K24 Engine Development: Adapting to User Demands

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine has undergone significant evolution since its inception, driven by changing user demands and technological advancements. Initially introduced in the late 1990s, the K24 engine was designed to provide a balance of performance and efficiency for Honda's mid-size vehicles.

In its early iterations, the K24 focused on delivering reliable power output while maintaining fuel economy. The first-generation K24A1 engine, introduced in 2002, featured a 2.4-liter displacement and produced around 160 horsepower. This version set the foundation for future developments, incorporating technologies such as i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) to optimize performance across different RPM ranges.

As user demands shifted towards increased power and improved fuel efficiency, Honda responded with subsequent generations of the K24 engine. The second-generation K24, introduced in the mid-2000s, saw power outputs increase to around 200 horsepower in some applications. This was achieved through refinements in the i-VTEC system, improved intake and exhaust flow, and enhanced engine management systems.

The third-generation K24, launched in the early 2010s, marked a significant leap in technology. It incorporated direct fuel injection, which allowed for more precise fuel delivery and improved combustion efficiency. This generation also saw the introduction of Earth Dreams Technology, Honda's suite of efficiency-enhancing features. Power outputs in this generation ranged from 185 to 205 horsepower, depending on the specific application.

Throughout its evolution, the K24 engine has consistently adapted to meet stricter emissions standards. This has been achieved through the implementation of advanced catalytic converters, improved exhaust gas recirculation systems, and more sophisticated engine control units. These advancements have allowed the K24 to maintain its performance characteristics while reducing its environmental impact.

Recent iterations of the K24 engine have focused on hybridization to meet the growing demand for electrified powertrains. The integration of electric motors with the K24 engine has resulted in hybrid systems that offer improved fuel efficiency and reduced emissions without sacrificing performance. This hybrid evolution represents a significant shift in the K24's development trajectory, aligning with global trends towards vehicle electrification.

The K24 engine's evolution reflects Honda's commitment to continuous improvement and adaptation to changing market demands. From its origins as a reliable, mid-range power plant to its current status as a versatile engine capable of integration with hybrid systems, the K24 has demonstrated remarkable flexibility and longevity in the automotive industry.

In its early iterations, the K24 focused on delivering reliable power output while maintaining fuel economy. The first-generation K24A1 engine, introduced in 2002, featured a 2.4-liter displacement and produced around 160 horsepower. This version set the foundation for future developments, incorporating technologies such as i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) to optimize performance across different RPM ranges.

As user demands shifted towards increased power and improved fuel efficiency, Honda responded with subsequent generations of the K24 engine. The second-generation K24, introduced in the mid-2000s, saw power outputs increase to around 200 horsepower in some applications. This was achieved through refinements in the i-VTEC system, improved intake and exhaust flow, and enhanced engine management systems.

The third-generation K24, launched in the early 2010s, marked a significant leap in technology. It incorporated direct fuel injection, which allowed for more precise fuel delivery and improved combustion efficiency. This generation also saw the introduction of Earth Dreams Technology, Honda's suite of efficiency-enhancing features. Power outputs in this generation ranged from 185 to 205 horsepower, depending on the specific application.

Throughout its evolution, the K24 engine has consistently adapted to meet stricter emissions standards. This has been achieved through the implementation of advanced catalytic converters, improved exhaust gas recirculation systems, and more sophisticated engine control units. These advancements have allowed the K24 to maintain its performance characteristics while reducing its environmental impact.

Recent iterations of the K24 engine have focused on hybridization to meet the growing demand for electrified powertrains. The integration of electric motors with the K24 engine has resulted in hybrid systems that offer improved fuel efficiency and reduced emissions without sacrificing performance. This hybrid evolution represents a significant shift in the K24's development trajectory, aligning with global trends towards vehicle electrification.

The K24 engine's evolution reflects Honda's commitment to continuous improvement and adaptation to changing market demands. From its origins as a reliable, mid-range power plant to its current status as a versatile engine capable of integration with hybrid systems, the K24 has demonstrated remarkable flexibility and longevity in the automotive industry.

Market Demand Analysis

The market demand for K24 engine development is driven by a complex interplay of consumer preferences, regulatory requirements, and technological advancements. As automotive manufacturers strive to meet increasingly stringent emissions standards and fuel efficiency targets, there is a growing need for engines that can deliver both performance and environmental sustainability.

Consumer trends indicate a shift towards vehicles that offer a balance of power, fuel economy, and reliability. The K24 engine, known for its versatility and potential for modification, has garnered significant interest from both everyday drivers and automotive enthusiasts. This demand is particularly evident in the compact and mid-size vehicle segments, where the K24's compact design and power-to-weight ratio make it an attractive option.

In the performance vehicle market, there is a notable demand for K24 engines that can be easily modified and tuned. Aftermarket parts manufacturers have responded to this trend by developing a wide range of performance upgrades, from intake and exhaust systems to turbocharger kits. This has created a thriving ecosystem around K24 engine customization, further driving market demand.

The rise of electric and hybrid vehicles has also influenced the K24 engine market. While there is a clear shift towards electrification, many consumers still prefer the reliability and familiarity of internal combustion engines. This has led to increased demand for K24 engines in hybrid powertrains, where they can be paired with electric motors to provide improved fuel efficiency without sacrificing performance.

Geographically, the demand for K24 engines varies. In regions with strict emissions regulations, such as Europe and parts of North America, there is a growing market for K24 engines that can meet these standards while still delivering desirable performance characteristics. In emerging markets, where fuel efficiency and reliability are often prioritized, the K24 engine's reputation for durability has contributed to its popularity.

The commercial vehicle sector also presents opportunities for K24 engine development. Light-duty trucks and vans used for delivery services and small businesses require engines that offer a balance of power, efficiency, and longevity. The K24's adaptability makes it a strong contender in this market segment, particularly as last-mile delivery services continue to expand.

As the automotive industry continues to evolve, the demand for K24 engines is expected to remain strong in the near term. However, manufacturers must be prepared to adapt to changing market conditions, including the potential for increased electrification and the development of alternative fuel technologies. The ability to integrate K24 engines into hybrid systems or modify them to run on alternative fuels may be key to sustaining long-term market demand.

Consumer trends indicate a shift towards vehicles that offer a balance of power, fuel economy, and reliability. The K24 engine, known for its versatility and potential for modification, has garnered significant interest from both everyday drivers and automotive enthusiasts. This demand is particularly evident in the compact and mid-size vehicle segments, where the K24's compact design and power-to-weight ratio make it an attractive option.

In the performance vehicle market, there is a notable demand for K24 engines that can be easily modified and tuned. Aftermarket parts manufacturers have responded to this trend by developing a wide range of performance upgrades, from intake and exhaust systems to turbocharger kits. This has created a thriving ecosystem around K24 engine customization, further driving market demand.

The rise of electric and hybrid vehicles has also influenced the K24 engine market. While there is a clear shift towards electrification, many consumers still prefer the reliability and familiarity of internal combustion engines. This has led to increased demand for K24 engines in hybrid powertrains, where they can be paired with electric motors to provide improved fuel efficiency without sacrificing performance.

Geographically, the demand for K24 engines varies. In regions with strict emissions regulations, such as Europe and parts of North America, there is a growing market for K24 engines that can meet these standards while still delivering desirable performance characteristics. In emerging markets, where fuel efficiency and reliability are often prioritized, the K24 engine's reputation for durability has contributed to its popularity.

The commercial vehicle sector also presents opportunities for K24 engine development. Light-duty trucks and vans used for delivery services and small businesses require engines that offer a balance of power, efficiency, and longevity. The K24's adaptability makes it a strong contender in this market segment, particularly as last-mile delivery services continue to expand.

As the automotive industry continues to evolve, the demand for K24 engines is expected to remain strong in the near term. However, manufacturers must be prepared to adapt to changing market conditions, including the potential for increased electrification and the development of alternative fuel technologies. The ability to integrate K24 engines into hybrid systems or modify them to run on alternative fuels may be key to sustaining long-term market demand.

Technical Challenges

The development of the K24 engine faces several significant technical challenges as it adapts to evolving user demands. One of the primary hurdles is achieving a balance between performance and fuel efficiency. As consumers increasingly prioritize eco-friendly options, engineers must find innovative ways to enhance engine power while simultaneously reducing fuel consumption and emissions.

Another major challenge lies in the integration of advanced materials and manufacturing techniques. The use of lightweight materials, such as high-strength aluminum alloys or composite materials, can significantly improve the engine's power-to-weight ratio. However, these materials often require specialized manufacturing processes and may present difficulties in terms of durability and cost-effectiveness.

The implementation of cutting-edge technologies, such as variable valve timing and lift systems, direct fuel injection, and turbocharging, presents its own set of challenges. While these technologies offer substantial improvements in performance and efficiency, they also increase the complexity of the engine design and control systems. This complexity can lead to higher production costs and potential reliability issues if not carefully managed.

Thermal management is another critical area of concern in K24 engine development. As engine power outputs increase, so does the heat generated during operation. Engineers must develop more effective cooling systems to maintain optimal operating temperatures without compromising engine efficiency or adding excessive weight to the overall package.

Meeting stringent emissions regulations while maintaining performance targets poses a significant challenge. The development of advanced aftertreatment systems, such as catalytic converters and particulate filters, is crucial to comply with increasingly strict environmental standards. However, these systems can potentially impact engine performance and add complexity to the overall design.

The integration of electrification technologies, such as mild hybrid systems or start-stop functionality, presents both opportunities and challenges. While these technologies can significantly improve fuel efficiency and reduce emissions, they require careful integration with the engine's mechanical systems and control architecture.

Lastly, the K24 engine must be adaptable to various vehicle platforms and applications, ranging from compact cars to SUVs. This versatility requirement adds another layer of complexity to the development process, as engineers must design an engine that can be easily modified to suit different power requirements and installation configurations while maintaining consistent performance and reliability across various applications.

Another major challenge lies in the integration of advanced materials and manufacturing techniques. The use of lightweight materials, such as high-strength aluminum alloys or composite materials, can significantly improve the engine's power-to-weight ratio. However, these materials often require specialized manufacturing processes and may present difficulties in terms of durability and cost-effectiveness.

The implementation of cutting-edge technologies, such as variable valve timing and lift systems, direct fuel injection, and turbocharging, presents its own set of challenges. While these technologies offer substantial improvements in performance and efficiency, they also increase the complexity of the engine design and control systems. This complexity can lead to higher production costs and potential reliability issues if not carefully managed.

Thermal management is another critical area of concern in K24 engine development. As engine power outputs increase, so does the heat generated during operation. Engineers must develop more effective cooling systems to maintain optimal operating temperatures without compromising engine efficiency or adding excessive weight to the overall package.

Meeting stringent emissions regulations while maintaining performance targets poses a significant challenge. The development of advanced aftertreatment systems, such as catalytic converters and particulate filters, is crucial to comply with increasingly strict environmental standards. However, these systems can potentially impact engine performance and add complexity to the overall design.

The integration of electrification technologies, such as mild hybrid systems or start-stop functionality, presents both opportunities and challenges. While these technologies can significantly improve fuel efficiency and reduce emissions, they require careful integration with the engine's mechanical systems and control architecture.

Lastly, the K24 engine must be adaptable to various vehicle platforms and applications, ranging from compact cars to SUVs. This versatility requirement adds another layer of complexity to the development process, as engineers must design an engine that can be easily modified to suit different power requirements and installation configurations while maintaining consistent performance and reliability across various applications.

Current K24 Solutions

01 Engine control and performance optimization

Adaptation of the K24 engine involves optimizing its control systems and performance parameters. This includes adjusting fuel injection, ignition timing, and valve timing to improve power output, fuel efficiency, and emissions. Advanced engine management systems can be implemented to fine-tune these parameters based on various operating conditions.- Engine control and performance optimization: Adaptation of the K24 engine involves optimizing its control systems and performance parameters. This includes adjusting fuel injection, ignition timing, and valve timing to improve power output, fuel efficiency, and emissions. Advanced engine management systems can be implemented to fine-tune these parameters based on various operating conditions.

- Turbocharging and forced induction: Implementing turbocharging or other forced induction methods can significantly enhance the K24 engine's power output. This adaptation involves designing and integrating a turbocharger system, including intercoolers and wastegates, to increase air intake and boost pressure while maintaining reliability.

- Cylinder head and valve train modifications: Adapting the K24 engine may involve modifications to the cylinder head and valve train components. This can include porting and polishing the cylinder head, installing larger valves, upgrading camshafts, and implementing variable valve timing systems to improve airflow and overall engine efficiency.

- Engine block strengthening and internal components: To handle increased power output and stress, the K24 engine block may require strengthening. This can involve using stronger materials for internal components such as pistons, connecting rods, and crankshafts. Additionally, improving the engine's cooling system and oil circulation may be necessary to maintain reliability under higher performance conditions.

- Electronic control unit (ECU) reprogramming: Adapting the K24 engine often requires reprogramming or replacing the ECU to accommodate modifications and optimize performance. This involves adjusting parameters such as fuel maps, ignition timing, and boost control. Advanced ECUs may also incorporate features like traction control, launch control, and data logging for performance monitoring.

02 Turbocharging and forced induction

Implementing turbocharging or other forced induction methods can significantly enhance the K24 engine's power output. This adaptation involves designing and integrating a turbocharger system, including intercoolers, wastegates, and boost control mechanisms. Proper tuning of the engine management system is crucial to accommodate the increased airflow and fuel requirements.Expand Specific Solutions03 Intake and exhaust system modifications

Adapting the K24 engine's intake and exhaust systems can improve airflow and overall engine efficiency. This may include installing high-flow air filters, redesigning the intake manifold, and upgrading to a performance exhaust system. These modifications can enhance engine breathing, reduce backpressure, and potentially increase horsepower and torque.Expand Specific Solutions04 Internal component upgrades

Enhancing the K24 engine's internal components can increase its durability and performance potential. This may involve installing forged pistons, stronger connecting rods, and a reinforced crankshaft. Upgrading the valvetrain with performance camshafts and valve springs can also improve high-RPM performance and overall engine output.Expand Specific Solutions05 Integration with hybrid and electric systems

Adapting the K24 engine for hybrid or electric vehicle applications involves integrating it with electric motors and battery systems. This may require modifications to the engine management system, development of power-split devices, and implementation of regenerative braking systems. Such adaptations can significantly improve fuel efficiency and reduce emissions while maintaining performance.Expand Specific Solutions

Key Manufacturers

The K24 Engine Development market is in a mature stage, characterized by established players and ongoing innovation to meet evolving user demands. The market size is substantial, driven by the automotive industry's continuous need for efficient and powerful engines. Technologically, the K24 engine has reached a high level of maturity, with companies like Dongfeng Commercial Vehicles, Chery Automobile, and Weichai Power leading the way in adapting the engine to user requirements. These firms, along with others such as Cummins and China FAW, are focusing on enhancing performance, fuel efficiency, and emissions compliance to maintain their competitive edge in this well-developed but still evolving market segment.

Dongfeng Motor Group Co., Ltd.

Technical Solution: Dongfeng Motor Group has been actively developing its K24 engine to meet evolving user demands. The company has implemented advanced combustion technologies, including direct injection and variable valve timing, to enhance fuel efficiency and reduce emissions[1]. The K24 engine features a lightweight aluminum block and cylinder head, contributing to improved power-to-weight ratio[2]. Dongfeng has also integrated turbocharging technology to boost performance while maintaining fuel economy[3]. The company has focused on noise, vibration, and harshness (NVH) reduction techniques, incorporating advanced materials and design optimizations to enhance user comfort[4].

Strengths: Strong domestic market presence, extensive R&D capabilities, and established manufacturing infrastructure. Weaknesses: Potential challenges in meeting international emission standards and competition from global automotive giants.

Weichai Power

Technical Solution: Weichai Power has made significant strides in K24 engine development, focusing on adaptability to user demands. The company has implemented advanced electronic control systems to optimize fuel injection and combustion processes, resulting in improved fuel efficiency and reduced emissions[1]. Weichai has also integrated variable geometry turbocharging technology, allowing for better power delivery across a wide range of engine speeds[2]. The K24 engine features a robust design with high-strength materials, ensuring durability and reliability in various operating conditions[3]. Weichai has incorporated advanced aftertreatment systems to meet stringent emission standards while maintaining performance[4].

Strengths: Strong expertise in diesel engine technology, extensive R&D capabilities, and a wide range of applications. Weaknesses: Potential challenges in transitioning to alternative fuel technologies and adapting to rapidly changing emission regulations.

Core K24 Innovations

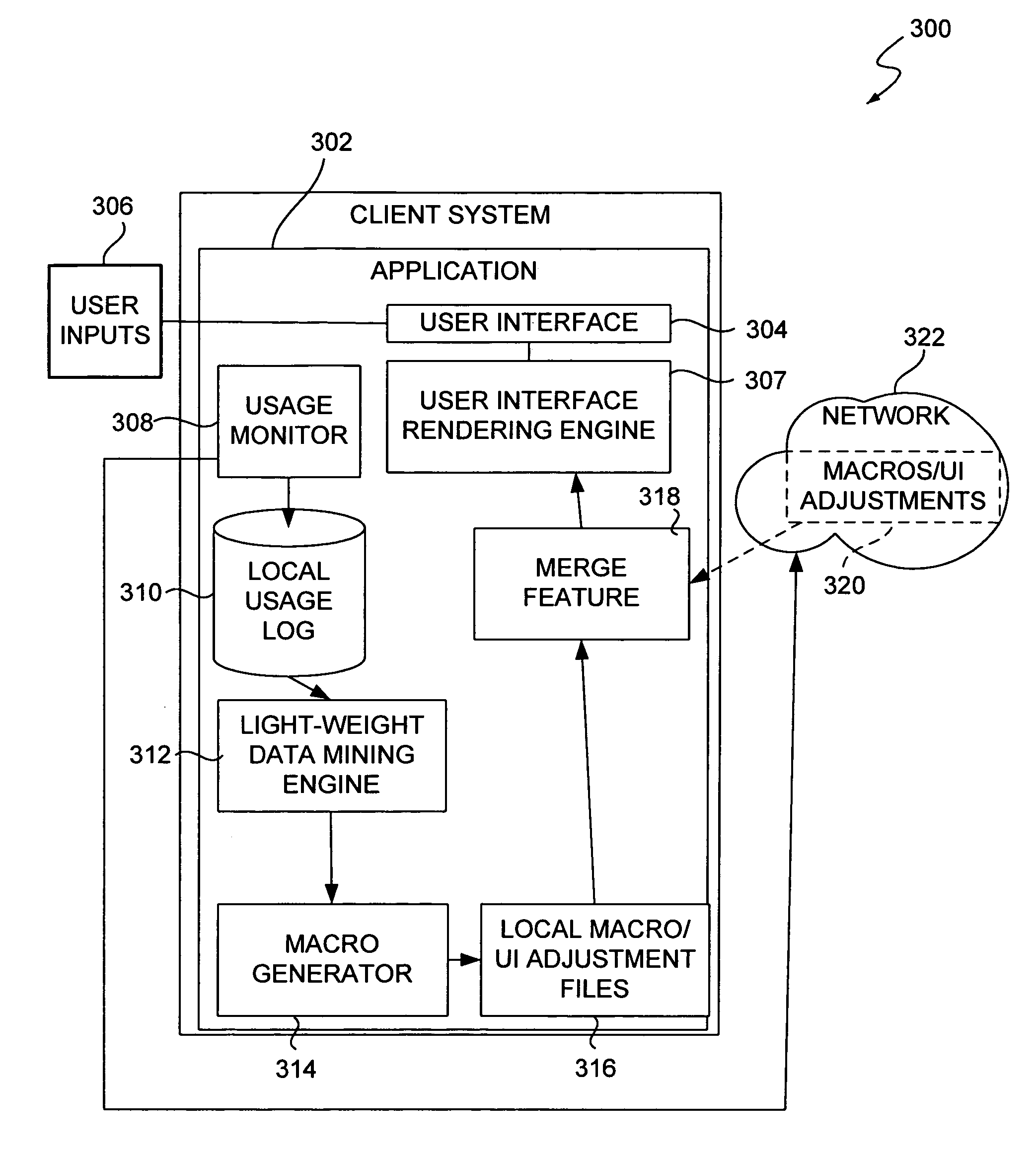

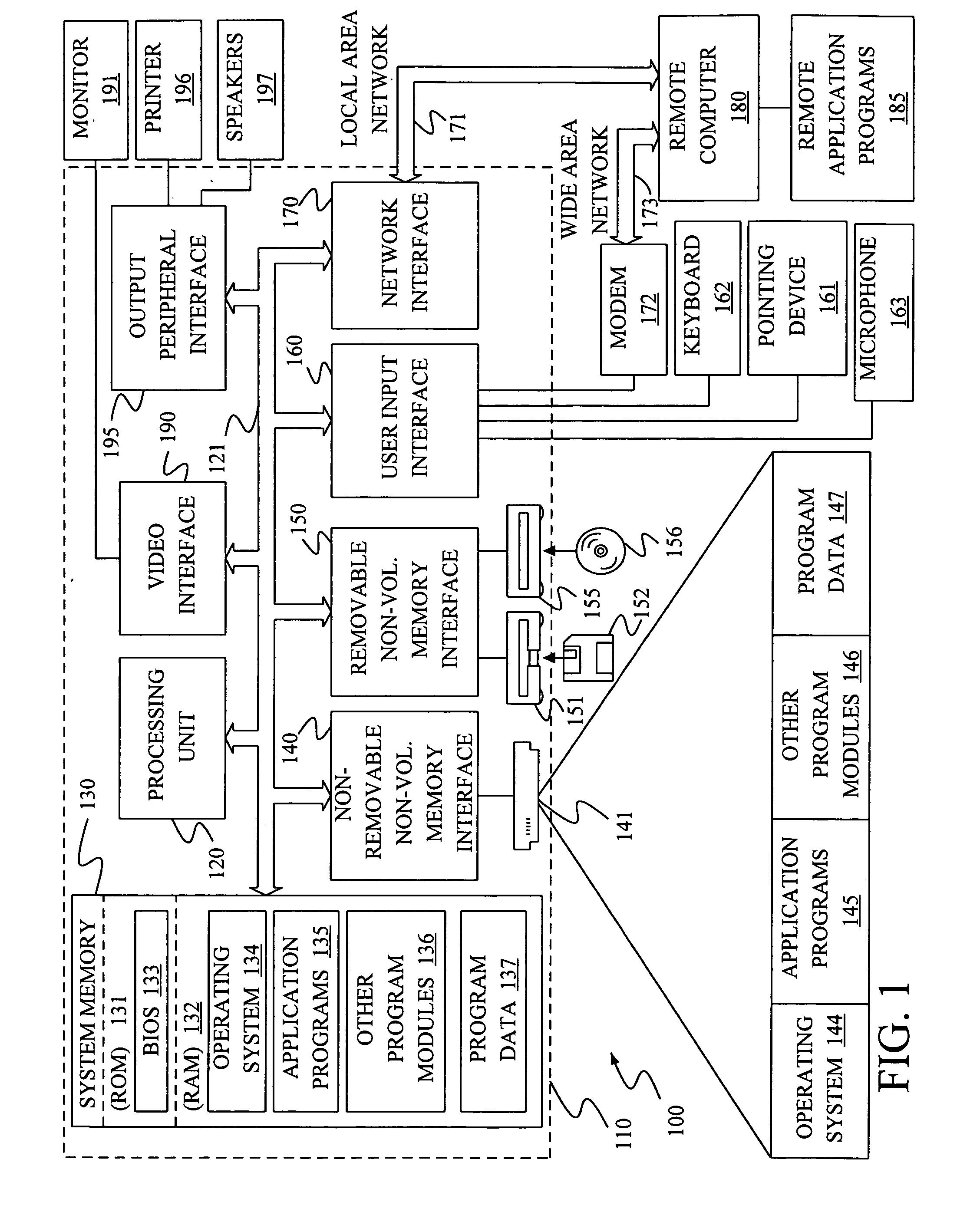

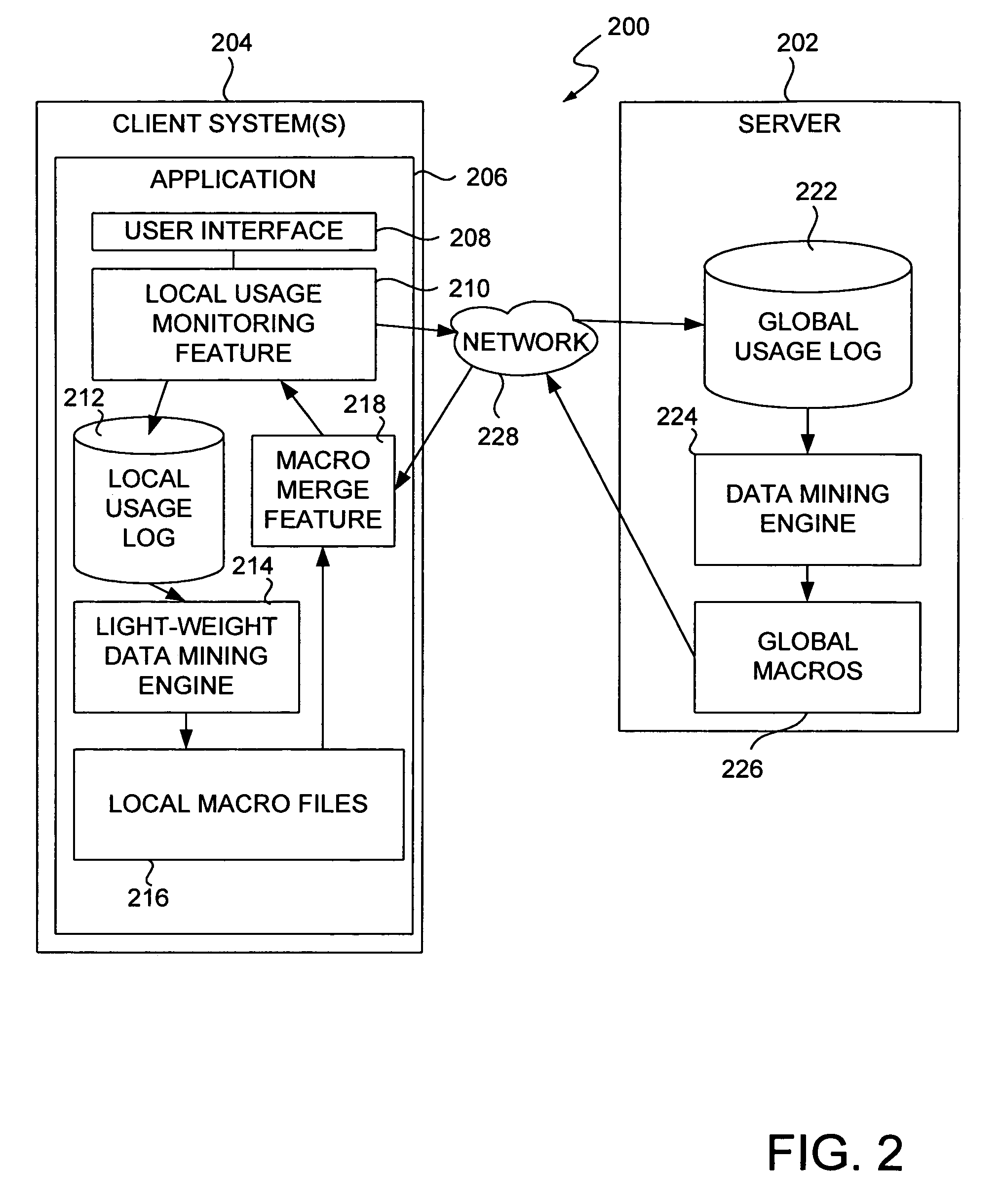

Adaptive systems and methods for making software easy to use via software usage mining

PatentActiveUS7802197B2

Innovation

- A system that dynamically updates user interface features by processing local and global usage data using a data mining engine, which records operator interactions, generates local and global adjustments, and merges these to optimize user interface accessibility and layout based on usage patterns.

Web browser accessible search engine which adapts based on user interaction

PatentInactiveUS20090282021A1

Innovation

- An adaptive search engine that learns user preferences by processing interactions and feedback, using a desirability number algorithm to prioritize and refine search results, providing a more focused and manageable list of relevant content.

Emissions Regulations

Emissions regulations have become a critical factor in the development of the K24 engine, as automotive manufacturers face increasingly stringent standards worldwide. The K24 engine, known for its versatility and performance, must adapt to meet these evolving requirements while maintaining its appeal to users.

In recent years, regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Union's Euro emissions standards have implemented progressively tighter limits on vehicle emissions. These regulations primarily target reductions in greenhouse gases, particulate matter, and nitrogen oxides. As a result, K24 engine development has focused on improving fuel efficiency and reducing harmful emissions without compromising performance.

One of the key strategies employed in K24 engine development is the integration of advanced fuel injection systems. Direct injection technology, coupled with precise electronic control units, allows for more efficient fuel combustion and reduced emissions. This approach has enabled the K24 engine to meet stricter emissions standards while maintaining its power output and drivability.

Another significant area of focus has been the implementation of exhaust gas recirculation (EGR) systems. By recirculating a portion of the exhaust gases back into the combustion chamber, EGR systems effectively lower combustion temperatures, reducing the formation of nitrogen oxides. The K24 engine's EGR system has undergone continuous refinement to optimize its effectiveness across various operating conditions.

Catalytic converter technology has also played a crucial role in meeting emissions regulations. The K24 engine utilizes advanced three-way catalytic converters that efficiently convert harmful pollutants into less harmful substances. Ongoing research and development in catalyst materials and designs have further enhanced the engine's ability to comply with stringent emissions standards.

To address particulate matter emissions, particularly in diesel variants of the K24 engine, diesel particulate filters (DPF) have been incorporated. These filters trap soot particles from the exhaust gases, periodically regenerating to maintain their effectiveness. The integration of DPF technology has been essential in meeting the latest emissions regulations for diesel engines.

As emissions regulations continue to evolve, the K24 engine development team has also explored hybrid and electrification technologies. By incorporating electric motors and advanced battery systems, hybrid variants of the K24 engine can achieve significant reductions in emissions while offering improved fuel economy. This approach aligns with the growing trend towards electrification in the automotive industry and positions the K24 engine for future regulatory challenges.

The ongoing development of the K24 engine in response to emissions regulations demonstrates the importance of adaptability in modern engine design. By leveraging advanced technologies and innovative engineering solutions, the K24 engine continues to meet user demands for performance while complying with increasingly stringent environmental standards.

In recent years, regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Union's Euro emissions standards have implemented progressively tighter limits on vehicle emissions. These regulations primarily target reductions in greenhouse gases, particulate matter, and nitrogen oxides. As a result, K24 engine development has focused on improving fuel efficiency and reducing harmful emissions without compromising performance.

One of the key strategies employed in K24 engine development is the integration of advanced fuel injection systems. Direct injection technology, coupled with precise electronic control units, allows for more efficient fuel combustion and reduced emissions. This approach has enabled the K24 engine to meet stricter emissions standards while maintaining its power output and drivability.

Another significant area of focus has been the implementation of exhaust gas recirculation (EGR) systems. By recirculating a portion of the exhaust gases back into the combustion chamber, EGR systems effectively lower combustion temperatures, reducing the formation of nitrogen oxides. The K24 engine's EGR system has undergone continuous refinement to optimize its effectiveness across various operating conditions.

Catalytic converter technology has also played a crucial role in meeting emissions regulations. The K24 engine utilizes advanced three-way catalytic converters that efficiently convert harmful pollutants into less harmful substances. Ongoing research and development in catalyst materials and designs have further enhanced the engine's ability to comply with stringent emissions standards.

To address particulate matter emissions, particularly in diesel variants of the K24 engine, diesel particulate filters (DPF) have been incorporated. These filters trap soot particles from the exhaust gases, periodically regenerating to maintain their effectiveness. The integration of DPF technology has been essential in meeting the latest emissions regulations for diesel engines.

As emissions regulations continue to evolve, the K24 engine development team has also explored hybrid and electrification technologies. By incorporating electric motors and advanced battery systems, hybrid variants of the K24 engine can achieve significant reductions in emissions while offering improved fuel economy. This approach aligns with the growing trend towards electrification in the automotive industry and positions the K24 engine for future regulatory challenges.

The ongoing development of the K24 engine in response to emissions regulations demonstrates the importance of adaptability in modern engine design. By leveraging advanced technologies and innovative engineering solutions, the K24 engine continues to meet user demands for performance while complying with increasingly stringent environmental standards.

Performance Benchmarks

Performance benchmarks are crucial in evaluating the K24 engine's adaptation to user demands. These metrics provide quantifiable data on the engine's capabilities, allowing for objective comparisons and informed decision-making in the development process.

One key benchmark is horsepower output. The K24 engine has shown significant improvements over its predecessors, with some variants producing up to 205 horsepower in stock form. This represents a substantial increase from earlier models, meeting the growing demand for more powerful engines in compact and mid-size vehicles.

Torque figures are equally important, as they directly impact the engine's responsiveness and acceleration. The K24 has demonstrated impressive torque output, with some versions generating up to 180 lb-ft. This torque profile contributes to the engine's versatility, making it suitable for a wide range of applications from daily drivers to performance-oriented vehicles.

Fuel efficiency is another critical benchmark, especially given increasing environmental concerns and stringent emissions regulations. The K24 engine has shown remarkable efficiency for its class, with some applications achieving up to 30 mpg in combined city/highway driving. This efficiency is partly attributed to Honda's i-VTEC technology, which optimizes valve timing and lift for different driving conditions.

Emissions performance is closely tied to fuel efficiency but warrants separate consideration. The K24 engine has consistently met or exceeded emissions standards in various markets, demonstrating its ability to balance performance with environmental responsibility.

Durability and longevity are less quantifiable but equally important benchmarks. The K24 has built a reputation for reliability, with many engines surpassing 200,000 miles with proper maintenance. This longevity is a testament to the engine's robust design and high-quality manufacturing processes.

Power-to-weight ratio is a benchmark that highlights the K24's efficiency in delivering performance. With its relatively lightweight aluminum construction, the engine offers an excellent balance of power and weight, contributing to improved vehicle dynamics and fuel economy.

Lastly, the engine's adaptability to aftermarket modifications serves as a benchmark for its potential beyond stock specifications. The K24's robust design and tuning potential have made it a favorite among enthusiasts, capable of significant power increases with relatively modest modifications.

These performance benchmarks collectively illustrate the K24 engine's success in meeting and exceeding user demands across various metrics, from power and efficiency to reliability and adaptability.

One key benchmark is horsepower output. The K24 engine has shown significant improvements over its predecessors, with some variants producing up to 205 horsepower in stock form. This represents a substantial increase from earlier models, meeting the growing demand for more powerful engines in compact and mid-size vehicles.

Torque figures are equally important, as they directly impact the engine's responsiveness and acceleration. The K24 has demonstrated impressive torque output, with some versions generating up to 180 lb-ft. This torque profile contributes to the engine's versatility, making it suitable for a wide range of applications from daily drivers to performance-oriented vehicles.

Fuel efficiency is another critical benchmark, especially given increasing environmental concerns and stringent emissions regulations. The K24 engine has shown remarkable efficiency for its class, with some applications achieving up to 30 mpg in combined city/highway driving. This efficiency is partly attributed to Honda's i-VTEC technology, which optimizes valve timing and lift for different driving conditions.

Emissions performance is closely tied to fuel efficiency but warrants separate consideration. The K24 engine has consistently met or exceeded emissions standards in various markets, demonstrating its ability to balance performance with environmental responsibility.

Durability and longevity are less quantifiable but equally important benchmarks. The K24 has built a reputation for reliability, with many engines surpassing 200,000 miles with proper maintenance. This longevity is a testament to the engine's robust design and high-quality manufacturing processes.

Power-to-weight ratio is a benchmark that highlights the K24's efficiency in delivering performance. With its relatively lightweight aluminum construction, the engine offers an excellent balance of power and weight, contributing to improved vehicle dynamics and fuel economy.

Lastly, the engine's adaptability to aftermarket modifications serves as a benchmark for its potential beyond stock specifications. The K24's robust design and tuning potential have made it a favorite among enthusiasts, capable of significant power increases with relatively modest modifications.

These performance benchmarks collectively illustrate the K24 engine's success in meeting and exceeding user demands across various metrics, from power and efficiency to reliability and adaptability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!