How to Design Current Collectors & Surface Textures

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Current Collector Design Background and Objectives

Current collectors serve as critical components in electrochemical energy storage and conversion devices, facilitating efficient electron transfer between active materials and external circuits. The evolution of current collector design has progressed from simple metal foils to sophisticated engineered structures with tailored surface textures. This technological progression has been driven by increasing demands for higher energy density, faster charging capabilities, and longer cycle life in batteries, fuel cells, and supercapacitors.

The historical development of current collectors began with conventional flat metal substrates, primarily copper and aluminum foils, which provided basic electrical conductivity. As energy storage technologies advanced, limitations in these simple designs became apparent, particularly regarding interfacial contact, adhesion to active materials, and electrochemical stability under various operating conditions.

Recent technological trends have shifted toward engineered current collectors with optimized surface textures. These designs aim to enhance the electrode-collector interface, increase active material loading, and improve overall device performance. Three-dimensional architectures, nano-textured surfaces, and hierarchical structures represent the cutting edge of current collector innovation, enabling greater surface area and more efficient electron pathways.

The primary objectives of modern current collector design focus on several key aspects. First, maximizing electrical conductivity while minimizing internal resistance to reduce energy losses during charge-discharge cycles. Second, enhancing mechanical stability to withstand volume changes in active materials during cycling, thereby extending device lifespan. Third, optimizing the interface between active materials and the collector surface to ensure robust adhesion and efficient charge transfer.

Additionally, current collector designs increasingly aim to facilitate mass production and cost-effective manufacturing while maintaining performance benefits. This includes developing surface texturing techniques compatible with roll-to-roll processing and other scalable manufacturing methods. Environmental considerations have also emerged as important design factors, with research focusing on reducing the use of rare or toxic materials and improving recyclability.

The technological goals for next-generation current collectors include developing multifunctional surfaces that not only conduct electrons efficiently but also address challenges such as dendrite formation in lithium-metal batteries, catalyst utilization in fuel cells, and electrolyte distribution in flow batteries. These advanced designs seek to transform current collectors from passive components to active elements that contribute significantly to overall device performance and longevity.

The historical development of current collectors began with conventional flat metal substrates, primarily copper and aluminum foils, which provided basic electrical conductivity. As energy storage technologies advanced, limitations in these simple designs became apparent, particularly regarding interfacial contact, adhesion to active materials, and electrochemical stability under various operating conditions.

Recent technological trends have shifted toward engineered current collectors with optimized surface textures. These designs aim to enhance the electrode-collector interface, increase active material loading, and improve overall device performance. Three-dimensional architectures, nano-textured surfaces, and hierarchical structures represent the cutting edge of current collector innovation, enabling greater surface area and more efficient electron pathways.

The primary objectives of modern current collector design focus on several key aspects. First, maximizing electrical conductivity while minimizing internal resistance to reduce energy losses during charge-discharge cycles. Second, enhancing mechanical stability to withstand volume changes in active materials during cycling, thereby extending device lifespan. Third, optimizing the interface between active materials and the collector surface to ensure robust adhesion and efficient charge transfer.

Additionally, current collector designs increasingly aim to facilitate mass production and cost-effective manufacturing while maintaining performance benefits. This includes developing surface texturing techniques compatible with roll-to-roll processing and other scalable manufacturing methods. Environmental considerations have also emerged as important design factors, with research focusing on reducing the use of rare or toxic materials and improving recyclability.

The technological goals for next-generation current collectors include developing multifunctional surfaces that not only conduct electrons efficiently but also address challenges such as dendrite formation in lithium-metal batteries, catalyst utilization in fuel cells, and electrolyte distribution in flow batteries. These advanced designs seek to transform current collectors from passive components to active elements that contribute significantly to overall device performance and longevity.

Market Analysis for Advanced Current Collector Solutions

The current collector market is experiencing significant growth driven by the expanding energy storage sector, particularly lithium-ion batteries for electric vehicles and renewable energy systems. Market research indicates that the global current collector market is projected to reach $5.2 billion by 2027, growing at a CAGR of 8.3% from 2022. This growth is primarily fueled by the electric vehicle revolution, with global EV sales exceeding 10 million units in 2022 and expected to reach 30 million by 2030.

Advanced current collector solutions are increasingly in demand as battery manufacturers seek to enhance energy density, charging rates, and overall battery performance. The market is segmented by material type, with aluminum foil dominating the cathode current collector segment and copper foil leading the anode segment. These materials account for approximately 70% of the total current collector market value.

Regional analysis reveals Asia-Pacific as the dominant market, holding over 60% of the global share, with China, Japan, and South Korea as key manufacturing hubs. North America and Europe are experiencing rapid growth rates of 9.5% and 8.7% respectively, driven by domestic battery production initiatives and government incentives for clean energy technologies.

The surface texture modification segment is emerging as a high-growth area, with specialized coatings and texturing technologies showing a market growth rate of 12.4% annually. This sub-segment is particularly valuable as it addresses critical performance issues such as adhesion strength, electrical conductivity, and electrochemical stability at the electrode-collector interface.

Consumer electronics remains the largest application segment, accounting for 42% of current collector demand, followed by automotive applications at 38%. However, the automotive sector is growing at a faster rate and is expected to become the dominant application by 2025.

Key market drivers include the push for fast-charging capabilities, which requires current collectors with enhanced thermal management properties and lower electrical resistance. Additionally, the trend toward thinner and lighter batteries is creating demand for ultra-thin current collectors with high mechanical strength and flexibility.

Market challenges include volatile raw material prices, particularly for copper, which has seen price fluctuations of up to 30% in recent years. Environmental concerns related to the manufacturing processes of current collectors are also influencing market dynamics, with sustainable production methods gaining traction among environmentally conscious consumers and regulatory bodies.

Advanced current collector solutions are increasingly in demand as battery manufacturers seek to enhance energy density, charging rates, and overall battery performance. The market is segmented by material type, with aluminum foil dominating the cathode current collector segment and copper foil leading the anode segment. These materials account for approximately 70% of the total current collector market value.

Regional analysis reveals Asia-Pacific as the dominant market, holding over 60% of the global share, with China, Japan, and South Korea as key manufacturing hubs. North America and Europe are experiencing rapid growth rates of 9.5% and 8.7% respectively, driven by domestic battery production initiatives and government incentives for clean energy technologies.

The surface texture modification segment is emerging as a high-growth area, with specialized coatings and texturing technologies showing a market growth rate of 12.4% annually. This sub-segment is particularly valuable as it addresses critical performance issues such as adhesion strength, electrical conductivity, and electrochemical stability at the electrode-collector interface.

Consumer electronics remains the largest application segment, accounting for 42% of current collector demand, followed by automotive applications at 38%. However, the automotive sector is growing at a faster rate and is expected to become the dominant application by 2025.

Key market drivers include the push for fast-charging capabilities, which requires current collectors with enhanced thermal management properties and lower electrical resistance. Additionally, the trend toward thinner and lighter batteries is creating demand for ultra-thin current collectors with high mechanical strength and flexibility.

Market challenges include volatile raw material prices, particularly for copper, which has seen price fluctuations of up to 30% in recent years. Environmental concerns related to the manufacturing processes of current collectors are also influencing market dynamics, with sustainable production methods gaining traction among environmentally conscious consumers and regulatory bodies.

Technical Challenges in Current Collector and Surface Texture Development

The development of current collectors and surface textures faces significant technical challenges that require innovative solutions. The primary obstacle lies in balancing electrical conductivity with mechanical stability. Current collectors must maintain excellent electrical contact with active materials while withstanding mechanical stresses during charge-discharge cycles. This becomes particularly challenging as battery technologies advance toward higher energy densities and faster charging capabilities.

Material selection presents another critical challenge. Traditional copper and aluminum collectors suffer from corrosion in certain electrolytes, limiting battery lifespan. Advanced materials like carbon-based collectors or metal alloys show promise but introduce manufacturing complexities and cost concerns. The interface between current collectors and active materials remains problematic, with delamination and contact resistance issues persisting despite various bonding techniques.

Surface texture optimization involves complex trade-offs between surface area, adhesion strength, and electrical resistance. While rougher textures generally improve adhesion, they may increase electrical resistance and create potential hotspots. Conversely, smoother surfaces offer better conductivity but weaker mechanical bonding. This delicate balance requires precise engineering at the micro and nano scales.

Manufacturing scalability represents a significant hurdle. Laboratory-scale techniques for creating optimal surface textures often prove difficult to implement in mass production environments. Techniques like laser texturing, chemical etching, and physical vapor deposition each present unique scaling challenges related to throughput, consistency, and cost-effectiveness.

The durability of current collectors under extreme operating conditions remains problematic. High-temperature environments, fast-charging protocols, and extended cycling can lead to collector degradation through mechanisms including oxidation, mechanical fatigue, and electrolyte-induced corrosion. These failure modes are difficult to predict and mitigate, particularly as new battery chemistries emerge.

Characterization and modeling capabilities lag behind development needs. Current analytical techniques struggle to accurately measure interfacial properties between collectors and active materials under dynamic operating conditions. Computational models often fail to capture the complex interplay between electrical, mechanical, and chemical phenomena at these interfaces.

Environmental and sustainability concerns add another layer of complexity. Traditional manufacturing processes for current collectors involve environmentally harmful chemicals and significant energy consumption. Developing greener alternatives while maintaining performance specifications presents technical challenges that intersect with regulatory and market pressures.

Material selection presents another critical challenge. Traditional copper and aluminum collectors suffer from corrosion in certain electrolytes, limiting battery lifespan. Advanced materials like carbon-based collectors or metal alloys show promise but introduce manufacturing complexities and cost concerns. The interface between current collectors and active materials remains problematic, with delamination and contact resistance issues persisting despite various bonding techniques.

Surface texture optimization involves complex trade-offs between surface area, adhesion strength, and electrical resistance. While rougher textures generally improve adhesion, they may increase electrical resistance and create potential hotspots. Conversely, smoother surfaces offer better conductivity but weaker mechanical bonding. This delicate balance requires precise engineering at the micro and nano scales.

Manufacturing scalability represents a significant hurdle. Laboratory-scale techniques for creating optimal surface textures often prove difficult to implement in mass production environments. Techniques like laser texturing, chemical etching, and physical vapor deposition each present unique scaling challenges related to throughput, consistency, and cost-effectiveness.

The durability of current collectors under extreme operating conditions remains problematic. High-temperature environments, fast-charging protocols, and extended cycling can lead to collector degradation through mechanisms including oxidation, mechanical fatigue, and electrolyte-induced corrosion. These failure modes are difficult to predict and mitigate, particularly as new battery chemistries emerge.

Characterization and modeling capabilities lag behind development needs. Current analytical techniques struggle to accurately measure interfacial properties between collectors and active materials under dynamic operating conditions. Computational models often fail to capture the complex interplay between electrical, mechanical, and chemical phenomena at these interfaces.

Environmental and sustainability concerns add another layer of complexity. Traditional manufacturing processes for current collectors involve environmentally harmful chemicals and significant energy consumption. Developing greener alternatives while maintaining performance specifications presents technical challenges that intersect with regulatory and market pressures.

State-of-the-Art Current Collector Design Methodologies

01 Surface texture modifications for enhanced current collection

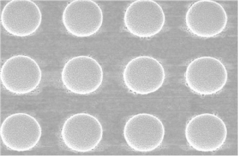

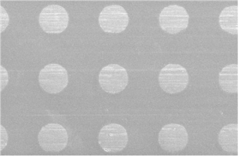

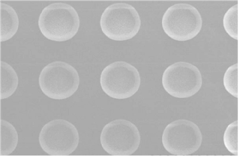

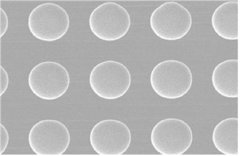

Surface texturing techniques can significantly improve the performance of current collectors by increasing the contact area between the collector and active materials. These modifications include creating micro or nano-scale patterns, roughened surfaces, or specific geometric structures that enhance electrical conductivity and reduce contact resistance. Such textured surfaces also improve adhesion of active materials to the current collector, leading to better electrochemical performance and longer cycle life in battery applications.- Textured surfaces for enhanced current collection: Surface texturing techniques can significantly improve the efficiency of current collectors by increasing the contact area between the collector and active materials. These textures can include micro or nano-scale patterns, roughened surfaces, or specific geometric designs that enhance electrical conductivity and reduce contact resistance. The textured surfaces also provide better adhesion for active materials, resulting in improved overall battery or electrical device performance.

- Conductive coatings and materials for current collectors: Various conductive materials and coatings can be applied to current collectors to enhance their performance. These include metal alloys, carbon-based materials, and conductive polymers that improve electrical conductivity while maintaining structural integrity. The selection of appropriate coating materials can reduce internal resistance, prevent corrosion, and extend the lifespan of energy storage devices while improving energy density and power output.

- 3D structured current collectors: Three-dimensional current collector designs offer advantages over traditional flat collectors by providing increased surface area and improved mechanical stability. These structures can include foam-like networks, pillared architectures, or other complex geometries that allow for better ion transport and electron collection. The 3D structures also accommodate volume changes in active materials during charge-discharge cycles, leading to enhanced cycling stability and performance.

- Flexible and stretchable current collectors: Flexible and stretchable current collectors are designed for applications requiring bendable or wearable energy storage solutions. These collectors typically incorporate specialized materials and structural designs that maintain electrical conductivity under mechanical deformation. The flexibility allows for integration into curved surfaces or dynamic environments while maintaining efficient current collection capabilities, making them suitable for next-generation flexible electronics and wearable devices.

- Current collector manufacturing techniques: Advanced manufacturing methods for current collectors include electrodeposition, etching, laser patterning, and additive manufacturing processes. These techniques enable precise control over surface morphology, thickness, and structural features of current collectors. The manufacturing approach significantly influences the final properties of the collector, including its conductivity, durability, and compatibility with active materials, ultimately affecting the performance of the energy storage or generation device.

02 Conductive coatings and materials for current collectors

Various conductive materials and coatings can be applied to current collectors to enhance their performance. These include carbon-based materials, metal alloys, and conductive polymers that improve electrical conductivity while maintaining mechanical integrity. The selection of appropriate coating materials depends on the specific application requirements, such as operating environment, temperature range, and compatibility with active materials. These coatings can also provide protection against corrosion and oxidation, extending the lifespan of the current collector.Expand Specific Solutions03 Three-dimensional current collector designs

Three-dimensional current collector architectures offer advantages over traditional flat designs by providing increased surface area for active material loading and improved electron transport pathways. These designs include foam-like structures, mesh networks, and hierarchical architectures that facilitate faster ion and electron transport. The 3D structures also accommodate volume changes during charge-discharge cycles, reducing mechanical stress and improving cycle stability. Such designs are particularly beneficial for high-capacity and high-power applications.Expand Specific Solutions04 Current collector designs for specific battery technologies

Specialized current collector designs are developed for specific battery chemistries and configurations to optimize performance. These designs consider factors such as the electrochemical properties of active materials, operating conditions, and form factor requirements. For lithium-ion batteries, thin metal foils with specific surface treatments are commonly used, while for solid-state batteries, different architectures may be required to ensure good contact with solid electrolytes. The design also accounts for thermal management and safety considerations specific to each battery technology.Expand Specific Solutions05 Manufacturing techniques for textured current collectors

Various manufacturing processes are employed to create textured current collectors with desired surface properties. These include electrodeposition, etching, laser patterning, roll-to-roll processing, and additive manufacturing techniques. Each method offers different capabilities in terms of feature resolution, scalability, and cost-effectiveness. Advanced manufacturing approaches enable precise control over surface morphology, porosity, and structural integrity, allowing for optimization of current collector performance for specific applications while maintaining compatibility with large-scale production requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions in the Field

The current collector and surface texture design market is in a growth phase, with increasing demand driven by the expanding electric vehicle and energy storage sectors. The market size is projected to reach significant scale as companies like Contemporary Amperex Technology, BYD, Samsung SDI, and Panasonic Holdings compete for dominance in battery technology. Technical maturity varies across applications, with established players like 3M Innovative Properties and DuPont offering advanced solutions, while newer entrants like Beihang University and Yunasko contribute innovative approaches. Automotive giants Toyota and GM are investing heavily in proprietary current collector technologies, indicating the strategic importance of this component in next-generation energy systems.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed advanced current collector designs featuring nano-structured surface textures that significantly enhance electrode-collector interfaces. Their proprietary technology employs a dual-layer copper current collector with a nano-porous surface layer that increases the effective surface area by up to 300% compared to traditional flat collectors[1]. This design incorporates controlled surface roughness patterns at the micro and nano scales, created through selective etching processes and electrodeposition techniques. CATL's approach includes applying specialized carbon-based conductive coatings with optimized thickness (typically 2-5μm) to reduce interfacial resistance while maintaining mechanical integrity. Their collectors feature engineered adhesion-promoting textures that enhance the mechanical bonding between active materials and collector surfaces, reducing delamination issues during cycling[3]. Recent innovations include gradient porosity structures that facilitate more uniform current distribution across the electrode surface.

Strengths: Superior electrode adhesion reducing delamination issues; enhanced electrical conductivity reducing internal resistance; improved cycle life performance due to better mechanical stability. Weaknesses: More complex manufacturing process increasing production costs; potential challenges in quality control for nano-textured surfaces; slightly increased weight compared to conventional collectors.

Panasonic Holdings Corp.

Technical Solution: Panasonic has pioneered a multi-faceted approach to current collector design focusing on surface modification technologies. Their collectors utilize a proprietary etching process that creates micro-scale honeycomb patterns with controlled depth (4-8μm) and diameter (10-20μm), optimizing the balance between surface area and mechanical strength[2]. This technology incorporates specialized metal alloys with copper or aluminum bases, modified with trace elements to enhance corrosion resistance while maintaining high conductivity. Panasonic's collectors feature gradient porosity designs where porosity decreases from the electrode interface toward the bulk collector, optimizing both adhesion and current flow. Their manufacturing process includes precision-controlled rolling techniques that introduce specific surface textures at multiple scales (macro, micro, and nano), creating hierarchical structures that maximize electrode contact area while minimizing material usage[4]. Additionally, Panasonic employs specialized surface treatments including plasma modification and application of nanoscale carbon coatings to further enhance interfacial properties.

Strengths: Excellent balance between electrical performance and manufacturing scalability; superior corrosion resistance extending battery lifetime; optimized weight-to-performance ratio. Weaknesses: Higher initial production costs compared to standard collectors; specialized equipment requirements for manufacturing; potential challenges in recycling modified collectors.

Key Patents and Innovations in Surface Texture Engineering

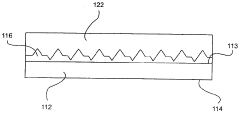

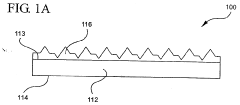

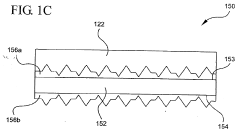

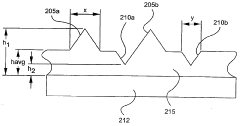

Current collectors having textured coating

PatentInactiveIN3054DELNP2012A

Innovation

- A current collector with a textured coating comprising peaks and valleys is used, which provides improved interfacial conduction and adhesion by balancing the advantages and disadvantages of thick and thin coatings, allowing for enhanced mechanical stability and thermal robustness without the need for preprocessing of the conductive layer.

Method for coating aluminum current collector surface having three-dimensional pattern structure using screen print

PatentInactiveJP2014229889A

Innovation

- A method using screen printing to form a three-dimensional pattern on the aluminum current collector, followed by selective etching and plating with nickel or tin to enhance contact area and prevent electrolyte reaction, involving steps like drying, masking, etching, and curing with controlled conditions.

Materials Selection and Compatibility Considerations

The selection of materials for current collectors in energy storage and conversion devices is a critical design consideration that directly impacts performance, durability, and cost-effectiveness. Copper and aluminum remain the industry standards for negative and positive electrodes respectively, primarily due to their excellent electrical conductivity, reasonable cost, and established manufacturing processes. However, these conventional materials face limitations in extreme operating conditions, particularly in high-temperature environments or when exposed to corrosive electrolytes.

Advanced material options include nickel-coated copper, which offers enhanced corrosion resistance while maintaining high conductivity. Carbon-based materials such as graphene and carbon nanotubes present promising alternatives with their exceptional mechanical flexibility and chemical stability, though challenges in mass production and cost remain significant barriers to widespread adoption.

Material compatibility with electrolytes demands particular attention, as unwanted chemical reactions at the interface can lead to performance degradation and safety concerns. The formation of passivation layers, while sometimes beneficial for stability, must be carefully controlled to prevent excessive electrical resistance. Recent research indicates that surface modification techniques, including atomic layer deposition of protective coatings, can significantly improve compatibility between current collectors and aggressive electrolyte formulations.

Thermal expansion coefficient matching between current collectors and active materials represents another critical consideration, especially for applications experiencing wide temperature fluctuations. Mismatched thermal expansion can induce mechanical stress, leading to delamination and connection failures. Composite materials with tailored expansion properties offer potential solutions to this challenge, though their implementation requires careful engineering and validation.

Environmental and economic factors increasingly influence material selection decisions. Sustainability concerns have prompted investigation into recyclable and less environmentally impactful alternatives to traditional materials. Aluminum, with its established recycling infrastructure, presents advantages in this regard, while research into bio-derived carbon materials shows promise for reducing environmental footprint.

Manufacturing compatibility must also be considered, as material choices directly impact production processes and scalability. Materials requiring specialized handling or processing techniques may offer superior technical performance but present challenges for mass production and cost management. The development of surface texturing techniques must therefore align with the selected material's properties to ensure manufacturability while achieving desired performance characteristics.

Advanced material options include nickel-coated copper, which offers enhanced corrosion resistance while maintaining high conductivity. Carbon-based materials such as graphene and carbon nanotubes present promising alternatives with their exceptional mechanical flexibility and chemical stability, though challenges in mass production and cost remain significant barriers to widespread adoption.

Material compatibility with electrolytes demands particular attention, as unwanted chemical reactions at the interface can lead to performance degradation and safety concerns. The formation of passivation layers, while sometimes beneficial for stability, must be carefully controlled to prevent excessive electrical resistance. Recent research indicates that surface modification techniques, including atomic layer deposition of protective coatings, can significantly improve compatibility between current collectors and aggressive electrolyte formulations.

Thermal expansion coefficient matching between current collectors and active materials represents another critical consideration, especially for applications experiencing wide temperature fluctuations. Mismatched thermal expansion can induce mechanical stress, leading to delamination and connection failures. Composite materials with tailored expansion properties offer potential solutions to this challenge, though their implementation requires careful engineering and validation.

Environmental and economic factors increasingly influence material selection decisions. Sustainability concerns have prompted investigation into recyclable and less environmentally impactful alternatives to traditional materials. Aluminum, with its established recycling infrastructure, presents advantages in this regard, while research into bio-derived carbon materials shows promise for reducing environmental footprint.

Manufacturing compatibility must also be considered, as material choices directly impact production processes and scalability. Materials requiring specialized handling or processing techniques may offer superior technical performance but present challenges for mass production and cost management. The development of surface texturing techniques must therefore align with the selected material's properties to ensure manufacturability while achieving desired performance characteristics.

Environmental Impact and Sustainability of Current Collector Materials

The environmental impact of current collector materials in energy storage and transmission systems represents a critical consideration in sustainable technology development. Traditional current collectors often utilize copper, aluminum, and other metals that require energy-intensive mining and processing operations. These processes contribute significantly to carbon emissions, with copper production alone generating approximately 3.3 tons of CO2 per ton of metal produced. Additionally, the extraction of these materials frequently results in habitat destruction, soil contamination, and water pollution in mining regions.

Recycling challenges present another environmental concern, as current collectors in batteries and electrical systems often incorporate composite materials or coatings that complicate end-of-life recovery processes. The efficiency of recycling these materials rarely exceeds 60-70% in commercial operations, resulting in substantial material loss and continued demand for virgin resources.

Water consumption represents a significant environmental burden, with copper processing requiring approximately 70-260 cubic meters of water per ton of metal produced. This intensive water usage creates particular sustainability challenges in water-stressed regions where many mining operations are located.

Recent innovations in sustainable current collector design include the development of carbon-based alternatives such as graphene and carbon nanotube structures, which demonstrate lower environmental impact during production while maintaining comparable electrical performance. These materials can reduce the embedded carbon footprint by up to 40% compared to traditional metallic collectors.

Surface texturing technologies have evolved to enhance performance while minimizing material requirements. Advanced laser etching and chemical treatment processes can improve current collector efficiency by 15-25% through optimized surface area and reduced contact resistance, thereby decreasing the overall material quantity needed for equivalent performance.

Biodegradable and bio-based current collectors represent an emerging research direction, with cellulose-derived conductive materials showing promise for low-power applications. These materials offer end-of-life advantages through natural decomposition pathways that traditional metallic collectors cannot match.

Life cycle assessment studies indicate that the environmental impact of current collectors extends beyond production to include operational efficiency and end-of-life management. The energy efficiency during operation can offset initial production impacts within 2-5 years of deployment in high-utilization scenarios, highlighting the importance of considering full lifecycle performance in sustainability evaluations.

Recycling challenges present another environmental concern, as current collectors in batteries and electrical systems often incorporate composite materials or coatings that complicate end-of-life recovery processes. The efficiency of recycling these materials rarely exceeds 60-70% in commercial operations, resulting in substantial material loss and continued demand for virgin resources.

Water consumption represents a significant environmental burden, with copper processing requiring approximately 70-260 cubic meters of water per ton of metal produced. This intensive water usage creates particular sustainability challenges in water-stressed regions where many mining operations are located.

Recent innovations in sustainable current collector design include the development of carbon-based alternatives such as graphene and carbon nanotube structures, which demonstrate lower environmental impact during production while maintaining comparable electrical performance. These materials can reduce the embedded carbon footprint by up to 40% compared to traditional metallic collectors.

Surface texturing technologies have evolved to enhance performance while minimizing material requirements. Advanced laser etching and chemical treatment processes can improve current collector efficiency by 15-25% through optimized surface area and reduced contact resistance, thereby decreasing the overall material quantity needed for equivalent performance.

Biodegradable and bio-based current collectors represent an emerging research direction, with cellulose-derived conductive materials showing promise for low-power applications. These materials offer end-of-life advantages through natural decomposition pathways that traditional metallic collectors cannot match.

Life cycle assessment studies indicate that the environmental impact of current collectors extends beyond production to include operational efficiency and end-of-life management. The energy efficiency during operation can offset initial production impacts within 2-5 years of deployment in high-utilization scenarios, highlighting the importance of considering full lifecycle performance in sustainability evaluations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!