How to Employ Graphene Oxide for Better Load-Bearing Capacity?

Graphene Oxide Background and Objectives

Graphene oxide (GO) has emerged as a revolutionary material in the field of materials science, offering exceptional mechanical, thermal, and electrical properties. Since its discovery in 2004, researchers have been exploring its potential applications across various industries, including aerospace, construction, and automotive. The primary objective of employing graphene oxide for better load-bearing capacity is to develop stronger, lighter, and more durable materials that can withstand higher stress and strain.

The evolution of graphene oxide technology has been marked by significant milestones in synthesis methods, characterization techniques, and application development. Initially, the Hummers method was the primary approach for producing graphene oxide. However, recent advancements have led to more efficient and environmentally friendly production processes, such as the improved Hummers method and electrochemical exfoliation techniques.

One of the key trends in graphene oxide research is the focus on enhancing its mechanical properties through functionalization and composite formation. By incorporating GO into polymer matrices or combining it with other nanomaterials, researchers aim to create hybrid materials with superior load-bearing capabilities. This approach has shown promising results in developing high-strength, lightweight composites for structural applications.

The potential of graphene oxide in improving load-bearing capacity stems from its unique structure and properties. Its two-dimensional sheet-like morphology, high surface area, and excellent mechanical strength make it an ideal candidate for reinforcing materials. When properly dispersed and integrated into a matrix, GO can significantly enhance the overall mechanical performance of the composite material.

Current research objectives in this field include optimizing the dispersion of graphene oxide in various matrices, improving the interfacial bonding between GO and host materials, and developing scalable production methods for GO-based composites. Additionally, there is a growing interest in understanding the fundamental mechanisms of load transfer and stress distribution in GO-reinforced materials to further improve their performance.

The application of graphene oxide for enhanced load-bearing capacity extends beyond traditional structural materials. Researchers are exploring its potential in developing smart materials that can sense and respond to mechanical stress, self-healing composites that can repair damage autonomously, and multifunctional materials that combine improved mechanical properties with other desirable characteristics such as electrical conductivity or thermal management.

As the field progresses, the focus is shifting towards addressing challenges such as the high production costs of high-quality graphene oxide, ensuring consistent quality and properties across large-scale production, and developing standardized testing and characterization methods for GO-based materials. Overcoming these hurdles is crucial for the widespread adoption of graphene oxide in load-bearing applications across various industries.

Market Demand Analysis for Enhanced Load-Bearing Materials

The market demand for enhanced load-bearing materials has been steadily increasing across various industries, driven by the need for stronger, lighter, and more durable structures. Graphene oxide, with its exceptional mechanical properties, has emerged as a promising candidate to meet these demands. The construction industry, in particular, shows significant interest in graphene oxide-enhanced materials for improving the strength and durability of concrete and other building materials.

In the aerospace and automotive sectors, there is a growing demand for lightweight materials that can withstand high stress and strain. Graphene oxide-based composites offer the potential to reduce vehicle weight while maintaining or improving structural integrity, leading to increased fuel efficiency and performance. This aligns with the global push for more sustainable transportation solutions and stricter emissions regulations.

The energy sector, especially in renewable energy infrastructure, requires materials with superior load-bearing capacity to support larger wind turbines and more efficient solar panels. Graphene oxide-enhanced materials could potentially extend the lifespan and improve the performance of these structures, making renewable energy more cost-effective and reliable.

In the marine industry, there is a demand for corrosion-resistant materials with high load-bearing capacity for shipbuilding and offshore structures. Graphene oxide's ability to enhance the mechanical properties of materials while providing a barrier against corrosion makes it an attractive option for this sector.

The sports and leisure industry also shows interest in graphene oxide-enhanced materials for producing lighter and stronger equipment, such as bicycles, tennis rackets, and protective gear. This market segment values innovation and performance improvements, creating opportunities for advanced materials.

Market analysis indicates that the global advanced materials market, which includes graphene-based materials, is expected to grow significantly in the coming years. Factors driving this growth include increasing research and development activities, government support for advanced materials development, and the expanding applications across various industries.

However, challenges remain in scaling up production and reducing costs associated with graphene oxide-enhanced materials. The market demand is also influenced by factors such as regulatory approvals, environmental considerations, and the ability to integrate these materials into existing manufacturing processes.

As industries continue to seek ways to improve efficiency, durability, and sustainability, the demand for enhanced load-bearing materials incorporating graphene oxide is likely to expand. This presents opportunities for innovation and collaboration between material scientists, engineers, and industry partners to develop and commercialize graphene oxide-based solutions that meet specific market needs.

Current Challenges in Graphene Oxide Load-Bearing Applications

Despite the promising potential of graphene oxide (GO) in load-bearing applications, several significant challenges hinder its widespread adoption and optimal performance. One of the primary obstacles is the difficulty in achieving uniform dispersion of GO within composite materials. The tendency of GO sheets to agglomerate due to strong van der Waals forces between layers can lead to inconsistent mechanical properties and reduced load-bearing capacity.

Another critical challenge lies in the interfacial bonding between GO and the matrix material. While GO's oxygen-containing functional groups can facilitate bonding, achieving strong and stable interfaces across various matrix materials remains a complex task. Weak interfacial bonding can result in premature failure under load, limiting the overall load-bearing capacity of GO-reinforced composites.

The scalability of GO production and integration into load-bearing structures poses a significant hurdle. Current methods for producing high-quality GO in large quantities are often costly and time-consuming, making it challenging to meet industrial-scale demands. Additionally, the integration of GO into existing manufacturing processes without compromising its unique properties requires further development.

Environmental stability is another concern in GO load-bearing applications. GO's susceptibility to moisture and temperature fluctuations can lead to degradation of mechanical properties over time. This sensitivity to environmental factors limits its applicability in certain load-bearing scenarios, particularly those exposed to harsh or variable conditions.

The anisotropic nature of GO sheets presents challenges in achieving consistent load-bearing properties in all directions. While GO exhibits exceptional strength and stiffness in-plane, its out-of-plane properties are significantly weaker. This anisotropy can lead to unpredictable behavior under complex loading conditions, necessitating careful design considerations.

Lastly, the long-term durability and fatigue resistance of GO-reinforced materials in load-bearing applications remain areas of concern. The behavior of GO under cyclic loading and its resistance to crack propagation are not fully understood, potentially limiting its use in applications requiring sustained performance under dynamic loads.

Addressing these challenges requires interdisciplinary research efforts, combining materials science, nanotechnology, and structural engineering. Innovations in GO functionalization, composite design, and manufacturing techniques are crucial for overcoming these obstacles and realizing the full potential of GO in load-bearing applications.

Existing Methods for Improving Load-Bearing Capacity with Graphene Oxide

01 Enhanced mechanical properties of graphene oxide composites

Graphene oxide can significantly improve the mechanical properties of composite materials, including load-bearing capacity. When incorporated into various matrices, it enhances strength, stiffness, and toughness. This improvement is attributed to the unique 2D structure and high surface area of graphene oxide, allowing for efficient stress transfer and distribution within the composite.- Enhanced mechanical properties of graphene oxide composites: Graphene oxide can be incorporated into various materials to significantly improve their mechanical properties, including load-bearing capacity. These composites exhibit increased strength, stiffness, and durability compared to traditional materials, making them suitable for high-performance applications in aerospace, automotive, and construction industries.

- Graphene oxide-reinforced polymer matrices: Polymer matrices reinforced with graphene oxide show remarkable improvements in load-bearing capacity. The addition of graphene oxide enhances the interfacial bonding between the polymer and the nanomaterial, resulting in superior mechanical properties, including increased tensile strength and elastic modulus.

- Graphene oxide-based structural materials: Structural materials incorporating graphene oxide demonstrate exceptional load-bearing capabilities. These materials can be used in the construction of lightweight yet strong structures, such as bridges, buildings, and aerospace components. The unique properties of graphene oxide contribute to improved stress distribution and crack resistance.

- Functionalized graphene oxide for enhanced load-bearing: Functionalization of graphene oxide can further improve its load-bearing capacity and compatibility with various matrices. Chemical modifications or surface treatments can enhance the interfacial interactions between graphene oxide and the host material, leading to superior mechanical performance and increased load-bearing capacity of the resulting composites.

- Graphene oxide in energy storage devices: Graphene oxide plays a crucial role in improving the load-bearing capacity of energy storage devices, such as batteries and supercapacitors. Its incorporation enhances the structural stability and mechanical integrity of electrodes, allowing for better performance under high mechanical stress and prolonged cycling.

02 Graphene oxide in energy storage applications

Graphene oxide demonstrates excellent load-bearing capacity in energy storage devices such as supercapacitors and batteries. Its high surface area and conductivity allow for improved charge storage and transfer, while its mechanical strength enables the development of flexible and durable energy storage systems with enhanced performance under various load conditions.Expand Specific Solutions03 Graphene oxide-reinforced polymer nanocomposites

Incorporating graphene oxide into polymer matrices creates nanocomposites with superior load-bearing capacity. These materials exhibit improved tensile strength, modulus, and fracture toughness compared to neat polymers. The enhanced properties are due to the strong interfacial interactions between graphene oxide and the polymer matrix, as well as the efficient load transfer mechanism.Expand Specific Solutions04 Graphene oxide in structural and construction materials

Graphene oxide can significantly enhance the load-bearing capacity of structural and construction materials such as concrete and cement composites. Its incorporation leads to improved compressive strength, flexural strength, and durability. These enhancements are attributed to the reinforcing effect of graphene oxide and its ability to promote the formation of a denser microstructure in cementitious materials.Expand Specific Solutions05 Functionalized graphene oxide for improved load-bearing applications

Functionalization of graphene oxide can further enhance its load-bearing capacity and compatibility with various matrices. Chemical modifications can improve dispersion, interfacial bonding, and overall mechanical properties of graphene oxide-based composites. This approach allows for tailoring the properties of graphene oxide to specific load-bearing applications across different fields.Expand Specific Solutions

Key Players in Graphene Oxide Research and Development

The graphene oxide market for load-bearing applications is in its growth phase, with increasing research and development efforts. The global market size for graphene-based materials is projected to expand significantly in the coming years. Technologically, graphene oxide's use in load-bearing applications is still evolving, with varying levels of maturity across different sectors. Key players like King Abdullah University of Science & Technology, Northwestern University, and Zhejiang University are advancing the field through innovative research. Companies such as Toray Industries, Inc. and SABIC Global Technologies BV are exploring commercial applications, while research institutions like Centre National de la Recherche Scientifique and Harbin Institute of Technology are contributing to fundamental understanding and potential breakthroughs in this promising area.

Toray Industries, Inc.

Semiconductor Energy Laboratory Co., Ltd.

Core Innovations in Graphene Oxide Structural Enhancement

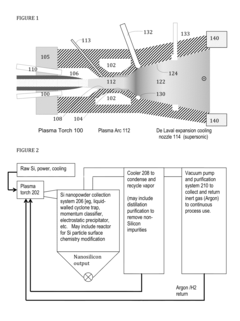

- The development of isentropic flash-quench silicon vapor processing and carbothermic reduction methods to produce high-purity silicon nanopowders with specific compositions, including boron, carbon, and other elements, which enhance energetic properties and stability.

- Graphene powder with a specific surface area of 80-250 m2/g and an oxygen-to-carbon ratio of 0.09-0.30, achieved through controlled oxidation and surface treatment, is used to enhance dispersibility and ionic conductivity, forming a conductive network within the electrode matrix.

Environmental Impact of Graphene Oxide Production and Use

The production and use of graphene oxide (GO) for enhancing load-bearing capacity have significant environmental implications that warrant careful consideration. The synthesis of GO typically involves the oxidation of graphite using strong oxidizing agents, such as potassium permanganate and sulfuric acid, in a process known as the Hummers method or its variations. This chemical-intensive process generates hazardous waste and potentially toxic by-products, raising concerns about water pollution and soil contamination if not properly managed.

The energy requirements for GO production are substantial, contributing to indirect environmental impacts through increased carbon emissions if non-renewable energy sources are used. However, recent advancements in green synthesis methods, utilizing more environmentally friendly reagents and processes, show promise in reducing the ecological footprint of GO manufacturing.

During the application phase, the potential release of GO nanoparticles into the environment poses risks to ecosystems. Studies have shown that GO can interact with various organisms, potentially causing toxicity in aquatic environments and affecting soil microbial communities. The long-term persistence of GO in the environment is not fully understood, raising questions about its bioaccumulation and potential impacts on food chains.

On the positive side, the use of GO for improving load-bearing capacity in materials can lead to significant environmental benefits. By enhancing the strength and durability of materials, GO enables the production of lighter and more efficient structures. This can result in reduced material consumption, lower energy requirements in transportation, and extended product lifespans, all contributing to a decrease in overall resource depletion and waste generation.

Furthermore, GO's potential in water purification and environmental remediation applications offers a counterbalance to its production impacts. Its high adsorption capacity and ability to remove contaminants from water and soil could contribute to environmental cleanup efforts, potentially offsetting some of the negative impacts associated with its production.

As research progresses, life cycle assessments of GO-enhanced materials are crucial to fully understand the net environmental impact. These assessments should consider the entire lifecycle, from raw material extraction to end-of-life disposal or recycling. Developing efficient recycling methods for GO-containing materials is essential to minimize waste and maximize the environmental benefits of this technology.

In conclusion, while the production of GO presents environmental challenges, its application in enhancing load-bearing capacity offers potential environmental benefits that could outweigh these concerns. Continued research into greener production methods, safe handling practices, and effective recycling strategies is essential to optimize the environmental profile of GO technology and ensure its sustainable integration into material science applications.

Scalability and Cost Analysis of Graphene Oxide Solutions

The scalability and cost analysis of graphene oxide solutions for enhancing load-bearing capacity is a critical consideration in the widespread adoption of this innovative material. As production techniques for graphene oxide continue to evolve, the potential for large-scale implementation in various industries becomes increasingly feasible.

Current manufacturing processes for graphene oxide have shown promising advancements in terms of scalability. The Hummers method, a widely used technique, has been optimized for industrial-scale production, allowing for the synthesis of high-quality graphene oxide in larger quantities. This scalability is crucial for meeting the growing demand in applications such as composite materials, coatings, and structural reinforcements.

However, challenges remain in maintaining consistent quality and properties across large-scale production batches. Variations in oxidation levels and sheet sizes can impact the material's performance in load-bearing applications. Addressing these consistency issues is essential for ensuring reliable and reproducible results in industrial settings.

From a cost perspective, the production of graphene oxide has become more economically viable in recent years. The declining prices of raw materials, coupled with improved manufacturing efficiencies, have contributed to a reduction in overall production costs. This trend is expected to continue as economies of scale are realized and new, more cost-effective synthesis methods are developed.

Despite these positive developments, the cost of graphene oxide solutions remains higher than traditional materials used for enhancing load-bearing capacity. This price differential presents a barrier to widespread adoption, particularly in cost-sensitive industries. However, the superior performance characteristics of graphene oxide, including its exceptional strength-to-weight ratio, may justify the higher initial investment in certain high-value applications.

The environmental impact and sustainability of graphene oxide production processes are also important factors in the scalability and cost analysis. As regulations around environmental protection become more stringent, the development of greener synthesis methods and waste reduction strategies will play a crucial role in determining the long-term viability and cost-effectiveness of graphene oxide solutions.

In conclusion, while challenges persist, the scalability and cost trajectory of graphene oxide solutions for load-bearing applications show promising trends. Continued research and development efforts focused on optimizing production processes, enhancing quality control, and reducing costs will be essential in realizing the full potential of this revolutionary material across various industries.