K24 Engine and Alternative Fuels: Exploring Compatibility

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, developed by Honda, has undergone significant evolution since its introduction in the late 1990s. Initially designed for the Honda Accord, this 2.4-liter inline-four engine has become a cornerstone of Honda's powertrain lineup, known for its reliability, efficiency, and performance.

The first generation K24A engine debuted in 2001, featuring an aluminum block, chain-driven dual overhead camshafts, and Honda's i-VTEC system. This initial version produced around 160 horsepower and 161 lb-ft of torque, setting a benchmark for four-cylinder engines in its class.

As environmental concerns grew, Honda focused on improving the K24's fuel efficiency and emissions. The second generation, introduced in 2008, incorporated advanced technologies such as a higher compression ratio, improved i-VTEC system, and more efficient intake and exhaust systems. These enhancements resulted in power outputs ranging from 180 to 200 horsepower, while simultaneously reducing fuel consumption and emissions.

The third generation K24, launched in 2013, marked a significant leap in technology. Honda introduced direct fuel injection, which improved fuel atomization and combustion efficiency. This version also featured a two-stage intake manifold and a more sophisticated i-VTEC system, pushing power outputs to over 200 horsepower in some applications while further reducing emissions.

Throughout its evolution, the K24 engine has demonstrated remarkable adaptability to changing market demands and regulatory requirements. Honda engineers have consistently refined the engine's design, incorporating lightweight materials, reducing internal friction, and optimizing combustion processes.

The K24's evolution also reflects broader trends in the automotive industry, such as the shift towards turbocharged engines. While the K24 remained naturally aspirated, its development influenced Honda's approach to smaller, turbocharged engines like the 1.5-liter turbo that has become prevalent in recent Honda models.

In terms of alternative fuel compatibility, the K24 engine has shown potential for adaptation. Some versions have been modified to run on E85 ethanol blends, demonstrating the engine's flexibility. However, significant modifications are required for full compatibility with alternative fuels, particularly in fuel delivery systems and engine management.

As the automotive industry moves towards electrification, the future of the K24 engine remains uncertain. However, its evolution over the past two decades serves as a testament to Honda's engineering prowess and ability to adapt to changing market conditions and environmental regulations.

The first generation K24A engine debuted in 2001, featuring an aluminum block, chain-driven dual overhead camshafts, and Honda's i-VTEC system. This initial version produced around 160 horsepower and 161 lb-ft of torque, setting a benchmark for four-cylinder engines in its class.

As environmental concerns grew, Honda focused on improving the K24's fuel efficiency and emissions. The second generation, introduced in 2008, incorporated advanced technologies such as a higher compression ratio, improved i-VTEC system, and more efficient intake and exhaust systems. These enhancements resulted in power outputs ranging from 180 to 200 horsepower, while simultaneously reducing fuel consumption and emissions.

The third generation K24, launched in 2013, marked a significant leap in technology. Honda introduced direct fuel injection, which improved fuel atomization and combustion efficiency. This version also featured a two-stage intake manifold and a more sophisticated i-VTEC system, pushing power outputs to over 200 horsepower in some applications while further reducing emissions.

Throughout its evolution, the K24 engine has demonstrated remarkable adaptability to changing market demands and regulatory requirements. Honda engineers have consistently refined the engine's design, incorporating lightweight materials, reducing internal friction, and optimizing combustion processes.

The K24's evolution also reflects broader trends in the automotive industry, such as the shift towards turbocharged engines. While the K24 remained naturally aspirated, its development influenced Honda's approach to smaller, turbocharged engines like the 1.5-liter turbo that has become prevalent in recent Honda models.

In terms of alternative fuel compatibility, the K24 engine has shown potential for adaptation. Some versions have been modified to run on E85 ethanol blends, demonstrating the engine's flexibility. However, significant modifications are required for full compatibility with alternative fuels, particularly in fuel delivery systems and engine management.

As the automotive industry moves towards electrification, the future of the K24 engine remains uncertain. However, its evolution over the past two decades serves as a testament to Honda's engineering prowess and ability to adapt to changing market conditions and environmental regulations.

Alternative Fuel Market

The alternative fuel market for automotive applications has been experiencing significant growth in recent years, driven by increasing environmental concerns, government regulations, and the need for energy security. This market encompasses a wide range of alternative fuels, including biofuels, hydrogen, natural gas, and synthetic fuels, each with its own unique characteristics and potential applications in the automotive sector.

Biofuels, particularly ethanol and biodiesel, have gained substantial traction in many countries. The global biofuels market has been expanding steadily, with major producers like the United States, Brazil, and European Union countries leading the way. Ethanol, derived from corn or sugarcane, has become a common additive to gasoline in many regions, while biodiesel, produced from vegetable oils or animal fats, is increasingly used as a substitute for diesel fuel.

Natural gas, in the form of compressed natural gas (CNG) and liquefied natural gas (LNG), has also seen growing adoption in the automotive sector. Countries with abundant natural gas resources, such as the United States, Russia, and Iran, have been promoting the use of natural gas vehicles (NGVs) as a cleaner alternative to traditional gasoline and diesel vehicles. The global NGV market has been expanding, particularly in the commercial vehicle segment and public transportation.

Hydrogen fuel cell vehicles (FCVs) represent another promising segment of the alternative fuel market. While still in the early stages of commercialization, FCVs have attracted significant investment from major automotive manufacturers and governments worldwide. Countries like Japan, South Korea, and Germany have been at the forefront of hydrogen fuel cell technology development and infrastructure deployment.

The market for synthetic fuels, also known as e-fuels or power-to-liquid fuels, is emerging as a potential solution for reducing carbon emissions in the transportation sector. These fuels are produced by combining hydrogen from renewable sources with captured carbon dioxide, resulting in carbon-neutral liquid fuels that can be used in existing internal combustion engines.

The growth of the alternative fuel market has been supported by various government initiatives, including tax incentives, subsidies, and mandates for renewable fuel use. Many countries have set ambitious targets for reducing greenhouse gas emissions and increasing the share of renewable energy in their transportation sectors, driving further investment and innovation in alternative fuel technologies.

However, the alternative fuel market faces several challenges, including the need for substantial infrastructure development, high production costs compared to conventional fuels, and technological limitations. The compatibility of alternative fuels with existing engine technologies, such as the K24 engine, remains a critical factor in their widespread adoption and market penetration.

Biofuels, particularly ethanol and biodiesel, have gained substantial traction in many countries. The global biofuels market has been expanding steadily, with major producers like the United States, Brazil, and European Union countries leading the way. Ethanol, derived from corn or sugarcane, has become a common additive to gasoline in many regions, while biodiesel, produced from vegetable oils or animal fats, is increasingly used as a substitute for diesel fuel.

Natural gas, in the form of compressed natural gas (CNG) and liquefied natural gas (LNG), has also seen growing adoption in the automotive sector. Countries with abundant natural gas resources, such as the United States, Russia, and Iran, have been promoting the use of natural gas vehicles (NGVs) as a cleaner alternative to traditional gasoline and diesel vehicles. The global NGV market has been expanding, particularly in the commercial vehicle segment and public transportation.

Hydrogen fuel cell vehicles (FCVs) represent another promising segment of the alternative fuel market. While still in the early stages of commercialization, FCVs have attracted significant investment from major automotive manufacturers and governments worldwide. Countries like Japan, South Korea, and Germany have been at the forefront of hydrogen fuel cell technology development and infrastructure deployment.

The market for synthetic fuels, also known as e-fuels or power-to-liquid fuels, is emerging as a potential solution for reducing carbon emissions in the transportation sector. These fuels are produced by combining hydrogen from renewable sources with captured carbon dioxide, resulting in carbon-neutral liquid fuels that can be used in existing internal combustion engines.

The growth of the alternative fuel market has been supported by various government initiatives, including tax incentives, subsidies, and mandates for renewable fuel use. Many countries have set ambitious targets for reducing greenhouse gas emissions and increasing the share of renewable energy in their transportation sectors, driving further investment and innovation in alternative fuel technologies.

However, the alternative fuel market faces several challenges, including the need for substantial infrastructure development, high production costs compared to conventional fuels, and technological limitations. The compatibility of alternative fuels with existing engine technologies, such as the K24 engine, remains a critical factor in their widespread adoption and market penetration.

K24 Fuel Challenges

The K24 engine, renowned for its reliability and performance, faces significant challenges in adapting to alternative fuels. As global environmental concerns grow, the automotive industry is under increasing pressure to reduce carbon emissions and explore sustainable fuel options. This shift presents both opportunities and obstacles for the K24 engine's compatibility with alternative fuels.

One of the primary challenges is the engine's fuel system design, which was originally optimized for gasoline. Alternative fuels often have different chemical properties, energy densities, and combustion characteristics. This disparity can lead to issues such as fuel system corrosion, altered fuel flow rates, and changes in engine performance. For instance, ethanol-based fuels can be more corrosive to certain materials used in traditional fuel systems, potentially leading to accelerated wear and component failure.

Another significant challenge lies in the engine's combustion process. The K24 engine's compression ratio and ignition timing are calibrated for gasoline. Alternative fuels may require different compression ratios or ignition timings to achieve optimal combustion efficiency. This mismatch can result in reduced power output, increased emissions, or even engine knocking if not properly addressed.

Fuel delivery and atomization present additional hurdles. The K24's fuel injectors are designed to deliver precise amounts of gasoline. Alternative fuels with different viscosities or molecular structures may not atomize as effectively, leading to incomplete combustion, increased emissions, and potential engine damage over time.

The engine's electronic control unit (ECU) also faces challenges in adapting to alternative fuels. The ECU's programming is based on specific fuel characteristics and combustion patterns of gasoline. Switching to alternative fuels may require significant reprogramming or even hardware modifications to ensure proper fuel-air mixture, ignition timing, and overall engine management.

Emissions control is another critical area of concern. The K24 engine's existing emissions control systems, including catalytic converters and oxygen sensors, are optimized for gasoline combustion byproducts. Alternative fuels may produce different emissions profiles, potentially rendering these systems less effective or requiring modifications to meet stringent environmental regulations.

Lastly, the long-term durability and reliability of the K24 engine when using alternative fuels remain uncertain. While the engine is known for its robustness, the prolonged use of alternative fuels may lead to unforeseen wear patterns, material degradation, or performance issues that were not anticipated in its original design.

One of the primary challenges is the engine's fuel system design, which was originally optimized for gasoline. Alternative fuels often have different chemical properties, energy densities, and combustion characteristics. This disparity can lead to issues such as fuel system corrosion, altered fuel flow rates, and changes in engine performance. For instance, ethanol-based fuels can be more corrosive to certain materials used in traditional fuel systems, potentially leading to accelerated wear and component failure.

Another significant challenge lies in the engine's combustion process. The K24 engine's compression ratio and ignition timing are calibrated for gasoline. Alternative fuels may require different compression ratios or ignition timings to achieve optimal combustion efficiency. This mismatch can result in reduced power output, increased emissions, or even engine knocking if not properly addressed.

Fuel delivery and atomization present additional hurdles. The K24's fuel injectors are designed to deliver precise amounts of gasoline. Alternative fuels with different viscosities or molecular structures may not atomize as effectively, leading to incomplete combustion, increased emissions, and potential engine damage over time.

The engine's electronic control unit (ECU) also faces challenges in adapting to alternative fuels. The ECU's programming is based on specific fuel characteristics and combustion patterns of gasoline. Switching to alternative fuels may require significant reprogramming or even hardware modifications to ensure proper fuel-air mixture, ignition timing, and overall engine management.

Emissions control is another critical area of concern. The K24 engine's existing emissions control systems, including catalytic converters and oxygen sensors, are optimized for gasoline combustion byproducts. Alternative fuels may produce different emissions profiles, potentially rendering these systems less effective or requiring modifications to meet stringent environmental regulations.

Lastly, the long-term durability and reliability of the K24 engine when using alternative fuels remain uncertain. While the engine is known for its robustness, the prolonged use of alternative fuels may lead to unforeseen wear patterns, material degradation, or performance issues that were not anticipated in its original design.

Current Fuel Solutions

01 Engine compatibility with electronic control systems

The K24 engine's compatibility with various electronic control systems is a key consideration. This includes integration with engine management systems, fuel injection control, and performance optimization software. Compatibility ensures efficient operation and allows for advanced features like real-time monitoring and adjustment of engine parameters.- Engine compatibility with electronic control systems: The K24 engine's compatibility with various electronic control systems is a key consideration. This includes integration with engine management units, fuel injection systems, and other electronic components to optimize performance and efficiency. Compatibility with modern diagnostic tools and software is also important for maintenance and troubleshooting.

- Mechanical compatibility and mounting considerations: The physical dimensions and mounting points of the K24 engine are crucial for compatibility with different vehicle models. This includes considerations for engine mounts, transmission connections, and accessory drive systems. Adapters or custom mounting solutions may be necessary for certain applications.

- Fuel system and emissions compatibility: Ensuring the K24 engine is compatible with various fuel systems and meets emissions standards is essential. This may involve adapting fuel delivery systems, exhaust systems, and catalytic converters to comply with different regional regulations while maintaining performance.

- Cooling system integration: The K24 engine's cooling system must be compatible with the vehicle's existing radiator, coolant lines, and temperature management systems. This may require modifications to ensure proper heat dissipation and prevent overheating issues in different applications.

- Electrical system and wiring harness compatibility: Adapting the K24 engine's electrical system to various vehicle platforms is crucial. This includes ensuring compatibility with alternators, starters, and sensors, as well as integrating the engine's wiring harness with the vehicle's existing electrical architecture.

02 Mechanical compatibility with vehicle components

The K24 engine's mechanical compatibility with various vehicle components is crucial for successful integration. This includes considerations for mounting points, transmission interfaces, cooling systems, and exhaust configurations. Ensuring proper fitment and alignment with existing vehicle architectures is essential for optimal performance and reliability.Expand Specific Solutions03 Fuel system compatibility and optimization

Compatibility of the K24 engine with different fuel systems and optimization for various fuel types is an important aspect. This includes considerations for fuel injectors, fuel pumps, and fuel pressure regulators. Ensuring proper fuel delivery and combustion efficiency across different fuel compositions and octane ratings is crucial for engine performance and emissions compliance.Expand Specific Solutions04 Aftermarket modifications and performance upgrades

The K24 engine's compatibility with aftermarket modifications and performance upgrades is a significant consideration for enthusiasts. This includes compatibility with turbochargers, superchargers, intake and exhaust systems, and engine management upgrades. Ensuring that these modifications can be integrated without compromising reliability or emissions compliance is crucial.Expand Specific Solutions05 Diagnostic and maintenance compatibility

Compatibility of the K24 engine with diagnostic tools and maintenance procedures is essential for long-term reliability and serviceability. This includes considerations for OBD-II compatibility, sensor integration, and accessibility of components for routine maintenance. Ensuring that the engine can be properly diagnosed and serviced using widely available tools and procedures is important for both owners and technicians.Expand Specific Solutions

Key Industry Players

The K24 Engine and Alternative Fuels compatibility landscape is characterized by a competitive and evolving market. The industry is in a growth phase, with increasing demand for sustainable fuel solutions driving innovation. Market size is expanding as automotive manufacturers and energy companies invest in alternative fuel technologies. Technical maturity varies, with established players like Ford, Caterpillar, and Renault leading in conventional engine adaptations, while newer entrants such as Westport Fuel Systems and Chery Automobile focus on innovative alternative fuel solutions. Research institutions like Southwest Research Institute and Purdue Research Foundation contribute to advancing the field, collaborating with industry partners to develop cutting-edge technologies for improved engine compatibility with alternative fuels.

Caterpillar, Inc.

Technical Solution: Caterpillar has adapted its K24 engine platform for use with alternative fuels, focusing on natural gas and biodiesel compatibility. They have developed a dual-fuel system that allows the engine to operate on a mixture of diesel and natural gas, with the ability to switch between fuel types seamlessly[2]. This system incorporates advanced fuel injection technology and modified combustion chambers to optimize performance and reduce emissions. Caterpillar has also implemented a proprietary engine control system that continuously monitors and adjusts fuel mixture ratios based on operating conditions[4]. For biodiesel compatibility, they have developed specialized fuel system components and seals that can withstand the higher corrosiveness of biodiesel blends up to B20 (20% biodiesel)[6].

Strengths: Flexibility in fuel options, reduced emissions, and potential for lower operating costs. Weaknesses: Increased complexity of fuel systems and potential for reduced power output with some alternative fuels.

Ford Global Technologies LLC

Technical Solution: Ford has been actively researching the compatibility of the K24 engine with alternative fuels, focusing on ethanol blends and biodiesel. They have developed a flexible fuel system that allows the K24 engine to run on gasoline, E85 (85% ethanol), or any mixture in between[1]. This system includes modified fuel injectors, fuel lines, and engine control software to optimize performance and efficiency across different fuel types. Ford has also implemented advanced combustion strategies, such as direct injection and variable valve timing, to enhance the engine's adaptability to alternative fuels[3]. Additionally, they have explored the use of hydrogen as a supplementary fuel in the K24 engine, utilizing a dual-fuel approach to reduce emissions and improve fuel economy[5].

Strengths: Versatile fuel compatibility, improved emissions, and potential for increased fuel efficiency. Weaknesses: Potential for increased complexity and cost of engine components, as well as the need for specialized maintenance.

K24 Fuel Innovations

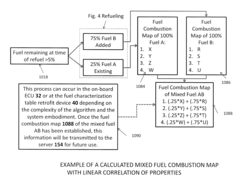

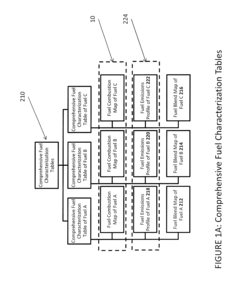

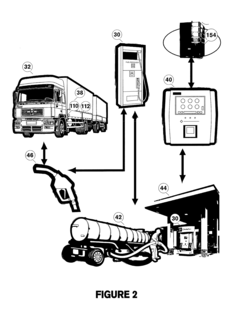

Dynamic variable fuel optimization system

PatentActiveUS20170037789A1

Innovation

- A system that automatically or manually configures a vehicle's fuel system to operate on blends of traditional and alternative fuels, using real-time communication of fuel properties to adjust engine parameters for optimal combustion, emission reduction, and performance, including the use of an auxiliary renewable fuel system and integration with on-board computer systems to optimize engine operation.

Alternative Fuel and Fuel Additive Compositions

PatentActiveUS20150275113A1

Innovation

- Incorporating glycerol ethers into fuel blends with conventional fuels like gasoline, diesel, and jet fuel to enhance energy content, reduce vapor pressure, and decrease particulate emissions, while replacing toxic additives with safer, renewable components.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and adoption of alternative fuels for engines like the K24. These regulations are designed to reduce harmful emissions and mitigate the environmental impact of internal combustion engines. As governments worldwide implement increasingly stringent emissions standards, the automotive industry is compelled to explore and develop cleaner fuel alternatives.

In recent years, emissions regulations have become more comprehensive, covering a wider range of pollutants and introducing stricter limits. The European Union's Euro 6 standards and the United States' Tier 3 regulations are prime examples of this trend. These standards typically focus on reducing emissions of nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbons (HC).

For the K24 engine, compliance with these regulations while maintaining performance and efficiency presents a significant challenge. This has led to increased interest in alternative fuels that can potentially offer lower emissions profiles. Biofuels, such as ethanol and biodiesel, have gained attention due to their potential to reduce greenhouse gas emissions and particulate matter.

However, the compatibility of these alternative fuels with existing engine designs, including the K24, requires careful consideration. Modifications to fuel systems, engine management software, and potentially engine components may be necessary to ensure optimal performance and emissions compliance when using alternative fuels.

The regulatory landscape is not static, with future emissions standards expected to become even more stringent. For instance, the proposed Euro 7 standards in Europe aim to further reduce emissions limits and introduce real-world driving emissions (RDE) tests. This evolving regulatory environment creates both challenges and opportunities for engine manufacturers and fuel developers.

As emissions regulations continue to tighten, the exploration of alternative fuels for the K24 engine becomes increasingly important. This includes not only biofuels but also synthetic fuels and hydrogen-based solutions. Each of these alternatives presents unique challenges in terms of production, distribution, and engine compatibility, but they also offer potential pathways to meet future emissions targets.

The interplay between emissions regulations and alternative fuel development is likely to drive significant innovation in engine technology. For the K24 engine, this may lead to the development of flexible fuel systems capable of running on multiple fuel types while maintaining compliance with emissions standards across various global markets.

In recent years, emissions regulations have become more comprehensive, covering a wider range of pollutants and introducing stricter limits. The European Union's Euro 6 standards and the United States' Tier 3 regulations are prime examples of this trend. These standards typically focus on reducing emissions of nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbons (HC).

For the K24 engine, compliance with these regulations while maintaining performance and efficiency presents a significant challenge. This has led to increased interest in alternative fuels that can potentially offer lower emissions profiles. Biofuels, such as ethanol and biodiesel, have gained attention due to their potential to reduce greenhouse gas emissions and particulate matter.

However, the compatibility of these alternative fuels with existing engine designs, including the K24, requires careful consideration. Modifications to fuel systems, engine management software, and potentially engine components may be necessary to ensure optimal performance and emissions compliance when using alternative fuels.

The regulatory landscape is not static, with future emissions standards expected to become even more stringent. For instance, the proposed Euro 7 standards in Europe aim to further reduce emissions limits and introduce real-world driving emissions (RDE) tests. This evolving regulatory environment creates both challenges and opportunities for engine manufacturers and fuel developers.

As emissions regulations continue to tighten, the exploration of alternative fuels for the K24 engine becomes increasingly important. This includes not only biofuels but also synthetic fuels and hydrogen-based solutions. Each of these alternatives presents unique challenges in terms of production, distribution, and engine compatibility, but they also offer potential pathways to meet future emissions targets.

The interplay between emissions regulations and alternative fuel development is likely to drive significant innovation in engine technology. For the K24 engine, this may lead to the development of flexible fuel systems capable of running on multiple fuel types while maintaining compliance with emissions standards across various global markets.

Fuel Economy Standards

Fuel economy standards play a crucial role in shaping the automotive industry's approach to engine design and fuel compatibility. As governments worldwide implement increasingly stringent regulations to reduce greenhouse gas emissions and improve energy efficiency, manufacturers are compelled to innovate and adapt their technologies. The K24 engine, known for its reliability and performance, faces new challenges in meeting these evolving standards while exploring compatibility with alternative fuels.

In the United States, the Corporate Average Fuel Economy (CAFE) standards set by the National Highway Traffic Safety Administration (NHTSA) have been driving improvements in fuel efficiency for decades. These standards require automakers to achieve specific fleet-wide average fuel economy targets, which have been progressively increasing. The latest CAFE standards aim for a fleet average of 49 miles per gallon (mpg) by 2026, representing a significant leap from previous requirements.

The European Union has implemented its own set of regulations, known as the EU CO2 emission standards for passenger cars. These standards are even more stringent, targeting a fleet-wide average of 95 grams of CO2 per kilometer by 2021, with further reductions planned for subsequent years. This equates to approximately 57 mpg when converted to the US standard, highlighting the global push towards higher fuel efficiency.

For the K24 engine to remain competitive in this regulatory landscape, engineers must explore various avenues for improvement. One approach is to optimize the engine's combustion efficiency through advanced technologies such as direct injection, variable valve timing, and cylinder deactivation. These enhancements can help squeeze more power and efficiency from the traditional gasoline-powered configuration.

However, meeting future fuel economy standards may require more radical changes. The exploration of alternative fuels becomes increasingly relevant in this context. Biofuels, such as ethanol and biodiesel, offer potential pathways to reduce carbon emissions while maintaining compatibility with existing engine architectures. The K24 engine's adaptability to these fuels could be a key factor in its longevity and compliance with future standards.

Hybrid and electric powertrains present another avenue for meeting fuel economy targets. Integrating the K24 engine into a hybrid system could significantly boost its efficiency, leveraging electric power to supplement the internal combustion engine during high-demand situations. This approach allows manufacturers to retain the proven reliability of the K24 while drastically improving overall fuel economy.

As fuel economy standards continue to evolve, the automotive industry must balance technological innovation with practical considerations. The K24 engine's future lies in its ability to adapt to these changing requirements, whether through incremental improvements in efficiency or more radical shifts in fuel compatibility and powertrain integration. The ongoing research and development in this area will be crucial in determining the engine's role in the next generation of fuel-efficient vehicles.

In the United States, the Corporate Average Fuel Economy (CAFE) standards set by the National Highway Traffic Safety Administration (NHTSA) have been driving improvements in fuel efficiency for decades. These standards require automakers to achieve specific fleet-wide average fuel economy targets, which have been progressively increasing. The latest CAFE standards aim for a fleet average of 49 miles per gallon (mpg) by 2026, representing a significant leap from previous requirements.

The European Union has implemented its own set of regulations, known as the EU CO2 emission standards for passenger cars. These standards are even more stringent, targeting a fleet-wide average of 95 grams of CO2 per kilometer by 2021, with further reductions planned for subsequent years. This equates to approximately 57 mpg when converted to the US standard, highlighting the global push towards higher fuel efficiency.

For the K24 engine to remain competitive in this regulatory landscape, engineers must explore various avenues for improvement. One approach is to optimize the engine's combustion efficiency through advanced technologies such as direct injection, variable valve timing, and cylinder deactivation. These enhancements can help squeeze more power and efficiency from the traditional gasoline-powered configuration.

However, meeting future fuel economy standards may require more radical changes. The exploration of alternative fuels becomes increasingly relevant in this context. Biofuels, such as ethanol and biodiesel, offer potential pathways to reduce carbon emissions while maintaining compatibility with existing engine architectures. The K24 engine's adaptability to these fuels could be a key factor in its longevity and compliance with future standards.

Hybrid and electric powertrains present another avenue for meeting fuel economy targets. Integrating the K24 engine into a hybrid system could significantly boost its efficiency, leveraging electric power to supplement the internal combustion engine during high-demand situations. This approach allows manufacturers to retain the proven reliability of the K24 while drastically improving overall fuel economy.

As fuel economy standards continue to evolve, the automotive industry must balance technological innovation with practical considerations. The K24 engine's future lies in its ability to adapt to these changing requirements, whether through incremental improvements in efficiency or more radical shifts in fuel compatibility and powertrain integration. The ongoing research and development in this area will be crucial in determining the engine's role in the next generation of fuel-efficient vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!