How to Identify Quality HDPE for Critical Application?

HDPE Quality Criteria and Objectives

High-density polyethylene (HDPE) has become a critical material in various industries due to its exceptional properties and versatility. Identifying quality HDPE for critical applications is paramount to ensure the reliability, safety, and performance of end products. The primary objective of this analysis is to establish comprehensive criteria for assessing HDPE quality and to define clear objectives for its use in critical applications.

Quality criteria for HDPE encompass a wide range of physical, chemical, and mechanical properties. These include molecular weight distribution, density, melt flow index, tensile strength, impact resistance, and environmental stress crack resistance. The molecular weight distribution directly influences the material's processability and mechanical properties, while density affects stiffness and chemical resistance. Melt flow index is crucial for determining the material's flow characteristics during processing.

For critical applications, it is essential to set stringent quality objectives that surpass standard industry requirements. These objectives should focus on enhancing the material's long-term performance, durability, and resistance to various environmental factors. Specific goals may include achieving a narrow molecular weight distribution for consistent processing, maintaining a high density for improved chemical resistance, and ensuring excellent environmental stress crack resistance for applications exposed to harsh conditions.

The identification of quality HDPE also involves evaluating its thermal properties, such as melting point and heat deflection temperature. These characteristics are vital for applications that may be subjected to extreme temperatures or thermal cycling. Additionally, the material's resistance to UV radiation and oxidation should be considered for outdoor applications or those exposed to harsh environmental conditions.

In critical applications, the purity of HDPE is of utmost importance. Objectives should be set to minimize the presence of contaminants, additives, or impurities that could compromise the material's performance or safety. This may involve implementing stringent quality control measures during the manufacturing process and conducting thorough testing and analysis of raw materials and finished products.

Furthermore, the consistency of HDPE properties across different batches is crucial for maintaining product quality in critical applications. Objectives should be established to ensure minimal variation in key properties between production runs, requiring robust process control and quality assurance protocols.

To meet these quality criteria and objectives, it is essential to implement comprehensive testing and characterization methods. These may include advanced analytical techniques such as gel permeation chromatography for molecular weight analysis, differential scanning calorimetry for thermal property assessment, and various mechanical testing procedures to evaluate strength and durability.

By establishing clear quality criteria and setting ambitious objectives for HDPE in critical applications, manufacturers and end-users can ensure the material's reliability, longevity, and optimal performance. This approach not only enhances product safety and functionality but also contributes to the overall advancement of HDPE technology in demanding industrial sectors.

Market Demand for High-Grade HDPE

The market demand for high-grade HDPE has been steadily increasing across various industries due to its exceptional properties and versatility. In critical applications, such as chemical storage tanks, pressure pipes, and medical devices, the need for quality HDPE is particularly pronounced. The global HDPE market size was valued at USD 84.79 billion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 4.2% from 2022 to 2030.

The packaging industry remains the largest consumer of high-grade HDPE, driven by the growing e-commerce sector and increased demand for sustainable packaging solutions. HDPE's excellent chemical resistance, durability, and recyclability make it a preferred choice for packaging manufacturers seeking to meet stringent environmental regulations and consumer preferences for eco-friendly products.

In the construction sector, the demand for high-grade HDPE pipes and fittings continues to rise, particularly in developing countries with expanding infrastructure projects. The material's corrosion resistance, flexibility, and long service life make it ideal for water supply systems, sewage networks, and gas distribution pipelines. The global HDPE pipes market is projected to reach USD 26.8 billion by 2027, with a CAGR of 5.6% during the forecast period.

The automotive industry is another significant driver of high-grade HDPE demand. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, HDPE is increasingly used in fuel tanks, interior components, and under-the-hood applications. The material's high strength-to-weight ratio and resistance to impact and chemicals make it an attractive alternative to traditional materials like metal and rubber.

In the healthcare sector, the demand for medical-grade HDPE is growing rapidly, especially in light of recent global health challenges. The material's biocompatibility, sterilizability, and chemical resistance make it suitable for a wide range of medical devices, pharmaceutical packaging, and laboratory equipment. The COVID-19 pandemic has further accelerated this trend, with increased demand for HDPE in personal protective equipment (PPE) and diagnostic kit components.

The agriculture industry is also contributing to the rising demand for high-grade HDPE. The material is widely used in irrigation systems, greenhouse films, and storage containers due to its UV resistance, durability, and cost-effectiveness. As precision agriculture and sustainable farming practices gain traction, the demand for HDPE products in this sector is expected to grow significantly.

As industries increasingly prioritize quality and reliability in critical applications, the ability to identify and source high-grade HDPE becomes crucial. This has led to a growing emphasis on advanced testing methods, quality control processes, and traceability systems throughout the HDPE supply chain. Manufacturers and end-users alike are investing in sophisticated analytical techniques and certification programs to ensure the consistent quality of HDPE materials used in their products and processes.

Current Challenges in HDPE Quality Assessment

The assessment of High-Density Polyethylene (HDPE) quality for critical applications faces several significant challenges in today's industrial landscape. One of the primary difficulties lies in the variability of HDPE properties due to differences in manufacturing processes and raw materials. This inconsistency makes it challenging to establish standardized quality criteria across different suppliers and batches.

Another major hurdle is the complexity of testing procedures required to accurately evaluate HDPE quality. Traditional methods often involve time-consuming and costly laboratory tests, which may not be feasible for rapid quality control in production environments. Moreover, these tests sometimes fail to capture the full range of properties relevant to specific critical applications.

The lack of comprehensive, real-time quality assessment tools presents a significant obstacle. While some inline measurement techniques exist, they often provide limited information about the material's overall performance characteristics. This gap in immediate, detailed analysis can lead to delays in production and potential quality issues in final products.

Environmental factors also pose challenges in HDPE quality assessment. Temperature fluctuations, humidity, and exposure to various chemicals during storage and transportation can affect the material's properties. Developing reliable methods to account for these environmental influences on HDPE quality remains a complex task.

Furthermore, the increasing demand for recycled HDPE in critical applications introduces new quality assessment challenges. Recycled materials often exhibit more variability in their properties compared to virgin HDPE, making it difficult to ensure consistent quality standards. The industry faces the challenge of developing robust assessment techniques that can effectively evaluate both virgin and recycled HDPE for critical use.

The rapid evolution of HDPE formulations and additives also complicates quality assessment. As manufacturers continually innovate to enhance material properties, existing quality control methods may become outdated or inadequate. Keeping pace with these advancements and adapting assessment techniques accordingly is an ongoing challenge for the industry.

Lastly, the interpretation of quality assessment data presents its own set of challenges. Determining which properties are most critical for specific applications and how they correlate with real-world performance requires extensive expertise and often involves subjective judgment. Developing more objective and application-specific quality metrics remains an area of active research and development in the field of HDPE quality assessment.

Existing HDPE Quality Testing Methods

01 Improving HDPE quality through catalyst systems

Advanced catalyst systems are employed to enhance the quality of HDPE. These systems can control molecular weight distribution, improve polymer morphology, and increase the overall performance of the material. Innovations in catalyst technology lead to better processability and mechanical properties of HDPE.- Improving HDPE quality through catalyst systems: Advanced catalyst systems are employed to enhance the quality of HDPE. These systems can control molecular weight distribution, improve polymer morphology, and increase the overall performance of the material. Innovations in catalyst technology contribute to producing HDPE with superior mechanical properties and processing characteristics.

- Optimizing HDPE production processes: Various methods are developed to optimize HDPE production processes, focusing on improving reactor design, polymerization conditions, and post-production treatments. These advancements aim to enhance product consistency, increase production efficiency, and reduce defects in the final HDPE material.

- Enhancing HDPE properties through additives and blends: The incorporation of specific additives and the development of HDPE blends are explored to enhance material properties. These approaches can improve the mechanical strength, thermal stability, and chemical resistance of HDPE, making it suitable for a wider range of applications.

- Quality control and testing methods for HDPE: Advanced quality control and testing methods are developed to ensure the consistency and reliability of HDPE products. These techniques include improved analytical methods, in-line monitoring systems, and standardized testing protocols to assess various quality parameters of HDPE throughout the production process.

- Specialized HDPE formulations for specific applications: Research focuses on developing specialized HDPE formulations tailored for specific end-use applications. These formulations may involve modifications to the polymer structure, incorporation of specific additives, or unique processing techniques to meet the demanding requirements of various industries such as packaging, automotive, and construction.

02 Optimizing HDPE production processes

Various methods are developed to optimize the production process of HDPE, including improvements in polymerization conditions, reactor design, and post-production treatments. These advancements aim to increase production efficiency, reduce defects, and enhance the overall quality of the final HDPE product.Expand Specific Solutions03 Enhancing HDPE properties through additives and blends

The incorporation of specific additives and the creation of polymer blends are utilized to enhance the properties of HDPE. These methods can improve characteristics such as impact strength, environmental stress crack resistance, and long-term stability, resulting in higher quality HDPE materials for various applications.Expand Specific Solutions04 Quality control and testing methods for HDPE

Advanced quality control techniques and testing methods are developed to ensure the consistency and reliability of HDPE products. These include innovative analytical tools, in-line monitoring systems, and standardized testing procedures to assess various quality parameters throughout the production process.Expand Specific Solutions05 Specialized HDPE formulations for specific applications

Tailored HDPE formulations are created to meet the quality requirements of specific applications. These specialized grades may have improved barrier properties, enhanced processability, or superior mechanical characteristics, catering to the demands of industries such as packaging, automotive, and construction.Expand Specific Solutions

Key HDPE Producers and Suppliers

The market for identifying quality HDPE for critical applications is in a mature stage, with a growing global market size driven by increasing demand in various industries. The technology for HDPE quality assessment is well-established, with continuous advancements in testing methods and analytical tools. Key players like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and DuPont de Nemours, Inc. are at the forefront of HDPE innovation and quality control. These companies, along with others such as Chevron Phillips Chemical Co. LP and SABIC Global Technologies BV, are investing in research and development to enhance HDPE properties and develop more sophisticated identification techniques for critical applications, ensuring the technology's continued evolution and market competitiveness.

Dow Global Technologies LLC

ExxonMobil Chemical Patents, Inc.

Advanced HDPE Characterization Technologies

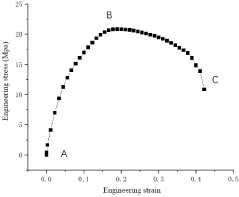

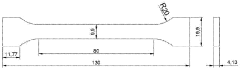

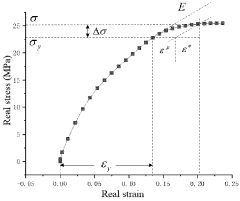

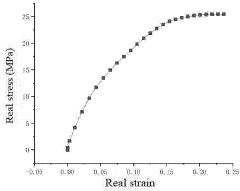

- A hydraulic bulge testing method and system that combines uniaxial tensile testing and hydraulic bulge testing with finite element modeling to obtain mechanical response relations, using Marlow constitutive models and isotropic power law hardening to analyze nonlinear elasticity and ductile damage, and ABAQUS/Explicit for explicit scheme integration to refine grid division and loading conditions.

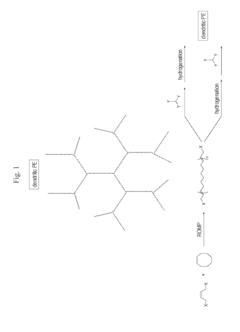

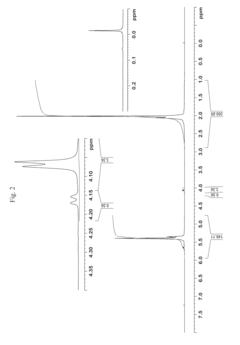

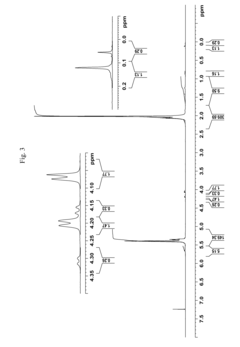

- The synthesis of dendritic polyethylenes through ring opening metathesis polymerization of cyclic olefins with bi-functional alkene chain terminating agents, followed by reaction with multifunctional coupling agents, to produce telechelic hydrocarbon polymers that are then reacted with trifunctional or tetrafunctional coupling agents to create dendritic structures, which can be used as additives in conventional polyethylenes.

Environmental Impact of HDPE Production

The production of High-Density Polyethylene (HDPE) has significant environmental implications that warrant careful consideration. The manufacturing process of HDPE primarily relies on fossil fuel-derived raw materials, contributing to the depletion of non-renewable resources. The extraction and processing of these materials result in greenhouse gas emissions, further exacerbating climate change concerns.

During HDPE production, substantial energy consumption is required for the polymerization process, leading to increased carbon footprint. The energy-intensive nature of HDPE manufacturing contributes to air pollution through the release of volatile organic compounds (VOCs) and other harmful emissions. These pollutants can have detrimental effects on local air quality and human health.

Water usage and potential contamination are additional environmental concerns associated with HDPE production. The manufacturing process often requires large volumes of water for cooling and other industrial purposes. Improper management of wastewater can lead to the release of pollutants into local water bodies, affecting aquatic ecosystems and potentially contaminating drinking water sources.

The disposal of HDPE products at the end of their lifecycle presents another environmental challenge. While HDPE is recyclable, a significant portion still ends up in landfills or as litter in the environment. The slow degradation rate of HDPE contributes to long-term pollution, particularly in marine ecosystems where it can persist for hundreds of years.

However, efforts are being made to mitigate the environmental impact of HDPE production. Advancements in manufacturing technologies have led to more efficient processes, reducing energy consumption and emissions. The development of bio-based HDPE, derived from renewable resources such as sugarcane, offers a more sustainable alternative to traditional petroleum-based production methods.

Recycling initiatives play a crucial role in minimizing the environmental footprint of HDPE. Improved collection and recycling systems help to reduce the amount of HDPE waste entering landfills and the environment. The recycling process itself consumes less energy compared to virgin HDPE production, further contributing to environmental conservation efforts.

In conclusion, while HDPE production does have significant environmental impacts, ongoing research and technological advancements are paving the way for more sustainable manufacturing practices. The industry's focus on energy efficiency, renewable raw materials, and improved recycling processes demonstrates a commitment to reducing the overall environmental footprint of HDPE production.

Regulatory Standards for Critical HDPE Applications

Regulatory standards play a crucial role in ensuring the quality and safety of High-Density Polyethylene (HDPE) used in critical applications. These standards are established by various international and national organizations to provide guidelines for manufacturers, suppliers, and end-users.

The International Organization for Standardization (ISO) has developed several standards relevant to HDPE in critical applications. ISO 17855-1 and ISO 17855-2 specify the nomenclature system and the methods for determining the density and melt mass-flow rate of polyethylene materials. These standards are essential for ensuring consistency in material properties across different batches and suppliers.

In the United States, the American Society for Testing and Materials (ASTM) has established numerous standards for HDPE. ASTM D3350 provides a cell classification system for polyethylene materials used in pressure-rated applications. This standard categorizes HDPE based on properties such as density, melt index, flexural modulus, tensile strength, and environmental stress crack resistance.

The European Committee for Standardization (CEN) has developed EN 12201, which specifies requirements for HDPE piping systems used in water supply and drainage applications. This standard covers aspects such as material properties, dimensions, and performance requirements for pipes, fittings, and valves.

For food contact applications, the U.S. Food and Drug Administration (FDA) has established regulations under 21 CFR 177.1520, which outlines the requirements for olefin polymers, including HDPE, used in food packaging and processing equipment. These regulations specify the permissible additives and processing aids, as well as migration limits for various substances.

In the pharmaceutical industry, the United States Pharmacopeia (USP) provides standards for HDPE used in packaging and delivery systems. USP <661.1> covers plastic materials of construction, while USP <661.2> addresses plastic packaging systems for pharmaceutical use. These standards ensure that HDPE used in pharmaceutical applications meets stringent quality and safety requirements.

The National Sanitation Foundation (NSF) has developed NSF/ANSI 61, which sets health effects criteria for materials used in drinking water systems. This standard is particularly relevant for HDPE pipes and fittings used in potable water applications.

Compliance with these regulatory standards is typically verified through third-party testing and certification programs. Organizations such as UL (Underwriters Laboratories), TÜV (Technischer Überwachungsverein), and DNV GL (Det Norske Veritas Germanischer Lloyd) offer testing and certification services to ensure that HDPE products meet the required standards for critical applications.