How to Apply HDPE in Health Sector Innovations?

HDPE in Healthcare: Background and Objectives

High-density polyethylene (HDPE) has emerged as a versatile material with significant potential for innovation in the healthcare sector. The evolution of HDPE applications in medical and health-related fields has been driven by its unique properties, including excellent chemical resistance, durability, and biocompatibility. As the healthcare industry continues to seek advanced materials for improved patient care and medical device performance, HDPE has garnered increasing attention from researchers and manufacturers alike.

The journey of HDPE in healthcare began with its use in simple medical packaging and containers. Over time, its applications have expanded to include more sophisticated medical devices, implants, and healthcare infrastructure components. This progression reflects the growing recognition of HDPE's advantages in meeting the stringent requirements of the medical field, such as sterilization compatibility and long-term stability.

The primary objective of exploring HDPE applications in health sector innovations is to leverage its properties to address current challenges in healthcare delivery and patient outcomes. Researchers and industry professionals aim to develop novel HDPE-based solutions that can enhance the safety, efficacy, and cost-effectiveness of medical treatments and devices. This includes improving the design of surgical instruments, creating more comfortable and durable prosthetics, and developing advanced drug delivery systems.

Another key goal is to investigate the potential of HDPE in creating more sustainable healthcare practices. As environmental concerns become increasingly prominent, the medical industry is seeking materials that can reduce waste and energy consumption while maintaining high performance standards. HDPE's recyclability and potential for bio-based variants align well with these sustainability objectives.

The technological trajectory of HDPE in healthcare is closely linked to advancements in polymer science and manufacturing processes. Ongoing research focuses on enhancing HDPE's properties through techniques such as nanocomposite integration, surface modification, and blending with other materials. These efforts aim to expand the range of medical applications for HDPE and overcome any limitations in its current use.

As we explore the application of HDPE in health sector innovations, it is crucial to consider the regulatory landscape and safety standards governing medical materials. The development of new HDPE-based healthcare solutions must navigate complex approval processes and demonstrate clear benefits over existing technologies. This necessitates a multidisciplinary approach, combining expertise in materials science, medical research, and regulatory affairs.

By examining the background and setting clear objectives for HDPE innovation in healthcare, we lay the foundation for understanding its current applications, identifying challenges, and envisioning future breakthroughs. This exploration will guide research efforts, inform industry strategies, and ultimately contribute to the advancement of medical technologies and patient care.

Market Analysis for HDPE in Medical Applications

The market for High-Density Polyethylene (HDPE) in medical applications has been experiencing significant growth, driven by the material's unique properties and the increasing demand for safe, durable, and cost-effective healthcare solutions. HDPE's excellent chemical resistance, impact strength, and low moisture absorption make it an ideal choice for various medical devices and packaging applications.

In recent years, the global HDPE market in the healthcare sector has shown a steady increase, with a compound annual growth rate (CAGR) exceeding 5%. This growth is primarily attributed to the rising prevalence of chronic diseases, aging populations in developed countries, and the expansion of healthcare infrastructure in emerging markets. The COVID-19 pandemic has further accelerated the demand for HDPE in medical applications, particularly in personal protective equipment (PPE) and diagnostic tools.

The medical packaging segment represents the largest share of HDPE usage in the healthcare sector. HDPE is widely used in pharmaceutical packaging, including bottles, vials, and blister packs, due to its excellent barrier properties and resistance to chemicals. The material's ability to maintain product integrity and extend shelf life has made it a preferred choice for drug manufacturers and healthcare providers.

Medical devices constitute another significant market for HDPE. The material is used in a wide range of applications, including surgical instruments, implants, prosthetics, and diagnostic equipment. HDPE's biocompatibility and sterilization resistance have contributed to its increasing adoption in this segment. The growing trend towards minimally invasive surgeries and personalized medicine is expected to further drive the demand for HDPE-based medical devices.

Geographically, North America and Europe dominate the HDPE market in medical applications, owing to their advanced healthcare systems and stringent regulatory standards. However, Asia-Pacific is emerging as the fastest-growing region, driven by rapid urbanization, increasing healthcare expenditure, and the expansion of medical tourism in countries like India and China.

The market landscape for HDPE in medical applications is characterized by intense competition among key players, including major chemical companies and specialized medical material manufacturers. These companies are focusing on product innovation, sustainability, and strategic partnerships to gain a competitive edge. The development of bio-based HDPE and the integration of antimicrobial properties are some of the emerging trends that are likely to shape the future of this market.

Despite the positive outlook, the HDPE market in medical applications faces challenges such as environmental concerns related to plastic waste and the growing preference for alternative materials in certain applications. However, ongoing research and development efforts aimed at improving HDPE's recyclability and enhancing its performance characteristics are expected to address these challenges and sustain market growth in the coming years.

Current Challenges in HDPE Healthcare Implementation

Despite the promising potential of High-Density Polyethylene (HDPE) in healthcare innovations, several challenges hinder its widespread implementation. One of the primary obstacles is the material's limited compatibility with certain medical applications. While HDPE exhibits excellent chemical resistance and durability, its non-polar nature makes it difficult to bond with other materials or to be coated, which is often necessary for specific medical devices or implants.

Another significant challenge is the regulatory hurdles associated with introducing new materials in healthcare settings. HDPE must undergo rigorous testing and approval processes to ensure its safety and efficacy in various medical applications. This process can be time-consuming and costly, potentially deterring some manufacturers from pursuing HDPE-based innovations.

The sterilization of HDPE products presents another hurdle. Traditional sterilization methods, such as high-temperature autoclaving, can potentially degrade HDPE's physical properties. While alternative sterilization techniques exist, such as ethylene oxide or gamma radiation, they may not be suitable for all HDPE applications or may require additional validation studies.

HDPE's recyclability, while generally considered an advantage, poses challenges in healthcare settings. The material's potential for contamination after use in medical applications complicates recycling efforts. Developing effective decontamination and recycling protocols for HDPE medical products remains a significant challenge.

The perception of plastics in healthcare also presents a barrier to HDPE adoption. With increasing environmental concerns, there is growing pressure to reduce plastic use in various industries, including healthcare. This sentiment may lead to resistance in adopting HDPE-based solutions, even when they offer significant advantages over existing materials.

Furthermore, the integration of HDPE into complex medical devices or advanced healthcare technologies presents technical challenges. For instance, incorporating HDPE into smart medical devices or combining it with electronics for monitoring purposes requires innovative engineering solutions that are still in development.

Lastly, the cost-effectiveness of HDPE in certain healthcare applications remains a challenge. While HDPE is generally an affordable material, the additional processing, testing, and regulatory compliance required for medical-grade HDPE can significantly increase its cost. This may limit its adoption in price-sensitive healthcare markets or applications where alternative materials are more established.

Existing HDPE Solutions in Healthcare

01 Composition and properties of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications, including packaging, pipes, and industrial products.- Composition and properties of HDPE: High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications in packaging, construction, and automotive industries.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites can improve mechanical strength, thermal stability, or specific functional characteristics. Common additives include other polymers, natural fibers, or inorganic particles, resulting in materials with tailored properties for specific applications.

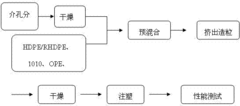

- HDPE processing techniques: Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, blow molding, and rotational molding. Each method offers unique advantages for producing different types of products, such as containers, pipes, or sheets. Advanced processing techniques can improve the material's performance or enable the production of complex shapes.

- Recycling and sustainability of HDPE: HDPE is recyclable and can be reprocessed multiple times without significant loss of properties. Recycling processes for HDPE include mechanical recycling, chemical recycling, and energy recovery. Efforts are being made to improve the recyclability of HDPE products and increase the use of recycled HDPE in various applications to promote sustainability and reduce environmental impact.

- HDPE applications in various industries: HDPE finds applications in numerous industries due to its versatile properties. It is widely used in packaging for bottles, containers, and films. In construction, HDPE is used for pipes, geomembranes, and insulation. Other applications include automotive parts, toys, and household items. Ongoing research focuses on expanding HDPE's use in new areas and improving its performance in existing applications.

02 HDPE blends and composites

HDPE can be blended with other materials or reinforced with additives to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, or specific functional properties. The resulting materials find applications in diverse industries, including automotive, construction, and consumer goods.Expand Specific Solutions03 HDPE processing techniques

Various processing techniques are employed to manufacture HDPE products, including injection molding, extrusion, and blow molding. These methods allow for the production of a wide range of HDPE items, from thin films to large containers. Advancements in processing technologies focus on improving efficiency, reducing cycle times, and enhancing product quality.Expand Specific Solutions04 Recycling and sustainability of HDPE

HDPE is recyclable and efforts are being made to improve its recycling processes and increase the use of recycled HDPE in new products. Research focuses on enhancing the properties of recycled HDPE, developing more efficient recycling methods, and creating closed-loop systems for HDPE products to promote sustainability and reduce environmental impact.Expand Specific Solutions05 Novel applications of HDPE

Ongoing research explores new applications for HDPE, leveraging its unique properties. These include the development of HDPE-based composites for specialized uses, such as radiation shielding materials, advanced packaging solutions, and innovative construction materials. The versatility of HDPE continues to drive its adoption in emerging fields and technologies.Expand Specific Solutions

Key Players in HDPE Medical Innovations

The application of HDPE in health sector innovations is in a growth phase, with increasing market size due to its versatile properties. The technology maturity varies across applications, ranging from established to emerging. Major players like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and Saudi Basic Industries Corp. are driving advancements in HDPE formulations for medical devices and packaging. Companies such as Fresenius Kabi Deutschland GmbH and Smith & Nephew Orthopaedics GmbH are focusing on HDPE applications in medical equipment and implants. Research institutions like Sichuan University and the University of North Carolina at Charlotte are contributing to innovative HDPE applications in healthcare, indicating a competitive landscape with diverse stakeholders from industry and academia.

Fresenius Kabi Deutschland GmbH

Smith & Nephew Orthopaedics GmbH

Breakthrough HDPE Technologies for Medical Use

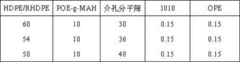

- HDPE/RHDPE/POE–g–MAH/mesoporous molecular sieve blend materials are used. Through the graft modification of POE–g–MAH and the reinforcement of mesoporous molecular sieves, the tensile strength and elongation at break of the material are improved, and the Antioxidants and lubricants to improve processing performance.

- A method involving fluorination of polyolefin containers using a fluorination gas and a second gas, such as oxygen or halogens, in a controlled chamber environment to reduce extractable components and enhance barrier properties, specifically by exposing the containers to these gases for a controlled duration, then evacuating and returning to atmospheric conditions, resulting in treated containers with low perfluoroalkyl substances and maintaining weight integrity.

Regulatory Framework for HDPE in Medical Devices

The regulatory framework for HDPE in medical devices is a critical aspect of applying this material in health sector innovations. In the United States, the Food and Drug Administration (FDA) oversees the regulation of medical devices, including those incorporating HDPE. The FDA classifies medical devices into three categories based on their risk level and intended use, with Class I being the lowest risk and Class III the highest.

For HDPE-based medical devices, the classification depends on the specific application and intended use. Many HDPE devices fall under Class I or Class II, requiring general controls and special controls, respectively. Manufacturers must comply with the FDA's Quality System Regulation (QSR), which outlines good manufacturing practices for medical devices.

In the European Union, the regulatory landscape for HDPE medical devices is governed by the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR). These regulations establish a comprehensive framework for the safety and performance of medical devices, including those made from HDPE. Manufacturers must obtain CE marking to market their devices in the EU, demonstrating compliance with essential requirements.

The ISO 10993 series of standards is crucial for evaluating the biocompatibility of HDPE in medical devices. These standards provide guidelines for assessing the biological safety of materials used in medical applications. HDPE manufacturers and device makers must conduct appropriate biocompatibility tests to ensure the material's safety for its intended use.

Regulatory bodies also focus on the chemical composition and purity of HDPE used in medical devices. The material must meet specific requirements for additives, stabilizers, and potential leachables. The FDA's guidance on the use of plastics in medical devices provides recommendations for assessing the safety of these materials.

Environmental considerations are increasingly important in the regulatory framework. As sustainability becomes a priority, regulations may evolve to address the lifecycle management of HDPE medical devices, including recycling and disposal practices.

Manufacturers must also comply with labeling requirements, which vary depending on the device classification and intended use. Clear and accurate labeling is essential for ensuring proper use and safety of HDPE medical devices.

As the field of medical device regulation is dynamic, manufacturers must stay informed about updates and changes to regulatory requirements. Continuous monitoring and adaptation to evolving standards are crucial for maintaining compliance and market access for HDPE-based medical innovations.

Environmental Impact of HDPE in Healthcare

The environmental impact of High-Density Polyethylene (HDPE) in healthcare is a complex issue that requires careful consideration. HDPE is widely used in the healthcare sector due to its durability, chemical resistance, and versatility. However, its environmental footprint has raised concerns among healthcare professionals and environmentalists alike.

One of the primary environmental challenges associated with HDPE in healthcare is its contribution to plastic waste. Healthcare facilities generate significant amounts of plastic waste, with HDPE products such as medical packaging, containers, and disposable items being major contributors. The non-biodegradable nature of HDPE means that these products can persist in the environment for hundreds of years, potentially harming ecosystems and wildlife.

The production of HDPE also has environmental implications. The manufacturing process relies heavily on fossil fuels, contributing to greenhouse gas emissions and climate change. Additionally, the extraction of raw materials for HDPE production can lead to habitat destruction and biodiversity loss.

However, it's important to note that HDPE does offer some environmental benefits in healthcare applications. Its durability and reusability can reduce the need for single-use plastics in certain scenarios. HDPE's resistance to chemicals and bacteria also makes it an excellent choice for maintaining sterile environments, potentially reducing the use of harsh cleaning chemicals.

Recycling presents both a challenge and an opportunity for mitigating the environmental impact of HDPE in healthcare. While HDPE is recyclable, contamination with biological materials or hazardous substances often renders healthcare-related HDPE products unsuitable for conventional recycling processes. This necessitates the development of specialized recycling methods for healthcare plastics.

Innovations in HDPE formulations are emerging as potential solutions to reduce environmental impact. Bio-based HDPE, derived from renewable resources such as sugarcane, offers a more sustainable alternative to traditional petroleum-based HDPE. These bio-based alternatives have a lower carbon footprint and can help reduce dependence on fossil fuels.

The healthcare industry is also exploring ways to minimize HDPE waste through improved product design and waste management practices. This includes the development of reusable HDPE products, implementation of more efficient packaging designs, and the adoption of closed-loop recycling systems within healthcare facilities.

As the healthcare sector continues to prioritize sustainability, the environmental impact of HDPE remains a critical consideration. Balancing the material's benefits with its environmental drawbacks will be crucial in developing innovative, sustainable healthcare solutions that meet both clinical and ecological needs.