How to Exploit K24 Engine Capabilities in Performance Cars?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, developed by Honda, has undergone significant evolution since its introduction in 2001. Initially designed for the Honda Accord, this 2.4-liter inline-four engine has become a popular choice for performance enthusiasts due to its robust design and tuning potential.

The first generation K24A1 engine debuted with 160 horsepower and 161 lb-ft of torque. Subsequent iterations saw incremental improvements in power output and efficiency. The K24A2 variant, introduced in 2003, featured i-VTEC technology, boosting performance to 200 horsepower in some applications.

A major milestone in the K24's evolution came with the introduction of the K24Z series in 2008. These engines incorporated advanced features such as a higher compression ratio, improved cylinder head design, and refined valve timing. The K24Z7, used in the 2012-2015 Honda Civic Si, produced 201 horsepower and 170 lb-ft of torque, showcasing the engine's continued development.

The K24W series, introduced in 2013, represented a significant leap forward. It featured direct injection technology, which improved fuel efficiency and power delivery. This series also saw the implementation of a two-stage intake manifold, further enhancing performance across the rev range.

Throughout its evolution, the K24 engine has maintained key characteristics that make it attractive for performance applications. Its aluminum block construction offers a favorable power-to-weight ratio, while the oversquare design (larger bore than stroke) allows for high-revving capabilities. The engine's robust internals, including forged connecting rods in some variants, provide a solid foundation for aftermarket modifications.

The K24's adaptability has been a crucial factor in its longevity and popularity. Its compatibility with various Honda platforms and its ability to accept parts from other K-series engines have made it a versatile choice for engine swaps and custom builds. This interchangeability has allowed enthusiasts to mix and match components to achieve desired performance characteristics.

Recent developments in K24 technology have focused on improving efficiency without sacrificing performance. Advanced thermal management systems, reduced friction components, and refined engine control units have all contributed to making the K24 a more potent and efficient powerplant.

As emissions regulations have become more stringent, Honda has adapted the K24 to meet these challenges. The integration of variable valve timing and lift electronic control (VTEC) systems has played a crucial role in balancing performance with environmental considerations, ensuring the engine's relevance in modern performance applications.

The first generation K24A1 engine debuted with 160 horsepower and 161 lb-ft of torque. Subsequent iterations saw incremental improvements in power output and efficiency. The K24A2 variant, introduced in 2003, featured i-VTEC technology, boosting performance to 200 horsepower in some applications.

A major milestone in the K24's evolution came with the introduction of the K24Z series in 2008. These engines incorporated advanced features such as a higher compression ratio, improved cylinder head design, and refined valve timing. The K24Z7, used in the 2012-2015 Honda Civic Si, produced 201 horsepower and 170 lb-ft of torque, showcasing the engine's continued development.

The K24W series, introduced in 2013, represented a significant leap forward. It featured direct injection technology, which improved fuel efficiency and power delivery. This series also saw the implementation of a two-stage intake manifold, further enhancing performance across the rev range.

Throughout its evolution, the K24 engine has maintained key characteristics that make it attractive for performance applications. Its aluminum block construction offers a favorable power-to-weight ratio, while the oversquare design (larger bore than stroke) allows for high-revving capabilities. The engine's robust internals, including forged connecting rods in some variants, provide a solid foundation for aftermarket modifications.

The K24's adaptability has been a crucial factor in its longevity and popularity. Its compatibility with various Honda platforms and its ability to accept parts from other K-series engines have made it a versatile choice for engine swaps and custom builds. This interchangeability has allowed enthusiasts to mix and match components to achieve desired performance characteristics.

Recent developments in K24 technology have focused on improving efficiency without sacrificing performance. Advanced thermal management systems, reduced friction components, and refined engine control units have all contributed to making the K24 a more potent and efficient powerplant.

As emissions regulations have become more stringent, Honda has adapted the K24 to meet these challenges. The integration of variable valve timing and lift electronic control (VTEC) systems has played a crucial role in balancing performance with environmental considerations, ensuring the engine's relevance in modern performance applications.

Performance Car Market

The performance car market has experienced significant growth and evolution in recent years, driven by technological advancements and changing consumer preferences. This segment of the automotive industry caters to enthusiasts and buyers seeking high-performance vehicles that offer superior speed, handling, and driving experience.

Performance cars typically feature powerful engines, advanced suspension systems, and aerodynamic designs. The market encompasses a wide range of vehicles, from sports coupes and hot hatchbacks to high-end supercars and hypercars. These vehicles often serve as halo products for automotive manufacturers, showcasing their engineering prowess and brand identity.

The global performance car market has shown steady growth, with increasing demand in both developed and emerging markets. Key regions driving this growth include North America, Europe, and Asia-Pacific, particularly China. The market has also seen a shift towards electrification, with many manufacturers introducing high-performance electric and hybrid models to meet evolving consumer preferences and stringent emissions regulations.

Consumer demographics for performance cars tend to skew towards higher-income individuals, often male and between the ages of 30 and 55. However, there is a growing trend of younger buyers entering the market, particularly in the entry-level performance car segment. This shift is partly attributed to the rise of social media and automotive influencers, which have increased the visibility and desirability of performance vehicles among younger generations.

The performance car market is highly competitive, with established luxury brands like Porsche, Ferrari, and Lamborghini competing alongside mainstream manufacturers offering high-performance variants of their standard models. In recent years, there has been an increase in the number of boutique and niche manufacturers entering the market, often focusing on limited production runs of ultra-high-performance vehicles.

Technology plays a crucial role in the performance car market, with continuous innovations in engine design, materials science, and aerodynamics. The integration of advanced driver assistance systems and connectivity features has also become increasingly important, as buyers expect cutting-edge technology alongside raw performance.

Looking ahead, the performance car market is expected to continue evolving, with a greater emphasis on sustainability and electrification. Many manufacturers are investing heavily in electric performance vehicles, aiming to combine high performance with zero-emissions technology. This trend is likely to reshape the market landscape in the coming years, potentially opening up new opportunities for innovation and competition.

Performance cars typically feature powerful engines, advanced suspension systems, and aerodynamic designs. The market encompasses a wide range of vehicles, from sports coupes and hot hatchbacks to high-end supercars and hypercars. These vehicles often serve as halo products for automotive manufacturers, showcasing their engineering prowess and brand identity.

The global performance car market has shown steady growth, with increasing demand in both developed and emerging markets. Key regions driving this growth include North America, Europe, and Asia-Pacific, particularly China. The market has also seen a shift towards electrification, with many manufacturers introducing high-performance electric and hybrid models to meet evolving consumer preferences and stringent emissions regulations.

Consumer demographics for performance cars tend to skew towards higher-income individuals, often male and between the ages of 30 and 55. However, there is a growing trend of younger buyers entering the market, particularly in the entry-level performance car segment. This shift is partly attributed to the rise of social media and automotive influencers, which have increased the visibility and desirability of performance vehicles among younger generations.

The performance car market is highly competitive, with established luxury brands like Porsche, Ferrari, and Lamborghini competing alongside mainstream manufacturers offering high-performance variants of their standard models. In recent years, there has been an increase in the number of boutique and niche manufacturers entering the market, often focusing on limited production runs of ultra-high-performance vehicles.

Technology plays a crucial role in the performance car market, with continuous innovations in engine design, materials science, and aerodynamics. The integration of advanced driver assistance systems and connectivity features has also become increasingly important, as buyers expect cutting-edge technology alongside raw performance.

Looking ahead, the performance car market is expected to continue evolving, with a greater emphasis on sustainability and electrification. Many manufacturers are investing heavily in electric performance vehicles, aiming to combine high performance with zero-emissions technology. This trend is likely to reshape the market landscape in the coming years, potentially opening up new opportunities for innovation and competition.

K24 Technical Challenges

The K24 engine, while renowned for its reliability and versatility, faces several technical challenges when being adapted for high-performance applications in sports cars. One of the primary issues is the engine's relatively low redline, typically around 7,000 RPM, which limits its potential power output in stock form. This constraint is partly due to the engine's long-stroke design, which prioritizes torque production over high-rpm performance.

Another significant challenge is the K24's stock valvetrain, which becomes a limiting factor at higher engine speeds. The standard valve springs and retainers are not designed to withstand the increased forces encountered during high-rpm operation, potentially leading to valve float and subsequent engine damage. Additionally, the camshaft profiles in stock K24 engines are optimized for everyday driving, rather than high-performance applications, further restricting the engine's potential in sports car applications.

The K24's intake and exhaust systems also present challenges when seeking to maximize performance. The stock intake manifold and throttle body are designed for efficiency and emissions compliance rather than maximum airflow, potentially creating bottlenecks in the pursuit of higher power outputs. Similarly, the exhaust manifold and catalytic converter system can restrict exhaust flow, limiting the engine's ability to expel spent gases efficiently at high rpm.

Heat management is another critical challenge when pushing the K24 engine to its limits in performance cars. The increased power output generates additional heat, which can lead to issues such as oil breakdown, reduced engine efficiency, and potential component failure if not properly addressed. The stock cooling system may struggle to dissipate this extra heat effectively, particularly in high-stress racing environments.

Furthermore, the K24's fuel system, including injectors and fuel pump, may become inadequate when significantly increasing the engine's power output. These components are typically sized for stock power levels and may not be capable of delivering the increased fuel volume required for high-performance applications, potentially leading to lean conditions and engine damage.

Lastly, the engine management system presents a challenge when adapting the K24 for performance use. The stock ECU (Engine Control Unit) is programmed with conservative parameters to ensure reliability and emissions compliance in standard applications. Unlocking the full potential of a modified K24 engine often requires extensive ECU tuning or even replacement with an aftermarket unit capable of managing advanced engine modifications and higher power outputs.

Another significant challenge is the K24's stock valvetrain, which becomes a limiting factor at higher engine speeds. The standard valve springs and retainers are not designed to withstand the increased forces encountered during high-rpm operation, potentially leading to valve float and subsequent engine damage. Additionally, the camshaft profiles in stock K24 engines are optimized for everyday driving, rather than high-performance applications, further restricting the engine's potential in sports car applications.

The K24's intake and exhaust systems also present challenges when seeking to maximize performance. The stock intake manifold and throttle body are designed for efficiency and emissions compliance rather than maximum airflow, potentially creating bottlenecks in the pursuit of higher power outputs. Similarly, the exhaust manifold and catalytic converter system can restrict exhaust flow, limiting the engine's ability to expel spent gases efficiently at high rpm.

Heat management is another critical challenge when pushing the K24 engine to its limits in performance cars. The increased power output generates additional heat, which can lead to issues such as oil breakdown, reduced engine efficiency, and potential component failure if not properly addressed. The stock cooling system may struggle to dissipate this extra heat effectively, particularly in high-stress racing environments.

Furthermore, the K24's fuel system, including injectors and fuel pump, may become inadequate when significantly increasing the engine's power output. These components are typically sized for stock power levels and may not be capable of delivering the increased fuel volume required for high-performance applications, potentially leading to lean conditions and engine damage.

Lastly, the engine management system presents a challenge when adapting the K24 for performance use. The stock ECU (Engine Control Unit) is programmed with conservative parameters to ensure reliability and emissions compliance in standard applications. Unlocking the full potential of a modified K24 engine often requires extensive ECU tuning or even replacement with an aftermarket unit capable of managing advanced engine modifications and higher power outputs.

Current K24 Tuning Methods

01 Engine control and optimization

Advanced control systems and algorithms are used to optimize the K24 engine's performance. These systems monitor various parameters such as fuel injection, ignition timing, and valve timing to enhance power output, fuel efficiency, and emissions control. Real-time adjustments are made based on driving conditions and engine load to ensure optimal performance across different scenarios.- Engine control and optimization: Advanced control systems and algorithms are employed to optimize the K24 engine's performance. These systems monitor various parameters such as fuel injection, ignition timing, and valve timing to enhance power output, fuel efficiency, and emissions control. Real-time adjustments are made based on driving conditions and environmental factors to ensure optimal engine performance.

- Turbocharging and forced induction: Turbocharging technology is implemented to increase the K24 engine's power output and efficiency. By forcing more air into the combustion chamber, turbochargers allow for improved fuel burning and increased horsepower. Advanced turbocharger designs and control systems are used to minimize turbo lag and optimize boost pressure across different engine speeds.

- Variable valve timing and lift: The K24 engine incorporates variable valve timing and lift mechanisms to enhance performance across a wide range of engine speeds. These systems allow for dynamic adjustment of valve operation, optimizing air intake and exhaust flow. This results in improved low-end torque, high-end power, and overall engine efficiency.

- Fuel injection and combustion optimization: Advanced fuel injection systems are utilized in the K24 engine to improve combustion efficiency and power output. Direct injection technology, coupled with precise fuel metering and spray patterns, ensures optimal fuel-air mixture for combustion. This leads to increased power, better fuel economy, and reduced emissions across various operating conditions.

- Engine diagnostics and performance monitoring: Sophisticated diagnostic and monitoring systems are integrated into the K24 engine to ensure peak performance and early detection of potential issues. These systems continuously analyze engine parameters, emissions, and overall performance metrics. Advanced sensors and data processing algorithms provide real-time feedback for maintenance and performance optimization.

02 Turbocharging and forced induction

Turbocharging technology is applied to the K24 engine to increase its power output and overall performance. This involves using exhaust gases to drive a turbine, which in turn compresses the intake air, allowing more air and fuel to be burned in each cylinder. The result is improved horsepower and torque across a wide range of engine speeds.Expand Specific Solutions03 Variable valve timing and lift

The K24 engine incorporates variable valve timing and lift systems to optimize performance across different engine speeds and loads. These systems allow for precise control of valve opening and closing times, as well as the amount of valve lift, resulting in improved power output, fuel efficiency, and emissions control throughout the engine's operating range.Expand Specific Solutions04 Fuel injection and combustion optimization

Advanced fuel injection systems and combustion chamber designs are utilized to enhance the K24 engine's performance. Direct injection technology, coupled with optimized injector placement and spray patterns, ensures efficient fuel atomization and mixing. This leads to more complete combustion, improved power output, and reduced emissions.Expand Specific Solutions05 Engine diagnostics and performance monitoring

Sophisticated diagnostic and monitoring systems are integrated into the K24 engine to ensure optimal performance and early detection of potential issues. These systems use various sensors and data analysis techniques to continuously monitor engine parameters, allowing for predictive maintenance and performance optimization. Real-time feedback enables drivers and technicians to make informed decisions about engine operation and maintenance.Expand Specific Solutions

Key K24 Manufacturers

The K24 engine capabilities in performance cars represent a competitive landscape in the automotive industry's advanced powertrain technology sector. This market is in a growth phase, with increasing demand for high-performance, fuel-efficient engines. The global market size for performance car engines is expanding, driven by consumer interest in powerful yet environmentally conscious vehicles. Technologically, the K24 engine is at a mature stage, with companies like Robert Bosch GmbH, GM Global Technology Operations LLC, and Volkswagen AG leading in innovation and implementation. These firms, along with emerging players like Zhejiang Geely Holding Group and Great Wall Motor Co., are investing heavily in R&D to enhance K24 engine performance, efficiency, and integration with hybrid and electric systems.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced engine management systems specifically tailored for the K24 engine to maximize its performance capabilities. Their solution includes a high-precision direct injection system with multiple injections per cycle, optimized for the K24's high-revving nature. The system incorporates adaptive fuel mapping and real-time combustion analysis to ensure optimal air-fuel ratios across the entire RPM range[1]. Additionally, Bosch has implemented a variable valve timing and lift system that allows for dynamic adjustment of valve events, enhancing both low-end torque and high-end power output[3]. The engine control unit (ECU) utilizes sophisticated algorithms to balance performance, fuel efficiency, and emissions, adapting to various driving conditions and user preferences.

Strengths: Highly optimized for K24 engine characteristics, excellent balance of performance and efficiency. Weaknesses: Potentially higher cost due to advanced technology, may require specialized maintenance.

GM Global Technology Operations LLC

Technical Solution: GM's approach to exploiting K24 engine capabilities focuses on integrating advanced materials and manufacturing techniques. They have developed a lightweight, high-strength aluminum alloy for the engine block and cylinder head, reducing overall engine weight while maintaining structural integrity[2]. GM's solution also incorporates a twin-scroll turbocharger system specifically designed for the K24's displacement and bore/stroke ratio, providing rapid boost response and minimizing turbo lag[4]. The company has implemented a sophisticated thermal management system that includes targeted oil jet cooling for pistons and an advanced water-to-air intercooler, ensuring optimal operating temperatures even under high-performance conditions. GM's ECU calibration strategy emphasizes adaptive learning algorithms that continuously optimize engine performance based on driving patterns and environmental factors.

Strengths: Significant weight reduction and improved power-to-weight ratio, excellent thermal management for sustained performance. Weaknesses: Potential increase in production costs, may require more frequent maintenance due to advanced components.

K24 Performance Innovations

A method to improve efficiency of an engine in a vehicle

PatentInactiveIN201841024311A

Innovation

- An electronic control unit in vehicles communicates with a fuel station's IoT server to receive knock adaptation values based on detected fuel parameters, adjusting ignition timing accordingly to optimize engine efficiency.

Method for controlling chargeable hybrid power vehicle

PatentInactiveCN102431547A

Innovation

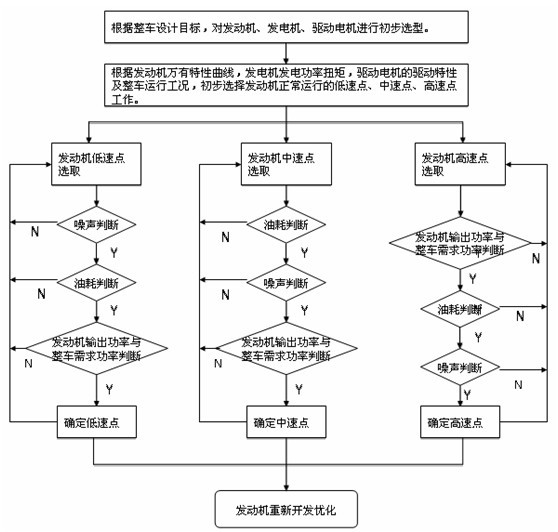

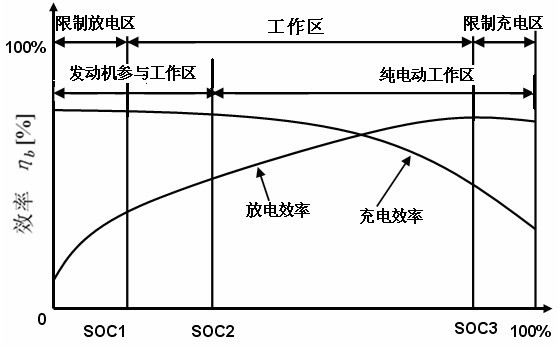

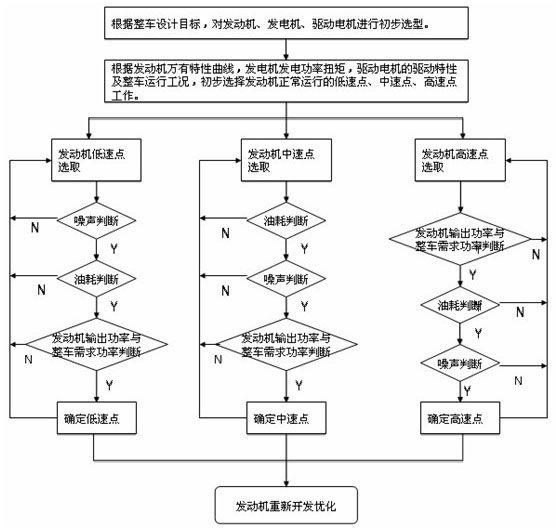

- The engine controller controls the engine operating status according to the vehicle's operating stage, power battery SOC value and vehicle speed, sets predetermined operating points of low, medium and high speeds, optimizes the engine speed range, and works jointly with the generator set to meet the power needs of the vehicle. And to reduce the impact of noise, the SOC value of the power battery is used to determine the engine operating mode, including charging, driving and pure electric modes.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and implementation of performance car engines, including the K24 engine. These regulations have become increasingly stringent over the years, driven by global efforts to reduce greenhouse gas emissions and improve air quality. For performance car manufacturers seeking to exploit the capabilities of the K24 engine, compliance with these regulations presents both challenges and opportunities.

The K24 engine, known for its high-performance potential, must be optimized to meet current and future emissions standards. This involves a delicate balance between maximizing power output and minimizing harmful emissions. Advanced technologies such as direct fuel injection, variable valve timing, and improved exhaust gas recirculation systems are essential in achieving this balance.

One of the key challenges in exploiting the K24 engine's capabilities while adhering to emissions regulations is the reduction of nitrogen oxides (NOx) and particulate matter. Performance cars typically operate at higher temperatures and pressures, which can lead to increased NOx formation. To address this, manufacturers are implementing sophisticated engine management systems that can precisely control fuel injection timing and duration, as well as adjust valve timing on the fly.

The use of lightweight materials in engine construction also plays a significant role in meeting emissions targets. By reducing the overall weight of the engine, manufacturers can improve fuel efficiency and reduce emissions without sacrificing performance. This approach aligns with the broader trend of weight reduction in performance cars to enhance both speed and environmental compliance.

Turbocharging and supercharging technologies are being increasingly employed to boost the K24 engine's performance while maintaining compliance with emissions regulations. These forced induction systems allow for smaller engine displacements without compromising power output, effectively reducing fuel consumption and emissions during normal driving conditions.

Another important consideration is the integration of hybrid technologies with the K24 engine. By combining electric motors with the internal combustion engine, manufacturers can significantly reduce emissions during city driving and low-speed operations while still providing the high-performance capabilities expected from sports cars during more demanding driving scenarios.

As emissions regulations continue to evolve, the development of advanced aftertreatment systems becomes crucial. Catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems are being refined to more effectively treat exhaust gases from high-performance engines like the K24. These systems must be carefully tuned to maintain optimal engine performance while ensuring compliance with the latest emissions standards.

The K24 engine, known for its high-performance potential, must be optimized to meet current and future emissions standards. This involves a delicate balance between maximizing power output and minimizing harmful emissions. Advanced technologies such as direct fuel injection, variable valve timing, and improved exhaust gas recirculation systems are essential in achieving this balance.

One of the key challenges in exploiting the K24 engine's capabilities while adhering to emissions regulations is the reduction of nitrogen oxides (NOx) and particulate matter. Performance cars typically operate at higher temperatures and pressures, which can lead to increased NOx formation. To address this, manufacturers are implementing sophisticated engine management systems that can precisely control fuel injection timing and duration, as well as adjust valve timing on the fly.

The use of lightweight materials in engine construction also plays a significant role in meeting emissions targets. By reducing the overall weight of the engine, manufacturers can improve fuel efficiency and reduce emissions without sacrificing performance. This approach aligns with the broader trend of weight reduction in performance cars to enhance both speed and environmental compliance.

Turbocharging and supercharging technologies are being increasingly employed to boost the K24 engine's performance while maintaining compliance with emissions regulations. These forced induction systems allow for smaller engine displacements without compromising power output, effectively reducing fuel consumption and emissions during normal driving conditions.

Another important consideration is the integration of hybrid technologies with the K24 engine. By combining electric motors with the internal combustion engine, manufacturers can significantly reduce emissions during city driving and low-speed operations while still providing the high-performance capabilities expected from sports cars during more demanding driving scenarios.

As emissions regulations continue to evolve, the development of advanced aftertreatment systems becomes crucial. Catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems are being refined to more effectively treat exhaust gases from high-performance engines like the K24. These systems must be carefully tuned to maintain optimal engine performance while ensuring compliance with the latest emissions standards.

K24 Racing Applications

The K24 engine, renowned for its robust design and versatility, has found significant applications in the racing world. Its popularity stems from its ability to deliver high performance while maintaining reliability, making it a favored choice for various motorsport categories. In circuit racing, the K24 has been extensively utilized in touring car championships and endurance events. Teams have successfully exploited its potential by implementing advanced tuning techniques, such as optimized camshaft profiles, high-compression pistons, and custom intake and exhaust systems.

In drag racing, the K24 engine has demonstrated impressive capabilities when properly modified. Racers have achieved remarkable quarter-mile times by employing forced induction systems, such as turbochargers or superchargers, coupled with strengthened internals to handle the increased power output. The engine's inherent strength allows for significant boost pressures, resulting in power figures well beyond stock specifications.

Time attack and hill climb events have also seen the K24 engine shine. Its compact size and lightweight nature make it an ideal choice for these disciplines, where power-to-weight ratio is crucial. Competitors have leveraged the engine's potential by implementing aggressive engine management strategies, often utilizing standalone ECUs to fine-tune fuel and ignition maps for optimal performance across varying conditions.

In the realm of drifting, the K24 has gained a following due to its torque characteristics and responsiveness. Drift cars equipped with modified K24 engines benefit from the linear power delivery and broad powerband, allowing drivers to maintain precise control during high-angle slides. Customized throttle bodies, individual throttle bodies, and dry sump oiling systems are common modifications in this application to enhance throttle response and ensure consistent oil pressure under extreme lateral forces.

The grassroots racing scene has embraced the K24 engine for its accessibility and tunability. Amateur racers and track day enthusiasts have found success in exploiting the engine's capabilities through a combination of bolt-on modifications and careful engine management. This has led to the development of a robust aftermarket support network, offering a wide range of performance parts specifically designed for the K24 platform.

As racing technology continues to evolve, new avenues for exploiting the K24's potential are emerging. Advanced materials and manufacturing techniques are enabling the creation of lighter, stronger engine components, pushing the boundaries of what the K24 can achieve in racing applications. Furthermore, the integration of hybrid technologies in motorsport is opening up possibilities for innovative K24-based powertrains that combine internal combustion efficiency with electric boost systems, potentially extending the engine's relevance in future racing categories.

In drag racing, the K24 engine has demonstrated impressive capabilities when properly modified. Racers have achieved remarkable quarter-mile times by employing forced induction systems, such as turbochargers or superchargers, coupled with strengthened internals to handle the increased power output. The engine's inherent strength allows for significant boost pressures, resulting in power figures well beyond stock specifications.

Time attack and hill climb events have also seen the K24 engine shine. Its compact size and lightweight nature make it an ideal choice for these disciplines, where power-to-weight ratio is crucial. Competitors have leveraged the engine's potential by implementing aggressive engine management strategies, often utilizing standalone ECUs to fine-tune fuel and ignition maps for optimal performance across varying conditions.

In the realm of drifting, the K24 has gained a following due to its torque characteristics and responsiveness. Drift cars equipped with modified K24 engines benefit from the linear power delivery and broad powerband, allowing drivers to maintain precise control during high-angle slides. Customized throttle bodies, individual throttle bodies, and dry sump oiling systems are common modifications in this application to enhance throttle response and ensure consistent oil pressure under extreme lateral forces.

The grassroots racing scene has embraced the K24 engine for its accessibility and tunability. Amateur racers and track day enthusiasts have found success in exploiting the engine's capabilities through a combination of bolt-on modifications and careful engine management. This has led to the development of a robust aftermarket support network, offering a wide range of performance parts specifically designed for the K24 platform.

As racing technology continues to evolve, new avenues for exploiting the K24's potential are emerging. Advanced materials and manufacturing techniques are enabling the creation of lighter, stronger engine components, pushing the boundaries of what the K24 can achieve in racing applications. Furthermore, the integration of hybrid technologies in motorsport is opening up possibilities for innovative K24-based powertrains that combine internal combustion efficiency with electric boost systems, potentially extending the engine's relevance in future racing categories.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!