How to Specify Separator for ZIBs — Porosity & Wetting

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ZIB Separator Technology Background and Objectives

Zinc-ion batteries (ZIBs) have emerged as promising alternatives to lithium-ion batteries due to their cost-effectiveness, environmental friendliness, and inherent safety advantages. The development of ZIBs can be traced back to the early 2000s, but significant advancements have only been achieved in the past decade. As energy storage demands continue to grow globally, ZIBs represent a sustainable solution that leverages zinc's abundance, low toxicity, and high theoretical capacity (820 mAh/g).

The separator component in ZIBs plays a crucial yet often overlooked role in battery performance and safety. Historically, separator technology has evolved from simple physical barriers to multifunctional components that actively contribute to electrochemical performance. The evolution of separator materials has progressed from traditional polyolefin membranes to advanced composite structures specifically designed for aqueous electrolyte systems.

Current technical objectives in ZIB separator development focus primarily on optimizing porosity and wetting properties, which directly impact ion transport efficiency, internal resistance, and overall battery performance. Porosity characteristics—including pore size distribution, tortuosity, and overall porosity percentage—determine the separator's ability to facilitate zinc ion migration while preventing dendrite penetration. Meanwhile, wetting properties affect electrolyte retention, interface stability, and long-term cycling performance.

The technological trajectory indicates a shift toward precisely engineered separator architectures with controlled porosity gradients and surface modifications to enhance hydrophilicity for aqueous electrolytes. Recent research demonstrates that optimizing these properties can significantly mitigate common ZIB failure mechanisms, including zinc dendrite growth, electrolyte depletion, and internal short circuits.

Industry objectives for ZIB separator technology include developing cost-effective manufacturing processes for advanced separators, establishing standardized testing protocols for porosity and wetting characterization, and creating design guidelines specific to zinc-based systems. The ultimate goal is to enable ZIBs with energy densities exceeding 150 Wh/kg, cycle lives of over 2000 cycles, and cost points below $100/kWh.

From a broader perspective, ZIB separator technology aims to address the limitations of current energy storage solutions by enabling safer, more sustainable batteries for applications ranging from grid-scale storage to portable electronics. The development of optimized separators with tailored porosity and wetting properties represents a critical pathway toward realizing the full potential of zinc-based energy storage technologies in the global transition to renewable energy systems.

The separator component in ZIBs plays a crucial yet often overlooked role in battery performance and safety. Historically, separator technology has evolved from simple physical barriers to multifunctional components that actively contribute to electrochemical performance. The evolution of separator materials has progressed from traditional polyolefin membranes to advanced composite structures specifically designed for aqueous electrolyte systems.

Current technical objectives in ZIB separator development focus primarily on optimizing porosity and wetting properties, which directly impact ion transport efficiency, internal resistance, and overall battery performance. Porosity characteristics—including pore size distribution, tortuosity, and overall porosity percentage—determine the separator's ability to facilitate zinc ion migration while preventing dendrite penetration. Meanwhile, wetting properties affect electrolyte retention, interface stability, and long-term cycling performance.

The technological trajectory indicates a shift toward precisely engineered separator architectures with controlled porosity gradients and surface modifications to enhance hydrophilicity for aqueous electrolytes. Recent research demonstrates that optimizing these properties can significantly mitigate common ZIB failure mechanisms, including zinc dendrite growth, electrolyte depletion, and internal short circuits.

Industry objectives for ZIB separator technology include developing cost-effective manufacturing processes for advanced separators, establishing standardized testing protocols for porosity and wetting characterization, and creating design guidelines specific to zinc-based systems. The ultimate goal is to enable ZIBs with energy densities exceeding 150 Wh/kg, cycle lives of over 2000 cycles, and cost points below $100/kWh.

From a broader perspective, ZIB separator technology aims to address the limitations of current energy storage solutions by enabling safer, more sustainable batteries for applications ranging from grid-scale storage to portable electronics. The development of optimized separators with tailored porosity and wetting properties represents a critical pathway toward realizing the full potential of zinc-based energy storage technologies in the global transition to renewable energy systems.

Market Analysis for Advanced ZIB Separators

The global market for zinc-ion battery (ZIB) separators is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions. Current market valuation stands at approximately $320 million in 2023, with projections indicating a compound annual growth rate of 18.7% through 2030, potentially reaching $1.2 billion by the end of the decade.

The demand for advanced ZIB separators is primarily fueled by the expanding renewable energy sector, which requires efficient and cost-effective energy storage systems. Additionally, the automotive industry's shift toward electrification has created substantial opportunities for ZIB technology as a complementary solution to lithium-ion batteries, particularly in applications where safety, cost, and sustainability are prioritized over energy density.

Market segmentation reveals that separators with optimized porosity and wetting properties command premium pricing, typically 30-40% higher than conventional alternatives. This price differential reflects the performance advantages these advanced separators offer, including improved cycle life, enhanced charge-discharge efficiency, and reduced dendrite formation.

Regionally, Asia-Pacific dominates the ZIB separator market with approximately 65% market share, led by China's aggressive investments in renewable energy infrastructure and battery manufacturing capabilities. North America and Europe follow with 18% and 14% respectively, with both regions showing accelerated adoption rates as environmental regulations tighten and renewable energy targets become more ambitious.

Consumer electronics represents the largest application segment (38% of market share), followed by grid storage (27%) and electric vehicles (21%). However, the fastest growth is observed in the stationary storage sector, which is expanding at nearly 25% annually as utilities and commercial entities invest in peak shaving and backup power solutions.

Market research indicates that separator manufacturers focusing on porosity optimization and enhanced wetting properties are experiencing above-average revenue growth. Specifically, companies offering separators with porosity ranges of 40-60% and advanced hydrophilic surface treatments have reported sales growth exceeding industry averages by 7-9 percentage points.

The competitive landscape features both established membrane manufacturers diversifying into ZIB applications and specialized startups focused exclusively on advanced separator technologies. Strategic partnerships between separator manufacturers and battery producers have increased by 35% in the past two years, indicating the critical importance of separator technology in overall battery performance and market acceptance.

The demand for advanced ZIB separators is primarily fueled by the expanding renewable energy sector, which requires efficient and cost-effective energy storage systems. Additionally, the automotive industry's shift toward electrification has created substantial opportunities for ZIB technology as a complementary solution to lithium-ion batteries, particularly in applications where safety, cost, and sustainability are prioritized over energy density.

Market segmentation reveals that separators with optimized porosity and wetting properties command premium pricing, typically 30-40% higher than conventional alternatives. This price differential reflects the performance advantages these advanced separators offer, including improved cycle life, enhanced charge-discharge efficiency, and reduced dendrite formation.

Regionally, Asia-Pacific dominates the ZIB separator market with approximately 65% market share, led by China's aggressive investments in renewable energy infrastructure and battery manufacturing capabilities. North America and Europe follow with 18% and 14% respectively, with both regions showing accelerated adoption rates as environmental regulations tighten and renewable energy targets become more ambitious.

Consumer electronics represents the largest application segment (38% of market share), followed by grid storage (27%) and electric vehicles (21%). However, the fastest growth is observed in the stationary storage sector, which is expanding at nearly 25% annually as utilities and commercial entities invest in peak shaving and backup power solutions.

Market research indicates that separator manufacturers focusing on porosity optimization and enhanced wetting properties are experiencing above-average revenue growth. Specifically, companies offering separators with porosity ranges of 40-60% and advanced hydrophilic surface treatments have reported sales growth exceeding industry averages by 7-9 percentage points.

The competitive landscape features both established membrane manufacturers diversifying into ZIB applications and specialized startups focused exclusively on advanced separator technologies. Strategic partnerships between separator manufacturers and battery producers have increased by 35% in the past two years, indicating the critical importance of separator technology in overall battery performance and market acceptance.

Current Challenges in ZIB Separator Development

Despite significant advancements in zinc-ion battery (ZIB) technology, separator development remains a critical bottleneck limiting widespread commercialization. Current commercial separators, primarily designed for lithium-ion batteries, fail to address the unique electrochemical environment of ZIBs, particularly regarding zinc dendrite growth and aqueous electrolyte compatibility.

The most pressing challenge involves optimizing porosity parameters. Conventional separators exhibit either excessive porosity, allowing zinc dendrite penetration, or insufficient porosity, restricting ion transport and increasing internal resistance. Finding the optimal porosity range (typically 40-60%) while maintaining mechanical integrity presents significant engineering difficulties. Moreover, achieving uniform pore size distribution remains elusive with current manufacturing techniques.

Wettability issues constitute another major hurdle. Many commercial separators demonstrate hydrophobic characteristics, resulting in poor electrolyte uptake and incomplete pore filling in aqueous ZIB systems. This creates dry spots that become preferential sites for dendrite nucleation and growth. Conversely, excessive hydrophilicity can compromise mechanical stability during cycling, especially in highly concentrated zinc salt electrolytes.

The trade-off between mechanical strength and electrochemical performance creates additional complications. Separators must withstand the mechanical stresses from zinc deposition/dissolution cycles while maintaining flexibility and thinness for high energy density. Current materials struggle to balance these competing requirements, often sacrificing one property for another.

Chemical stability presents further challenges in the highly corrosive environment of ZIB electrolytes. Zinc salts and mildly acidic conditions accelerate degradation of many polymer-based separators, leading to dimensional instability and compromised barrier function over extended cycling. This degradation accelerates capacity fade and shortens battery lifespan.

Manufacturing scalability remains problematic for advanced separator designs. Laboratory-scale techniques like electrospinning produce excellent separators with controlled porosity and wettability but face significant barriers to industrial-scale production. Meanwhile, commercially viable manufacturing processes struggle to achieve the precise microstructural control needed for optimal ZIB performance.

Cost considerations further complicate development efforts. While high-performance separators incorporating specialized coatings or composite structures demonstrate impressive results in research settings, their complex manufacturing processes and expensive materials make commercial adoption challenging in a market where cost competitiveness with lithium-ion technologies is crucial.

The most pressing challenge involves optimizing porosity parameters. Conventional separators exhibit either excessive porosity, allowing zinc dendrite penetration, or insufficient porosity, restricting ion transport and increasing internal resistance. Finding the optimal porosity range (typically 40-60%) while maintaining mechanical integrity presents significant engineering difficulties. Moreover, achieving uniform pore size distribution remains elusive with current manufacturing techniques.

Wettability issues constitute another major hurdle. Many commercial separators demonstrate hydrophobic characteristics, resulting in poor electrolyte uptake and incomplete pore filling in aqueous ZIB systems. This creates dry spots that become preferential sites for dendrite nucleation and growth. Conversely, excessive hydrophilicity can compromise mechanical stability during cycling, especially in highly concentrated zinc salt electrolytes.

The trade-off between mechanical strength and electrochemical performance creates additional complications. Separators must withstand the mechanical stresses from zinc deposition/dissolution cycles while maintaining flexibility and thinness for high energy density. Current materials struggle to balance these competing requirements, often sacrificing one property for another.

Chemical stability presents further challenges in the highly corrosive environment of ZIB electrolytes. Zinc salts and mildly acidic conditions accelerate degradation of many polymer-based separators, leading to dimensional instability and compromised barrier function over extended cycling. This degradation accelerates capacity fade and shortens battery lifespan.

Manufacturing scalability remains problematic for advanced separator designs. Laboratory-scale techniques like electrospinning produce excellent separators with controlled porosity and wettability but face significant barriers to industrial-scale production. Meanwhile, commercially viable manufacturing processes struggle to achieve the precise microstructural control needed for optimal ZIB performance.

Cost considerations further complicate development efforts. While high-performance separators incorporating specialized coatings or composite structures demonstrate impressive results in research settings, their complex manufacturing processes and expensive materials make commercial adoption challenging in a market where cost competitiveness with lithium-ion technologies is crucial.

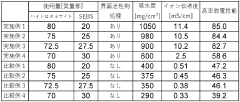

Current Approaches to Optimize Separator Porosity and Wettability

01 Porous polymer separators for ZIBs

Porous polymer separators are crucial components in zinc-ion batteries that provide mechanical support while allowing ion transport. These separators typically feature controlled porosity (30-80%) to balance ion conductivity and mechanical strength. Materials such as polyethylene (PE), polypropylene (PP), and polyolefin blends are commonly used due to their chemical stability and appropriate pore structure. The porosity and pore size distribution significantly affect the wetting properties and overall battery performance.- Porous separator materials for ZIBs: Porous materials are essential for zinc-ion battery separators as they allow ion transport while preventing short circuits. Various materials with controlled porosity structures are used, including polymer membranes, cellulose-based materials, and composite structures. The porosity characteristics (pore size, distribution, and interconnectivity) directly impact battery performance by affecting ion diffusion rates and internal resistance. Optimized porous separators enhance battery cycle life and charge-discharge efficiency.

- Wetting agents and electrolyte compatibility: Wetting properties of separators are crucial for efficient electrolyte uptake and retention in zinc-ion batteries. Hydrophilic surface modifications and wetting agents are incorporated to improve electrolyte absorption and distribution throughout the separator. These modifications ensure complete wetting of the separator pores, reducing internal resistance and enhancing ionic conductivity. Compatibility between the separator material and zinc-based electrolytes is essential to prevent degradation and maintain stable performance during cycling.

- Composite and modified separators: Composite separators combining multiple materials offer enhanced properties for zinc-ion batteries. These typically consist of a base polymer matrix modified with functional additives such as ceramic particles, metal oxides, or conductive materials. Surface modifications through coating or grafting techniques improve wettability, mechanical strength, and ion selectivity. These composite structures can effectively suppress zinc dendrite growth while maintaining high ionic conductivity, addressing key challenges in zinc-ion battery performance and safety.

- Separator thickness and mechanical properties: The thickness and mechanical properties of separators significantly impact zinc-ion battery performance. Thinner separators reduce internal resistance but must maintain sufficient mechanical integrity to prevent short circuits. Separators with high tensile strength and puncture resistance better withstand the mechanical stresses during battery assembly and operation. Dimensional stability under various temperature and humidity conditions is essential for preventing separator deformation that could lead to battery failure or reduced cycle life.

- Zinc dendrite suppression techniques: Specialized separator designs help suppress zinc dendrite formation, a common failure mode in zinc-ion batteries. Approaches include creating tortuous ion transport pathways, incorporating dendrite-inhibiting additives, and developing asymmetric pore structures. Some separators feature functional coatings that chemically interact with zinc ions to regulate deposition patterns. These techniques extend battery cycle life by preventing internal short circuits while maintaining efficient ion transport between electrodes.

02 Surface modification for improved wettability

Surface modification techniques are employed to enhance the wettability of separators in zinc-ion batteries. Hydrophilic coatings, plasma treatments, and grafting of functional groups can transform the naturally hydrophobic polymer surfaces to improve electrolyte uptake and retention. These modifications reduce interfacial resistance and enhance ion transport through the separator. Common approaches include coating with metal oxides, polymers with polar functional groups, or applying surfactants to improve the compatibility between the separator and aqueous zinc electrolytes.Expand Specific Solutions03 Composite separators with inorganic fillers

Composite separators incorporating inorganic fillers offer enhanced porosity and wetting characteristics for zinc-ion batteries. Materials such as SiO2, Al2O3, TiO2, and ceramic particles are dispersed within polymer matrices to create tortuous pathways for ion transport while maintaining mechanical integrity. These fillers increase the hydrophilicity of the separator, improve electrolyte retention, and prevent dendrite penetration. The synergistic combination of organic polymers and inorganic components results in separators with optimized porosity, wettability, and electrochemical performance.Expand Specific Solutions04 Nanofiber-based separators for enhanced porosity

Nanofiber-based separators manufactured through electrospinning or other nanofabrication techniques provide exceptional porosity and surface area for zinc-ion batteries. These separators feature interconnected pore structures with diameters typically ranging from 50-500 nm, facilitating efficient ion transport while maintaining mechanical strength. The high surface-to-volume ratio enhances electrolyte wetting and retention. Various polymers including PVA, PAN, PVDF, and cellulose derivatives can be processed into nanofibers with tailored porosity and wetting properties specific to zinc-ion battery applications.Expand Specific Solutions05 Gel polymer electrolyte separators

Gel polymer electrolyte (GPE) separators combine the functions of traditional separators and liquid electrolytes in zinc-ion batteries. These materials feature a three-dimensional polymer network that immobilizes the liquid electrolyte while maintaining high ionic conductivity. The polymer matrix provides mechanical support while the trapped electrolyte ensures excellent wetting and ion transport. Common polymers used include PVA, PAA, PEO, and their derivatives, often cross-linked to enhance mechanical stability. These separators effectively address issues of electrolyte leakage while maintaining the high ionic conductivity needed for efficient battery operation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in ZIB Separators

The zinc-ion battery separator market is in an early growth phase, characterized by increasing research activity and commercial interest. Market size remains relatively modest compared to lithium-ion technology but is expanding rapidly due to ZIBs' cost advantages and safety benefits. Technologically, separator development is progressing with companies at varying maturity levels. Industry leaders like Asahi Kasei (Celgard), Toray Industries, and Resonac are leveraging their lithium-ion separator expertise to develop ZIB-specific solutions focusing on porosity optimization and wetting properties. Meanwhile, specialized players like Shenzhen Senior Technology and Sinoma Lithium Battery Separator are advancing dedicated ZIB separator technologies. Academic-industrial collaborations with institutions like Arizona State University and Jilin University are accelerating innovation in this space, particularly in addressing the unique electrolyte compatibility challenges of zinc-ion systems.

Celgard LLC

Technical Solution: Celgard has developed specialized microporous membrane separators for zinc-ion batteries with controlled porosity parameters. Their technology employs a dry-process manufacturing method that creates a unique microstructure with uniform pore distribution ranging from 30-100 nm. For ZIB applications, Celgard has modified their polyolefin-based separators with hydrophilic coatings to enhance wettability with aqueous electrolytes. Their proprietary PP/PE/PP trilayer design maintains mechanical integrity while specialized surface treatments improve electrolyte retention. Recent developments include incorporating ceramic particles (Al2O3, SiO2) into the separator matrix to enhance wetting properties while maintaining dimensional stability. Celgard's separators demonstrate Gurley values between 150-300 seconds, indicating optimal porosity for ion transport while preventing zinc dendrite penetration.

Strengths: Industry-leading mechanical strength preventing dendrite penetration; excellent dimensional stability under aqueous conditions; proven manufacturing scalability. Weaknesses: Higher cost compared to non-specialized alternatives; some formulations show decreased ionic conductivity in highly concentrated zinc salt electrolytes; potential for coating delamination during extended cycling.

Sinoma Lithium Battery Separator Co., Ltd.

Technical Solution: Sinoma has adapted their lithium battery separator expertise to develop specialized ZIB separators focusing on porosity optimization and wetting characteristics. Their technology employs a wet process manufacturing method creating asymmetric pore structures with gradient porosity (40-60%) specifically engineered for zinc-ion transport. The company has developed composite separators combining polyethylene substrates with hydrophilic ceramic coatings (primarily Al2O3 and ZrO2) to enhance wettability with aqueous zinc electrolytes while maintaining mechanical integrity. Their proprietary surface modification techniques include plasma treatment and grafting of hydrophilic functional groups to achieve contact angles below 30° with aqueous electrolytes. Sinoma's separators feature controlled tortuosity factors (1.5-2.5) to balance ion transport efficiency with dendrite suppression capabilities. Recent innovations include nano-fiber reinforced structures that maintain porosity while enhancing mechanical strength to withstand the volume changes associated with zinc plating/stripping processes.

Strengths: Cost-effective manufacturing process suitable for mass production; excellent wettability with aqueous zinc electrolytes; good mechanical properties preventing short circuits. Weaknesses: Lower tensile strength compared to dry-process competitors; potential for increased swelling in certain electrolyte formulations; relatively new to ZIB-specific separator development compared to lithium battery separators.

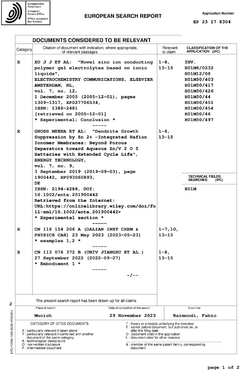

Key Patents and Research on ZIB Separator Materials

Porous membrane and zinc battery

PatentInactiveJP2020080284A

Innovation

- A porous membrane composed of hydrotalcite and a resin material, surface-treated with a surfactant, particularly nonionic surfactants like alkylphenol ethoxylate, enhances ionic conductivity of hydroxide ions.

Separator for a zinc-ion battery and process for the manufacture thereof

PatentPendingEP4475236A1

Innovation

- A solid, impervious zinc-ion conductive membrane made from semi-crystalline thermoplastic resin with ion-conductive additives and reinforced with synthetic fibers, integrated into a multi-layer separator, and a protective layer on a copper conductor to prevent dendrite formation and water corrosion, while maintaining ion conductivity.

Environmental Impact and Sustainability of ZIB Separators

The environmental impact of zinc-ion battery (ZIB) separators represents a critical consideration in the broader context of sustainable energy storage solutions. Unlike lithium-ion batteries, ZIBs utilize more abundant and environmentally benign materials, positioning them as potentially greener alternatives. However, the environmental footprint of separators specifically requires careful assessment across their entire lifecycle.

The production phase of ZIB separators presents significant environmental challenges. Traditional polymer-based separators such as polyethylene (PE) and polypropylene (PP) derive from petroleum resources, contributing to fossil fuel depletion and carbon emissions. The manufacturing processes for these materials typically involve energy-intensive extrusion and stretching techniques that further increase their carbon footprint.

Water consumption during separator production represents another environmental concern, particularly relevant when considering the separator's porosity and wetting properties. Processes that create optimal porosity structures often require substantial water usage for washing and treatment steps. Additionally, chemical treatments to enhance wettability may introduce potentially harmful substances into wastewater streams.

Biodegradability emerges as a key sustainability metric for ZIB separators. Conventional petroleum-based separators persist in the environment for hundreds of years, while bio-derived alternatives such as cellulose-based separators offer significantly improved end-of-life characteristics. These natural polymer-based separators decompose more readily, reducing long-term environmental accumulation.

Recent research has focused on developing eco-friendly separator materials that maintain optimal porosity and wetting properties while reducing environmental impact. Cellulose nanofibers, bacterial cellulose, and other bio-derived polymers show promising performance characteristics while offering improved sustainability profiles. These materials typically require less energy-intensive processing and originate from renewable resources.

Recycling considerations also factor prominently in separator sustainability. The ideal separator design would facilitate easy separation and recovery at end-of-life, allowing for material reclamation. However, current separator designs often complicate recycling efforts due to intimate integration with electrode materials and electrolyte residues. Innovations in separator design that maintain performance while improving recyclability represent an important research direction.

Life cycle assessment (LCA) studies indicate that while ZIBs generally offer environmental advantages over lithium-ion technologies, the separator component still presents opportunities for sustainability improvements. Optimizing porosity formation techniques to reduce energy and water consumption while maintaining performance represents a key challenge for the field. Similarly, developing wetting properties through environmentally benign surface treatments rather than persistent chemical additives would further enhance the sustainability profile of these critical battery components.

The production phase of ZIB separators presents significant environmental challenges. Traditional polymer-based separators such as polyethylene (PE) and polypropylene (PP) derive from petroleum resources, contributing to fossil fuel depletion and carbon emissions. The manufacturing processes for these materials typically involve energy-intensive extrusion and stretching techniques that further increase their carbon footprint.

Water consumption during separator production represents another environmental concern, particularly relevant when considering the separator's porosity and wetting properties. Processes that create optimal porosity structures often require substantial water usage for washing and treatment steps. Additionally, chemical treatments to enhance wettability may introduce potentially harmful substances into wastewater streams.

Biodegradability emerges as a key sustainability metric for ZIB separators. Conventional petroleum-based separators persist in the environment for hundreds of years, while bio-derived alternatives such as cellulose-based separators offer significantly improved end-of-life characteristics. These natural polymer-based separators decompose more readily, reducing long-term environmental accumulation.

Recent research has focused on developing eco-friendly separator materials that maintain optimal porosity and wetting properties while reducing environmental impact. Cellulose nanofibers, bacterial cellulose, and other bio-derived polymers show promising performance characteristics while offering improved sustainability profiles. These materials typically require less energy-intensive processing and originate from renewable resources.

Recycling considerations also factor prominently in separator sustainability. The ideal separator design would facilitate easy separation and recovery at end-of-life, allowing for material reclamation. However, current separator designs often complicate recycling efforts due to intimate integration with electrode materials and electrolyte residues. Innovations in separator design that maintain performance while improving recyclability represent an important research direction.

Life cycle assessment (LCA) studies indicate that while ZIBs generally offer environmental advantages over lithium-ion technologies, the separator component still presents opportunities for sustainability improvements. Optimizing porosity formation techniques to reduce energy and water consumption while maintaining performance represents a key challenge for the field. Similarly, developing wetting properties through environmentally benign surface treatments rather than persistent chemical additives would further enhance the sustainability profile of these critical battery components.

Performance Testing Standards and Protocols for ZIB Separators

Standardized testing protocols for zinc-ion battery (ZIB) separators are essential for ensuring consistent performance evaluation and facilitating meaningful comparisons across different separator materials. The porosity and wetting properties of separators significantly influence ZIB performance, necessitating specific testing methodologies to accurately characterize these parameters.

Porosity testing for ZIB separators typically employs mercury intrusion porosimetry (MIP) and Brunauer-Emmett-Teller (BET) analysis. MIP provides comprehensive data on pore size distribution, total porosity percentage, and pore interconnectivity—critical factors affecting ion transport. The standard protocol involves sample degassing followed by controlled mercury intrusion under increasing pressure, with measurements taken at 25°C and relative humidity below 30%.

Wetting property assessment requires standardized contact angle measurements using the sessile drop method with electrolyte solutions relevant to ZIB chemistry (typically zinc sulfate or zinc triflate solutions). The protocol specifies a 5μL droplet volume, measurement within 60 seconds of droplet placement, and temperature control at 20±2°C. Additionally, electrolyte uptake tests measure absorption capacity and rate, with standardized immersion times of 30 minutes, 2 hours, and 24 hours.

Mechanical integrity testing protocols for ZIB separators include tensile strength measurements according to ASTM D882, with samples prepared as 50mm×10mm strips and tested at a strain rate of 5mm/min. Puncture resistance tests follow ASTM F1306, using a 1mm diameter probe at 25mm/min penetration speed.

Ion transport efficiency evaluation employs electrochemical impedance spectroscopy (EIS) under standardized conditions: frequency range of 100kHz to 0.01Hz, amplitude of 10mV, and temperature control at 25°C. The MacMullin number calculation requires conductivity measurements of both the electrolyte-soaked separator and the neat electrolyte.

Chemical stability assessment protocols mandate immersion tests in ZIB electrolytes for extended periods (7, 30, and 90 days) at both room temperature and elevated temperature (60°C), followed by FTIR analysis to detect chemical degradation. Weight loss measurements and dimensional stability assessments are performed after standardized drying procedures.

Dendrite resistance testing employs symmetric Zn|separator|Zn cells cycled at 0.5mA/cm² for standardized evaluation periods, with post-mortem SEM analysis to quantify dendrite penetration depth and morphology according to established classification criteria.

Porosity testing for ZIB separators typically employs mercury intrusion porosimetry (MIP) and Brunauer-Emmett-Teller (BET) analysis. MIP provides comprehensive data on pore size distribution, total porosity percentage, and pore interconnectivity—critical factors affecting ion transport. The standard protocol involves sample degassing followed by controlled mercury intrusion under increasing pressure, with measurements taken at 25°C and relative humidity below 30%.

Wetting property assessment requires standardized contact angle measurements using the sessile drop method with electrolyte solutions relevant to ZIB chemistry (typically zinc sulfate or zinc triflate solutions). The protocol specifies a 5μL droplet volume, measurement within 60 seconds of droplet placement, and temperature control at 20±2°C. Additionally, electrolyte uptake tests measure absorption capacity and rate, with standardized immersion times of 30 minutes, 2 hours, and 24 hours.

Mechanical integrity testing protocols for ZIB separators include tensile strength measurements according to ASTM D882, with samples prepared as 50mm×10mm strips and tested at a strain rate of 5mm/min. Puncture resistance tests follow ASTM F1306, using a 1mm diameter probe at 25mm/min penetration speed.

Ion transport efficiency evaluation employs electrochemical impedance spectroscopy (EIS) under standardized conditions: frequency range of 100kHz to 0.01Hz, amplitude of 10mV, and temperature control at 25°C. The MacMullin number calculation requires conductivity measurements of both the electrolyte-soaked separator and the neat electrolyte.

Chemical stability assessment protocols mandate immersion tests in ZIB electrolytes for extended periods (7, 30, and 90 days) at both room temperature and elevated temperature (60°C), followed by FTIR analysis to detect chemical degradation. Weight loss measurements and dimensional stability assessments are performed after standardized drying procedures.

Dendrite resistance testing employs symmetric Zn|separator|Zn cells cycled at 0.5mA/cm² for standardized evaluation periods, with post-mortem SEM analysis to quantify dendrite penetration depth and morphology according to established classification criteria.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!