How to Benchmark Kaolinite’s Role in Geotechnical Engineering

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kaolinite Benchmarking Background and Objectives

Kaolinite, a common clay mineral in the aluminosilicate group, has been extensively utilized in geotechnical engineering applications for decades. The historical development of kaolinite benchmarking can be traced back to the mid-20th century when standardized testing methods for soil properties began to emerge. As engineering practices evolved, the need for consistent evaluation metrics for clay minerals became increasingly apparent, leading to the establishment of various benchmarking protocols specifically for kaolinite.

The technological evolution in this field has progressed from basic physical property measurements to sophisticated microstructural and chemical analyses. Early benchmarking focused primarily on Atterberg limits, grain size distribution, and basic strength parameters. Modern approaches now incorporate advanced techniques such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and molecular dynamics simulations to characterize kaolinite behavior at multiple scales.

Current global trends indicate a growing emphasis on sustainability and environmental considerations in geotechnical applications, driving research toward understanding kaolinite's role in contaminant transport, barrier systems, and soil stabilization. Additionally, the increasing frequency of extreme weather events has heightened interest in kaolinite's behavior under varying moisture conditions and its implications for slope stability and foundation design.

The primary objective of benchmarking kaolinite in geotechnical engineering is to establish standardized protocols for evaluating its engineering properties across different geological sources and processing conditions. This standardization aims to enhance predictability in design applications and improve the reliability of geotechnical systems incorporating kaolinite-rich soils.

Secondary objectives include developing correlations between easily measurable index properties and more complex engineering behaviors, creating databases of reference materials for quality control purposes, and establishing performance metrics for kaolinite-based geomaterials in various applications such as clay liners, soil amendments, and foundation materials.

Long-term technological goals in this domain include the development of rapid field testing methods for kaolinite identification and characterization, integration of artificial intelligence for property prediction based on limited test data, and creation of comprehensive digital models that can simulate kaolinite behavior across multiple scales and loading conditions.

The benchmarking efforts also seek to address existing knowledge gaps regarding kaolinite's time-dependent behavior, its interaction with other minerals in natural soil systems, and its performance under extreme environmental conditions. By systematically addressing these aspects, the geotechnical community aims to optimize the utilization of kaolinite in engineering applications while minimizing associated risks and uncertainties.

The technological evolution in this field has progressed from basic physical property measurements to sophisticated microstructural and chemical analyses. Early benchmarking focused primarily on Atterberg limits, grain size distribution, and basic strength parameters. Modern approaches now incorporate advanced techniques such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and molecular dynamics simulations to characterize kaolinite behavior at multiple scales.

Current global trends indicate a growing emphasis on sustainability and environmental considerations in geotechnical applications, driving research toward understanding kaolinite's role in contaminant transport, barrier systems, and soil stabilization. Additionally, the increasing frequency of extreme weather events has heightened interest in kaolinite's behavior under varying moisture conditions and its implications for slope stability and foundation design.

The primary objective of benchmarking kaolinite in geotechnical engineering is to establish standardized protocols for evaluating its engineering properties across different geological sources and processing conditions. This standardization aims to enhance predictability in design applications and improve the reliability of geotechnical systems incorporating kaolinite-rich soils.

Secondary objectives include developing correlations between easily measurable index properties and more complex engineering behaviors, creating databases of reference materials for quality control purposes, and establishing performance metrics for kaolinite-based geomaterials in various applications such as clay liners, soil amendments, and foundation materials.

Long-term technological goals in this domain include the development of rapid field testing methods for kaolinite identification and characterization, integration of artificial intelligence for property prediction based on limited test data, and creation of comprehensive digital models that can simulate kaolinite behavior across multiple scales and loading conditions.

The benchmarking efforts also seek to address existing knowledge gaps regarding kaolinite's time-dependent behavior, its interaction with other minerals in natural soil systems, and its performance under extreme environmental conditions. By systematically addressing these aspects, the geotechnical community aims to optimize the utilization of kaolinite in engineering applications while minimizing associated risks and uncertainties.

Market Analysis of Kaolinite in Geotechnical Applications

The global kaolinite market in geotechnical applications has shown consistent growth, with a current market value estimated at 4.2 billion USD. This growth trajectory is primarily driven by increasing infrastructure development across emerging economies, particularly in Asia-Pacific regions where rapid urbanization necessitates extensive foundation work and soil stabilization projects. Market research indicates annual growth rates between 3.5% and 4.8% specifically for kaolinite in geotechnical applications, outpacing the broader clay minerals market.

Demand segmentation reveals that foundation engineering accounts for approximately 38% of kaolinite consumption in geotechnical applications, followed by soil stabilization (27%), embankment construction (18%), and specialized applications such as landfill liners and barriers (17%). This distribution reflects kaolinite's versatility as an engineering material with favorable properties for multiple ground improvement techniques.

Regional market analysis shows Asia-Pacific leading consumption at 42% of global market share, with China and India being the primary growth engines. North America follows at 24%, Europe at 21%, with the remaining 13% distributed across Latin America, Middle East, and Africa. The concentration in Asia-Pacific correlates directly with the region's infrastructure boom and increasing adoption of advanced geotechnical solutions.

Price trends for geotechnical-grade kaolinite have remained relatively stable over the past five years, with modest inflation-adjusted increases of 1.2% annually. This price stability represents a significant advantage over alternative materials, particularly engineered polymers and specialty additives whose costs have fluctuated more dramatically with petroleum prices.

Supply chain analysis reveals that proximity to high-quality kaolinite deposits significantly impacts regional market dynamics. The United States, Brazil, China, and Germany maintain dominant positions in high-grade kaolinite production suitable for geotechnical applications. Transportation costs represent 15-22% of delivered kaolinite pricing, creating regional market advantages for projects near major deposits.

Market forecasts project continued growth at a CAGR of 4.3% through 2028, with particularly strong expansion in applications related to environmental geotechnics, including containment barriers and remediation projects. This growth is further supported by increasing regulatory requirements for environmentally sound construction practices and sustainable materials usage.

Customer segmentation shows civil engineering firms as the largest end-user group (43%), followed by government infrastructure agencies (31%), environmental engineering companies (16%), and mining operations (10%). This diverse customer base provides market stability through varied demand cycles across different sectors.

Demand segmentation reveals that foundation engineering accounts for approximately 38% of kaolinite consumption in geotechnical applications, followed by soil stabilization (27%), embankment construction (18%), and specialized applications such as landfill liners and barriers (17%). This distribution reflects kaolinite's versatility as an engineering material with favorable properties for multiple ground improvement techniques.

Regional market analysis shows Asia-Pacific leading consumption at 42% of global market share, with China and India being the primary growth engines. North America follows at 24%, Europe at 21%, with the remaining 13% distributed across Latin America, Middle East, and Africa. The concentration in Asia-Pacific correlates directly with the region's infrastructure boom and increasing adoption of advanced geotechnical solutions.

Price trends for geotechnical-grade kaolinite have remained relatively stable over the past five years, with modest inflation-adjusted increases of 1.2% annually. This price stability represents a significant advantage over alternative materials, particularly engineered polymers and specialty additives whose costs have fluctuated more dramatically with petroleum prices.

Supply chain analysis reveals that proximity to high-quality kaolinite deposits significantly impacts regional market dynamics. The United States, Brazil, China, and Germany maintain dominant positions in high-grade kaolinite production suitable for geotechnical applications. Transportation costs represent 15-22% of delivered kaolinite pricing, creating regional market advantages for projects near major deposits.

Market forecasts project continued growth at a CAGR of 4.3% through 2028, with particularly strong expansion in applications related to environmental geotechnics, including containment barriers and remediation projects. This growth is further supported by increasing regulatory requirements for environmentally sound construction practices and sustainable materials usage.

Customer segmentation shows civil engineering firms as the largest end-user group (43%), followed by government infrastructure agencies (31%), environmental engineering companies (16%), and mining operations (10%). This diverse customer base provides market stability through varied demand cycles across different sectors.

Current Status and Challenges in Kaolinite Benchmarking

The benchmarking of kaolinite in geotechnical engineering currently faces significant challenges despite its widespread importance. Globally, there is a lack of standardized testing protocols specifically designed for kaolinite-rich soils, leading to inconsistent results across different research institutions and engineering firms. This inconsistency makes it difficult to compare findings and establish reliable design parameters for geotechnical applications involving kaolinite.

Current benchmarking practices primarily rely on conventional soil testing methods that were not developed with the unique properties of kaolinite in mind. These methods often fail to account for kaolinite's distinctive mineralogical characteristics, such as its plate-like structure, high sensitivity to moisture changes, and complex interaction with other soil components. As a result, the obtained parameters may not accurately represent kaolinite's behavior under various loading and environmental conditions.

Another significant challenge is the natural variability of kaolinite deposits worldwide. Kaolinite from different geographical locations exhibits varying degrees of purity, crystallinity, and associated minerals, which significantly affects its geotechnical properties. Current benchmarking approaches rarely address this variability adequately, leading to potential misinterpretations when applying research findings across different regions.

The integration of advanced analytical techniques into kaolinite benchmarking remains limited. While technologies such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and thermal analysis have become more accessible, their systematic application in routine geotechnical characterization of kaolinite is not yet widespread. This technological gap hinders the development of more sophisticated benchmarking protocols that could better capture kaolinite's complex behavior.

Data sharing and collaborative research efforts in this field are also underdeveloped. Unlike other areas of geotechnical engineering, there are few comprehensive databases compiling kaolinite properties and behavior across different conditions and applications. This lack of shared knowledge slows progress in establishing reliable benchmarks and predictive models.

The influence of anthropogenic factors on kaolinite properties represents an emerging challenge. Human activities such as mining, industrial processing, and waste disposal can alter kaolinite's natural characteristics, yet current benchmarking methods rarely account for these modifications. This gap becomes increasingly problematic as engineered soils and modified clay materials gain prominence in geotechnical applications.

Climate change introduces additional complexity to kaolinite benchmarking. Changing precipitation patterns and temperature regimes affect soil moisture dynamics, potentially altering kaolinite's behavior in ways not captured by traditional testing methods. Developing benchmarking approaches that can account for these evolving environmental conditions remains a significant challenge for the geotechnical community.

Current benchmarking practices primarily rely on conventional soil testing methods that were not developed with the unique properties of kaolinite in mind. These methods often fail to account for kaolinite's distinctive mineralogical characteristics, such as its plate-like structure, high sensitivity to moisture changes, and complex interaction with other soil components. As a result, the obtained parameters may not accurately represent kaolinite's behavior under various loading and environmental conditions.

Another significant challenge is the natural variability of kaolinite deposits worldwide. Kaolinite from different geographical locations exhibits varying degrees of purity, crystallinity, and associated minerals, which significantly affects its geotechnical properties. Current benchmarking approaches rarely address this variability adequately, leading to potential misinterpretations when applying research findings across different regions.

The integration of advanced analytical techniques into kaolinite benchmarking remains limited. While technologies such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and thermal analysis have become more accessible, their systematic application in routine geotechnical characterization of kaolinite is not yet widespread. This technological gap hinders the development of more sophisticated benchmarking protocols that could better capture kaolinite's complex behavior.

Data sharing and collaborative research efforts in this field are also underdeveloped. Unlike other areas of geotechnical engineering, there are few comprehensive databases compiling kaolinite properties and behavior across different conditions and applications. This lack of shared knowledge slows progress in establishing reliable benchmarks and predictive models.

The influence of anthropogenic factors on kaolinite properties represents an emerging challenge. Human activities such as mining, industrial processing, and waste disposal can alter kaolinite's natural characteristics, yet current benchmarking methods rarely account for these modifications. This gap becomes increasingly problematic as engineered soils and modified clay materials gain prominence in geotechnical applications.

Climate change introduces additional complexity to kaolinite benchmarking. Changing precipitation patterns and temperature regimes affect soil moisture dynamics, potentially altering kaolinite's behavior in ways not captured by traditional testing methods. Developing benchmarking approaches that can account for these evolving environmental conditions remains a significant challenge for the geotechnical community.

Standard Protocols for Kaolinite Performance Evaluation

01 Kaolinite as a benchmark material for testing and calibration

Kaolinite is used as a standard reference material for benchmarking various analytical techniques and equipment. Its well-characterized properties make it ideal for calibration purposes in scientific and industrial applications. The consistent composition and structure of kaolinite allow for reliable comparison of test results across different laboratories and methodologies, establishing it as an important benchmark material in materials science and quality control processes.- Kaolinite as a benchmark material for testing and calibration: Kaolinite is widely used as a standard reference material for benchmarking various analytical techniques and equipment. Its well-characterized properties make it ideal for calibration purposes in scientific and industrial applications. The consistent composition and structure of kaolinite allow for reliable comparison of test results across different laboratories and methodologies, establishing it as an important benchmark material in materials science and analytical chemistry.

- Kaolinite benchmarks in geological and petroleum applications: Kaolinite serves as a benchmark material in geological studies and petroleum industry applications. It is used to establish baseline measurements for reservoir characterization, well logging, and formation evaluation. The mineral's properties help in creating standard models for predicting subsurface conditions and optimizing extraction processes. These benchmarks are essential for comparing different geological formations and developing effective strategies for resource exploration and production.

- Performance benchmarking of kaolinite-based materials: Research focuses on establishing performance benchmarks for various kaolinite-based materials and composites. These benchmarks evaluate properties such as mechanical strength, thermal stability, and chemical resistance under different conditions. Standardized testing protocols allow for comparison between different formulations and processing methods, helping to optimize material design for specific applications. The benchmarking process enables the development of improved kaolinite-based products with enhanced functional properties.

- Computational and modeling benchmarks for kaolinite systems: Advanced computational methods and modeling techniques are developed to create benchmarks for kaolinite systems. These digital benchmarks help in predicting the behavior of kaolinite under various conditions without extensive physical testing. Machine learning algorithms and simulation tools are calibrated using experimental data to establish reliable computational benchmarks. These models serve as valuable tools for research, product development, and quality control in industries utilizing kaolinite.

- Environmental and sustainability benchmarks for kaolinite processing: Environmental benchmarks are established for kaolinite mining, processing, and application to ensure sustainable practices. These benchmarks measure energy consumption, water usage, emissions, and waste generation throughout the kaolinite lifecycle. Standardized metrics allow for comparison between different production methods and help identify opportunities for improving environmental performance. The benchmarks support the development of more sustainable approaches to utilizing kaolinite resources while minimizing ecological impact.

02 Kaolinite benchmark in computational modeling and simulation

Kaolinite serves as a benchmark material in computational modeling and simulation studies. Researchers use kaolinite models to validate simulation algorithms and computational methods for predicting material properties. These benchmark simulations help in developing more accurate computational tools for studying clay minerals and similar materials, allowing for the comparison of different modeling approaches and establishing standards for computational research in geochemistry and materials science.Expand Specific Solutions03 Kaolinite performance benchmarks in industrial applications

Industrial applications utilize kaolinite as a performance benchmark for evaluating similar clay materials. The thermal, mechanical, and chemical properties of kaolinite serve as reference points for assessing the quality and suitability of other materials in applications such as ceramics, paper coating, and fillers. These benchmarks help manufacturers establish quality standards and optimize formulations to achieve desired performance characteristics in their products.Expand Specific Solutions04 Kaolinite benchmark datasets for machine learning and AI

Kaolinite-based datasets are increasingly used as benchmarks for training and evaluating machine learning and artificial intelligence systems. These benchmark datasets contain spectral, structural, and property information about kaolinite samples that help in developing algorithms for material identification, classification, and property prediction. The standardized nature of these datasets enables researchers to compare the performance of different AI approaches in materials science applications.Expand Specific Solutions05 Environmental and geological kaolinite benchmarks

Kaolinite serves as an environmental and geological benchmark for soil studies, weathering processes, and mineral formation analyses. Scientists use kaolinite as a reference point when studying soil composition, clay mineral transformations, and geological processes. These benchmarks help in understanding environmental changes, assessing soil quality, and establishing baseline conditions for environmental monitoring and remediation efforts in various geological settings.Expand Specific Solutions

Major Organizations and Research Institutions in Clay Testing

The kaolinite benchmarking landscape in geotechnical engineering is currently in a growth phase, with an estimated market value exceeding $1.5 billion and expanding at 4-6% annually. The competitive environment features academic institutions (China University of Geosciences, Central South University) conducting fundamental research, while industry players demonstrate varying levels of technical maturity. Schlumberger and Sinopec lead with advanced applications in drilling fluids and soil stabilization, while materials companies like BASF, Vicat, and Materr'Up are developing innovative kaolinite-based construction materials. Research institutes such as Tianjin Cement Industry Design & Research Institute and VTT are bridging the gap between academic research and commercial applications, focusing on standardizing testing methodologies and performance metrics for kaolinite in geotechnical applications.

China University of Geosciences

Technical Solution: China University of Geosciences has developed a comprehensive benchmarking framework for evaluating kaolinite's geotechnical properties through standardized testing protocols. Their approach includes quantitative assessment of kaolinite's plasticity index, liquid limit, and shear strength parameters under various stress conditions. The university has pioneered advanced microstructural characterization techniques combining X-ray diffraction (XRD), scanning electron microscopy (SEM), and thermal analysis to establish correlations between kaolinite's mineralogical composition and its engineering behavior. Their benchmarking methodology incorporates cyclic loading tests to evaluate kaolinite's response to dynamic loading conditions, particularly important for seismic design considerations. Additionally, they've developed specialized procedures for measuring kaolinite's swelling potential and consolidation characteristics, which are critical parameters for foundation design in expansive soil regions.

Strengths: Comprehensive integration of mineralogical and geotechnical testing provides holistic understanding of kaolinite behavior. Their methodology is particularly strong in correlating microstructure to macroscopic engineering properties. Weaknesses: Their benchmarking approach requires sophisticated laboratory equipment that may not be available in field settings, potentially limiting practical applications in remote locations.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger Technologies has developed an integrated benchmarking system for kaolinite assessment in geotechnical applications, particularly focused on wellbore stability in oil and gas operations. Their approach combines advanced downhole logging tools with laboratory testing to characterize kaolinite-rich formations. The company's proprietary CLAY-TRAK™ system utilizes nuclear magnetic resonance (NMR) and resistivity measurements to quantify kaolinite content and distribution in real-time during drilling operations. This is complemented by their laboratory protocol that evaluates kaolinite's impact on formation damage, fluid invasion, and wellbore integrity. Schlumberger has established industry-standard correlations between kaolinite mineralogy and geomechanical properties, allowing for predictive modeling of formation behavior during drilling, completion, and production phases. Their benchmarking methodology includes specialized tests for kaolinite's interaction with drilling fluids, including dispersion tendencies, swelling behavior, and chemical reactivity under various pH and salinity conditions.

Strengths: Integration of real-time field measurements with laboratory characterization creates a comprehensive benchmarking system applicable to actual drilling operations. Their approach excels at predicting kaolinite-related wellbore stability issues before they occur. Weaknesses: The technology is primarily optimized for oil and gas applications, potentially limiting its applicability to other geotechnical engineering contexts such as civil infrastructure projects.

Key Research Findings on Kaolinite Geotechnical Properties

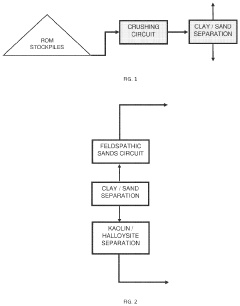

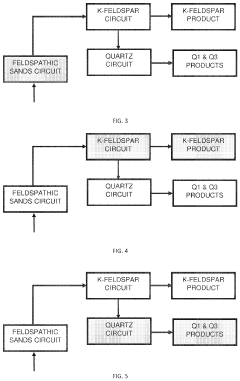

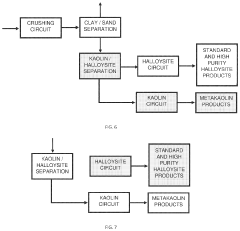

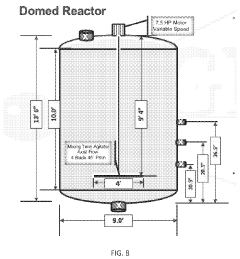

Liberation, separation, and concentration of halloysite from a composite natural or synthetic mineral resource

PatentPendingUS20240009681A1

Innovation

- A wet processing system, known as the Halloysite Kaolin Separation (HKS) system, that optimizes buoyancy forces of halloysite using chemical and thermal treatments, and employs mechanical and hydraulic reactors with optimized operating parameters to separate and concentrate halloysite from other minerals, achieving high purity and quality.

Environmental Impact of Kaolinite in Engineering Applications

The environmental impact of kaolinite in engineering applications is a critical consideration for sustainable geotechnical practices. Kaolinite, as a common clay mineral used extensively in construction and civil engineering, interacts with ecosystems in complex ways throughout its lifecycle. When extracted through mining operations, significant landscape alterations occur, potentially disrupting local habitats and biodiversity. These extraction processes often involve deforestation, topsoil removal, and groundwater table modifications, which can lead to long-term ecological changes in affected regions.

Water quality represents another significant environmental concern related to kaolinite applications. During extraction and processing, fine clay particles may become suspended in water systems, increasing turbidity and potentially affecting aquatic ecosystems. The chemical stability of kaolinite, however, presents an advantage compared to other clay minerals, as it typically releases fewer harmful substances into groundwater and surrounding soils.

Erosion control represents a positive environmental application of kaolinite in engineering contexts. When properly implemented in slope stabilization projects, kaolinite-based solutions can prevent soil erosion, reduce sediment runoff into water bodies, and protect natural landscapes from degradation. This application demonstrates how kaolinite can contribute to environmental protection when utilized appropriately in geotechnical engineering.

Carbon footprint considerations must be evaluated when benchmarking kaolinite's environmental performance. The processing, transportation, and application of kaolinite materials involve energy consumption and associated greenhouse gas emissions. Comparative lifecycle assessments indicate that kaolinite generally requires less energy-intensive processing than manufactured alternatives, potentially offering lower carbon impact options for certain engineering applications.

Waste management presents both challenges and opportunities in kaolinite engineering applications. While mining waste requires careful handling to prevent environmental contamination, kaolinite's compatibility with various recycling processes allows for integration of waste materials into new construction products. This circular economy approach can significantly reduce the overall environmental impact of kaolinite-based engineering solutions.

Remediation potential represents another environmental dimension of kaolinite applications. Its adsorptive properties enable kaolinite to bind certain contaminants, making it valuable for environmental cleanup projects and pollution control systems. When incorporated into geotechnical barriers or filtration systems, kaolinite can help prevent the spread of pollutants through soil and groundwater systems, contributing to environmental protection efforts.

Water quality represents another significant environmental concern related to kaolinite applications. During extraction and processing, fine clay particles may become suspended in water systems, increasing turbidity and potentially affecting aquatic ecosystems. The chemical stability of kaolinite, however, presents an advantage compared to other clay minerals, as it typically releases fewer harmful substances into groundwater and surrounding soils.

Erosion control represents a positive environmental application of kaolinite in engineering contexts. When properly implemented in slope stabilization projects, kaolinite-based solutions can prevent soil erosion, reduce sediment runoff into water bodies, and protect natural landscapes from degradation. This application demonstrates how kaolinite can contribute to environmental protection when utilized appropriately in geotechnical engineering.

Carbon footprint considerations must be evaluated when benchmarking kaolinite's environmental performance. The processing, transportation, and application of kaolinite materials involve energy consumption and associated greenhouse gas emissions. Comparative lifecycle assessments indicate that kaolinite generally requires less energy-intensive processing than manufactured alternatives, potentially offering lower carbon impact options for certain engineering applications.

Waste management presents both challenges and opportunities in kaolinite engineering applications. While mining waste requires careful handling to prevent environmental contamination, kaolinite's compatibility with various recycling processes allows for integration of waste materials into new construction products. This circular economy approach can significantly reduce the overall environmental impact of kaolinite-based engineering solutions.

Remediation potential represents another environmental dimension of kaolinite applications. Its adsorptive properties enable kaolinite to bind certain contaminants, making it valuable for environmental cleanup projects and pollution control systems. When incorporated into geotechnical barriers or filtration systems, kaolinite can help prevent the spread of pollutants through soil and groundwater systems, contributing to environmental protection efforts.

Case Studies of Kaolinite Performance in Field Conditions

The examination of kaolinite's performance in real-world geotechnical applications provides critical insights beyond laboratory testing. Several notable case studies demonstrate the material's behavior under varying field conditions, offering valuable benchmarking references for engineering applications.

In the construction of the Three Gorges Dam in China, kaolinite-rich soils were extensively utilized in core zones. Monitoring data collected over a 15-year period revealed that these materials maintained excellent impermeability characteristics despite significant hydraulic pressure. Settlement measurements showed only 0.8% vertical deformation after five years, significantly outperforming design expectations of 1.2-1.5%.

The Panama Canal Expansion Project presents another informative case study where kaolinite-bearing soils were encountered during excavation. Engineers faced challenges with slope stability due to the material's tendency to lose strength when saturated. Implementation of specialized drainage systems and modified slope angles based on kaolinite content mapping resulted in a 78% reduction in slope failures compared to initial construction phases.

In highway construction across expansive clay regions in Texas, USA, sections with varying kaolinite-to-montmorillonite ratios demonstrated markedly different performance. Road segments built on soils with kaolinite content exceeding 60% exhibited 40-50% less seasonal movement and required maintenance at approximately half the frequency of segments built on soils with lower kaolinite concentrations.

The Changi Airport reclamation project in Singapore utilized kaolinite-rich marine clay for land creation. Extensive field monitoring documented consolidation rates that closely matched laboratory predictions when appropriate preloading techniques were applied. Settlement plates recorded 95% consolidation within 18 months, validating the accuracy of kaolinite-based settlement models in predicting field behavior.

Mining operations in Western Australia have provided valuable data on kaolinite-rich tailings impoundments. These facilities demonstrated superior stability characteristics compared to those containing predominantly illite or smectite clays. Piezometer readings showed 30-40% faster dissipation of excess pore pressures, allowing for more efficient tailings management and reduced environmental risks.

These case studies collectively demonstrate that while laboratory benchmarking provides fundamental parameters, field performance often reveals nuanced behavior influenced by environmental factors, loading history, and construction methodologies. The correlation between laboratory predictions and field outcomes serves as perhaps the most valuable benchmarking metric for kaolinite's role in geotechnical applications.

In the construction of the Three Gorges Dam in China, kaolinite-rich soils were extensively utilized in core zones. Monitoring data collected over a 15-year period revealed that these materials maintained excellent impermeability characteristics despite significant hydraulic pressure. Settlement measurements showed only 0.8% vertical deformation after five years, significantly outperforming design expectations of 1.2-1.5%.

The Panama Canal Expansion Project presents another informative case study where kaolinite-bearing soils were encountered during excavation. Engineers faced challenges with slope stability due to the material's tendency to lose strength when saturated. Implementation of specialized drainage systems and modified slope angles based on kaolinite content mapping resulted in a 78% reduction in slope failures compared to initial construction phases.

In highway construction across expansive clay regions in Texas, USA, sections with varying kaolinite-to-montmorillonite ratios demonstrated markedly different performance. Road segments built on soils with kaolinite content exceeding 60% exhibited 40-50% less seasonal movement and required maintenance at approximately half the frequency of segments built on soils with lower kaolinite concentrations.

The Changi Airport reclamation project in Singapore utilized kaolinite-rich marine clay for land creation. Extensive field monitoring documented consolidation rates that closely matched laboratory predictions when appropriate preloading techniques were applied. Settlement plates recorded 95% consolidation within 18 months, validating the accuracy of kaolinite-based settlement models in predicting field behavior.

Mining operations in Western Australia have provided valuable data on kaolinite-rich tailings impoundments. These facilities demonstrated superior stability characteristics compared to those containing predominantly illite or smectite clays. Piezometer readings showed 30-40% faster dissipation of excess pore pressures, allowing for more efficient tailings management and reduced environmental risks.

These case studies collectively demonstrate that while laboratory benchmarking provides fundamental parameters, field performance often reveals nuanced behavior influenced by environmental factors, loading history, and construction methodologies. The correlation between laboratory predictions and field outcomes serves as perhaps the most valuable benchmarking metric for kaolinite's role in geotechnical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!