ZIBs for Cold Chain Backup: Use-Case Guide

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ZIB Technology Background and Objectives

Zinc-ion batteries (ZIBs) have emerged as a promising energy storage technology over the past decade, evolving from laboratory curiosity to commercially viable solutions. The development of ZIBs represents a significant advancement in the quest for safer, more sustainable alternatives to traditional lithium-ion batteries. Initially conceptualized in the early 2000s, ZIBs have gained substantial research momentum since 2015, with exponential growth in published studies and patent applications.

The fundamental appeal of ZIBs lies in their unique combination of safety, environmental friendliness, and cost-effectiveness. Unlike lithium-ion batteries, ZIBs utilize abundant zinc resources, which constitute approximately 0.02% of the Earth's crust, making them significantly more accessible and economically viable. The aqueous electrolyte systems employed in ZIBs substantially reduce fire and explosion risks that plague many conventional battery technologies.

The technical evolution of ZIBs has focused on addressing key challenges including zinc dendrite formation, limited cycle life, and capacity fading. Recent breakthroughs in electrode materials, electrolyte formulations, and cell design have dramatically improved performance metrics, with modern ZIBs achieving energy densities of 50-100 Wh/kg and cycle lives exceeding 1000 cycles under optimal conditions.

In the context of cold chain applications, ZIBs present a particularly compelling value proposition. Cold chain logistics—the temperature-controlled supply chain necessary for food, pharmaceuticals, and biological materials—has traditionally relied on either continuous power supply or conventional battery backup systems with significant limitations in extreme temperature environments. The primary objective of ZIB implementation in cold chain backup systems is to provide reliable, safe, and cost-effective power redundancy across the temperature range of -20°C to +40°C typically encountered in cold chain operations.

Current technological objectives for ZIBs in cold chain applications include enhancing low-temperature performance, where ionic conductivity traditionally decreases; extending operational lifetime under partial state-of-charge conditions common in backup scenarios; and developing intelligent battery management systems specifically optimized for the unique discharge profiles of cold chain equipment.

The development trajectory aims to achieve ZIB systems capable of maintaining at least 80% of room temperature capacity at -20°C, with minimal self-discharge rates below 3% monthly, and operational lifespans exceeding five years in backup applications. These parameters would position ZIBs as an ideal technology for cold chain resilience, particularly in regions with unstable grid infrastructure or for mobile cold chain solutions.

The fundamental appeal of ZIBs lies in their unique combination of safety, environmental friendliness, and cost-effectiveness. Unlike lithium-ion batteries, ZIBs utilize abundant zinc resources, which constitute approximately 0.02% of the Earth's crust, making them significantly more accessible and economically viable. The aqueous electrolyte systems employed in ZIBs substantially reduce fire and explosion risks that plague many conventional battery technologies.

The technical evolution of ZIBs has focused on addressing key challenges including zinc dendrite formation, limited cycle life, and capacity fading. Recent breakthroughs in electrode materials, electrolyte formulations, and cell design have dramatically improved performance metrics, with modern ZIBs achieving energy densities of 50-100 Wh/kg and cycle lives exceeding 1000 cycles under optimal conditions.

In the context of cold chain applications, ZIBs present a particularly compelling value proposition. Cold chain logistics—the temperature-controlled supply chain necessary for food, pharmaceuticals, and biological materials—has traditionally relied on either continuous power supply or conventional battery backup systems with significant limitations in extreme temperature environments. The primary objective of ZIB implementation in cold chain backup systems is to provide reliable, safe, and cost-effective power redundancy across the temperature range of -20°C to +40°C typically encountered in cold chain operations.

Current technological objectives for ZIBs in cold chain applications include enhancing low-temperature performance, where ionic conductivity traditionally decreases; extending operational lifetime under partial state-of-charge conditions common in backup scenarios; and developing intelligent battery management systems specifically optimized for the unique discharge profiles of cold chain equipment.

The development trajectory aims to achieve ZIB systems capable of maintaining at least 80% of room temperature capacity at -20°C, with minimal self-discharge rates below 3% monthly, and operational lifespans exceeding five years in backup applications. These parameters would position ZIBs as an ideal technology for cold chain resilience, particularly in regions with unstable grid infrastructure or for mobile cold chain solutions.

Cold Chain Backup Market Demand Analysis

The cold chain backup market is experiencing significant growth driven by the increasing demand for reliable temperature-controlled storage solutions across various industries. The global cold chain market was valued at approximately $220 billion in 2021 and is projected to reach $366 billion by 2026, growing at a CAGR of 10.8%. Within this broader market, backup power solutions represent a critical segment as businesses seek to mitigate risks associated with power outages and equipment failures.

Healthcare and pharmaceutical sectors constitute the largest demand drivers for cold chain backup solutions, accounting for nearly 35% of the market share. The COVID-19 pandemic has substantially accelerated this demand, particularly for vaccine storage requiring ultra-low temperatures. Hospitals, clinics, research laboratories, and pharmaceutical companies are increasingly investing in reliable backup systems to protect temperature-sensitive biologics and medications.

Food and beverage industry represents the second-largest market segment, contributing approximately 28% of the demand. With growing consumer preference for fresh and frozen products, retailers and distributors are enhancing their cold storage infrastructure with dependable backup systems. The economic impact of inventory loss due to cold chain failures in this sector can reach millions of dollars per incident, justifying significant investments in backup technologies.

Emerging markets, particularly in Asia-Pacific and Latin America, are showing the fastest growth rates for cold chain backup solutions, with annual increases exceeding 15%. This growth is driven by expanding healthcare access, rising middle-class consumption of perishable goods, and the development of more sophisticated supply chain networks in these regions.

Energy efficiency has emerged as a key market requirement, with over 70% of procurement decisions now considering operational efficiency metrics. Traditional backup systems like diesel generators are increasingly being replaced by more sustainable alternatives that offer lower operational costs and reduced environmental impact.

Reliability metrics have become paramount in purchase decisions, with businesses willing to pay premium prices for solutions that offer 99.99% or higher uptime guarantees. The average cost of cold chain failures ranges from $10,000 to over $1 million per incident depending on the industry, making investment in reliable backup systems a strategic priority rather than merely an operational expense.

The market shows increasing demand for integrated monitoring and management systems that provide real-time alerts and remote control capabilities. Approximately 65% of new cold chain backup installations now include IoT-enabled monitoring features, reflecting the growing importance of data-driven management in cold chain operations.

Healthcare and pharmaceutical sectors constitute the largest demand drivers for cold chain backup solutions, accounting for nearly 35% of the market share. The COVID-19 pandemic has substantially accelerated this demand, particularly for vaccine storage requiring ultra-low temperatures. Hospitals, clinics, research laboratories, and pharmaceutical companies are increasingly investing in reliable backup systems to protect temperature-sensitive biologics and medications.

Food and beverage industry represents the second-largest market segment, contributing approximately 28% of the demand. With growing consumer preference for fresh and frozen products, retailers and distributors are enhancing their cold storage infrastructure with dependable backup systems. The economic impact of inventory loss due to cold chain failures in this sector can reach millions of dollars per incident, justifying significant investments in backup technologies.

Emerging markets, particularly in Asia-Pacific and Latin America, are showing the fastest growth rates for cold chain backup solutions, with annual increases exceeding 15%. This growth is driven by expanding healthcare access, rising middle-class consumption of perishable goods, and the development of more sophisticated supply chain networks in these regions.

Energy efficiency has emerged as a key market requirement, with over 70% of procurement decisions now considering operational efficiency metrics. Traditional backup systems like diesel generators are increasingly being replaced by more sustainable alternatives that offer lower operational costs and reduced environmental impact.

Reliability metrics have become paramount in purchase decisions, with businesses willing to pay premium prices for solutions that offer 99.99% or higher uptime guarantees. The average cost of cold chain failures ranges from $10,000 to over $1 million per incident depending on the industry, making investment in reliable backup systems a strategic priority rather than merely an operational expense.

The market shows increasing demand for integrated monitoring and management systems that provide real-time alerts and remote control capabilities. Approximately 65% of new cold chain backup installations now include IoT-enabled monitoring features, reflecting the growing importance of data-driven management in cold chain operations.

ZIB Technical Status and Challenges

Zinc-ion batteries (ZIBs) have emerged as a promising technology for cold chain backup power solutions, yet their widespread adoption faces several technical challenges. Currently, ZIBs demonstrate significant advantages in safety, cost-effectiveness, and environmental compatibility compared to traditional lithium-ion batteries. However, their performance in low-temperature environments—critical for cold chain applications—remains a major technical hurdle.

Global research indicates that ZIB technology has reached commercial viability in certain applications, with companies in China, the United States, and Europe leading development efforts. The energy density of current ZIBs ranges from 70-120 Wh/kg, substantially lower than lithium-ion counterparts (200-300 Wh/kg), limiting their application in space-constrained cold chain scenarios.

A primary technical challenge for ZIBs in cold chain backup is their diminished capacity and increased internal resistance at low temperatures. Below 0°C, conventional zinc-based electrolytes experience significantly reduced ionic conductivity, resulting in power output decreases of up to 50%. This performance degradation makes them unreliable for critical cold storage backup applications without additional engineering solutions.

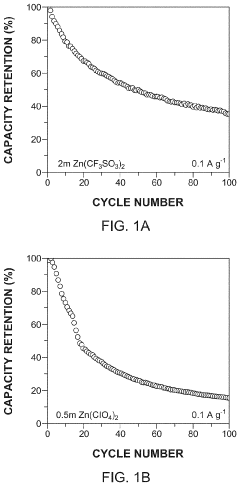

Dendrite formation during charging cycles represents another substantial technical barrier. In cold chain environments, the irregular zinc deposition process is exacerbated, accelerating capacity fade and shortening battery lifespan. Current research indicates that after 500 cycles at standard temperatures, capacity retention averages 80%, but this drops to approximately 65% in sub-zero conditions.

The geographical distribution of ZIB technology development shows concentration in East Asia (particularly China), North America, and Western Europe. Chinese institutions and companies hold approximately 60% of patents related to ZIB technology, followed by the United States (18%) and European countries (15%). This distribution reflects both research capabilities and strategic interests in battery technology independence.

Self-discharge rates present another challenge for cold chain backup applications. Current ZIB formulations exhibit monthly self-discharge rates of 3-5% at room temperature, increasing to 7-10% in cold environments. This necessitates more frequent maintenance and reduces reliability for long-term backup scenarios.

Manufacturing scalability remains problematic, with current production techniques unable to consistently produce high-quality electrodes at industrial scales. Variations in electrode thickness and zinc distribution can reach 8-12% in mass production settings, leading to performance inconsistencies that are particularly problematic in critical backup applications.

Despite these challenges, recent advancements in electrolyte formulations incorporating antifreeze compounds and electrode surface modifications show promise for enhancing low-temperature performance, with some laboratory prototypes maintaining 85% capacity at -20°C compared to room temperature operation.

Global research indicates that ZIB technology has reached commercial viability in certain applications, with companies in China, the United States, and Europe leading development efforts. The energy density of current ZIBs ranges from 70-120 Wh/kg, substantially lower than lithium-ion counterparts (200-300 Wh/kg), limiting their application in space-constrained cold chain scenarios.

A primary technical challenge for ZIBs in cold chain backup is their diminished capacity and increased internal resistance at low temperatures. Below 0°C, conventional zinc-based electrolytes experience significantly reduced ionic conductivity, resulting in power output decreases of up to 50%. This performance degradation makes them unreliable for critical cold storage backup applications without additional engineering solutions.

Dendrite formation during charging cycles represents another substantial technical barrier. In cold chain environments, the irregular zinc deposition process is exacerbated, accelerating capacity fade and shortening battery lifespan. Current research indicates that after 500 cycles at standard temperatures, capacity retention averages 80%, but this drops to approximately 65% in sub-zero conditions.

The geographical distribution of ZIB technology development shows concentration in East Asia (particularly China), North America, and Western Europe. Chinese institutions and companies hold approximately 60% of patents related to ZIB technology, followed by the United States (18%) and European countries (15%). This distribution reflects both research capabilities and strategic interests in battery technology independence.

Self-discharge rates present another challenge for cold chain backup applications. Current ZIB formulations exhibit monthly self-discharge rates of 3-5% at room temperature, increasing to 7-10% in cold environments. This necessitates more frequent maintenance and reduces reliability for long-term backup scenarios.

Manufacturing scalability remains problematic, with current production techniques unable to consistently produce high-quality electrodes at industrial scales. Variations in electrode thickness and zinc distribution can reach 8-12% in mass production settings, leading to performance inconsistencies that are particularly problematic in critical backup applications.

Despite these challenges, recent advancements in electrolyte formulations incorporating antifreeze compounds and electrode surface modifications show promise for enhancing low-temperature performance, with some laboratory prototypes maintaining 85% capacity at -20°C compared to room temperature operation.

Current ZIB Implementation for Cold Chain Backup

01 Electrode materials for zinc-ion batteries

Various materials can be used as electrodes in zinc-ion batteries to improve performance. These include manganese-based compounds, vanadium-based materials, and carbon-based structures. The selection and optimization of electrode materials significantly impact the battery's capacity, cycling stability, and rate capability. Novel electrode designs with hierarchical structures or composite formations can enhance ion diffusion and electron transport within the battery system.- Electrode materials for zinc-ion batteries: Various materials can be used as electrodes in zinc-ion batteries to improve performance. These include manganese-based oxides, vanadium-based compounds, and carbon-based materials. The selection and optimization of electrode materials significantly impact the battery's capacity, cycling stability, and rate capability. Novel electrode designs and composite structures can enhance ion diffusion and electron transport within the battery system.

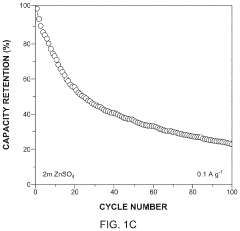

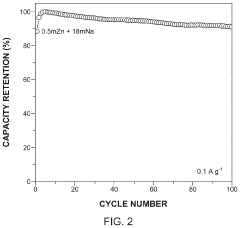

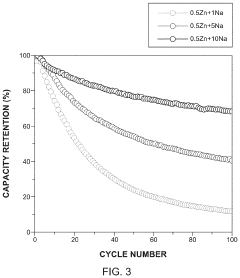

- Electrolyte formulations for zinc-ion batteries: Electrolyte composition plays a crucial role in zinc-ion battery performance. Aqueous electrolytes containing zinc salts (such as zinc sulfate or zinc chloride) can be modified with additives to suppress dendrite formation and side reactions. Gel electrolytes and solid-state electrolytes are being developed to enhance safety and stability. The concentration of zinc ions and pH of the electrolyte significantly affect the electrochemical performance and cycle life of the battery.

- Structural design and manufacturing processes: The structural design of zinc-ion batteries affects their performance and durability. Innovations include flexible and bendable battery designs, sandwich structures, and 3D architectures. Manufacturing processes such as electrospinning, hydrothermal synthesis, and solution processing can be optimized to create high-performance battery components. Assembly techniques and packaging methods also influence the battery's energy density and mechanical stability.

- Performance enhancement strategies: Various strategies can enhance the performance of zinc-ion batteries, including surface modification of electrodes, interface engineering, and the use of functional separators. Doping electrode materials with heteroatoms can improve conductivity and stability. Hierarchical porous structures facilitate ion transport and accommodate volume changes during cycling. These enhancements aim to address challenges such as capacity fading, self-discharge, and limited rate capability.

- Applications and system integration: Zinc-ion batteries are being developed for various applications including grid energy storage, portable electronics, and wearable devices. System integration considerations include battery management systems, thermal management, and safety features. The scalability of zinc-ion battery technology and its compatibility with existing manufacturing infrastructure make it promising for commercial deployment. Environmental factors and cost considerations also influence the application scope of these batteries.

02 Electrolyte formulations for zinc-ion batteries

Electrolyte composition plays a crucial role in zinc-ion battery performance. Aqueous electrolytes containing zinc salts can be modified with additives to suppress dendrite formation and side reactions. Gel electrolytes offer improved safety and flexibility compared to liquid electrolytes. The concentration of zinc ions, pH value, and supporting salts in the electrolyte significantly affect the electrochemical stability window and overall battery performance.Expand Specific Solutions03 Zinc-ion battery structural design and assembly

The structural design of zinc-ion batteries impacts their performance and application range. Flexible and wearable zinc-ion batteries require special design considerations for maintaining performance under mechanical stress. Stacked, wound, or pouch cell configurations offer different advantages in terms of energy density and manufacturing complexity. Novel cell architectures can address issues like volume expansion during cycling and improve the overall energy density of the battery system.Expand Specific Solutions04 Zinc anode protection and modification strategies

Zinc anodes in zinc-ion batteries face challenges such as dendrite formation and corrosion. Surface modification techniques, including coating with protective layers or introducing additives, can enhance the stability and cycling performance of zinc anodes. Alloying zinc with other metals can also improve the electrochemical properties and suppress unwanted side reactions. These strategies aim to extend battery life and improve safety by maintaining the structural integrity of the zinc anode during repeated charge-discharge cycles.Expand Specific Solutions05 Advanced manufacturing methods for zinc-ion batteries

Manufacturing techniques significantly impact the performance and cost of zinc-ion batteries. Advanced methods such as 3D printing, roll-to-roll processing, and spray coating can be employed to fabricate battery components with precise control over their structure and composition. These techniques enable the production of batteries with complex architectures and improved interfaces between components. Scalable and environmentally friendly manufacturing processes are essential for the commercial viability of zinc-ion batteries as alternatives to lithium-ion technology.Expand Specific Solutions

Key Players in ZIB Cold Chain Solutions

The ZIB (Zinc-Ion Battery) cold chain backup market is in its early growth stage, with increasing adoption driven by sustainable energy storage demands. The market is projected to expand significantly as cold chain logistics requires reliable backup power solutions. Technologically, ZIBs are advancing rapidly with companies at varying maturity levels. Shenzhen Hanshu Technology leads with specialized energy storage solutions, while Huawei and Intel are leveraging their technological expertise to develop integrated systems. Traditional cold chain players like Carrier and Siemens are incorporating ZIB technology into their product ecosystems. Academic institutions including Tianjin University and Shenzhen University are accelerating innovation through research partnerships with industry leaders, creating a competitive landscape balanced between established corporations and emerging specialists.

Shenzhen Hanshu Technology New Energy Co Ltd.

Technical Solution: Shenzhen Hanshu has developed advanced zinc-ion battery (ZIB) solutions specifically engineered for cold chain backup applications. Their technology utilizes aqueous zinc-ion electrolytes with manganese oxide cathodes that maintain performance at temperatures as low as -20°C. The company's proprietary electrolyte additives prevent zinc dendrite formation during charging cycles, extending battery lifespan in cold environments. Their ZIB systems feature integrated thermal management that optimizes battery performance across varying temperature conditions, crucial for cold chain applications. Hanshu's batteries deliver up to 2000 charge-discharge cycles while maintaining 80% capacity, significantly outperforming traditional lead-acid alternatives in cold storage facilities. The company has implemented these systems in pharmaceutical cold storage facilities across China, demonstrating reliable performance during power outages.

Strengths: Superior low-temperature performance compared to lithium-ion alternatives; environmentally friendly aqueous electrolyte system; longer cycle life in cold environments; lower maintenance requirements. Weaknesses: Lower energy density compared to some lithium-based systems; limited high-current discharge capabilities; relatively new technology with less field validation data compared to established backup solutions.

Shanghai Origincell Biological Cryo Equipment Co. Ltd.

Technical Solution: Shanghai Origincell has pioneered specialized ZIB backup systems designed specifically for ultra-low temperature biological storage applications. Their technology incorporates zinc-ion batteries with modified carbon-based cathodes and specialized electrolyte formulations that maintain conductivity at temperatures down to -40°C. The company's proprietary battery management system includes predictive analytics that anticipate power requirements based on cooling system demands, optimizing battery discharge profiles. Their ZIB solutions feature redundant cell architecture that ensures continued operation even if individual cells fail, critical for preserving irreplaceable biological samples. Origincell's systems provide up to 12 hours of backup power for -80°C freezers during grid outages, with intelligent load management that prioritizes critical systems. The technology has been deployed in major biobanks and research institutions across Asia.

Strengths: Specifically engineered for ultra-low temperature applications; intelligent power management system optimized for cryogenic equipment; redundant design for mission-critical reliability; purpose-built for biological sample preservation. Weaknesses: Higher initial cost compared to traditional backup solutions; requires specialized installation and maintenance; limited scalability for very large facilities; relatively new technology in the biopreservation market.

Core ZIB Patents and Technical Literature

Aqueous zinc-ion battery with stable performance during overcharging

PatentPendingUS20250219158A1

Innovation

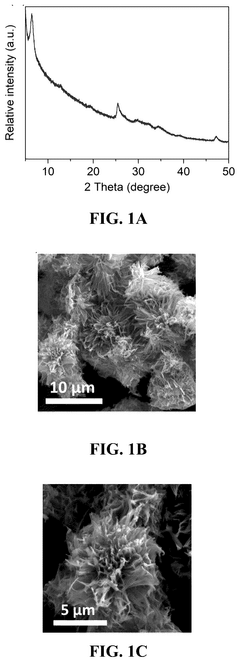

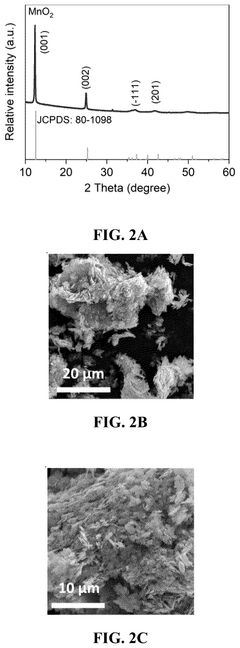

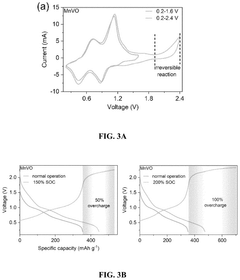

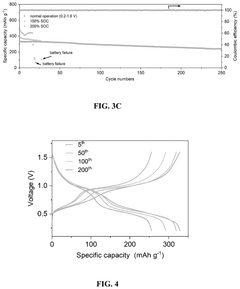

- Incorporation of bromine-based self-sacrificial additives into the electrolyte that undergo oxidation before electrolyte decomposition, providing overcharge protection and maintaining stable electrolyte environments, using cathode materials like Mn2+ expanded hydrated vanadium (MnVO) and manganese dioxide (MnO2).

Cathode and electrolyte chemistry for scalable zinc ion battery

PatentPendingUS20230039527A1

Innovation

- A highly concentrated aqueous electrolyte composed of zinc perchlorate and sodium perchlorate with a ratio of at least 30, combined with a vanadium-based cathode material in the form of nanowires, enhances stability and reversibility, reducing cathode dissolution and facilitating scalable production.

Environmental Impact and Sustainability

Zinc-ion batteries (ZIBs) represent a significant advancement in sustainable energy storage solutions for cold chain applications. When evaluating their environmental impact, ZIBs demonstrate considerable advantages over traditional lead-acid and lithium-ion alternatives. The aqueous electrolyte system in ZIBs eliminates the fire and explosion risks associated with organic electrolytes, making them inherently safer for cold storage environments where temperature control is critical.

From a lifecycle perspective, ZIBs exhibit a reduced carbon footprint compared to conventional battery technologies. The manufacturing process requires approximately 30% less energy than lithium-ion production, primarily due to the abundance and accessibility of zinc resources. Zinc is the 24th most abundant element in Earth's crust, with global reserves estimated at 250 million tons, ensuring long-term supply sustainability without the geopolitical complications associated with lithium and cobalt extraction.

The end-of-life management of ZIBs presents another sustainability advantage. With recycling rates for zinc exceeding 80% in developed markets, these batteries contribute significantly to circular economy principles. The recycling process for zinc is well-established and less energy-intensive than for lithium-ion batteries, requiring approximately 76% less energy than primary zinc production. This efficiency translates to reduced greenhouse gas emissions throughout the battery lifecycle.

In cold chain applications specifically, ZIBs' environmental benefits are amplified by their performance characteristics. Their stable operation at low temperatures reduces the energy required for auxiliary heating systems often needed for lithium-ion batteries in cold environments. Studies indicate that ZIBs maintain up to 85% of their capacity at -20°C, compared to lithium-ion batteries which may retain only 50-60% capacity under similar conditions.

Water consumption represents another critical environmental consideration. ZIB manufacturing requires approximately 40% less water than lithium-ion production processes. Additionally, the absence of toxic materials like lead or cadmium reduces the risk of environmental contamination during production, use, or disposal phases.

For cold chain operators implementing sustainability initiatives, ZIBs offer quantifiable environmental benefits that can be incorporated into corporate social responsibility reporting. The technology aligns with several United Nations Sustainable Development Goals, particularly Goal 7 (Affordable and Clean Energy), Goal 12 (Responsible Consumption and Production), and Goal 13 (Climate Action), providing organizations with tangible metrics for sustainability performance evaluation.

From a lifecycle perspective, ZIBs exhibit a reduced carbon footprint compared to conventional battery technologies. The manufacturing process requires approximately 30% less energy than lithium-ion production, primarily due to the abundance and accessibility of zinc resources. Zinc is the 24th most abundant element in Earth's crust, with global reserves estimated at 250 million tons, ensuring long-term supply sustainability without the geopolitical complications associated with lithium and cobalt extraction.

The end-of-life management of ZIBs presents another sustainability advantage. With recycling rates for zinc exceeding 80% in developed markets, these batteries contribute significantly to circular economy principles. The recycling process for zinc is well-established and less energy-intensive than for lithium-ion batteries, requiring approximately 76% less energy than primary zinc production. This efficiency translates to reduced greenhouse gas emissions throughout the battery lifecycle.

In cold chain applications specifically, ZIBs' environmental benefits are amplified by their performance characteristics. Their stable operation at low temperatures reduces the energy required for auxiliary heating systems often needed for lithium-ion batteries in cold environments. Studies indicate that ZIBs maintain up to 85% of their capacity at -20°C, compared to lithium-ion batteries which may retain only 50-60% capacity under similar conditions.

Water consumption represents another critical environmental consideration. ZIB manufacturing requires approximately 40% less water than lithium-ion production processes. Additionally, the absence of toxic materials like lead or cadmium reduces the risk of environmental contamination during production, use, or disposal phases.

For cold chain operators implementing sustainability initiatives, ZIBs offer quantifiable environmental benefits that can be incorporated into corporate social responsibility reporting. The technology aligns with several United Nations Sustainable Development Goals, particularly Goal 7 (Affordable and Clean Energy), Goal 12 (Responsible Consumption and Production), and Goal 13 (Climate Action), providing organizations with tangible metrics for sustainability performance evaluation.

Regulatory Compliance for Cold Chain Applications

Regulatory compliance in cold chain applications represents a critical framework that governs the implementation of Zinc-ion batteries (ZIBs) as backup power solutions. The pharmaceutical and food industries face particularly stringent requirements under FDA 21 CFR Part 11, EU GDP Guidelines, and ISO 13485 standards, which mandate continuous temperature monitoring and uninterrupted power supply to storage facilities. ZIBs must demonstrate compliance with these regulations through proper documentation, validation processes, and performance verification.

Temperature excursion prevention constitutes a primary regulatory concern, with most biologics and vaccines requiring storage between 2-8°C. Power backup systems utilizing ZIBs must maintain these conditions during outages, with documented evidence of performance reliability. The FDA's Risk Evaluation and Mitigation Strategy (REMS) specifically addresses backup power requirements for critical cold storage applications, positioning ZIBs as viable alternatives to traditional lead-acid batteries when properly implemented.

Environmental regulations further impact ZIB deployment in cold chain applications. The EU's Restriction of Hazardous Substances (RoHS) directive and the Battery Directive (2006/66/EC) establish parameters for battery composition and disposal. ZIBs offer advantages in this regulatory landscape due to their reduced environmental impact compared to lead-acid alternatives, potentially simplifying compliance with waste management regulations such as the Resource Conservation and Recovery Act (RCRA) in the United States.

Documentation requirements for regulatory compliance include Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) protocols. ZIB implementations must maintain comprehensive records demonstrating consistent performance under various conditions, including power outage scenarios. These records must be available for regulatory inspections and audits, with electronic documentation systems requiring compliance with data integrity standards outlined in FDA guidance documents.

International transport regulations present additional compliance considerations for ZIB cold chain applications. The International Air Transport Association (IATA) Dangerous Goods Regulations and UN Recommendations on the Transport of Dangerous Goods establish specific requirements for battery shipment. ZIBs generally face fewer restrictions than lithium-ion batteries due to their non-flammable aqueous electrolytes, potentially simplifying global supply chain logistics for cold chain equipment manufacturers.

Emerging regulatory frameworks addressing energy efficiency and sustainability may provide additional advantages for ZIB adoption. The EU's Ecodesign Directive and similar initiatives worldwide increasingly emphasize energy-efficient backup power solutions, with ZIBs potentially qualifying for incentives under various green technology programs when deployed in cold chain applications.

Temperature excursion prevention constitutes a primary regulatory concern, with most biologics and vaccines requiring storage between 2-8°C. Power backup systems utilizing ZIBs must maintain these conditions during outages, with documented evidence of performance reliability. The FDA's Risk Evaluation and Mitigation Strategy (REMS) specifically addresses backup power requirements for critical cold storage applications, positioning ZIBs as viable alternatives to traditional lead-acid batteries when properly implemented.

Environmental regulations further impact ZIB deployment in cold chain applications. The EU's Restriction of Hazardous Substances (RoHS) directive and the Battery Directive (2006/66/EC) establish parameters for battery composition and disposal. ZIBs offer advantages in this regulatory landscape due to their reduced environmental impact compared to lead-acid alternatives, potentially simplifying compliance with waste management regulations such as the Resource Conservation and Recovery Act (RCRA) in the United States.

Documentation requirements for regulatory compliance include Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) protocols. ZIB implementations must maintain comprehensive records demonstrating consistent performance under various conditions, including power outage scenarios. These records must be available for regulatory inspections and audits, with electronic documentation systems requiring compliance with data integrity standards outlined in FDA guidance documents.

International transport regulations present additional compliance considerations for ZIB cold chain applications. The International Air Transport Association (IATA) Dangerous Goods Regulations and UN Recommendations on the Transport of Dangerous Goods establish specific requirements for battery shipment. ZIBs generally face fewer restrictions than lithium-ion batteries due to their non-flammable aqueous electrolytes, potentially simplifying global supply chain logistics for cold chain equipment manufacturers.

Emerging regulatory frameworks addressing energy efficiency and sustainability may provide additional advantages for ZIB adoption. The EU's Ecodesign Directive and similar initiatives worldwide increasingly emphasize energy-efficient backup power solutions, with ZIBs potentially qualifying for incentives under various green technology programs when deployed in cold chain applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!