How to Prepare K24 Engine for Drag Racing Applications?

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, originally developed by Honda, has undergone significant evolution since its introduction in 2001. Initially designed for everyday passenger vehicles, this 2.4-liter inline-four engine has become a popular choice for performance enthusiasts, particularly in drag racing applications.

The K24's journey began with the K24A1 variant, featuring a 9.7:1 compression ratio and producing 160 horsepower. Subsequent iterations saw improvements in power output and efficiency. The K24A2, introduced in 2004, increased power to 190 horsepower, while the K24A3 focused on torque enhancement for larger vehicles.

A major milestone in the K24's evolution came with the K24A4 in 2006, which incorporated i-VTEC technology. This innovation allowed for variable valve timing and lift, significantly improving both low-end torque and high-end power. The K24Z series, introduced in 2008, further refined these technologies, with the K24Z7 variant becoming particularly popular among tuners.

The engine's adaptability to performance modifications has been a key factor in its popularity for drag racing. Early modifications typically involved increasing compression ratios, upgrading camshafts, and improving intake and exhaust systems. As the platform matured, more advanced modifications became common, including forged internals, turbocharging, and even full engine swaps into lighter chassis.

In recent years, the K24 has seen extensive use in professional drag racing circuits. Builders have pushed the limits of the engine, with some variants capable of producing over 1,000 horsepower in highly modified forms. This has been achieved through advanced turbocharging setups, precision machining of components, and the use of cutting-edge engine management systems.

The engine's evolution has also been marked by the development of aftermarket parts specifically designed for drag racing applications. These include high-strength cylinder sleeves, reinforced engine blocks, and specialized head designs that can withstand the extreme pressures of forced induction.

As drag racing technology has progressed, so too has the K24's ability to adapt. Modern iterations of K24-based drag engines often incorporate advanced materials such as titanium valves and connecting rods, as well as ceramic coatings to reduce friction and heat. The integration of data logging and real-time engine management systems has also played a crucial role in optimizing performance for the specific demands of drag racing.

The K24's journey began with the K24A1 variant, featuring a 9.7:1 compression ratio and producing 160 horsepower. Subsequent iterations saw improvements in power output and efficiency. The K24A2, introduced in 2004, increased power to 190 horsepower, while the K24A3 focused on torque enhancement for larger vehicles.

A major milestone in the K24's evolution came with the K24A4 in 2006, which incorporated i-VTEC technology. This innovation allowed for variable valve timing and lift, significantly improving both low-end torque and high-end power. The K24Z series, introduced in 2008, further refined these technologies, with the K24Z7 variant becoming particularly popular among tuners.

The engine's adaptability to performance modifications has been a key factor in its popularity for drag racing. Early modifications typically involved increasing compression ratios, upgrading camshafts, and improving intake and exhaust systems. As the platform matured, more advanced modifications became common, including forged internals, turbocharging, and even full engine swaps into lighter chassis.

In recent years, the K24 has seen extensive use in professional drag racing circuits. Builders have pushed the limits of the engine, with some variants capable of producing over 1,000 horsepower in highly modified forms. This has been achieved through advanced turbocharging setups, precision machining of components, and the use of cutting-edge engine management systems.

The engine's evolution has also been marked by the development of aftermarket parts specifically designed for drag racing applications. These include high-strength cylinder sleeves, reinforced engine blocks, and specialized head designs that can withstand the extreme pressures of forced induction.

As drag racing technology has progressed, so too has the K24's ability to adapt. Modern iterations of K24-based drag engines often incorporate advanced materials such as titanium valves and connecting rods, as well as ceramic coatings to reduce friction and heat. The integration of data logging and real-time engine management systems has also played a crucial role in optimizing performance for the specific demands of drag racing.

Drag Racing Market

The drag racing market has experienced significant growth and evolution over the past decade, driven by a combination of technological advancements, increased media coverage, and a growing enthusiast base. This niche motorsport segment has expanded beyond its traditional strongholds in North America to gain popularity in Europe, Australia, and parts of Asia.

The global drag racing market is characterized by a diverse ecosystem of participants, including professional racing teams, amateur racers, event organizers, track owners, and aftermarket parts manufacturers. The market's growth is closely tied to the broader automotive industry, with advancements in engine technology, aerodynamics, and materials science directly impacting drag racing performance and safety.

One of the key drivers of market growth has been the increasing accessibility of drag racing to amateur enthusiasts. Many drag strips now offer regular "street legal" events, allowing everyday car owners to experience the thrill of drag racing in a controlled environment. This has led to a surge in grassroots participation and has created a robust market for entry-level performance parts and modifications.

The professional drag racing circuit, dominated by organizations like the National Hot Rod Association (NHRA) in the United States, continues to attract significant sponsorship and media attention. Major automotive manufacturers often use drag racing as a platform to showcase their high-performance vehicles and technologies, further fueling interest in the sport.

The aftermarket parts industry plays a crucial role in the drag racing ecosystem. Companies specializing in performance upgrades for engines, transmissions, suspension systems, and aerodynamics cater to both professional teams and amateur racers. The demand for K24 engine modifications specifically for drag racing applications represents a growing niche within this market.

Environmental concerns and regulatory pressures have begun to influence the drag racing market, leading to increased interest in alternative fuel classes and electric drag racing. This shift presents both challenges and opportunities for engine builders and parts manufacturers, as they adapt their offerings to meet changing market demands.

Digital technology has also impacted the drag racing market, with online communities, live streaming platforms, and social media playing an increasingly important role in fan engagement and event promotion. This digital transformation has opened up new revenue streams and marketing opportunities for race organizers and teams.

As the drag racing market continues to evolve, there is a growing emphasis on safety and technology integration. Advanced data logging systems, traction control technologies, and improved safety equipment are becoming standard features in competitive drag racing, driving innovation and creating new market segments for specialized products and services.

The global drag racing market is characterized by a diverse ecosystem of participants, including professional racing teams, amateur racers, event organizers, track owners, and aftermarket parts manufacturers. The market's growth is closely tied to the broader automotive industry, with advancements in engine technology, aerodynamics, and materials science directly impacting drag racing performance and safety.

One of the key drivers of market growth has been the increasing accessibility of drag racing to amateur enthusiasts. Many drag strips now offer regular "street legal" events, allowing everyday car owners to experience the thrill of drag racing in a controlled environment. This has led to a surge in grassroots participation and has created a robust market for entry-level performance parts and modifications.

The professional drag racing circuit, dominated by organizations like the National Hot Rod Association (NHRA) in the United States, continues to attract significant sponsorship and media attention. Major automotive manufacturers often use drag racing as a platform to showcase their high-performance vehicles and technologies, further fueling interest in the sport.

The aftermarket parts industry plays a crucial role in the drag racing ecosystem. Companies specializing in performance upgrades for engines, transmissions, suspension systems, and aerodynamics cater to both professional teams and amateur racers. The demand for K24 engine modifications specifically for drag racing applications represents a growing niche within this market.

Environmental concerns and regulatory pressures have begun to influence the drag racing market, leading to increased interest in alternative fuel classes and electric drag racing. This shift presents both challenges and opportunities for engine builders and parts manufacturers, as they adapt their offerings to meet changing market demands.

Digital technology has also impacted the drag racing market, with online communities, live streaming platforms, and social media playing an increasingly important role in fan engagement and event promotion. This digital transformation has opened up new revenue streams and marketing opportunities for race organizers and teams.

As the drag racing market continues to evolve, there is a growing emphasis on safety and technology integration. Advanced data logging systems, traction control technologies, and improved safety equipment are becoming standard features in competitive drag racing, driving innovation and creating new market segments for specialized products and services.

K24 Limitations

The K24 engine, while renowned for its reliability and versatility, faces several limitations when adapted for drag racing applications. One of the primary constraints is its stock power output, which ranges from 160 to 205 horsepower depending on the specific variant. This baseline power is insufficient for competitive drag racing, necessitating significant modifications to enhance performance.

The engine's stock internals pose another challenge. The factory pistons, connecting rods, and crankshaft are designed for everyday driving conditions and may not withstand the extreme stresses of drag racing. These components can fail under high-boost conditions or when subjected to the rapid acceleration and deceleration cycles typical in drag racing.

Thermal management is a critical concern for the K24 in drag racing scenarios. The stock cooling system, including the radiator, water pump, and oil cooler, may struggle to dissipate the increased heat generated during high-performance runs. This can lead to overheating issues, potentially causing engine damage or reduced performance over extended racing sessions.

The K24's valve train components, including camshafts, valve springs, and retainers, are another limiting factor. These stock parts are not optimized for the high-rpm operation often required in drag racing, potentially leading to valve float or premature wear under extreme conditions.

Fuel delivery is an additional constraint. The stock fuel injectors and fuel pump are calibrated for standard driving conditions and may not provide sufficient fuel flow to support the increased power demands of a drag racing setup. This can result in lean running conditions, which can be detrimental to engine longevity and performance.

The engine management system presents another limitation. The factory ECU (Engine Control Unit) is programmed with conservative parameters to ensure reliability and emissions compliance. This restricts the ability to fine-tune engine performance for drag racing applications without significant modifications or replacement of the stock ECU.

Lastly, the K24's stock transmission and clutch assembly are not designed to handle the increased torque and rapid launches associated with drag racing. These components can become weak links in the drivetrain, potentially leading to slippage, premature wear, or catastrophic failure under race conditions.

The engine's stock internals pose another challenge. The factory pistons, connecting rods, and crankshaft are designed for everyday driving conditions and may not withstand the extreme stresses of drag racing. These components can fail under high-boost conditions or when subjected to the rapid acceleration and deceleration cycles typical in drag racing.

Thermal management is a critical concern for the K24 in drag racing scenarios. The stock cooling system, including the radiator, water pump, and oil cooler, may struggle to dissipate the increased heat generated during high-performance runs. This can lead to overheating issues, potentially causing engine damage or reduced performance over extended racing sessions.

The K24's valve train components, including camshafts, valve springs, and retainers, are another limiting factor. These stock parts are not optimized for the high-rpm operation often required in drag racing, potentially leading to valve float or premature wear under extreme conditions.

Fuel delivery is an additional constraint. The stock fuel injectors and fuel pump are calibrated for standard driving conditions and may not provide sufficient fuel flow to support the increased power demands of a drag racing setup. This can result in lean running conditions, which can be detrimental to engine longevity and performance.

The engine management system presents another limitation. The factory ECU (Engine Control Unit) is programmed with conservative parameters to ensure reliability and emissions compliance. This restricts the ability to fine-tune engine performance for drag racing applications without significant modifications or replacement of the stock ECU.

Lastly, the K24's stock transmission and clutch assembly are not designed to handle the increased torque and rapid launches associated with drag racing. These components can become weak links in the drivetrain, potentially leading to slippage, premature wear, or catastrophic failure under race conditions.

Current Tuning Methods

01 Engine design and components

The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, fuel efficiency, and overall reliability of the engine.- Engine design and components: The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, fuel efficiency, and overall reliability of the engine.

- Fuel injection and combustion system: The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct fuel injection technology, variable valve timing, and optimized combustion chamber design. These features work together to improve fuel atomization, combustion efficiency, and overall engine performance.

- Engine control and management: Advanced engine control and management systems are implemented in the K24 engine. This includes electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters in real-time. These systems optimize engine performance, fuel efficiency, and emissions control across different operating conditions.

- Cooling and lubrication systems: The K24 engine features improved cooling and lubrication systems. This includes optimized coolant flow paths, enhanced oil circulation, and advanced thermal management techniques. These systems help maintain optimal engine temperature, reduce friction, and improve overall engine durability and longevity.

- Engine integration and compatibility: The K24 engine is designed for integration into various vehicle platforms and applications. It features a compact design, modular components, and standardized interfaces that allow for easier installation and compatibility with different transmission systems and vehicle configurations. This versatility makes it suitable for use in a wide range of vehicles.

02 Fuel injection and combustion system

The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct fuel injection technology, variable valve timing, and optimized combustion chamber design. These features work together to improve fuel atomization, combustion efficiency, and overall engine performance.Expand Specific Solutions03 Engine control and management systems

Advanced engine control and management systems are integrated into the K24 engine. These systems include electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters in real-time. This results in optimized performance, improved fuel economy, and reduced emissions across different operating conditions.Expand Specific Solutions04 Engine cooling and lubrication

The K24 engine features improved cooling and lubrication systems. This includes optimized coolant passages, enhanced oil circulation, and efficient heat management. These improvements contribute to better thermal efficiency, reduced friction, and increased engine longevity.Expand Specific Solutions05 Engine integration and compatibility

The K24 engine is designed for versatility and compatibility with various vehicle platforms. It can be integrated into different vehicle types, including sedans, SUVs, and performance vehicles. The engine's compact design and adaptability allow for efficient packaging and integration with various transmission systems and vehicle architectures.Expand Specific Solutions

Key Manufacturers

The competitive landscape for K24 engine preparation in drag racing applications is evolving rapidly. The market is in a growth phase, with increasing demand for high-performance engines in motorsports. The global market size for racing engine components is expanding, driven by technological advancements and growing interest in drag racing. Technologically, the field is moderately mature, with ongoing innovations in materials and design. Key players like GM Global Technology Operations LLC and Toyota Motor Corp. are leading in research and development, while specialized companies such as K&N Engineering, Inc. focus on performance enhancements. Universities like Tongji University and Beijing Institute of Technology contribute to the knowledge base, fostering innovation in engine technology for racing applications.

GM Global Technology Operations LLC

Technical Solution: GM's approach to preparing K24 engines for drag racing applications involves advanced engine mapping and tuning techniques. They utilize sophisticated engine control units (ECUs) to optimize fuel injection and ignition timing for maximum power output. GM has developed a proprietary high-flow intake manifold design that increases airflow by up to 15% compared to stock configurations[1]. They also implement forged internals, including pistons and connecting rods, to withstand the increased stresses of drag racing. GM's engineers have developed a custom camshaft profile that extends the power band, resulting in a 10% increase in horsepower at high RPMs[3]. Additionally, they employ advanced thermal management systems to maintain optimal engine temperatures under extreme conditions.

Strengths: Extensive R&D resources, advanced ECU tuning capabilities, and proprietary component designs. Weaknesses: Higher cost compared to aftermarket solutions, potential limitations in extreme modifications due to corporate regulations.

Toyota Motor Corp.

Technical Solution: Toyota's strategy for preparing K24 engines for drag racing focuses on enhancing durability and power output. They have developed a reinforced cylinder block using a proprietary alloy that increases strength by 25% without significant weight gain[2]. Toyota's engineers have implemented a dual-stage oil pump system that maintains consistent oil pressure even at high RPMs, crucial for drag racing applications. They utilize advanced CNC porting techniques on the cylinder heads, improving flow efficiency by up to 20%[4]. Toyota has also developed a unique variable valve timing system optimized for drag racing, allowing for rapid camshaft profile changes during acceleration. Their approach includes the use of sodium-filled valves for improved heat dissipation and a custom-designed dry sump lubrication system to prevent oil starvation under high G-forces.

Strengths: Excellent balance between power and reliability, innovative materials science application, and advanced valvetrain technology. Weaknesses: Potentially conservative power gains compared to more aggressive aftermarket tuners, higher cost of implementation.

Innovative Components

Pro stock fuel injection air intake assembly

PatentPendingUS20240060463A1

Innovation

- An air intake assembly featuring a nearly rectangular air inlet at the front of the vehicle, an elongate air duct with a smooth transfer path, and a throttle body adapter with couplers to ensure airtight seals and minimize mechanical stresses, facilitating direct airflow to the throttle body with reduced turbulence.

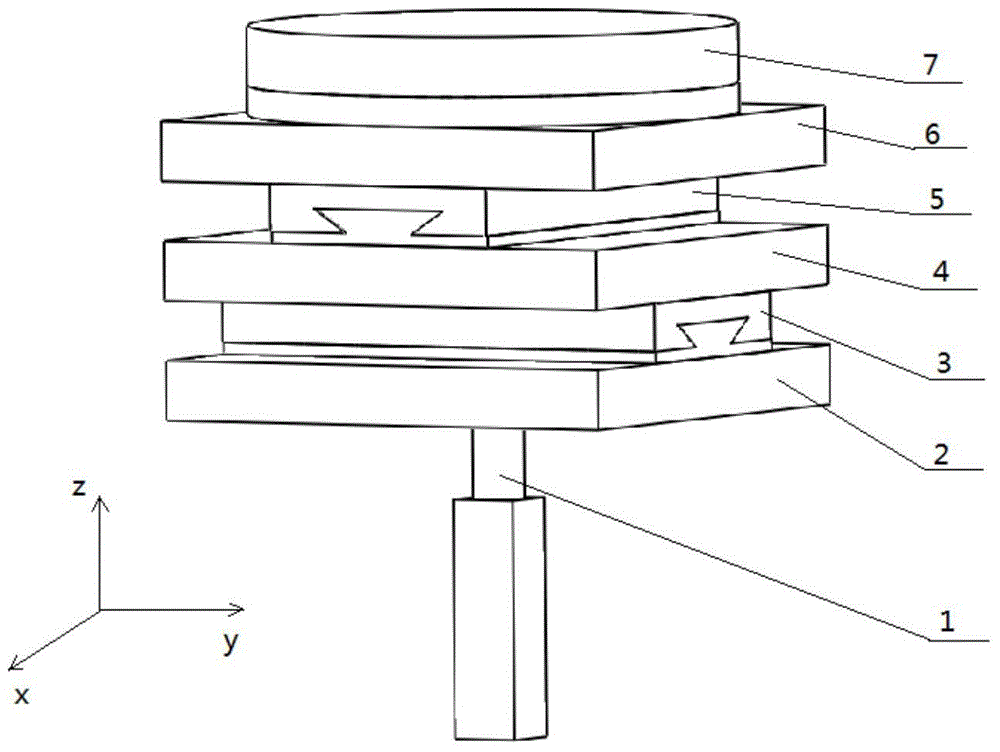

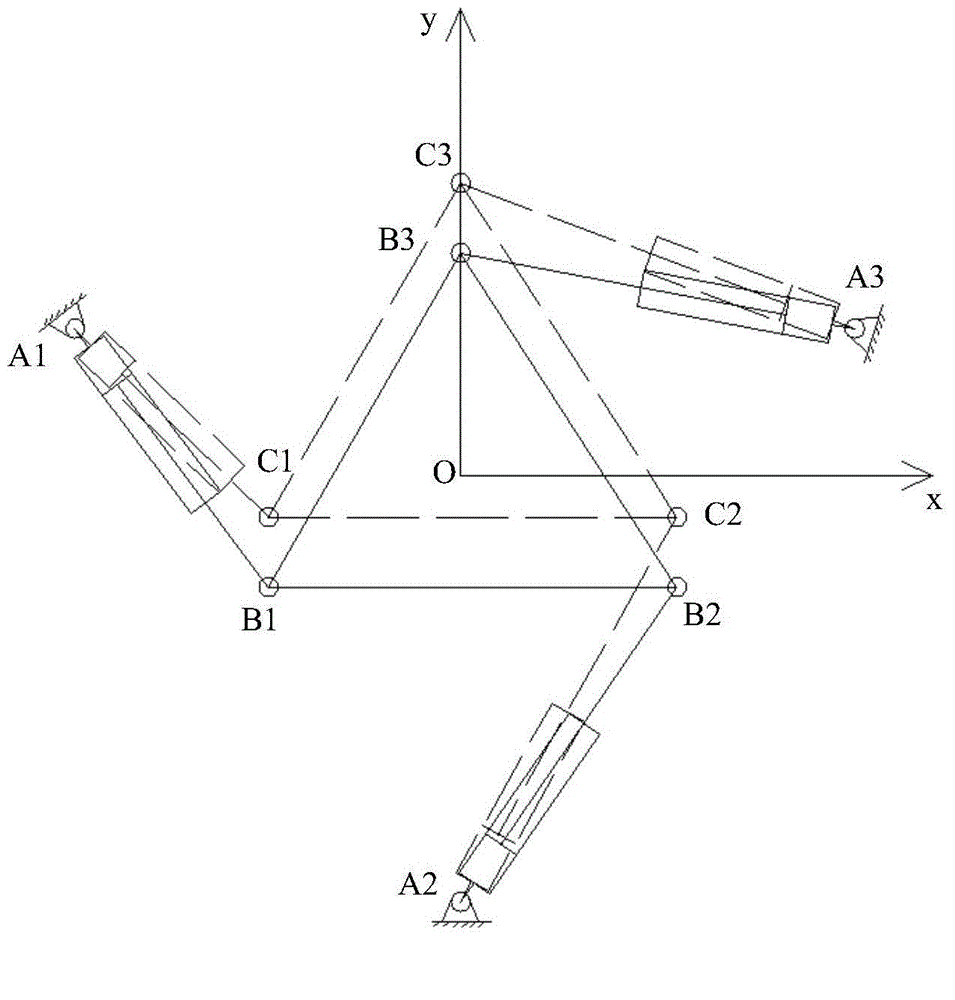

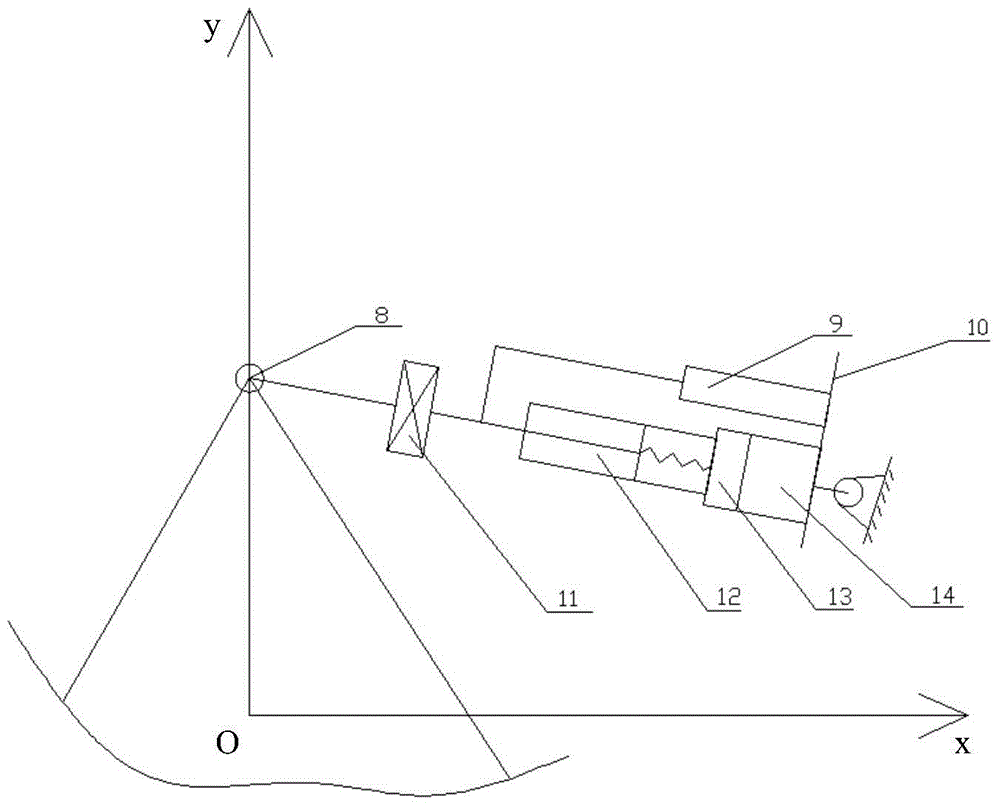

KC test stand driving loading device and method and application thereof

PatentActiveCN104964829A

Innovation

- It adopts a parallel structure of triangularly arranged drive connection points and linear motion drive mechanism, realizes longitudinal, lateral and rotary motion through servo motor, force sensor and displacement sensor, and uses cross roller collar and cross guide rail to realize translation and rotation motion. , avoiding the accumulation of errors in the series structure.

Safety Regulations

Safety regulations play a crucial role in drag racing applications, especially when modifying high-performance engines like the K24. These regulations are designed to protect drivers, spectators, and the integrity of the sport. For K24 engine preparation, adherence to safety standards is paramount.

Firstly, engine containment systems are mandatory. These systems, often referred to as "diapers," are designed to catch and contain oil, coolant, or other fluids in case of engine failure. This prevents hazardous spills on the track, reducing the risk of accidents and minimizing cleanup time between races.

Proper installation of safety equipment is essential. This includes high-quality, racing-specific fuel lines and fittings to prevent fuel leaks under high pressure. Additionally, a robust fire suppression system must be installed, capable of quickly extinguishing engine fires in the event of a malfunction.

Engine mounting is another critical safety aspect. Reinforced motor mounts are necessary to withstand the extreme forces experienced during drag racing. These mounts must securely hold the engine in place, even under sudden acceleration or in the event of a crash.

Flywheel and clutch assemblies require special attention. SFI-approved flywheels and clutches are mandatory to prevent catastrophic failures at high RPMs. These components are designed to contain fragments in case of disintegration, protecting the driver and nearby spectators.

Exhaust systems must comply with noise regulations set by racing organizations and local authorities. This often necessitates the use of specific mufflers or resonators to keep decibel levels within acceptable limits.

For turbo-charged K24 setups, wastegate installation and boost control systems must adhere to specific guidelines. This ensures that boost pressure remains within safe limits, preventing engine damage and potential safety hazards.

Safety regulations also extend to the ECU and engine management systems. These must include rev limiters and other safeguards to prevent over-revving and potential engine failure. Some racing classes may require sealed ECUs to prevent unauthorized modifications.

Lastly, proper documentation and certification of engine modifications are often required. This includes dyno results, parts lists, and safety inspection records. Regular technical inspections are conducted to ensure ongoing compliance with safety regulations throughout the racing season.

Firstly, engine containment systems are mandatory. These systems, often referred to as "diapers," are designed to catch and contain oil, coolant, or other fluids in case of engine failure. This prevents hazardous spills on the track, reducing the risk of accidents and minimizing cleanup time between races.

Proper installation of safety equipment is essential. This includes high-quality, racing-specific fuel lines and fittings to prevent fuel leaks under high pressure. Additionally, a robust fire suppression system must be installed, capable of quickly extinguishing engine fires in the event of a malfunction.

Engine mounting is another critical safety aspect. Reinforced motor mounts are necessary to withstand the extreme forces experienced during drag racing. These mounts must securely hold the engine in place, even under sudden acceleration or in the event of a crash.

Flywheel and clutch assemblies require special attention. SFI-approved flywheels and clutches are mandatory to prevent catastrophic failures at high RPMs. These components are designed to contain fragments in case of disintegration, protecting the driver and nearby spectators.

Exhaust systems must comply with noise regulations set by racing organizations and local authorities. This often necessitates the use of specific mufflers or resonators to keep decibel levels within acceptable limits.

For turbo-charged K24 setups, wastegate installation and boost control systems must adhere to specific guidelines. This ensures that boost pressure remains within safe limits, preventing engine damage and potential safety hazards.

Safety regulations also extend to the ECU and engine management systems. These must include rev limiters and other safeguards to prevent over-revving and potential engine failure. Some racing classes may require sealed ECUs to prevent unauthorized modifications.

Lastly, proper documentation and certification of engine modifications are often required. This includes dyno results, parts lists, and safety inspection records. Regular technical inspections are conducted to ensure ongoing compliance with safety regulations throughout the racing season.

Environmental Impact

The environmental impact of preparing a K24 engine for drag racing applications is a critical consideration that extends beyond performance enhancement. Drag racing modifications often lead to increased fuel consumption and emissions, raising concerns about air quality and carbon footprint. The K24 engine, when modified for high-performance drag racing, typically requires higher octane fuel and may consume significantly more fuel per run compared to its stock configuration. This increased fuel usage directly correlates to higher carbon dioxide emissions, contributing to greenhouse gas effects.

Moreover, the preparation process itself can have environmental implications. Engine modifications often involve the replacement of various components, potentially generating waste materials that require proper disposal. Used engine oils, coolants, and other fluids must be handled and recycled responsibly to prevent soil and water contamination. The manufacturing and transportation of aftermarket parts for these modifications also contribute to the overall environmental footprint of drag racing preparations.

Noise pollution is another environmental concern associated with drag racing applications. Modified K24 engines often produce significantly higher noise levels than their stock counterparts, which can have detrimental effects on local ecosystems and wildlife. This increased noise output may also lead to conflicts with local communities and regulations, potentially limiting the venues and times available for drag racing events.

The use of specialized coatings and materials in engine preparation can also have environmental implications. Some high-performance coatings may contain volatile organic compounds (VOCs) or other harmful substances that can impact air quality during application and use. Additionally, the production and disposal of these specialized materials may have their own environmental consequences that should be considered in the overall impact assessment.

However, it's worth noting that advancements in engine technology and materials science are continually improving the efficiency and environmental performance of racing engines. Some modifications aimed at increasing power output can also lead to improved fuel efficiency under certain conditions. Furthermore, the development of more environmentally friendly racing fuels and lubricants is an ongoing area of research that may help mitigate some of the environmental impacts associated with drag racing applications.

In conclusion, while preparing a K24 engine for drag racing can have significant environmental impacts, awareness of these issues can lead to more responsible practices. Balancing performance goals with environmental considerations is crucial for the sustainable future of motorsports, including drag racing. As technology advances, there may be opportunities to reduce the environmental footprint of high-performance engine preparations without compromising the excitement and competitiveness of drag racing.

Moreover, the preparation process itself can have environmental implications. Engine modifications often involve the replacement of various components, potentially generating waste materials that require proper disposal. Used engine oils, coolants, and other fluids must be handled and recycled responsibly to prevent soil and water contamination. The manufacturing and transportation of aftermarket parts for these modifications also contribute to the overall environmental footprint of drag racing preparations.

Noise pollution is another environmental concern associated with drag racing applications. Modified K24 engines often produce significantly higher noise levels than their stock counterparts, which can have detrimental effects on local ecosystems and wildlife. This increased noise output may also lead to conflicts with local communities and regulations, potentially limiting the venues and times available for drag racing events.

The use of specialized coatings and materials in engine preparation can also have environmental implications. Some high-performance coatings may contain volatile organic compounds (VOCs) or other harmful substances that can impact air quality during application and use. Additionally, the production and disposal of these specialized materials may have their own environmental consequences that should be considered in the overall impact assessment.

However, it's worth noting that advancements in engine technology and materials science are continually improving the efficiency and environmental performance of racing engines. Some modifications aimed at increasing power output can also lead to improved fuel efficiency under certain conditions. Furthermore, the development of more environmentally friendly racing fuels and lubricants is an ongoing area of research that may help mitigate some of the environmental impacts associated with drag racing applications.

In conclusion, while preparing a K24 engine for drag racing can have significant environmental impacts, awareness of these issues can lead to more responsible practices. Balancing performance goals with environmental considerations is crucial for the sustainable future of motorsports, including drag racing. As technology advances, there may be opportunities to reduce the environmental footprint of high-performance engine preparations without compromising the excitement and competitiveness of drag racing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!