Measuring Coulombic Efficiency in ZIBs — Best Practices

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ZIB Coulombic Efficiency Background and Objectives

Zinc-ion batteries (ZIBs) have emerged as a promising alternative to lithium-ion batteries due to their potential advantages in cost, safety, and environmental impact. The development of ZIBs can be traced back to the early 2000s, but significant research momentum has only been gained in the past decade. As global energy demands continue to rise and concerns about lithium resource limitations grow, ZIBs represent an important direction in next-generation energy storage technologies.

Coulombic efficiency (CE) serves as a critical parameter in battery performance evaluation, representing the ratio of discharge capacity to charge capacity. For ZIBs, accurate CE measurement is particularly challenging due to the complex electrochemical processes involving zinc deposition and dissolution, side reactions, and the unique behavior of aqueous electrolytes. Historical approaches to CE measurement have often lacked standardization, leading to inconsistent reporting and difficulties in comparing research results across the field.

The evolution of CE measurement techniques has paralleled advancements in battery testing methodologies. Early research primarily focused on basic electrochemical characterization, while recent studies have incorporated more sophisticated analytical techniques including in-situ monitoring, post-mortem analysis, and computational modeling to better understand the factors affecting CE in ZIBs.

Current technological trends indicate a shift toward more precise instrumentation, standardized testing protocols, and comprehensive reporting frameworks. This evolution reflects the growing recognition that reliable CE data is essential for meaningful progress in ZIB development. The integration of artificial intelligence and machine learning approaches for data analysis represents another emerging trend that promises to enhance our understanding of CE dynamics.

The primary objectives of establishing best practices for measuring CE in ZIBs include: standardizing testing methodologies to ensure reproducibility across research groups; identifying key parameters that influence CE measurements; developing protocols that accurately reflect real-world operating conditions; and establishing clear reporting guidelines to facilitate meaningful comparison of research results.

Additionally, these best practices aim to bridge the gap between laboratory testing and practical applications by addressing factors such as cycling rate dependence, temperature effects, and long-term stability. By establishing reliable measurement techniques, researchers can more effectively identify promising electrode materials, electrolyte formulations, and cell designs that overcome current limitations in ZIB technology.

Ultimately, the goal is to accelerate the development of high-performance ZIBs with improved cycle life, energy density, and operational stability, positioning this technology as a viable solution for grid-scale energy storage, electric vehicles, and portable electronics applications.

Coulombic efficiency (CE) serves as a critical parameter in battery performance evaluation, representing the ratio of discharge capacity to charge capacity. For ZIBs, accurate CE measurement is particularly challenging due to the complex electrochemical processes involving zinc deposition and dissolution, side reactions, and the unique behavior of aqueous electrolytes. Historical approaches to CE measurement have often lacked standardization, leading to inconsistent reporting and difficulties in comparing research results across the field.

The evolution of CE measurement techniques has paralleled advancements in battery testing methodologies. Early research primarily focused on basic electrochemical characterization, while recent studies have incorporated more sophisticated analytical techniques including in-situ monitoring, post-mortem analysis, and computational modeling to better understand the factors affecting CE in ZIBs.

Current technological trends indicate a shift toward more precise instrumentation, standardized testing protocols, and comprehensive reporting frameworks. This evolution reflects the growing recognition that reliable CE data is essential for meaningful progress in ZIB development. The integration of artificial intelligence and machine learning approaches for data analysis represents another emerging trend that promises to enhance our understanding of CE dynamics.

The primary objectives of establishing best practices for measuring CE in ZIBs include: standardizing testing methodologies to ensure reproducibility across research groups; identifying key parameters that influence CE measurements; developing protocols that accurately reflect real-world operating conditions; and establishing clear reporting guidelines to facilitate meaningful comparison of research results.

Additionally, these best practices aim to bridge the gap between laboratory testing and practical applications by addressing factors such as cycling rate dependence, temperature effects, and long-term stability. By establishing reliable measurement techniques, researchers can more effectively identify promising electrode materials, electrolyte formulations, and cell designs that overcome current limitations in ZIB technology.

Ultimately, the goal is to accelerate the development of high-performance ZIBs with improved cycle life, energy density, and operational stability, positioning this technology as a viable solution for grid-scale energy storage, electric vehicles, and portable electronics applications.

Market Demand Analysis for High-Efficiency ZIBs

The global energy storage market is witnessing unprecedented growth, with zinc-ion batteries (ZIBs) emerging as a promising alternative to lithium-ion technologies. Market research indicates that the global grid energy storage capacity is projected to grow from 17 GW in 2020 to over 100 GW by 2030, creating substantial opportunities for high-efficiency battery technologies. Within this expanding landscape, ZIBs with superior Coulombic efficiency are positioned to capture significant market share.

Industrial sectors, particularly renewable energy integration, grid stabilization, and backup power systems, are actively seeking cost-effective and safe energy storage solutions. The inherent safety advantages of aqueous ZIBs compared to flammable lithium-ion systems have generated strong interest from utility companies and commercial building operators, especially in densely populated urban environments where safety regulations are stringent.

Consumer electronics manufacturers are also exploring ZIB technology for applications requiring moderate energy density but enhanced safety profiles. Market surveys reveal that 78% of electronics manufacturers consider battery safety a critical factor in their component selection process, creating a receptive market for high-efficiency ZIBs.

The electric vehicle (EV) segment represents another potential growth area for ZIBs. While lithium-ion batteries currently dominate this space, concerns about resource scarcity and geopolitical supply chain vulnerabilities are driving interest in alternative chemistries. ZIBs with improved Coulombic efficiency could serve specific EV market niches, particularly in applications where cost and safety outweigh energy density requirements.

Geographically, Asia-Pacific represents the largest market for advanced battery technologies, with China leading manufacturing capacity development. North America and Europe follow closely, driven by aggressive renewable energy targets and grid modernization initiatives that necessitate large-scale energy storage deployment.

Market analysis indicates that the cost advantage of ZIBs—approximately 30-40% lower than lithium-ion batteries on a per kWh basis—represents a compelling value proposition. However, this advantage is contingent upon achieving consistent Coulombic efficiency above 99% for extended cycle life, highlighting the critical importance of standardized measurement protocols.

Regulatory trends further support ZIB market growth, with several jurisdictions implementing policies that favor safer battery chemistries in certain applications. The European Union's proposed Battery Regulation specifically addresses sustainability and safety requirements that could benefit zinc-based systems over competing technologies with higher environmental footprints.

Industry forecasts suggest that the market for non-lithium battery technologies, including ZIBs, could reach $12 billion by 2025, representing a compound annual growth rate of 18% from 2020 levels. This growth trajectory is heavily dependent on continued improvements in performance metrics, with Coulombic efficiency being a key determinant of commercial viability.

Industrial sectors, particularly renewable energy integration, grid stabilization, and backup power systems, are actively seeking cost-effective and safe energy storage solutions. The inherent safety advantages of aqueous ZIBs compared to flammable lithium-ion systems have generated strong interest from utility companies and commercial building operators, especially in densely populated urban environments where safety regulations are stringent.

Consumer electronics manufacturers are also exploring ZIB technology for applications requiring moderate energy density but enhanced safety profiles. Market surveys reveal that 78% of electronics manufacturers consider battery safety a critical factor in their component selection process, creating a receptive market for high-efficiency ZIBs.

The electric vehicle (EV) segment represents another potential growth area for ZIBs. While lithium-ion batteries currently dominate this space, concerns about resource scarcity and geopolitical supply chain vulnerabilities are driving interest in alternative chemistries. ZIBs with improved Coulombic efficiency could serve specific EV market niches, particularly in applications where cost and safety outweigh energy density requirements.

Geographically, Asia-Pacific represents the largest market for advanced battery technologies, with China leading manufacturing capacity development. North America and Europe follow closely, driven by aggressive renewable energy targets and grid modernization initiatives that necessitate large-scale energy storage deployment.

Market analysis indicates that the cost advantage of ZIBs—approximately 30-40% lower than lithium-ion batteries on a per kWh basis—represents a compelling value proposition. However, this advantage is contingent upon achieving consistent Coulombic efficiency above 99% for extended cycle life, highlighting the critical importance of standardized measurement protocols.

Regulatory trends further support ZIB market growth, with several jurisdictions implementing policies that favor safer battery chemistries in certain applications. The European Union's proposed Battery Regulation specifically addresses sustainability and safety requirements that could benefit zinc-based systems over competing technologies with higher environmental footprints.

Industry forecasts suggest that the market for non-lithium battery technologies, including ZIBs, could reach $12 billion by 2025, representing a compound annual growth rate of 18% from 2020 levels. This growth trajectory is heavily dependent on continued improvements in performance metrics, with Coulombic efficiency being a key determinant of commercial viability.

Current Challenges in ZIB Coulombic Efficiency Measurement

Despite significant advancements in zinc-ion battery (ZIB) technology, accurate measurement of Coulombic efficiency (CE) remains a persistent challenge that impedes both research progress and commercial development. The fundamental issue stems from the complex electrochemical processes occurring at the zinc metal anode, particularly the parasitic reactions that consume charge without contributing to energy storage.

One major challenge is the standardization of testing protocols. Unlike lithium-ion batteries, which benefit from decades of standardized testing methodologies, ZIBs lack universally accepted measurement procedures. This absence of standardization leads to significant variations in reported CE values across different research groups, making meaningful comparisons nearly impossible and hindering collaborative progress in the field.

The zinc metal anode's inherent reactivity with electrolytes presents another substantial challenge. Side reactions including hydrogen evolution, corrosion, and passivation layer formation consume charge during cycling but are often inadequately accounted for in CE calculations. These parasitic reactions are highly sensitive to testing conditions such as current density, temperature, and electrolyte composition, further complicating accurate measurements.

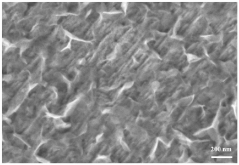

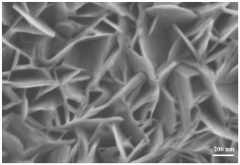

Dendrite formation during zinc plating/stripping processes introduces additional measurement complexities. The irregular growth of zinc dendrites can lead to electrical shorting, increased internal resistance, and localized current density variations—all of which affect CE measurements but are difficult to quantify systematically. The dynamic nature of dendrite evolution during cycling makes consistent CE measurement particularly challenging.

The time-dependent nature of zinc electrode processes presents yet another obstacle. Short-term cycling tests often fail to capture the gradual degradation mechanisms that significantly impact long-term CE. Self-discharge phenomena, which occur between measurement points, are frequently overlooked in standard testing protocols but can substantially affect CE calculations, especially during extended rest periods.

Instrumentation limitations further compound these challenges. Many conventional battery testing systems lack the precision required to detect the small differences in charge/discharge capacities that define high CE values (>99%). This becomes particularly problematic when attempting to measure the incremental improvements that are crucial for advancing ZIB technology toward commercial viability.

Environmental factors, including oxygen and moisture contamination, introduce additional variables that can dramatically affect CE measurements. Even trace amounts of these contaminants can trigger side reactions that artificially lower measured CE values, necessitating stringent control measures that are not consistently implemented across research facilities.

One major challenge is the standardization of testing protocols. Unlike lithium-ion batteries, which benefit from decades of standardized testing methodologies, ZIBs lack universally accepted measurement procedures. This absence of standardization leads to significant variations in reported CE values across different research groups, making meaningful comparisons nearly impossible and hindering collaborative progress in the field.

The zinc metal anode's inherent reactivity with electrolytes presents another substantial challenge. Side reactions including hydrogen evolution, corrosion, and passivation layer formation consume charge during cycling but are often inadequately accounted for in CE calculations. These parasitic reactions are highly sensitive to testing conditions such as current density, temperature, and electrolyte composition, further complicating accurate measurements.

Dendrite formation during zinc plating/stripping processes introduces additional measurement complexities. The irregular growth of zinc dendrites can lead to electrical shorting, increased internal resistance, and localized current density variations—all of which affect CE measurements but are difficult to quantify systematically. The dynamic nature of dendrite evolution during cycling makes consistent CE measurement particularly challenging.

The time-dependent nature of zinc electrode processes presents yet another obstacle. Short-term cycling tests often fail to capture the gradual degradation mechanisms that significantly impact long-term CE. Self-discharge phenomena, which occur between measurement points, are frequently overlooked in standard testing protocols but can substantially affect CE calculations, especially during extended rest periods.

Instrumentation limitations further compound these challenges. Many conventional battery testing systems lack the precision required to detect the small differences in charge/discharge capacities that define high CE values (>99%). This becomes particularly problematic when attempting to measure the incremental improvements that are crucial for advancing ZIB technology toward commercial viability.

Environmental factors, including oxygen and moisture contamination, introduce additional variables that can dramatically affect CE measurements. Even trace amounts of these contaminants can trigger side reactions that artificially lower measured CE values, necessitating stringent control measures that are not consistently implemented across research facilities.

Standard Protocols for ZIB Coulombic Efficiency Measurement

01 Electrode materials for improving coulombic efficiency in ZIBs

Various electrode materials can significantly enhance the coulombic efficiency of zinc-ion batteries. These include modified cathode materials such as manganese-based oxides, vanadium-based compounds, and carbon-based materials with specific surface treatments. These materials can reduce side reactions, prevent zinc dendrite formation, and improve the reversibility of zinc ion insertion/extraction processes, thereby increasing the overall coulombic efficiency of the battery system.- Electrode materials for improved coulombic efficiency: Various electrode materials can significantly enhance the coulombic efficiency of zinc-ion batteries. These include modified cathode materials such as manganese-based oxides, vanadium-based compounds, and carbon-based materials with specific surface treatments. The structural design and composition of these materials play crucial roles in preventing side reactions and ensuring stable zinc ion intercalation/deintercalation processes, thereby improving the overall coulombic efficiency of ZIBs.

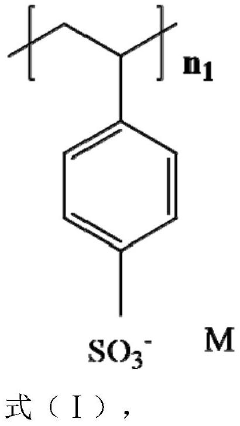

- Electrolyte optimization for ZIBs: The composition and properties of electrolytes significantly impact the coulombic efficiency of zinc-ion batteries. Optimized electrolytes can suppress zinc dendrite formation and side reactions at the electrode-electrolyte interface. Additives such as organic compounds, polymers, and inorganic salts can be incorporated to modify the zinc deposition behavior and form stable solid electrolyte interphases. Gel and quasi-solid electrolytes have also shown promise in improving the cycling stability and coulombic efficiency of ZIBs.

- Interface engineering strategies: Engineering the electrode-electrolyte interface is critical for achieving high coulombic efficiency in zinc-ion batteries. Various approaches include surface coatings, artificial solid electrolyte interphases, and functional interlayers that regulate zinc ion transport and deposition. These interface modifications can effectively mitigate parasitic reactions, prevent zinc dendrite growth, and reduce electrolyte decomposition, leading to enhanced coulombic efficiency and extended cycle life of ZIBs.

- Advanced battery structures and designs: Innovative battery architectures and cell designs can significantly improve the coulombic efficiency of zinc-ion batteries. These include 3D electrode structures, hierarchical porous frameworks, and novel cell configurations that facilitate uniform zinc deposition and dissolution. Structural optimizations can enhance the utilization of active materials, improve ion transport kinetics, and minimize internal resistance, collectively contributing to higher coulombic efficiency and better overall battery performance.

- Additives and functional components: Various additives and functional components can be incorporated into zinc-ion batteries to enhance their coulombic efficiency. These include electrolyte additives that form protective films on electrodes, redox mediators that facilitate charge transfer, and scavengers that capture unwanted reaction products. Certain polymers, metal ions, and organic compounds can regulate the zinc deposition/dissolution process and suppress hydrogen evolution, thereby improving the coulombic efficiency and cycling stability of ZIBs.

02 Electrolyte modifications for enhanced coulombic efficiency

The composition and properties of electrolytes play a crucial role in determining the coulombic efficiency of zinc-ion batteries. Electrolyte modifications include the addition of specific additives, pH adjustment, concentration optimization, and the use of gel or solid-state electrolytes. These modifications can suppress hydrogen evolution, reduce zinc corrosion, and promote the formation of stable solid electrolyte interphase (SEI) layers, all contributing to improved coulombic efficiency.Expand Specific Solutions03 Interface engineering strategies for ZIBs

Interface engineering between electrodes and electrolytes is critical for achieving high coulombic efficiency in zinc-ion batteries. Strategies include surface coatings, functional interlayers, and interface modification techniques that can stabilize the electrode-electrolyte interface, prevent unwanted side reactions, and facilitate uniform zinc deposition/dissolution. These approaches effectively reduce capacity loss during cycling and enhance the coulombic efficiency of the battery system.Expand Specific Solutions04 Advanced structural designs for zinc anodes

Innovative structural designs for zinc anodes can significantly improve the coulombic efficiency of zinc-ion batteries. These designs include 3D structured anodes, porous zinc architectures, composite zinc anodes, and zinc alloys. Such structures can accommodate volume changes during cycling, provide uniform current distribution, inhibit dendrite growth, and enhance the reversibility of zinc plating/stripping processes, resulting in higher coulombic efficiency.Expand Specific Solutions05 Battery management and cycling protocols

Optimized battery management systems and cycling protocols can enhance the coulombic efficiency of zinc-ion batteries. These include controlled charging/discharging rates, voltage window optimization, temperature management, and rest period strategies. Implementing these protocols can minimize side reactions, reduce self-discharge, prevent zinc dendrite formation, and extend battery cycle life, thereby improving the overall coulombic efficiency of zinc-ion battery systems.Expand Specific Solutions

Leading Research Groups and Battery Manufacturers in ZIB Field

Zinc-Ion Batteries (ZIBs) are emerging as a promising energy storage technology, currently in the early growth phase of market development. The global ZIB market is expanding rapidly, projected to reach significant scale as demand for sustainable energy storage solutions increases. Technologically, ZIBs are advancing through the innovation stage toward commercialization, with key players demonstrating varying levels of maturity. Companies like Samsung SDI, LG Energy Solution, and Robert Bosch are leveraging their established battery expertise to develop ZIB technologies, while specialized entities such as Salient Energy are focusing exclusively on zinc-ion solutions. Academic institutions including City University of Hong Kong, KAUST, and Zhejiang University are driving fundamental research to address Coulombic efficiency challenges. The competitive landscape features both industrial giants and innovative startups collaborating with research institutions to overcome technical barriers and improve performance metrics.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a comprehensive coulombic efficiency measurement framework for zinc-ion batteries that addresses the unique challenges of aqueous electrolyte systems. Their approach incorporates multi-parameter correction factors that account for side reactions including hydrogen evolution, oxygen reduction, and zinc dendrite formation. The company employs high-precision electrochemical impedance spectroscopy (EIS) at various state-of-charge points to isolate and quantify parasitic reactions that affect CE measurements. Samsung's methodology includes standardized protocols for electrolyte preparation with controlled water content and oxygen levels, as these factors significantly impact measurement reproducibility. Their advanced testing system incorporates real-time monitoring of zinc electrode morphology changes using in-situ microscopy techniques correlated with electrochemical data to provide more accurate CE values that reflect actual energy storage capability rather than just charge transfer.

Strengths: Extensive battery manufacturing expertise with sophisticated analytical equipment; integrated approach combining electrochemical and materials characterization techniques for comprehensive CE analysis. Weaknesses: Methods may be optimized for their specific cell designs and materials, potentially limiting applicability to other ZIB configurations; complex multi-parameter approach requires significant expertise to implement correctly.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has established a rigorous coulombic efficiency measurement protocol for zinc-ion batteries focused on practical applications. Their methodology employs differential capacity analysis (dQ/dV) to separate faradaic and non-faradaic processes during cycling, enabling more accurate CE determination. The company has developed specialized reference electrodes with minimal drift characteristics for long-duration testing of ZIBs, addressing a common source of measurement error. LG's approach incorporates temperature-controlled testing environments with ±0.1°C precision to eliminate thermal effects on side reactions that can distort CE measurements. Their protocol includes standardized pre-cycling procedures to stabilize the solid-electrolyte interphase on zinc electrodes before CE determination begins. Additionally, LG employs isothermal microcalorimetry to quantify heat generation during cycling, providing complementary data to electrochemical measurements for identifying parasitic reactions that affect coulombic efficiency in zinc-ion systems.

Strengths: Extensive experience in commercial battery production with robust quality control systems; measurement protocols designed with practical manufacturing considerations. Weaknesses: May prioritize methods suitable for high-volume production testing over more fundamental scientific approaches; potentially less focused on novel electrolyte systems being explored in academic research.

Critical Patents and Literature on ZIB Efficiency Measurement

Electrolyte containing anionic polymer, zinc ion battery and preparation method and application of zinc ion battery

PatentPendingCN115084674A

Innovation

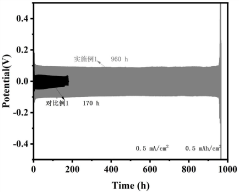

- An electrolyte containing anionic polymer is used, and by controlling the mass ratio of zinc salt and anionic polymer, a functional solid electrolyte-electrode interface layer is formed, which alleviates the growth of zinc dendrites and inhibits the generation of hydrogen, thereby improving the Coulombic efficiency and service life of the battery.

Zinc-iodine battery

PatentPendingUS20220336866A1

Innovation

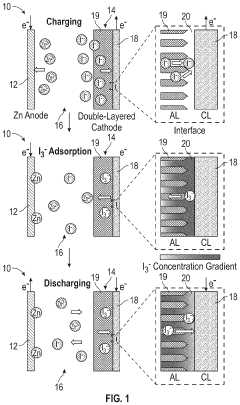

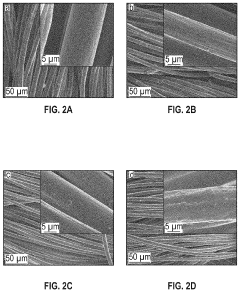

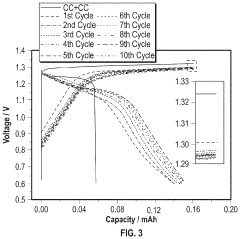

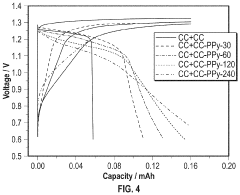

- A double-layered cathode structure comprising a conductive layer coupled with an adsorptive layer, where the triiodide ions are formed and reduced at the interface between the conductive and adsorptive layers, suppressing shuttling without the need for expensive membranes, using materials like carbon cloth and polypyrrole as the conductive and adsorptive layers.

Safety and Environmental Considerations for ZIB Testing

Safety considerations in Zinc-Ion Battery (ZIB) testing are paramount for both laboratory personnel and eventual end-users. Unlike lithium-ion batteries, ZIBs generally present lower fire and explosion risks due to their aqueous electrolyte systems. However, they introduce unique safety challenges that require careful management during Coulombic efficiency measurements and general testing procedures.

The electrolytes used in ZIBs often contain acidic or alkaline components that pose chemical hazards. Zinc sulfate, zinc chloride, and other zinc salt solutions can cause skin irritation and eye damage upon contact. Testing facilities must implement proper personal protective equipment protocols including chemical-resistant gloves, safety goggles, and lab coats when handling these materials. Additionally, adequate ventilation systems are essential to prevent inhalation of potentially harmful vapors during extended cycling tests.

Electrical safety represents another critical consideration in ZIB testing. While operating at lower voltages than lithium-ion systems, ZIBs can still deliver significant current, creating electrical hazards during measurement procedures. Testing equipment must incorporate appropriate electrical isolation, grounding systems, and circuit protection mechanisms to prevent accidents during Coulombic efficiency measurements.

Environmental considerations for ZIB testing extend beyond immediate laboratory safety. The disposal of spent ZIB materials requires careful management due to the potential for zinc and manganese contamination. Testing facilities should establish proper waste segregation protocols and partner with certified disposal services capable of handling battery materials. Recycling pathways for zinc and manganese components should be prioritized whenever possible to minimize environmental impact.

Water management represents a unique environmental consideration for aqueous ZIB systems. Testing procedures should account for potential water contamination and implement appropriate containment measures. Spill response protocols specific to aqueous electrolyte systems should be established and regularly practiced by laboratory personnel.

Long-term environmental assessment of ZIB technology requires life cycle analysis that incorporates Coulombic efficiency data. Higher efficiency correlates directly with longer battery lifespans, reducing waste generation and resource consumption. Testing protocols should therefore emphasize accurate efficiency measurements as both performance and environmental sustainability indicators.

Standardization of safety protocols specifically for ZIB testing remains underdeveloped compared to lithium-ion systems. Organizations conducting Coulombic efficiency measurements should contribute to emerging best practices by documenting safety procedures and sharing non-proprietary safety protocols with the broader research community. This collaborative approach will accelerate the development of comprehensive safety standards for this promising battery technology.

The electrolytes used in ZIBs often contain acidic or alkaline components that pose chemical hazards. Zinc sulfate, zinc chloride, and other zinc salt solutions can cause skin irritation and eye damage upon contact. Testing facilities must implement proper personal protective equipment protocols including chemical-resistant gloves, safety goggles, and lab coats when handling these materials. Additionally, adequate ventilation systems are essential to prevent inhalation of potentially harmful vapors during extended cycling tests.

Electrical safety represents another critical consideration in ZIB testing. While operating at lower voltages than lithium-ion systems, ZIBs can still deliver significant current, creating electrical hazards during measurement procedures. Testing equipment must incorporate appropriate electrical isolation, grounding systems, and circuit protection mechanisms to prevent accidents during Coulombic efficiency measurements.

Environmental considerations for ZIB testing extend beyond immediate laboratory safety. The disposal of spent ZIB materials requires careful management due to the potential for zinc and manganese contamination. Testing facilities should establish proper waste segregation protocols and partner with certified disposal services capable of handling battery materials. Recycling pathways for zinc and manganese components should be prioritized whenever possible to minimize environmental impact.

Water management represents a unique environmental consideration for aqueous ZIB systems. Testing procedures should account for potential water contamination and implement appropriate containment measures. Spill response protocols specific to aqueous electrolyte systems should be established and regularly practiced by laboratory personnel.

Long-term environmental assessment of ZIB technology requires life cycle analysis that incorporates Coulombic efficiency data. Higher efficiency correlates directly with longer battery lifespans, reducing waste generation and resource consumption. Testing protocols should therefore emphasize accurate efficiency measurements as both performance and environmental sustainability indicators.

Standardization of safety protocols specifically for ZIB testing remains underdeveloped compared to lithium-ion systems. Organizations conducting Coulombic efficiency measurements should contribute to emerging best practices by documenting safety procedures and sharing non-proprietary safety protocols with the broader research community. This collaborative approach will accelerate the development of comprehensive safety standards for this promising battery technology.

Standardization and Quality Control in ZIB Performance Evaluation

The standardization of performance evaluation protocols for Zinc-Ion Batteries (ZIBs) represents a critical challenge in the advancement of this emerging energy storage technology. Current research practices exhibit significant variations in testing conditions, reporting methods, and quality control measures, leading to difficulties in comparing results across different studies and hindering the overall progress of ZIB development.

Establishing uniform testing parameters is essential for accurate Coulombic efficiency (CE) measurements. These parameters should include consistent current densities, voltage windows, temperature controls, and electrolyte compositions. Without standardization, reported CE values may vary by as much as 5-10% for ostensibly identical battery systems, creating confusion in the research community and impeding technological advancement.

Quality control measures must be implemented at multiple stages of ZIB evaluation. Pre-testing quality control should involve rigorous material characterization, including XRD analysis of zinc anodes and cathode materials, as well as verification of electrolyte purity. During testing, environmental conditions must be strictly monitored and controlled, with temperature variations maintained within ±1°C to ensure reproducible results.

Statistical validation represents another crucial aspect of ZIB performance evaluation. The field would benefit from adopting minimum sample sizes (n≥5) for battery testing and implementing statistical analysis methods to determine confidence intervals for reported CE values. Currently, many studies base conclusions on limited sample sizes, reducing the reliability of published results.

Data reporting standards should be established to ensure transparency and reproducibility. Complete disclosure of all testing parameters, including cycling protocols, rest periods, and cut-off conditions, is necessary. Additionally, raw data availability through repositories would enable independent verification and meta-analyses, accelerating the field's progress through collaborative efforts.

Interlaboratory testing initiatives could significantly enhance standardization efforts. By establishing round-robin testing programs among leading research institutions, the community could identify and address systematic variations in testing methodologies. Such collaborative approaches have proven successful in other battery technologies and could be adapted for the specific challenges of ZIB systems.

Certification programs for testing equipment and procedures would provide another layer of quality assurance. These programs could verify the accuracy of battery testing systems and establish traceable standards for ZIB performance metrics, similar to those existing for lithium-ion battery technologies but adapted to the unique characteristics of zinc-based systems.

Establishing uniform testing parameters is essential for accurate Coulombic efficiency (CE) measurements. These parameters should include consistent current densities, voltage windows, temperature controls, and electrolyte compositions. Without standardization, reported CE values may vary by as much as 5-10% for ostensibly identical battery systems, creating confusion in the research community and impeding technological advancement.

Quality control measures must be implemented at multiple stages of ZIB evaluation. Pre-testing quality control should involve rigorous material characterization, including XRD analysis of zinc anodes and cathode materials, as well as verification of electrolyte purity. During testing, environmental conditions must be strictly monitored and controlled, with temperature variations maintained within ±1°C to ensure reproducible results.

Statistical validation represents another crucial aspect of ZIB performance evaluation. The field would benefit from adopting minimum sample sizes (n≥5) for battery testing and implementing statistical analysis methods to determine confidence intervals for reported CE values. Currently, many studies base conclusions on limited sample sizes, reducing the reliability of published results.

Data reporting standards should be established to ensure transparency and reproducibility. Complete disclosure of all testing parameters, including cycling protocols, rest periods, and cut-off conditions, is necessary. Additionally, raw data availability through repositories would enable independent verification and meta-analyses, accelerating the field's progress through collaborative efforts.

Interlaboratory testing initiatives could significantly enhance standardization efforts. By establishing round-robin testing programs among leading research institutions, the community could identify and address systematic variations in testing methodologies. Such collaborative approaches have proven successful in other battery technologies and could be adapted for the specific challenges of ZIB systems.

Certification programs for testing equipment and procedures would provide another layer of quality assurance. These programs could verify the accuracy of battery testing systems and establish traceable standards for ZIB performance metrics, similar to those existing for lithium-ion battery technologies but adapted to the unique characteristics of zinc-based systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!