market, accounting for over 40% of the global share. This is primarily due to rapid industrialization, urbanization, and increasing automotive production in countries like China and India. North America and Europe follow closely, driven by technological advancements and stringent regulations promoting eco-friendly coating solutions.

The market is characterized by intense competition among key players such as BASF SE, 3M Company, PPG Industries, and Aculon Inc. These companies are investing heavily in research and development to improve coating performance and expand their product portfolios. The introduction of nanotechnology-based hydrophobic coatings has emerged as a significant trend, offering superior water repellency and durability.

Graphene oxide has gained considerable attention in the hydrophobic coatings market due to its exceptional properties. The incorporation of graphene oxide in coatings has shown potential to enhance water repellency, mechanical strength, and thermal stability. However, challenges remain in terms of large-scale production and cost-effectiveness.

Consumer demand for sustainable and environmentally friendly coatings is driving innovation in bio-based hydrophobic materials. This trend is expected to create new opportunities for market growth, particularly in regions with strict environmental regulations. Furthermore, the development of multifunctional coatings that combine hydrophobicity with other properties such as anti-corrosion or self-healing capabilities is gaining traction.

The COVID-19 pandemic has had a mixed impact on the hydrophobic coatings market. While some sectors experienced a slowdown, there has been an increased demand for antimicrobial and easy-to-clean surfaces in healthcare and public spaces, potentially boosting the adoption of hydrophobic coatings in these areas.

Graphene Oxide Challenges in Hydrophobic Applications

Graphene oxide (GO) has emerged as a promising material for hydrophobic coatings due to its unique properties and potential for surface modification. However, several challenges hinder its widespread application in this field. One of the primary obstacles is the inherent hydrophilicity of GO, which contradicts the desired hydrophobic nature of the coatings. This characteristic stems from the presence of oxygen-containing functional groups on the GO surface, making it naturally attracted to water molecules.

Another significant challenge lies in achieving uniform dispersion and stability of GO within coating formulations. The tendency of GO sheets to aggregate and restack due to strong van der Waals forces between layers can compromise the coating's performance and durability. This aggregation not only affects the hydrophobic properties but also impacts other functional attributes of the coating, such as mechanical strength and barrier properties.

The scalability of GO production for large-scale coating applications presents another hurdle. Current synthesis methods often yield limited quantities of high-quality GO, making it difficult to meet the demands of industrial-scale coating production. Additionally, the cost-effectiveness of GO-based hydrophobic coatings compared to traditional alternatives remains a concern for widespread adoption.

Ensuring long-term stability and durability of GO-based hydrophobic coatings under various environmental conditions poses another challenge. Exposure to UV radiation, temperature fluctuations, and mechanical stress can potentially degrade the coating's performance over time. Developing strategies to enhance the resilience of these coatings without compromising their hydrophobic properties is crucial for their practical implementation.

The environmental impact and potential toxicity of GO-based coatings also require careful consideration. While GO itself is generally considered less toxic than pristine graphene, concerns remain about its long-term effects on ecosystems and human health, particularly when used in large-scale applications. Addressing these safety concerns is essential for regulatory approval and public acceptance of GO-based hydrophobic coatings.

Furthermore, achieving precise control over the surface chemistry and structure of GO to tailor its hydrophobic properties presents a significant technical challenge. The ability to fine-tune the degree of oxidation, functionalization, and reduction of GO is critical for optimizing its performance in hydrophobic coatings. Developing reproducible and scalable methods for such precise modifications remains an active area of research.

Lastly, integrating GO-based hydrophobic coatings into existing manufacturing processes and ensuring compatibility with various substrate materials pose additional challenges. Adapting current coating technologies to accommodate GO-based formulations without significant modifications to production lines is crucial for industrial adoption. Overcoming these multifaceted challenges is essential for advancing the use of graphene oxide in hydrophobic coatings and realizing its full potential in this application domain.

Current Graphene Oxide Hydrophobic Coating Solutions

01 Modification of graphene oxide surface for hydrophobicity

Various methods can be employed to modify the surface of graphene oxide to increase its hydrophobicity. These modifications can include chemical treatments, functionalization with specific groups, or coating with hydrophobic materials. The altered surface properties enhance the material's water-repellent characteristics, making it suitable for applications requiring hydrophobic surfaces.- Modification of graphene oxide surface for hydrophobicity: Various methods can be employed to modify the surface of graphene oxide to increase its hydrophobicity. These modifications can include chemical treatments, functionalization with specific groups, or coating with hydrophobic materials. The altered surface properties enhance the material's water-repellent characteristics, making it suitable for applications requiring hydrophobic surfaces.

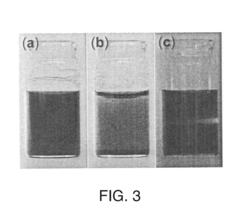

- Reduction of graphene oxide to enhance hydrophobicity: Reducing graphene oxide can significantly increase its hydrophobicity. This process involves removing oxygen-containing functional groups from the graphene oxide surface, resulting in a more hydrophobic material. Various reduction methods, such as thermal, chemical, or electrochemical approaches, can be utilized to achieve the desired level of hydrophobicity.

- Composite materials incorporating hydrophobic graphene oxide: Hydrophobic graphene oxide can be incorporated into composite materials to impart water-repellent properties. These composites can combine the unique properties of graphene oxide with other materials, resulting in enhanced hydrophobicity and improved performance in various applications, such as coatings, membranes, or electronic devices.

- Characterization and measurement of graphene oxide hydrophobicity: Various techniques and methods can be used to characterize and measure the hydrophobicity of graphene oxide. These may include contact angle measurements, surface energy analysis, or spectroscopic techniques. Accurate characterization is crucial for understanding the material's properties and optimizing its performance in different applications.

- Applications of hydrophobic graphene oxide: Hydrophobic graphene oxide finds applications in various fields due to its unique properties. These applications can include water treatment, oil-water separation, self-cleaning surfaces, anti-corrosion coatings, and electronic devices. The material's hydrophobicity, combined with its other properties, makes it suitable for addressing challenges in diverse industries.

02 Reduction of graphene oxide to enhance hydrophobicity

Reducing graphene oxide can significantly increase its hydrophobicity. This process involves removing oxygen-containing functional groups from the graphene oxide surface, resulting in a more hydrophobic material. Various reduction methods, such as thermal, chemical, or electrochemical approaches, can be utilized to achieve this transformation.Expand Specific Solutions03 Composite materials incorporating hydrophobic graphene oxide

Hydrophobic graphene oxide can be incorporated into composite materials to impart water-repellent properties. These composites can combine the unique characteristics of graphene oxide with other materials, resulting in enhanced hydrophobicity and improved performance in various applications, such as coatings, membranes, or electronic devices.Expand Specific Solutions04 Tuning graphene oxide hydrophobicity for specific applications

The hydrophobicity of graphene oxide can be fine-tuned to meet the requirements of specific applications. This can involve controlling the degree of reduction, selective functionalization, or combining with other materials. By adjusting the hydrophobic properties, graphene oxide can be optimized for use in areas such as water treatment, oil-water separation, or self-cleaning surfaces.Expand Specific Solutions05 Characterization and measurement of graphene oxide hydrophobicity

Various techniques and methods can be employed to characterize and measure the hydrophobicity of graphene oxide. These may include contact angle measurements, surface energy analysis, or spectroscopic techniques. Accurate characterization is crucial for understanding the material's properties and optimizing its performance in different applications.Expand Specific Solutions

Key Players in Graphene Oxide Coating Industry

The development of graphene oxide in hydrophobic coatings is in a growth phase, with increasing market potential and technological advancements. The global market for graphene-based coatings is expanding rapidly, driven by demand in various industries. While the technology is progressing, it's not yet fully mature, as evidenced by ongoing research at institutions like William Marsh Rice University, The University of Manchester, and Massachusetts Institute of Technology. Companies such as LG Chem Ltd. and Applied Graphene Materials UK Ltd. are actively developing commercial applications, indicating a competitive landscape with both academic and industrial players. The involvement of diverse organizations, from universities to major corporations, suggests a dynamic field with significant room for innovation and market growth.

William Marsh Rice University

The University of Manchester

Breakthrough Patents in Graphene Oxide Coatings

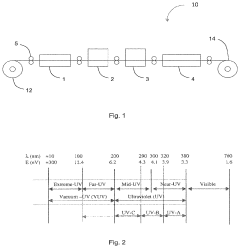

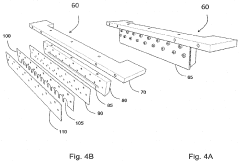

- A process involving cleaning and activating the substrate with VUV radiation and oxidizing radical species to increase wettability, followed by applying a graphene oxide (GO) dispersion and converting it into a graphene-like coating using VUV radiation in an inert atmosphere, potentially with reactive gases to form defect-free or functionalized coatings.

- A water-based, non-fluorinated dispersion using a hydrophobic polymer and exfoliated graphite filler particles with acid functional groups, stabilized at a pH greater than 7, to create a superhydrophobic composite coating that eliminates the need for organic solvents and fluoropolymers.

Environmental Impact of Graphene Oxide Coatings

The environmental impact of graphene oxide coatings is a critical consideration in their development and application. These coatings, while offering significant benefits in terms of hydrophobicity and durability, also raise concerns about their potential effects on ecosystems and human health.

One of the primary environmental considerations is the release of graphene oxide particles into water systems. As hydrophobic coatings wear over time, there is a risk of nanoparticles detaching and entering aquatic environments. Studies have shown that these particles can interact with various organisms, potentially disrupting food chains and ecosystem balance. The long-term effects of such contamination are still not fully understood, necessitating ongoing research and monitoring.

Air quality is another area of concern, particularly during the manufacturing and application processes of graphene oxide coatings. The production of these materials often involves the use of chemicals and processes that can release volatile organic compounds (VOCs) and other pollutants. Proper containment and filtration systems are essential to mitigate these emissions and protect both workers and the surrounding environment.

The persistence of graphene oxide in the environment is a double-edged sword. While its durability contributes to the longevity of coatings, it also means that any environmental contamination may be long-lasting. This raises questions about the potential for bioaccumulation in organisms and the long-term impact on biodiversity.

On the positive side, the hydrophobic properties of graphene oxide coatings can contribute to environmental protection in certain applications. For instance, when used on ship hulls, these coatings can reduce biofouling, potentially decreasing the need for toxic anti-fouling agents and improving fuel efficiency, thereby reducing overall emissions from maritime transport.

The recyclability and end-of-life management of products treated with graphene oxide coatings are also important environmental considerations. Current recycling processes may not be equipped to handle these advanced materials, potentially leading to increased waste or the need for specialized disposal methods.

As research in this field progresses, there is a growing focus on developing more environmentally friendly synthesis methods for graphene oxide and exploring bio-based alternatives that could offer similar hydrophobic properties with reduced environmental impact. These efforts are crucial in balancing the technological advantages of graphene oxide coatings with the imperative of environmental stewardship.

Scalability and Manufacturing Processes

The scalability and manufacturing processes for advancing graphene oxide in hydrophobic coatings present both challenges and opportunities. Current production methods for graphene oxide (GO) typically involve chemical exfoliation of graphite, which can be scaled up to industrial levels. However, the quality and consistency of GO produced at large scales remain concerns that need to be addressed for widespread application in hydrophobic coatings.

One promising approach to improve scalability is the development of continuous flow reactors for GO synthesis. These systems allow for more precise control over reaction conditions and can potentially produce higher quality GO at larger volumes. Additionally, the use of microfluidic devices for GO production has shown potential for enhancing both quality and scalability, though further research is needed to optimize these processes for industrial-scale manufacturing.

The integration of GO into hydrophobic coatings presents its own set of manufacturing challenges. Uniform dispersion of GO within the coating matrix is crucial for achieving optimal hydrophobic properties. Techniques such as spray coating, dip coating, and spin coating have been successfully employed at laboratory scales, but scaling these methods to industrial production requires careful consideration of factors such as coating thickness uniformity, adhesion, and durability.

Advances in roll-to-roll manufacturing processes offer promising solutions for large-scale production of GO-based hydrophobic coatings. This continuous production method allows for the deposition of GO-containing coatings on flexible substrates at high speeds, potentially enabling the production of large areas of hydrophobic surfaces. However, ensuring consistent GO dispersion and coating quality across the entire substrate remains a challenge that requires further research and development.

Another critical aspect of scalability is the development of environmentally friendly and cost-effective manufacturing processes. Traditional GO production methods often involve the use of harsh chemicals and generate significant waste. Research into green synthesis methods, such as electrochemical exfoliation or mechanochemical approaches, shows potential for reducing environmental impact and production costs. These alternative methods could play a crucial role in making GO-based hydrophobic coatings more economically viable for large-scale applications.

As the demand for hydrophobic coatings grows across various industries, addressing these scalability and manufacturing challenges will be essential for the widespread adoption of GO-based solutions. Collaborative efforts between materials scientists, chemical engineers, and manufacturing experts will be crucial in developing innovative processes that can bridge the gap between laboratory-scale production and industrial-scale manufacturing of advanced GO-based hydrophobic coatings.