ZIB Recycling Pathways: Cathode & Zn Recovery

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ZIB Recycling Technology Background and Objectives

Zinc-ion batteries (ZIBs) have emerged as a promising alternative to lithium-ion batteries due to their cost-effectiveness, safety, and environmental friendliness. As the deployment of ZIBs continues to grow, the need for efficient recycling pathways becomes increasingly critical. The evolution of ZIB recycling technology has progressed from rudimentary physical separation methods to sophisticated hydrometallurgical and pyrometallurgical processes specifically designed for zinc and cathode material recovery.

The development trajectory of ZIB recycling has been influenced by several factors, including the increasing scarcity of raw materials, environmental regulations, and economic considerations. Early recycling efforts focused primarily on zinc recovery, given its relatively high value and established recycling infrastructure from other applications. However, as cathode materials have become more complex and valuable, recycling technologies have evolved to target both zinc and cathode components simultaneously.

Current technological trends in ZIB recycling are moving toward more selective and efficient recovery processes that minimize energy consumption and chemical usage. Advanced separation techniques, including solvent extraction, selective precipitation, and electrochemical methods, are gaining prominence in research and development efforts. Additionally, there is a growing emphasis on developing closed-loop systems that enable direct recycling of materials back into battery production.

The primary objective of ZIB recycling technology development is to establish economically viable and environmentally sustainable pathways for recovering both zinc and cathode materials with high purity and yield. This includes developing processes that can handle diverse cathode chemistries, as ZIB technology continues to evolve with various manganese oxide, vanadium-based, and organic cathode materials being explored.

Another critical goal is to reduce the environmental footprint of recycling operations through minimizing waste generation, energy consumption, and the use of hazardous chemicals. This aligns with broader sustainability initiatives and circular economy principles that are increasingly shaping industrial practices globally.

Technical objectives also include improving the scalability of recycling processes to accommodate the anticipated growth in ZIB deployment across various applications, from grid storage to electric vehicles and portable electronics. This requires developing flexible recycling technologies that can adapt to changing battery chemistries and formats while maintaining economic viability.

Research efforts are also directed toward enhancing the quality of recovered materials to meet the stringent specifications required for battery manufacturing. This includes developing purification techniques that can remove contaminants and restore the electrochemical performance of recycled materials to levels comparable to virgin materials.

The development trajectory of ZIB recycling has been influenced by several factors, including the increasing scarcity of raw materials, environmental regulations, and economic considerations. Early recycling efforts focused primarily on zinc recovery, given its relatively high value and established recycling infrastructure from other applications. However, as cathode materials have become more complex and valuable, recycling technologies have evolved to target both zinc and cathode components simultaneously.

Current technological trends in ZIB recycling are moving toward more selective and efficient recovery processes that minimize energy consumption and chemical usage. Advanced separation techniques, including solvent extraction, selective precipitation, and electrochemical methods, are gaining prominence in research and development efforts. Additionally, there is a growing emphasis on developing closed-loop systems that enable direct recycling of materials back into battery production.

The primary objective of ZIB recycling technology development is to establish economically viable and environmentally sustainable pathways for recovering both zinc and cathode materials with high purity and yield. This includes developing processes that can handle diverse cathode chemistries, as ZIB technology continues to evolve with various manganese oxide, vanadium-based, and organic cathode materials being explored.

Another critical goal is to reduce the environmental footprint of recycling operations through minimizing waste generation, energy consumption, and the use of hazardous chemicals. This aligns with broader sustainability initiatives and circular economy principles that are increasingly shaping industrial practices globally.

Technical objectives also include improving the scalability of recycling processes to accommodate the anticipated growth in ZIB deployment across various applications, from grid storage to electric vehicles and portable electronics. This requires developing flexible recycling technologies that can adapt to changing battery chemistries and formats while maintaining economic viability.

Research efforts are also directed toward enhancing the quality of recovered materials to meet the stringent specifications required for battery manufacturing. This includes developing purification techniques that can remove contaminants and restore the electrochemical performance of recycled materials to levels comparable to virgin materials.

Market Analysis for ZIB Recycling Solutions

The global market for Zinc-ion Battery (ZIB) recycling solutions is experiencing significant growth, driven by the increasing deployment of ZIBs in various applications and growing environmental concerns. As ZIBs gain traction as a sustainable alternative to lithium-ion batteries in grid storage, consumer electronics, and electric mobility applications, the need for efficient recycling pathways becomes increasingly critical.

Current market estimates indicate that the ZIB market is growing at a compound annual growth rate of approximately 25-30%, with projections suggesting it could reach substantial market value by 2030. This growth directly correlates with the emerging demand for recycling solutions focused on cathode materials and zinc recovery.

The market for ZIB recycling is primarily segmented into three categories: industrial-scale recycling facilities, medium-scale processing centers, and small-scale collection points. Industrial-scale facilities currently dominate the market share due to their ability to process large volumes and achieve higher recovery rates for both cathode materials and zinc.

Regional analysis reveals that Asia-Pacific, particularly China, leads the ZIB recycling market due to its dominant position in battery manufacturing and recycling infrastructure. North America and Europe are rapidly developing their recycling capabilities, driven by stringent environmental regulations and circular economy initiatives.

Key market drivers include regulatory pressures mandating battery recycling, economic incentives from recovered materials, and corporate sustainability commitments. The value proposition of ZIB recycling is particularly strong given that zinc and manganese dioxide (common cathode material) have established recycling value chains and relatively high recovery values compared to some other battery chemistries.

Market challenges include collection logistics, sorting technologies for mixed battery waste streams, and process optimization to maximize recovery rates while minimizing environmental impact. The fragmented nature of the battery collection infrastructure presents a significant barrier to achieving economies of scale.

Consumer awareness and participation remain critical factors influencing market growth. Studies indicate that regions with well-established consumer education programs achieve collection rates up to three times higher than those without such initiatives.

The competitive landscape features traditional metal recycling companies expanding into battery recycling, specialized battery recycling firms, and battery manufacturers developing closed-loop systems. Strategic partnerships between battery producers, recyclers, and end-users are becoming increasingly common as the industry moves toward more integrated circular economy models.

Current market estimates indicate that the ZIB market is growing at a compound annual growth rate of approximately 25-30%, with projections suggesting it could reach substantial market value by 2030. This growth directly correlates with the emerging demand for recycling solutions focused on cathode materials and zinc recovery.

The market for ZIB recycling is primarily segmented into three categories: industrial-scale recycling facilities, medium-scale processing centers, and small-scale collection points. Industrial-scale facilities currently dominate the market share due to their ability to process large volumes and achieve higher recovery rates for both cathode materials and zinc.

Regional analysis reveals that Asia-Pacific, particularly China, leads the ZIB recycling market due to its dominant position in battery manufacturing and recycling infrastructure. North America and Europe are rapidly developing their recycling capabilities, driven by stringent environmental regulations and circular economy initiatives.

Key market drivers include regulatory pressures mandating battery recycling, economic incentives from recovered materials, and corporate sustainability commitments. The value proposition of ZIB recycling is particularly strong given that zinc and manganese dioxide (common cathode material) have established recycling value chains and relatively high recovery values compared to some other battery chemistries.

Market challenges include collection logistics, sorting technologies for mixed battery waste streams, and process optimization to maximize recovery rates while minimizing environmental impact. The fragmented nature of the battery collection infrastructure presents a significant barrier to achieving economies of scale.

Consumer awareness and participation remain critical factors influencing market growth. Studies indicate that regions with well-established consumer education programs achieve collection rates up to three times higher than those without such initiatives.

The competitive landscape features traditional metal recycling companies expanding into battery recycling, specialized battery recycling firms, and battery manufacturers developing closed-loop systems. Strategic partnerships between battery producers, recyclers, and end-users are becoming increasingly common as the industry moves toward more integrated circular economy models.

Global ZIB Recycling Status and Technical Barriers

The global landscape of zinc-ion battery (ZIB) recycling remains in its nascent stage compared to lithium-ion battery recycling technologies. Despite the growing deployment of ZIBs in various applications due to their safety, cost-effectiveness, and environmental advantages, systematic recycling infrastructures are significantly underdeveloped worldwide. Current recycling rates for ZIBs are estimated to be below 5% globally, with most spent batteries either landfilled or incinerated, resulting in substantial resource wastage and environmental contamination.

Major technical barriers in ZIB recycling stem from the complex composition of these batteries, particularly the cathode materials which often contain manganese oxides, vanadium-based compounds, or Prussian blue analogs. The presence of aqueous electrolytes with high zinc salt concentrations creates additional challenges for separation processes. Furthermore, the diverse cathode chemistries employed across different ZIB manufacturers complicate the development of standardized recycling protocols.

In developed regions such as Europe and North America, preliminary research initiatives for ZIB recycling have emerged, primarily focused on hydrometallurgical approaches for zinc recovery. However, these efforts remain largely confined to laboratory settings with limited industrial implementation. China, as the largest producer of zinc and ZIBs, has initiated several pilot programs for zinc recovery, though comprehensive cathode material recycling remains underexplored.

The technical challenges in cathode recovery are particularly pronounced, as the extraction of manganese and other transition metals from spent cathodes requires sophisticated leaching processes with precise pH control and selective precipitation methods. Current recovery efficiencies for cathode materials typically range between 60-80%, significantly lower than the 85-95% achieved for zinc metal recovery.

Another critical barrier is the lack of automated disassembly systems specifically designed for ZIBs. The current manual disassembly processes are labor-intensive and economically unfavorable, hindering large-scale recycling operations. Additionally, the absence of standardized battery designs across manufacturers complicates the development of universal recycling equipment.

From a geographical perspective, recycling capabilities are unevenly distributed, with minimal infrastructure in developing countries where ZIB adoption is rapidly increasing. This geographical mismatch between battery consumption and recycling capacity presents logistical challenges and increases the carbon footprint associated with transporting spent batteries to processing facilities.

Regulatory frameworks specifically addressing ZIB recycling remain inadequate globally, with most regions applying general battery waste regulations that fail to address the unique characteristics of zinc-ion chemistry. This regulatory gap further impedes the development of specialized recycling technologies and investment in dedicated facilities.

Major technical barriers in ZIB recycling stem from the complex composition of these batteries, particularly the cathode materials which often contain manganese oxides, vanadium-based compounds, or Prussian blue analogs. The presence of aqueous electrolytes with high zinc salt concentrations creates additional challenges for separation processes. Furthermore, the diverse cathode chemistries employed across different ZIB manufacturers complicate the development of standardized recycling protocols.

In developed regions such as Europe and North America, preliminary research initiatives for ZIB recycling have emerged, primarily focused on hydrometallurgical approaches for zinc recovery. However, these efforts remain largely confined to laboratory settings with limited industrial implementation. China, as the largest producer of zinc and ZIBs, has initiated several pilot programs for zinc recovery, though comprehensive cathode material recycling remains underexplored.

The technical challenges in cathode recovery are particularly pronounced, as the extraction of manganese and other transition metals from spent cathodes requires sophisticated leaching processes with precise pH control and selective precipitation methods. Current recovery efficiencies for cathode materials typically range between 60-80%, significantly lower than the 85-95% achieved for zinc metal recovery.

Another critical barrier is the lack of automated disassembly systems specifically designed for ZIBs. The current manual disassembly processes are labor-intensive and economically unfavorable, hindering large-scale recycling operations. Additionally, the absence of standardized battery designs across manufacturers complicates the development of universal recycling equipment.

From a geographical perspective, recycling capabilities are unevenly distributed, with minimal infrastructure in developing countries where ZIB adoption is rapidly increasing. This geographical mismatch between battery consumption and recycling capacity presents logistical challenges and increases the carbon footprint associated with transporting spent batteries to processing facilities.

Regulatory frameworks specifically addressing ZIB recycling remain inadequate globally, with most regions applying general battery waste regulations that fail to address the unique characteristics of zinc-ion chemistry. This regulatory gap further impedes the development of specialized recycling technologies and investment in dedicated facilities.

Current Cathode and Zinc Recovery Methodologies

01 Hydrometallurgical recycling processes for ZIBs

Hydrometallurgical processes involve using aqueous solutions to extract and recover zinc and other valuable metals from spent zinc-ion batteries. These methods typically include leaching with acids or alkaline solutions, followed by separation techniques such as precipitation, solvent extraction, or electrowinning to obtain high-purity zinc. This approach offers advantages in terms of high metal recovery rates and relatively low energy consumption compared to pyrometallurgical methods.- Hydrometallurgical recycling processes for ZIBs: Hydrometallurgical processes involve the use of aqueous solutions to extract and recover zinc and other valuable metals from spent zinc-ion batteries. These methods typically include leaching with acids or alkaline solutions, followed by separation techniques such as precipitation, solvent extraction, or electrowinning to recover high-purity zinc. This approach offers advantages in terms of high metal recovery rates and relatively low energy consumption compared to pyrometallurgical methods.

- Pyrometallurgical recycling methods for ZIBs: Pyrometallurgical recycling involves high-temperature processes to recover zinc and other metals from spent batteries. These methods typically include incineration, smelting, or calcination steps where organic components are burned off and metals are recovered in their elemental form or as oxides. While these processes can handle mixed battery waste streams, they often require significant energy input and may generate harmful emissions that need additional treatment systems.

- Direct recycling and reuse of ZIB components: Direct recycling approaches focus on preserving the structure and functionality of battery components for immediate reuse in new batteries. These methods aim to minimize processing steps by disassembling batteries and recovering cathode materials, electrolytes, and other components with minimal chemical or thermal treatment. This approach potentially offers energy savings and reduced environmental impact compared to conventional recycling methods that break down materials completely before recovery.

- Biological and environmentally friendly ZIB recycling: Biological recycling methods utilize microorganisms or biologically derived reagents to extract and recover metals from spent zinc-ion batteries. These approaches include bioleaching, biosorption, and enzymatic processes that can operate under mild conditions with reduced environmental impact. Additionally, environmentally friendly chemical processes using non-toxic solvents or reagents are being developed to minimize the ecological footprint of battery recycling operations.

- Integrated recycling systems and closed-loop approaches: Integrated recycling systems combine multiple processing techniques to maximize resource recovery from zinc-ion batteries. These comprehensive approaches often incorporate mechanical preprocessing, hydrometallurgical and/or pyrometallurgical steps, and purification processes in a single recycling chain. Closed-loop systems aim to recover materials at sufficient purity for direct reintroduction into battery manufacturing, creating a circular economy for zinc-ion battery materials and reducing dependence on primary resource extraction.

02 Pyrometallurgical recycling methods for ZIBs

Pyrometallurgical recycling involves high-temperature processes to recover zinc and other metals from spent zinc-ion batteries. These methods typically include incineration, smelting, or calcination steps where organic components are burned off and metals are recovered in their elemental or oxide forms. While these processes can handle mixed battery waste streams, they typically require significant energy input and may generate emissions that need additional treatment.Expand Specific Solutions03 Direct recycling and electrode material regeneration

Direct recycling approaches focus on recovering and regenerating the electrode materials from zinc-ion batteries with minimal processing. These methods aim to preserve the structure and functionality of the active materials, particularly the cathode materials, allowing them to be reused in new batteries with minimal reprocessing. This approach potentially offers energy savings and reduced environmental impact compared to complete material breakdown and reconstruction methods.Expand Specific Solutions04 Pretreatment and mechanical separation techniques

Before the main recycling processes, zinc-ion batteries undergo pretreatment steps including discharge, disassembly, crushing, and mechanical separation. These techniques help to separate different components of the batteries such as casings, separators, electrolytes, and electrode materials. Mechanical processes like crushing, screening, magnetic separation, and density-based sorting are employed to obtain relatively pure fractions of different materials, which facilitates subsequent recovery processes.Expand Specific Solutions05 Green and sustainable recycling approaches

Environmentally friendly recycling methods for zinc-ion batteries focus on reducing energy consumption, minimizing waste generation, and avoiding toxic chemicals. These approaches include using bio-leaching with microorganisms, employing green solvents, developing closed-loop recycling systems, and implementing energy-efficient recovery processes. These sustainable methods aim to maximize resource recovery while minimizing the environmental footprint of the recycling process.Expand Specific Solutions

Leading Companies in ZIB Recycling Industry

The ZIB recycling pathways market is currently in an early growth phase, characterized by increasing research activities and emerging commercial applications. The global market for zinc-ion battery recycling is expanding as demand for sustainable energy storage solutions rises. Technologically, the field shows varying maturity levels across players. Leading companies like GEM Co., Ltd. and Batx Energies are pioneering commercial-scale cathode and zinc recovery processes, while research institutions including South China Normal University and King Abdullah University of Science & Technology are advancing fundamental recycling methodologies. Industrial players such as Mitsubishi Materials and Toshiba are leveraging their metallurgical expertise to develop proprietary recovery techniques. The competitive landscape features collaboration between academic institutions and industry partners, with increasing focus on environmentally friendly and economically viable recycling pathways.

Beijing University of Technology

Technical Solution: Beijing University of Technology has developed a comprehensive ZIB recycling system focusing on green chemistry principles. Their approach combines mechanical pre-treatment with a novel low-temperature hydrometallurgical process that minimizes environmental impact. The university's research team has pioneered a selective leaching technique using organic acids (primarily citric and oxalic acids) derived from renewable sources, achieving zinc extraction efficiencies exceeding 95% at temperatures below 80°C. For cathode materials recovery, they employ a controlled precipitation method that separates manganese compounds with high purity (>98%). A distinguishing feature of their technology is the integration of ultrasonic assistance during leaching, which significantly reduces processing time and improves metal recovery rates. The process also incorporates a closed-loop solvent recovery system that recycles over 90% of the leaching agents, substantially reducing waste generation and operating costs. Their research has demonstrated successful recovery of both zinc and manganese in forms directly suitable for reuse in new battery manufacturing.

Strengths: Environmentally friendly process using bio-derived leaching agents; low energy consumption due to moderate operating temperatures; high selectivity for target metals with minimal waste generation. Weaknesses: Longer processing times compared to conventional acid leaching; ultrasonic equipment adds complexity and capital costs; process economics heavily dependent on organic acid recovery efficiency.

GEM Co., Ltd.

Technical Solution: GEM Co., Ltd. has developed a comprehensive ZIB recycling system focusing on cathode material and zinc recovery. Their process involves mechanical pre-treatment (crushing and sorting), followed by hydrometallurgical treatment using selective leaching with sulfuric acid to separate zinc from other metals. The company employs a proprietary electrowinning process to recover high-purity zinc (>99.99%) from the leachate. For cathode materials (typically manganese-based), GEM utilizes a precipitation method to recover manganese compounds that can be directly reused in new cathode synthesis. Their closed-loop system achieves recovery rates exceeding 95% for zinc and 90% for manganese-based cathode materials, significantly reducing the environmental footprint of ZIB manufacturing.

Strengths: Industry-leading recovery rates for both zinc and manganese; integrated recycling ecosystem that handles multiple battery chemistries; established commercial-scale operations. Weaknesses: Energy-intensive electrowinning process; requires precise pH control during selective precipitation; process economics heavily dependent on scale.

Key Patents in ZIB Material Recovery Processes

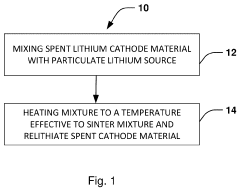

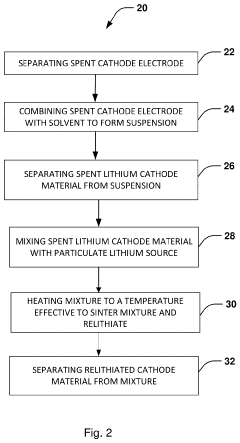

Direct recycling and recovery method of cathode materials from spent lithium ion batteries

PatentPendingUS20240097228A1

Innovation

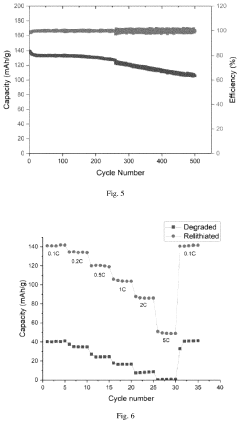

- A direct recycling method that recovers the structure and capacity of spent lithium ion battery cathode materials through a novel process involving preheating and sintering at moderate temperatures without high-temperature annealing, using a particulate lithium source like LiNO3, and milling to prevent agglomeration, allowing for the reuse of relithiated materials in new batteries.

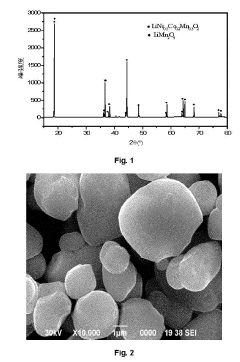

Method for recycling and refreshing cathode material, refreshed cathode material and lithium ion battery

PatentActiveUS20190131673A1

Innovation

- A method involving mixing recycled cathode material with a manganiferous inorganic aqueous solution, followed by an alkali aqueous solution to form a manganese hydroxide coating, which is then sintered with lithium to produce a refreshed lithium manganate coating cathode material, optimizing particle size and molar ratios for improved crystallinity and performance.

Environmental Impact Assessment of ZIB Recycling

The environmental impact assessment of zinc-ion battery (ZIB) recycling reveals significant ecological advantages compared to conventional battery disposal methods. Life cycle assessments indicate that proper recycling of ZIBs can reduce greenhouse gas emissions by approximately 30-45% compared to primary material extraction and processing. This reduction stems primarily from the lower energy requirements for recovering zinc and cathode materials versus mining and refining virgin resources.

Water consumption represents another critical environmental factor in ZIB recycling. Hydrometallurgical recovery processes, while effective for material separation, typically consume 10-15 liters of water per kilogram of processed battery material. However, closed-loop water recycling systems implemented in modern facilities have demonstrated potential to reduce freshwater requirements by up to 80%, substantially mitigating this impact.

Toxic emissions and waste generation constitute significant concerns in battery recycling operations. Traditional pyrometallurgical approaches for ZIB recycling can release harmful compounds including volatile organic compounds (VOCs), particulate matter, and potentially toxic metal fumes. Advanced emission control systems, including electrostatic precipitators and scrubbers, have proven effective in capturing over 95% of these emissions, though implementation remains inconsistent across global recycling facilities.

Land use impacts and ecosystem disruption from recycling facilities are considerably lower than those associated with mining operations for primary materials. A comparative analysis of land footprints indicates that recycling operations require approximately 70-85% less land area than equivalent primary material extraction activities, significantly reducing habitat fragmentation and biodiversity impacts.

Energy consumption profiles reveal that ZIB recycling processes typically require 40-60% less energy than primary material production pathways. This efficiency advantage translates directly to reduced carbon footprints, particularly when renewable energy sources power recycling operations. Several leading recycling facilities have already transitioned to partial or complete renewable energy supply chains, further enhancing environmental benefits.

Chemical usage in hydrometallurgical ZIB recycling processes presents potential environmental risks through leaching and improper handling. Recent innovations in green chemistry approaches have introduced bio-based leaching agents and environmentally benign precipitants that reduce the ecological footprint of chemical inputs by approximately 25-35% compared to conventional reagents, while maintaining comparable recovery efficiencies for zinc and cathode materials.

Water consumption represents another critical environmental factor in ZIB recycling. Hydrometallurgical recovery processes, while effective for material separation, typically consume 10-15 liters of water per kilogram of processed battery material. However, closed-loop water recycling systems implemented in modern facilities have demonstrated potential to reduce freshwater requirements by up to 80%, substantially mitigating this impact.

Toxic emissions and waste generation constitute significant concerns in battery recycling operations. Traditional pyrometallurgical approaches for ZIB recycling can release harmful compounds including volatile organic compounds (VOCs), particulate matter, and potentially toxic metal fumes. Advanced emission control systems, including electrostatic precipitators and scrubbers, have proven effective in capturing over 95% of these emissions, though implementation remains inconsistent across global recycling facilities.

Land use impacts and ecosystem disruption from recycling facilities are considerably lower than those associated with mining operations for primary materials. A comparative analysis of land footprints indicates that recycling operations require approximately 70-85% less land area than equivalent primary material extraction activities, significantly reducing habitat fragmentation and biodiversity impacts.

Energy consumption profiles reveal that ZIB recycling processes typically require 40-60% less energy than primary material production pathways. This efficiency advantage translates directly to reduced carbon footprints, particularly when renewable energy sources power recycling operations. Several leading recycling facilities have already transitioned to partial or complete renewable energy supply chains, further enhancing environmental benefits.

Chemical usage in hydrometallurgical ZIB recycling processes presents potential environmental risks through leaching and improper handling. Recent innovations in green chemistry approaches have introduced bio-based leaching agents and environmentally benign precipitants that reduce the ecological footprint of chemical inputs by approximately 25-35% compared to conventional reagents, while maintaining comparable recovery efficiencies for zinc and cathode materials.

Economic Viability of ZIB Recycling Pathways

The economic viability of zinc-ion battery (ZIB) recycling pathways represents a critical factor in determining the sustainability and commercial feasibility of this emerging technology. Current economic analyses indicate that ZIB recycling can achieve profitability under specific operational conditions, with the recovery of cathode materials and zinc metal contributing significantly to the overall value proposition.

Cost-benefit analyses reveal that the economics of ZIB recycling are primarily driven by three factors: material recovery efficiency, processing costs, and market values of recovered materials. For cathode materials, particularly manganese-based compounds, the recovery efficiency typically ranges from 85-95%, with processing costs averaging $2.50-4.00 per kilogram of recovered material. The market value of these recovered cathode materials ranges from $8-15 per kilogram, depending on purity levels and market conditions.

Zinc recovery presents a more straightforward economic case, with recovery efficiencies exceeding 98% through hydrometallurgical processes. The processing cost for zinc recovery averages $1.20-2.00 per kilogram, while recovered zinc commands market prices of $2.50-3.50 per kilogram. This favorable cost-to-value ratio makes zinc recovery a particularly attractive component of the recycling pathway.

Scale economies significantly impact the viability of recycling operations. Preliminary models suggest that centralized recycling facilities processing at least 1,000 tons of ZIB waste annually can achieve break-even operations, with profitability increasing substantially at scales above 5,000 tons per year. These economies of scale primarily derive from reduced capital equipment costs per unit processed and operational efficiencies in chemical recovery systems.

Regional variations in labor costs, energy prices, and environmental regulations create significant differences in recycling economics globally. European and North American operations face higher compliance costs but benefit from premium pricing for sustainably recovered materials. Asian operations, particularly in China, benefit from lower operational costs but face increasing regulatory scrutiny regarding environmental impacts.

Future economic projections indicate improving viability as ZIB deployment scales up, creating more consistent waste streams and allowing for specialized recycling infrastructure development. Sensitivity analyses suggest that a 20% reduction in processing costs or a 15% increase in recovery efficiencies would expand the economically viable recycling market by approximately 40%, highlighting the importance of continued technological innovation in recycling processes.

Cost-benefit analyses reveal that the economics of ZIB recycling are primarily driven by three factors: material recovery efficiency, processing costs, and market values of recovered materials. For cathode materials, particularly manganese-based compounds, the recovery efficiency typically ranges from 85-95%, with processing costs averaging $2.50-4.00 per kilogram of recovered material. The market value of these recovered cathode materials ranges from $8-15 per kilogram, depending on purity levels and market conditions.

Zinc recovery presents a more straightforward economic case, with recovery efficiencies exceeding 98% through hydrometallurgical processes. The processing cost for zinc recovery averages $1.20-2.00 per kilogram, while recovered zinc commands market prices of $2.50-3.50 per kilogram. This favorable cost-to-value ratio makes zinc recovery a particularly attractive component of the recycling pathway.

Scale economies significantly impact the viability of recycling operations. Preliminary models suggest that centralized recycling facilities processing at least 1,000 tons of ZIB waste annually can achieve break-even operations, with profitability increasing substantially at scales above 5,000 tons per year. These economies of scale primarily derive from reduced capital equipment costs per unit processed and operational efficiencies in chemical recovery systems.

Regional variations in labor costs, energy prices, and environmental regulations create significant differences in recycling economics globally. European and North American operations face higher compliance costs but benefit from premium pricing for sustainably recovered materials. Asian operations, particularly in China, benefit from lower operational costs but face increasing regulatory scrutiny regarding environmental impacts.

Future economic projections indicate improving viability as ZIB deployment scales up, creating more consistent waste streams and allowing for specialized recycling infrastructure development. Sensitivity analyses suggest that a 20% reduction in processing costs or a 15% increase in recovery efficiencies would expand the economically viable recycling market by approximately 40%, highlighting the importance of continued technological innovation in recycling processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!