How to Enhance Silicone Rubber for Textile Innovation?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber in Textiles: Background and Objectives

Silicone rubber has emerged as a revolutionary material in the textile industry, offering unique properties that have transformed the way we approach fabric innovation. This versatile elastomer, known for its exceptional flexibility, durability, and resistance to extreme temperatures, has been steadily gaining prominence in textile applications since its introduction in the mid-20th century.

The journey of silicone rubber in textiles began with its use in simple waterproofing and coating applications. However, as manufacturing techniques and material science advanced, so did the potential of silicone rubber in fabric enhancement. Today, it plays a crucial role in creating high-performance textiles for various sectors, including sports apparel, medical textiles, and protective gear.

The primary objective in enhancing silicone rubber for textile innovation is to overcome its inherent limitations while amplifying its beneficial properties. One key goal is to improve the material's breathability without compromising its water-resistant qualities. This balance is essential for creating comfortable, functional garments that can withstand diverse environmental conditions.

Another significant aim is to enhance the bonding capabilities of silicone rubber with different fabric types. Improved adhesion would expand the range of textiles that can benefit from silicone treatments, opening up new possibilities in fashion and technical textiles. Additionally, researchers are focusing on developing silicone rubber formulations that offer improved UV resistance and color stability, addressing the material's tendency to yellow over time.

The textile industry is also exploring ways to incorporate smart functionalities into silicone-enhanced fabrics. This includes the integration of conductive properties for e-textiles and the development of silicone rubbers that can change properties in response to external stimuli, such as temperature or pressure.

Sustainability is another critical objective in the enhancement of silicone rubber for textiles. As environmental concerns take center stage in material development, there is a growing emphasis on creating bio-based silicone alternatives and improving the recyclability of silicone-treated fabrics.

The evolution of silicone rubber in textiles reflects a broader trend towards high-performance, multifunctional materials in the industry. By addressing current limitations and exploring new functionalities, researchers and manufacturers aim to position silicone rubber as a cornerstone of future textile innovations, capable of meeting the ever-increasing demands for comfort, durability, and sustainability in modern fabrics.

The journey of silicone rubber in textiles began with its use in simple waterproofing and coating applications. However, as manufacturing techniques and material science advanced, so did the potential of silicone rubber in fabric enhancement. Today, it plays a crucial role in creating high-performance textiles for various sectors, including sports apparel, medical textiles, and protective gear.

The primary objective in enhancing silicone rubber for textile innovation is to overcome its inherent limitations while amplifying its beneficial properties. One key goal is to improve the material's breathability without compromising its water-resistant qualities. This balance is essential for creating comfortable, functional garments that can withstand diverse environmental conditions.

Another significant aim is to enhance the bonding capabilities of silicone rubber with different fabric types. Improved adhesion would expand the range of textiles that can benefit from silicone treatments, opening up new possibilities in fashion and technical textiles. Additionally, researchers are focusing on developing silicone rubber formulations that offer improved UV resistance and color stability, addressing the material's tendency to yellow over time.

The textile industry is also exploring ways to incorporate smart functionalities into silicone-enhanced fabrics. This includes the integration of conductive properties for e-textiles and the development of silicone rubbers that can change properties in response to external stimuli, such as temperature or pressure.

Sustainability is another critical objective in the enhancement of silicone rubber for textiles. As environmental concerns take center stage in material development, there is a growing emphasis on creating bio-based silicone alternatives and improving the recyclability of silicone-treated fabrics.

The evolution of silicone rubber in textiles reflects a broader trend towards high-performance, multifunctional materials in the industry. By addressing current limitations and exploring new functionalities, researchers and manufacturers aim to position silicone rubber as a cornerstone of future textile innovations, capable of meeting the ever-increasing demands for comfort, durability, and sustainability in modern fabrics.

Market Analysis for Enhanced Silicone Textiles

The market for enhanced silicone textiles is experiencing significant growth, driven by increasing demand for high-performance fabrics across various industries. The global silicone textile chemicals market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other textile segments. This growth is primarily attributed to the unique properties that silicone-enhanced textiles offer, including improved durability, water repellency, and enhanced comfort.

Key industries driving the demand for enhanced silicone textiles include sportswear and athleisure, outdoor apparel, automotive interiors, and medical textiles. The sportswear sector, in particular, has shown robust growth, with consumers increasingly seeking moisture-wicking, breathable, and durable fabrics for athletic and leisure activities. The outdoor apparel market also contributes significantly to the demand, as silicone-enhanced textiles provide excellent weather resistance and thermal regulation properties.

In the automotive industry, there is a growing trend towards using silicone-enhanced textiles for interior applications due to their durability, stain resistance, and ability to withstand extreme temperatures. The medical textile sector is another area of substantial growth, with silicone-enhanced fabrics being used in wound dressings, surgical gowns, and other healthcare applications due to their biocompatibility and antimicrobial properties.

Geographically, Asia-Pacific dominates the market for enhanced silicone textiles, with China and India being the major contributors. The region's strong textile manufacturing base, coupled with increasing disposable incomes and changing consumer preferences, drives this market leadership. North America and Europe follow, with a focus on technical textiles and high-performance fabrics for specialized applications.

The market is characterized by ongoing innovation, with manufacturers continuously developing new formulations and application techniques to enhance the properties of silicone-treated textiles. This includes advancements in nanotechnology, which allows for even more precise control over fabric properties at the molecular level.

Consumer trends are also shaping the market, with a growing emphasis on sustainability and eco-friendly products. This has led to the development of bio-based silicone alternatives and improved recycling processes for silicone-treated textiles. As environmental concerns continue to influence purchasing decisions, manufacturers are investing in research and development to create more sustainable silicone-enhanced textile solutions.

Key industries driving the demand for enhanced silicone textiles include sportswear and athleisure, outdoor apparel, automotive interiors, and medical textiles. The sportswear sector, in particular, has shown robust growth, with consumers increasingly seeking moisture-wicking, breathable, and durable fabrics for athletic and leisure activities. The outdoor apparel market also contributes significantly to the demand, as silicone-enhanced textiles provide excellent weather resistance and thermal regulation properties.

In the automotive industry, there is a growing trend towards using silicone-enhanced textiles for interior applications due to their durability, stain resistance, and ability to withstand extreme temperatures. The medical textile sector is another area of substantial growth, with silicone-enhanced fabrics being used in wound dressings, surgical gowns, and other healthcare applications due to their biocompatibility and antimicrobial properties.

Geographically, Asia-Pacific dominates the market for enhanced silicone textiles, with China and India being the major contributors. The region's strong textile manufacturing base, coupled with increasing disposable incomes and changing consumer preferences, drives this market leadership. North America and Europe follow, with a focus on technical textiles and high-performance fabrics for specialized applications.

The market is characterized by ongoing innovation, with manufacturers continuously developing new formulations and application techniques to enhance the properties of silicone-treated textiles. This includes advancements in nanotechnology, which allows for even more precise control over fabric properties at the molecular level.

Consumer trends are also shaping the market, with a growing emphasis on sustainability and eco-friendly products. This has led to the development of bio-based silicone alternatives and improved recycling processes for silicone-treated textiles. As environmental concerns continue to influence purchasing decisions, manufacturers are investing in research and development to create more sustainable silicone-enhanced textile solutions.

Current Challenges in Silicone Rubber Textile Applications

Despite the widespread use of silicone rubber in textile applications, several challenges persist in fully harnessing its potential for innovative textile products. One of the primary issues is the inherent hydrophobicity of silicone rubber, which can limit its compatibility with hydrophilic textile fibers. This incompatibility often results in poor adhesion between silicone coatings and fabric substrates, leading to reduced durability and performance of the final product.

Another significant challenge is the difficulty in achieving uniform and controlled deposition of silicone rubber on textile surfaces. The viscosity and surface tension of silicone formulations can lead to uneven coating thickness and inconsistent coverage, affecting the overall quality and functionality of the treated textiles. This issue is particularly pronounced when dealing with complex fabric structures or attempting to create precise patterns or gradients in silicone application.

The thermal stability of silicone rubber at high temperatures poses another hurdle in textile applications. While silicone rubber generally exhibits good heat resistance, prolonged exposure to extreme temperatures during textile processing or end-use can lead to degradation of its properties. This limitation restricts the use of silicone-treated textiles in high-temperature environments or applications requiring frequent heat exposure.

Achieving the right balance between flexibility and durability remains a persistent challenge in silicone rubber textile applications. While silicone rubber is known for its elasticity, enhancing its mechanical strength without compromising flexibility is crucial for developing textiles that can withstand repeated stretching, bending, and abrasion. This balance is particularly important in performance apparel and technical textiles where both comfort and durability are essential.

The environmental impact of silicone rubber in textiles is an emerging concern. Although silicone rubber is generally considered inert, questions about its long-term environmental persistence and potential microplastic generation during wear and laundering are gaining attention. Developing more sustainable and biodegradable silicone formulations for textile applications is becoming increasingly important to address these environmental concerns.

Lastly, the cost-effectiveness of silicone rubber treatments in textile manufacturing remains a challenge, especially for large-scale production. The relatively high cost of silicone materials and the specialized equipment often required for their application can limit widespread adoption in certain textile sectors. Balancing the enhanced performance benefits with economic viability is crucial for broader implementation of silicone rubber innovations in the textile industry.

Another significant challenge is the difficulty in achieving uniform and controlled deposition of silicone rubber on textile surfaces. The viscosity and surface tension of silicone formulations can lead to uneven coating thickness and inconsistent coverage, affecting the overall quality and functionality of the treated textiles. This issue is particularly pronounced when dealing with complex fabric structures or attempting to create precise patterns or gradients in silicone application.

The thermal stability of silicone rubber at high temperatures poses another hurdle in textile applications. While silicone rubber generally exhibits good heat resistance, prolonged exposure to extreme temperatures during textile processing or end-use can lead to degradation of its properties. This limitation restricts the use of silicone-treated textiles in high-temperature environments or applications requiring frequent heat exposure.

Achieving the right balance between flexibility and durability remains a persistent challenge in silicone rubber textile applications. While silicone rubber is known for its elasticity, enhancing its mechanical strength without compromising flexibility is crucial for developing textiles that can withstand repeated stretching, bending, and abrasion. This balance is particularly important in performance apparel and technical textiles where both comfort and durability are essential.

The environmental impact of silicone rubber in textiles is an emerging concern. Although silicone rubber is generally considered inert, questions about its long-term environmental persistence and potential microplastic generation during wear and laundering are gaining attention. Developing more sustainable and biodegradable silicone formulations for textile applications is becoming increasingly important to address these environmental concerns.

Lastly, the cost-effectiveness of silicone rubber treatments in textile manufacturing remains a challenge, especially for large-scale production. The relatively high cost of silicone materials and the specialized equipment often required for their application can limit widespread adoption in certain textile sectors. Balancing the enhanced performance benefits with economic viability is crucial for broader implementation of silicone rubber innovations in the textile industry.

Existing Silicone Rubber Enhancement Techniques

01 Incorporation of reinforcing fillers

Silicone rubber properties can be enhanced by incorporating reinforcing fillers such as silica, carbon black, or other nanoparticles. These fillers improve mechanical strength, tear resistance, and overall durability of the silicone rubber. The type and amount of filler used can be optimized to achieve desired properties for specific applications.- Incorporation of reinforcing fillers: Silicone rubber properties can be enhanced by incorporating reinforcing fillers such as silica, carbon black, or other nanoparticles. These fillers improve mechanical strength, tear resistance, and overall durability of the silicone rubber. The type and amount of filler can be adjusted to achieve specific performance characteristics.

- Crosslinking and curing methods: Various crosslinking and curing methods can be employed to enhance silicone rubber properties. These include peroxide curing, platinum-catalyzed addition curing, and UV-initiated curing. The choice of curing method affects the final properties of the silicone rubber, such as heat resistance, compression set, and chemical resistance.

- Blending with other polymers: Silicone rubber can be blended with other polymers to create hybrid materials with enhanced properties. Common blending partners include fluorosilicone, EPDM, and thermoplastic elastomers. These blends can improve oil resistance, flame retardancy, or processability while maintaining the desirable characteristics of silicone rubber.

- Surface modification techniques: Surface modification of silicone rubber can enhance its adhesion, wettability, and compatibility with other materials. Techniques such as plasma treatment, corona discharge, and chemical etching can be used to alter the surface properties of silicone rubber, improving its performance in various applications.

- Incorporation of functional additives: Various functional additives can be incorporated into silicone rubber to enhance specific properties. These may include antioxidants, UV stabilizers, flame retardants, and conductive fillers. The selection and concentration of additives can be tailored to meet the requirements of different applications, such as improved weatherability or electrical conductivity.

02 Crosslinking and curing methods

Various crosslinking and curing methods can be employed to enhance silicone rubber properties. These include peroxide curing, platinum-catalyzed addition curing, and UV-initiated curing. The choice of curing method affects the final properties of the silicone rubber, such as heat resistance, compression set, and chemical resistance.Expand Specific Solutions03 Blending with other polymers

Silicone rubber can be blended with other polymers to create hybrid materials with enhanced properties. Common blending partners include fluorosilicone, fluorocarbon elastomers, or thermoplastic elastomers. These blends can improve chemical resistance, low-temperature flexibility, or processability of the resulting material.Expand Specific Solutions04 Surface modification techniques

Surface modification of silicone rubber can enhance its properties for specific applications. Techniques such as plasma treatment, chemical etching, or grafting of functional groups can improve adhesion, wettability, or biocompatibility of the silicone rubber surface. These modifications are particularly useful in medical, electronic, and coating applications.Expand Specific Solutions05 Incorporation of additives

Various additives can be incorporated into silicone rubber formulations to enhance specific properties. These may include antioxidants, UV stabilizers, flame retardants, or conductive fillers. The selection and concentration of additives are tailored to meet the requirements of different applications, such as improved weather resistance, flame retardancy, or electrical conductivity.Expand Specific Solutions

Key Players in Silicone Textile Innovation

The textile innovation landscape for enhancing silicone rubber is characterized by a competitive and evolving market. The industry is in a growth phase, with increasing demand for advanced materials in textiles. Market size is expanding as more companies invest in research and development. Technologically, the field is progressing rapidly, with varying levels of maturity among key players. Companies like Shin-Etsu Chemical, Momentive Performance Materials, and Wacker Chemie are at the forefront, leveraging their extensive experience in silicone technologies. Emerging players such as Dongguan Langsheng Material Technology and Qingdao Huilu Silicone are also making strides, particularly in specialized applications. Academic institutions like Sichuan University and Beijing University of Chemical Technology contribute significantly to fundamental research, fostering innovation in this dynamic sector.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical Co., Ltd. has developed advanced silicone rubber technologies for textile innovation. Their KE-2090 series offers silicone emulsions specifically designed for fabric treatment, providing excellent water repellency and softness[1]. Shin-Etsu has also introduced their X-52-1621 silicone elastomer, which can be used for coating fabrics to enhance durability and elasticity[2]. The company's silicone technologies allow for the creation of breathable, water-resistant textiles while maintaining fabric flexibility. Shin-Etsu's products can be applied through various methods, including padding, spraying, and exhaustion, making them suitable for different textile manufacturing processes[3]. Their silicone treatments can improve fabric performance in areas such as moisture management, thermal regulation, and UV protection.

Strengths: High-performance silicone emulsions and elastomers, multiple application methods, improvements in various fabric properties. Weaknesses: May require specialized application equipment, potential for higher production costs compared to traditional fabric treatments.

Evonik Operations GmbH

Technical Solution: Evonik Operations GmbH has developed innovative silicone technologies for textile enhancement. Their TEGOPREN® series offers silicone-based products specifically designed for textile applications, providing properties such as softness, hydrophobicity, and wrinkle resistance[1]. Evonik has also introduced their TEGO® Phobe series, which includes water-repellent treatments based on silicone chemistry[2]. The company's silicone technologies enable the creation of durable, easy-care fabrics with improved comfort and performance. Evonik's products can be applied through various methods, including padding, spraying, and foam application, allowing for versatile textile modifications[3]. Their silicone treatments can enhance fabric properties such as soil release, anti-static performance, and dimensional stability, while maintaining the textile's breathability and natural feel.

Strengths: Specialized silicone products for various textile finishing needs, eco-friendly options available, multiple application methods. Weaknesses: May require specific processing conditions, potentially higher initial costs compared to conventional textile treatments.

Breakthrough Technologies for Silicone Textile Improvement

Recycled silicone rubber and preparation method thereof

PatentPendingEP4105269A1

Innovation

- A method involving the physical grinding of vulcanized silicone rubber into specific particle sizes, which are then used as raw materials in a mixture with methyl vinyl silicone gum, white carbon black, silane coupling agents, and releasing agents to produce recycled silicone rubber, addressing the issues of cost, pollution, and safety by improving the recycling process and material properties.

Method of improving the releasability of silicone rubber

PatentInactiveKR1020230139999A

Innovation

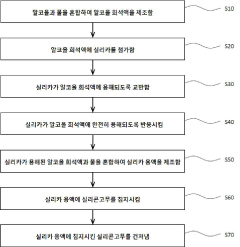

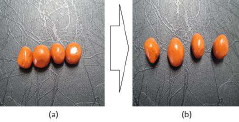

- A method involving the preparation of a silica solution by mixing alcohol and water, adding silica, stirring, reacting, and immersing silicone rubber to enhance mold release properties without affecting the rubber's physical properties.

Environmental Impact of Silicone-Enhanced Textiles

The integration of silicone rubber into textiles presents both opportunities and challenges from an environmental perspective. While silicone-enhanced textiles offer improved durability and performance, their environmental impact must be carefully considered throughout their lifecycle.

During production, silicone rubber manufacturing typically requires less energy and generates fewer greenhouse gas emissions compared to many traditional textile treatments. The process also produces minimal waste and does not involve harmful solvents, contributing to a reduced environmental footprint. Additionally, silicone treatments can be applied in smaller quantities than conventional finishes, potentially reducing overall chemical usage in textile production.

The durability and longevity of silicone-enhanced textiles can lead to extended product lifespans, potentially reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation. This aspect aligns with sustainable fashion principles and circular economy models, which prioritize long-lasting, high-quality products.

However, the environmental benefits of silicone-enhanced textiles are not without caveats. The non-biodegradable nature of silicone rubber poses challenges for end-of-life management. When silicone-treated textiles are discarded, they may persist in landfills for extended periods, contributing to long-term environmental pollution. This issue is exacerbated by the current limitations in recycling technologies for silicone-textile composites.

Water repellency, a common feature of silicone-treated textiles, raises concerns about microfiber shedding during washing. While silicone treatments may reduce overall fiber loss, the potential release of silicone particles into waterways requires further investigation to assess their impact on aquatic ecosystems.

The production of silicone rubber relies on silicon, a relatively abundant element. However, the extraction and processing of silicon can have localized environmental impacts, including habitat disruption and energy-intensive refining processes. Balancing these impacts against the potential environmental benefits of silicone-enhanced textiles requires a comprehensive lifecycle assessment.

As the textile industry moves towards more sustainable practices, innovations in silicone rubber technology may offer solutions to some of these environmental challenges. Research into biodegradable silicone formulations and improved recycling methods for silicone-textile composites could significantly enhance the environmental profile of these materials. Furthermore, the development of bio-based silicone alternatives may provide a more sustainable pathway for future textile innovations.

During production, silicone rubber manufacturing typically requires less energy and generates fewer greenhouse gas emissions compared to many traditional textile treatments. The process also produces minimal waste and does not involve harmful solvents, contributing to a reduced environmental footprint. Additionally, silicone treatments can be applied in smaller quantities than conventional finishes, potentially reducing overall chemical usage in textile production.

The durability and longevity of silicone-enhanced textiles can lead to extended product lifespans, potentially reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation. This aspect aligns with sustainable fashion principles and circular economy models, which prioritize long-lasting, high-quality products.

However, the environmental benefits of silicone-enhanced textiles are not without caveats. The non-biodegradable nature of silicone rubber poses challenges for end-of-life management. When silicone-treated textiles are discarded, they may persist in landfills for extended periods, contributing to long-term environmental pollution. This issue is exacerbated by the current limitations in recycling technologies for silicone-textile composites.

Water repellency, a common feature of silicone-treated textiles, raises concerns about microfiber shedding during washing. While silicone treatments may reduce overall fiber loss, the potential release of silicone particles into waterways requires further investigation to assess their impact on aquatic ecosystems.

The production of silicone rubber relies on silicon, a relatively abundant element. However, the extraction and processing of silicon can have localized environmental impacts, including habitat disruption and energy-intensive refining processes. Balancing these impacts against the potential environmental benefits of silicone-enhanced textiles requires a comprehensive lifecycle assessment.

As the textile industry moves towards more sustainable practices, innovations in silicone rubber technology may offer solutions to some of these environmental challenges. Research into biodegradable silicone formulations and improved recycling methods for silicone-textile composites could significantly enhance the environmental profile of these materials. Furthermore, the development of bio-based silicone alternatives may provide a more sustainable pathway for future textile innovations.

Regulatory Framework for Innovative Textile Materials

The regulatory framework for innovative textile materials plays a crucial role in ensuring the safety, quality, and environmental sustainability of silicone rubber-enhanced textiles. As the textile industry continues to evolve with technological advancements, regulatory bodies must adapt to address the unique challenges posed by these novel materials.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation is a key component of the regulatory landscape. REACH requires manufacturers and importers to register chemical substances, including those used in silicone rubber formulations for textiles. This regulation aims to protect human health and the environment while promoting innovation in the chemical industry.

The United States has a different approach, with the Toxic Substances Control Act (TSCA) administered by the Environmental Protection Agency (EPA). The TSCA regulates the introduction of new or existing chemicals, including those used in silicone rubber for textile applications. Manufacturers must comply with reporting, record-keeping, and testing requirements to ensure the safety of their products.

In addition to chemical regulations, textile-specific standards also apply to silicone rubber-enhanced fabrics. The International Organization for Standardization (ISO) has developed several standards relevant to textile materials, such as ISO 13934 for tensile properties and ISO 105 for color fastness. These standards help ensure the quality and performance of innovative textile materials.

Environmental considerations are increasingly important in the regulatory framework. The Global Organic Textile Standard (GOTS) and OEKO-TEX Standard 100 are voluntary certifications that address the use of chemicals in textiles, including silicone-based materials. These standards promote the use of environmentally friendly processes and restrict the use of harmful substances.

As nanotechnology becomes more prevalent in textile innovation, regulatory bodies are developing frameworks to address potential risks. The European Union's nanomaterial definition and reporting requirements, as well as the US FDA's guidance on nanotechnology, are examples of evolving regulations that may impact silicone rubber-enhanced textiles incorporating nanoparticles.

Intellectual property protection is another crucial aspect of the regulatory framework. Patents and trade secrets related to silicone rubber formulations and application techniques must be carefully managed to encourage innovation while ensuring fair competition in the market.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation is a key component of the regulatory landscape. REACH requires manufacturers and importers to register chemical substances, including those used in silicone rubber formulations for textiles. This regulation aims to protect human health and the environment while promoting innovation in the chemical industry.

The United States has a different approach, with the Toxic Substances Control Act (TSCA) administered by the Environmental Protection Agency (EPA). The TSCA regulates the introduction of new or existing chemicals, including those used in silicone rubber for textile applications. Manufacturers must comply with reporting, record-keeping, and testing requirements to ensure the safety of their products.

In addition to chemical regulations, textile-specific standards also apply to silicone rubber-enhanced fabrics. The International Organization for Standardization (ISO) has developed several standards relevant to textile materials, such as ISO 13934 for tensile properties and ISO 105 for color fastness. These standards help ensure the quality and performance of innovative textile materials.

Environmental considerations are increasingly important in the regulatory framework. The Global Organic Textile Standard (GOTS) and OEKO-TEX Standard 100 are voluntary certifications that address the use of chemicals in textiles, including silicone-based materials. These standards promote the use of environmentally friendly processes and restrict the use of harmful substances.

As nanotechnology becomes more prevalent in textile innovation, regulatory bodies are developing frameworks to address potential risks. The European Union's nanomaterial definition and reporting requirements, as well as the US FDA's guidance on nanotechnology, are examples of evolving regulations that may impact silicone rubber-enhanced textiles incorporating nanoparticles.

Intellectual property protection is another crucial aspect of the regulatory framework. Patents and trade secrets related to silicone rubber formulations and application techniques must be carefully managed to encourage innovation while ensuring fair competition in the market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!