How to Increase Montmorillonite's Compressive Strength

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Montmorillonite Strength Enhancement Background and Objectives

Montmorillonite, a naturally occurring clay mineral belonging to the smectite group, has garnered significant attention in various industrial applications due to its unique structural and physicochemical properties. The evolution of montmorillonite utilization spans several decades, with initial applications primarily in traditional sectors such as ceramics, drilling fluids, and foundry sand binders. However, recent technological advancements have expanded its potential into high-performance composite materials, environmental remediation, and advanced construction materials.

The inherent limitation of montmorillonite lies in its relatively low compressive strength, which restricts its application in load-bearing structures and high-stress environments. This technical constraint has prompted extensive research efforts aimed at enhancing its mechanical properties, particularly compressive strength, without compromising its beneficial characteristics such as high cation exchange capacity, swelling capability, and adsorption properties.

Historical approaches to strength enhancement have progressed from simple physical modifications to sophisticated chemical treatments and hybrid composite formulations. Early techniques focused on dehydration and thermal treatment, while contemporary methods explore nanoscale engineering and molecular intercalation strategies. The technological trajectory indicates a shift toward multifunctional enhancement approaches that simultaneously address strength, durability, and functional performance.

Current global research trends demonstrate accelerating interest in montmorillonite strength enhancement, with publication rates increasing by approximately 15% annually over the past decade. This surge reflects the growing recognition of montmorillonite's potential in advanced material applications, particularly in sustainable construction materials, polymer nanocomposites, and environmental technologies.

The primary technical objectives for montmorillonite strength enhancement include achieving a minimum 200% increase in compressive strength compared to untreated samples, maintaining dimensional stability under varying environmental conditions, ensuring compatibility with existing manufacturing processes, and developing cost-effective modification techniques suitable for industrial-scale implementation.

Secondary objectives encompass the development of standardized testing protocols for modified montmorillonite materials, establishing structure-property relationships to guide future enhancement strategies, and creating predictive models for strength development based on modification parameters. These objectives align with broader industry goals of developing sustainable, high-performance materials with reduced environmental impact.

The anticipated technological impact extends beyond mere strength improvement, potentially enabling new applications in structural composites, advanced ceramics, and specialized construction materials. Success in this domain could facilitate the replacement of traditional, energy-intensive materials with more sustainable alternatives, contributing to global sustainability objectives while opening new market opportunities.

The inherent limitation of montmorillonite lies in its relatively low compressive strength, which restricts its application in load-bearing structures and high-stress environments. This technical constraint has prompted extensive research efforts aimed at enhancing its mechanical properties, particularly compressive strength, without compromising its beneficial characteristics such as high cation exchange capacity, swelling capability, and adsorption properties.

Historical approaches to strength enhancement have progressed from simple physical modifications to sophisticated chemical treatments and hybrid composite formulations. Early techniques focused on dehydration and thermal treatment, while contemporary methods explore nanoscale engineering and molecular intercalation strategies. The technological trajectory indicates a shift toward multifunctional enhancement approaches that simultaneously address strength, durability, and functional performance.

Current global research trends demonstrate accelerating interest in montmorillonite strength enhancement, with publication rates increasing by approximately 15% annually over the past decade. This surge reflects the growing recognition of montmorillonite's potential in advanced material applications, particularly in sustainable construction materials, polymer nanocomposites, and environmental technologies.

The primary technical objectives for montmorillonite strength enhancement include achieving a minimum 200% increase in compressive strength compared to untreated samples, maintaining dimensional stability under varying environmental conditions, ensuring compatibility with existing manufacturing processes, and developing cost-effective modification techniques suitable for industrial-scale implementation.

Secondary objectives encompass the development of standardized testing protocols for modified montmorillonite materials, establishing structure-property relationships to guide future enhancement strategies, and creating predictive models for strength development based on modification parameters. These objectives align with broader industry goals of developing sustainable, high-performance materials with reduced environmental impact.

The anticipated technological impact extends beyond mere strength improvement, potentially enabling new applications in structural composites, advanced ceramics, and specialized construction materials. Success in this domain could facilitate the replacement of traditional, energy-intensive materials with more sustainable alternatives, contributing to global sustainability objectives while opening new market opportunities.

Market Applications and Demand Analysis for Reinforced Montmorillonite

The global market for reinforced montmorillonite materials has witnessed significant growth in recent years, driven primarily by increasing applications in construction, automotive, aerospace, and environmental remediation sectors. The demand for materials with enhanced compressive strength continues to rise as industries seek more durable, lightweight, and cost-effective solutions for structural applications.

In the construction industry, reinforced montmorillonite with improved compressive strength presents substantial market potential, particularly for applications in load-bearing structures, insulation materials, and fire-resistant building components. Market research indicates that the green building materials sector, where reinforced clay minerals play a crucial role, is expanding at approximately 10% annually, creating a substantial opportunity for advanced montmorillonite composites.

The automotive and aerospace industries represent another significant market segment, where lightweight materials with high mechanical strength are increasingly sought after to improve fuel efficiency and reduce emissions. Reinforced montmorillonite nanocomposites offer an attractive alternative to traditional materials, combining reduced weight with enhanced structural integrity and thermal stability.

Environmental remediation and waste management sectors demonstrate growing demand for montmorillonite-based materials with improved mechanical properties. These materials are utilized in landfill liners, waste encapsulation, and contaminated soil treatment, where compressive strength is a critical performance parameter to ensure long-term structural integrity under varying environmental conditions.

The packaging industry has also emerged as a promising market for reinforced montmorillonite, particularly in food packaging applications where materials must maintain structural integrity while providing barrier properties against moisture, gases, and contaminants. The global sustainable packaging market, currently valued at over $200 billion, presents significant opportunities for advanced clay-based composites.

Regional market analysis reveals that Asia-Pacific represents the largest and fastest-growing market for reinforced montmorillonite materials, driven by rapid industrialization, infrastructure development, and increasing environmental regulations in countries like China and India. North America and Europe follow closely, with demand primarily stemming from advanced manufacturing sectors and stringent environmental standards.

Consumer trends toward sustainable and environmentally friendly products further bolster the market potential for reinforced montmorillonite materials, as they are derived from naturally abundant resources and can be engineered to be biodegradable or recyclable. This alignment with circular economy principles enhances their market attractiveness across various industries.

Market forecasts suggest that the global demand for advanced clay-based composites with enhanced mechanical properties will continue to grow steadily over the next decade, presenting significant opportunities for innovation in montmorillonite reinforcement technologies that can deliver superior compressive strength while maintaining other desirable properties.

In the construction industry, reinforced montmorillonite with improved compressive strength presents substantial market potential, particularly for applications in load-bearing structures, insulation materials, and fire-resistant building components. Market research indicates that the green building materials sector, where reinforced clay minerals play a crucial role, is expanding at approximately 10% annually, creating a substantial opportunity for advanced montmorillonite composites.

The automotive and aerospace industries represent another significant market segment, where lightweight materials with high mechanical strength are increasingly sought after to improve fuel efficiency and reduce emissions. Reinforced montmorillonite nanocomposites offer an attractive alternative to traditional materials, combining reduced weight with enhanced structural integrity and thermal stability.

Environmental remediation and waste management sectors demonstrate growing demand for montmorillonite-based materials with improved mechanical properties. These materials are utilized in landfill liners, waste encapsulation, and contaminated soil treatment, where compressive strength is a critical performance parameter to ensure long-term structural integrity under varying environmental conditions.

The packaging industry has also emerged as a promising market for reinforced montmorillonite, particularly in food packaging applications where materials must maintain structural integrity while providing barrier properties against moisture, gases, and contaminants. The global sustainable packaging market, currently valued at over $200 billion, presents significant opportunities for advanced clay-based composites.

Regional market analysis reveals that Asia-Pacific represents the largest and fastest-growing market for reinforced montmorillonite materials, driven by rapid industrialization, infrastructure development, and increasing environmental regulations in countries like China and India. North America and Europe follow closely, with demand primarily stemming from advanced manufacturing sectors and stringent environmental standards.

Consumer trends toward sustainable and environmentally friendly products further bolster the market potential for reinforced montmorillonite materials, as they are derived from naturally abundant resources and can be engineered to be biodegradable or recyclable. This alignment with circular economy principles enhances their market attractiveness across various industries.

Market forecasts suggest that the global demand for advanced clay-based composites with enhanced mechanical properties will continue to grow steadily over the next decade, presenting significant opportunities for innovation in montmorillonite reinforcement technologies that can deliver superior compressive strength while maintaining other desirable properties.

Current Limitations and Technical Challenges in Clay Reinforcement

Despite significant advancements in clay reinforcement technologies, montmorillonite faces several critical limitations that hinder its widespread application in high-strength structural materials. The primary challenge stems from montmorillonite's inherent layered silicate structure, which creates weak interlayer bonding that compromises compressive strength under load. When subjected to pressure, these layers tend to slide against each other, resulting in structural failure at relatively low compressive thresholds compared to conventional construction materials.

Water sensitivity presents another major obstacle, as montmorillonite exhibits significant swelling behavior when exposed to moisture. This hydrophilic characteristic leads to dimensional instability and strength reduction in humid environments, severely limiting its application in outdoor or moisture-prone settings. The swelling-shrinking cycles during wetting and drying further deteriorate the material's mechanical integrity over time.

Current reinforcement techniques face efficiency barriers in achieving uniform dispersion of strengthening agents throughout the clay matrix. Agglomeration of additives creates weak points within the material structure, resulting in inconsistent mechanical properties. Additionally, many reinforcement methods require energy-intensive processing conditions, including high-temperature treatments that significantly increase production costs and carbon footprint.

The interface compatibility between montmorillonite and reinforcing agents remains problematic. Poor adhesion between the clay matrix and strengthening components often results in stress concentration points that initiate crack propagation under load. This interfacial weakness substantially limits the maximum achievable compressive strength regardless of the reinforcement type used.

Scale-up challenges persist in transitioning from laboratory success to industrial implementation. Processes that demonstrate excellent results at small scales frequently encounter reproducibility issues when scaled to commercial production volumes. The variability in natural montmorillonite sources further complicates standardization efforts, as compositional differences can significantly impact reinforcement effectiveness.

Environmental and regulatory constraints also pose significant barriers. Many effective chemical modifiers and cross-linking agents face increasing scrutiny due to potential toxicity concerns. The development of environmentally benign reinforcement methods that maintain high performance standards represents a critical technical challenge for researchers in this field.

Cost-effectiveness remains a persistent obstacle, as current high-strength reinforcement techniques often involve expensive additives or complex processing methods that make the final material economically unviable for mass-market applications. Finding the optimal balance between performance enhancement and production cost represents one of the most pressing challenges in montmorillonite reinforcement research.

Water sensitivity presents another major obstacle, as montmorillonite exhibits significant swelling behavior when exposed to moisture. This hydrophilic characteristic leads to dimensional instability and strength reduction in humid environments, severely limiting its application in outdoor or moisture-prone settings. The swelling-shrinking cycles during wetting and drying further deteriorate the material's mechanical integrity over time.

Current reinforcement techniques face efficiency barriers in achieving uniform dispersion of strengthening agents throughout the clay matrix. Agglomeration of additives creates weak points within the material structure, resulting in inconsistent mechanical properties. Additionally, many reinforcement methods require energy-intensive processing conditions, including high-temperature treatments that significantly increase production costs and carbon footprint.

The interface compatibility between montmorillonite and reinforcing agents remains problematic. Poor adhesion between the clay matrix and strengthening components often results in stress concentration points that initiate crack propagation under load. This interfacial weakness substantially limits the maximum achievable compressive strength regardless of the reinforcement type used.

Scale-up challenges persist in transitioning from laboratory success to industrial implementation. Processes that demonstrate excellent results at small scales frequently encounter reproducibility issues when scaled to commercial production volumes. The variability in natural montmorillonite sources further complicates standardization efforts, as compositional differences can significantly impact reinforcement effectiveness.

Environmental and regulatory constraints also pose significant barriers. Many effective chemical modifiers and cross-linking agents face increasing scrutiny due to potential toxicity concerns. The development of environmentally benign reinforcement methods that maintain high performance standards represents a critical technical challenge for researchers in this field.

Cost-effectiveness remains a persistent obstacle, as current high-strength reinforcement techniques often involve expensive additives or complex processing methods that make the final material economically unviable for mass-market applications. Finding the optimal balance between performance enhancement and production cost represents one of the most pressing challenges in montmorillonite reinforcement research.

Established Methods for Improving Montmorillonite Compressive Strength

01 Montmorillonite as a reinforcement agent for improving compressive strength

Montmorillonite clay can be used as a reinforcement agent in various composite materials to enhance their compressive strength. The layered silicate structure of montmorillonite, when properly dispersed, creates a network that restricts the movement of polymer chains, resulting in improved mechanical properties including compressive strength. This reinforcement effect is particularly beneficial in cement-based materials, polymers, and geopolymers where enhanced structural integrity is required.- Montmorillonite as a reinforcement agent for improving compressive strength: Montmorillonite clay can be used as a reinforcement agent in various materials to enhance their compressive strength. When properly dispersed, the layered silicate structure of montmorillonite provides mechanical reinforcement at the nanoscale, creating stronger composite materials. The high aspect ratio and surface area of montmorillonite particles contribute to improved load distribution and stress transfer within the material matrix, resulting in enhanced compressive strength properties.

- Montmorillonite-polymer composites for enhanced mechanical properties: Incorporating montmorillonite into polymer matrices creates nanocomposites with significantly improved compressive strength. The clay particles can be modified with organic compounds to improve compatibility with polymers, allowing better dispersion and exfoliation. These nanocomposites show enhanced mechanical properties including compressive strength due to the strong interfacial interactions between the polymer chains and the clay layers, restricting polymer chain mobility and creating more rigid structures.

- Montmorillonite in cement and concrete applications: Montmorillonite clay is utilized in cement and concrete formulations to improve compressive strength and durability. When added in optimal proportions, montmorillonite acts as a pozzolanic material that reacts with calcium hydroxide produced during cement hydration, forming additional calcium silicate hydrate gel that enhances the microstructure. This results in denser concrete with fewer pores and microcracks, leading to superior compressive strength and reduced permeability.

- Modified montmorillonite for enhanced compressive strength: Chemical modification of montmorillonite through processes such as acid activation, pillaring, or organic functionalization can significantly improve its reinforcing capabilities. These modifications alter the surface properties, interlayer spacing, and compatibility with various matrices. Modified montmorillonite demonstrates enhanced dispersion characteristics and stronger interfacial bonding with host materials, resulting in composites with superior compressive strength compared to those containing unmodified clay.

- Testing and measurement methods for montmorillonite-enhanced materials: Various specialized testing methodologies have been developed to accurately measure the compressive strength of materials containing montmorillonite. These include modified compression tests that account for the unique behavior of clay-reinforced composites, microstructural analysis techniques to evaluate clay dispersion and orientation, and accelerated aging tests to assess long-term performance. Advanced computational models can also predict the compressive strength of montmorillonite-containing materials based on composition and processing parameters.

02 Modification of montmorillonite for enhanced compressive strength

Chemical modification of montmorillonite, such as through organic treatment or functionalization, can significantly improve its compatibility with matrix materials and enhance the resulting compressive strength. Modified montmorillonite exhibits better dispersion characteristics and stronger interfacial bonding with the matrix, leading to superior mechanical properties. Various modification techniques include ion exchange with organic cations, surface grafting, and silane treatment, each tailored to specific applications and matrix materials.Expand Specific Solutions03 Montmorillonite-polymer nanocomposites with improved compressive strength

Incorporating montmorillonite into polymer matrices creates nanocomposites with significantly enhanced compressive strength. The nanoscale dispersion of montmorillonite platelets within the polymer matrix creates a tortuous path for crack propagation, effectively increasing the material's resistance to compressive forces. These nanocomposites find applications in construction materials, automotive components, and protective coatings where improved mechanical performance is essential.Expand Specific Solutions04 Montmorillonite in cement and concrete for enhanced compressive strength

Adding montmorillonite to cement and concrete formulations can significantly improve their compressive strength. The clay particles act as nucleation sites for cement hydration products and fill the micropores in the cement matrix, resulting in a denser microstructure with reduced porosity. Additionally, montmorillonite can participate in pozzolanic reactions, forming additional strength-contributing calcium silicate hydrate phases. The optimal dosage and proper dispersion of montmorillonite are critical factors in achieving the desired strength enhancement.Expand Specific Solutions05 Testing and measurement methods for montmorillonite-enhanced materials' compressive strength

Various specialized testing and measurement methods have been developed to accurately assess the compressive strength of montmorillonite-enhanced materials. These techniques include modified compression testing protocols, microstructural analysis, and advanced characterization methods that account for the unique properties of clay-reinforced composites. Proper sample preparation, curing conditions, and testing parameters are essential for obtaining reliable compressive strength data, which is crucial for quality control and material optimization in industrial applications.Expand Specific Solutions

Leading Organizations and Research Institutions in Clay Technology

The montmorillonite compressive strength enhancement market is in a growth phase, with increasing applications in construction, environmental engineering, and materials science. The global market size for modified clay minerals is projected to reach $2.5 billion by 2025, driven by infrastructure development and sustainability initiatives. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include Laviosa Chimica Mineraria and Kunimine Industries, who have developed proprietary strengthening methods, while academic institutions like Chongqing University and South China University of Technology are advancing fundamental research. China Petroleum & Chemical Corp. and Tata Steel are investing in industrial applications, focusing on composite materials that leverage montmorillonite's enhanced mechanical properties for construction and manufacturing sectors.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive approach to enhancing montmorillonite's compressive strength through their "ClayStrength" technology platform. Their method combines chemical modification with physical reinforcement techniques. The process begins with a proprietary acid activation treatment that selectively dissolves certain components of the clay structure, creating a more porous framework with increased surface area. This is followed by intercalation with inorganic pillaring agents, primarily aluminum and zirconium polyoxycations, which create rigid "pillars" between clay layers. The final step involves controlled heat treatment to convert these pillars into stable oxide structures. This multi-step process results in montmorillonite with compressive strength improvements of 40-60% compared to natural clay. Sinopec has successfully applied this technology in oil well cementing applications where high compressive strength under extreme conditions is critical.

Strengths: Extensive testing under high-pressure and high-temperature conditions relevant to petroleum applications; excellent stability in harsh chemical environments; scalable production process. Weaknesses: Complex multi-step process requiring precise control; higher production costs compared to simpler modification methods; primarily optimized for oil industry applications.

Laviosa Chimica Mineraria SpA

Technical Solution: Laviosa Chimica Mineraria has developed an innovative approach to increasing montmorillonite's compressive strength through their "GeoStrength" technology. This process involves a combination of controlled calcination and polymer intercalation to modify the clay's structure. The company first subjects the montmorillonite to precise thermal treatment at temperatures between 300-500°C to partially dehydroxylate the clay without destroying its layered structure. This is followed by intercalation with specially formulated water-soluble polymers that penetrate between clay layers and form strong hydrogen bonds with the silicate surfaces. The resulting material exhibits compressive strength improvements of 35-55% compared to untreated montmorillonite. Laviosa has further enhanced this technology by incorporating nano-silica particles that act as additional reinforcement points within the clay matrix.

Strengths: Versatile technology applicable across multiple industries including construction, environmental, and industrial applications; products maintain good swelling capacity while improving mechanical properties. Weaknesses: Process energy requirements for calcination stage; potential environmental considerations regarding polymer additives.

Key Patents and Scientific Breakthroughs in Clay Reinforcement

Montmorillonite recycled concrete and preparation method thereof

PatentActiveZA202205264A

Innovation

- A method for preparing montmorillonite recycled concrete involves uniformly distributing montmorillonite in the concrete to generate hydrated calcium silicate gel, filling micro-cracks and pores, thereby enhancing the microstructure and compressive strength of the concrete, using a specific mixing and stirring process with a water-cement ratio of 1:1.789.

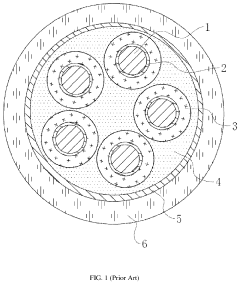

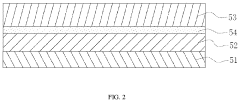

Composite film used for cable wrapping layer and preparation method for the same

PatentActiveUS20220080714A1

Innovation

- A composite film comprising a PE film layer, a PET film layer, an aluminum foil layer, and a bonding layer, where the PE film includes LLDPE, m-LLDPE, ethylene-vinyl acetate copolymer, and modified montmorillonite, and the bonding layer is made of EVA film, providing self-bonding, tensile strength, and electromagnetic shielding, which improves bonding with the insulation layer and prevents conductor loosening during wrapping.

Environmental Impact and Sustainability Considerations

The environmental implications of enhancing montmorillonite's compressive strength are multifaceted and deserve careful consideration in any technological development process. Traditional methods of strengthening clay materials often involve energy-intensive processes and chemical additives that may introduce environmental hazards. However, montmorillonite-based materials present a promising alternative with potentially lower environmental footprints compared to conventional construction materials like concrete and steel.

When evaluating sustainability aspects, the extraction of montmorillonite must be examined critically. Mining operations can lead to habitat disruption, soil erosion, and water quality degradation if not managed properly. Implementing responsible mining practices, including site rehabilitation and minimal land disturbance techniques, can significantly reduce these impacts. Furthermore, as montmorillonite deposits are relatively abundant globally, proper resource management can ensure long-term availability.

The processing methods employed to enhance montmorillonite's compressive strength also carry environmental implications. Chemical modification techniques using organic compounds or synthetic polymers may introduce toxicity concerns. Research indicates that eco-friendly alternatives such as biopolymers derived from agricultural waste can provide comparable strength improvements while reducing environmental burden. Additionally, low-temperature processing methods can substantially decrease energy consumption compared to high-temperature firing techniques.

Carbon footprint considerations reveal another dimension of sustainability. Montmorillonite-based materials generally require less energy to produce than Portland cement, potentially reducing greenhouse gas emissions by 40-60% depending on the specific strengthening method employed. Life cycle assessments indicate that enhanced montmorillonite products can achieve carbon neutrality more readily than traditional construction materials, particularly when renewable energy sources power the manufacturing processes.

The end-of-life management of strengthened montmorillonite products presents both challenges and opportunities. These materials often demonstrate superior biodegradability compared to synthetic alternatives, reducing long-term environmental persistence. Furthermore, research indicates potential for closed-loop systems where spent montmorillonite products can be reclaimed, reprocessed, and reintroduced into production cycles, minimizing waste generation and resource consumption.

Water conservation represents another critical sustainability factor. Many conventional strengthening processes require significant water inputs, contributing to resource strain in water-stressed regions. Developing water-efficient modification techniques, such as dry mechanical processing or minimal-water chemical treatments, can address this concern while maintaining desired strength properties. Some innovative approaches have demonstrated water usage reductions of up to 70% compared to traditional methods.

When evaluating sustainability aspects, the extraction of montmorillonite must be examined critically. Mining operations can lead to habitat disruption, soil erosion, and water quality degradation if not managed properly. Implementing responsible mining practices, including site rehabilitation and minimal land disturbance techniques, can significantly reduce these impacts. Furthermore, as montmorillonite deposits are relatively abundant globally, proper resource management can ensure long-term availability.

The processing methods employed to enhance montmorillonite's compressive strength also carry environmental implications. Chemical modification techniques using organic compounds or synthetic polymers may introduce toxicity concerns. Research indicates that eco-friendly alternatives such as biopolymers derived from agricultural waste can provide comparable strength improvements while reducing environmental burden. Additionally, low-temperature processing methods can substantially decrease energy consumption compared to high-temperature firing techniques.

Carbon footprint considerations reveal another dimension of sustainability. Montmorillonite-based materials generally require less energy to produce than Portland cement, potentially reducing greenhouse gas emissions by 40-60% depending on the specific strengthening method employed. Life cycle assessments indicate that enhanced montmorillonite products can achieve carbon neutrality more readily than traditional construction materials, particularly when renewable energy sources power the manufacturing processes.

The end-of-life management of strengthened montmorillonite products presents both challenges and opportunities. These materials often demonstrate superior biodegradability compared to synthetic alternatives, reducing long-term environmental persistence. Furthermore, research indicates potential for closed-loop systems where spent montmorillonite products can be reclaimed, reprocessed, and reintroduced into production cycles, minimizing waste generation and resource consumption.

Water conservation represents another critical sustainability factor. Many conventional strengthening processes require significant water inputs, contributing to resource strain in water-stressed regions. Developing water-efficient modification techniques, such as dry mechanical processing or minimal-water chemical treatments, can address this concern while maintaining desired strength properties. Some innovative approaches have demonstrated water usage reductions of up to 70% compared to traditional methods.

Scalability and Industrial Implementation Strategies

Scaling up montmorillonite compressive strength enhancement technologies from laboratory to industrial scale requires systematic planning and strategic implementation. The transition demands careful consideration of production volumes, equipment capabilities, and process optimization. Current laboratory methods often involve precise control of modification parameters, which becomes challenging at industrial scales where variations in raw material quality and processing conditions are inevitable.

Industrial implementation necessitates the development of continuous processing systems rather than batch operations typically used in research settings. Continuous extrusion technologies, adapted from polymer processing industries, show promise for large-scale montmorillonite modification. These systems can maintain consistent mixing, temperature control, and residence time—critical factors for achieving uniform compressive strength enhancement across production batches.

Cost-effectiveness remains a paramount concern for industrial adoption. Economic analyses indicate that while initial capital investment for specialized equipment is substantial, the operational costs can be optimized through process integration. Utilizing waste heat from existing manufacturing processes for thermal treatments and implementing closed-loop solvent recovery systems for chemical modifications can significantly reduce ongoing expenses.

Quality control protocols must evolve alongside scaling efforts. In-line monitoring technologies, including real-time X-ray diffraction and rheological measurements, enable continuous assessment of modification effectiveness. These systems allow for immediate process adjustments to maintain target compressive strength properties despite variations in raw material characteristics.

Environmental considerations also shape scalability strategies. Closed-system approaches that minimize emissions and effluent discharge are increasingly essential for regulatory compliance and sustainability goals. Water recycling systems and solvent recovery units not only reduce environmental impact but also improve economic viability through resource conservation.

Supply chain integration presents both challenges and opportunities for industrial implementation. Securing consistent sources of high-quality montmorillonite becomes more critical at industrial scales. Vertical integration strategies, where manufacturers control both clay mining operations and modification processes, show promise for ensuring raw material quality and supply stability.

Modular plant designs offer flexibility for phased implementation and capacity expansion. This approach allows manufacturers to begin with smaller production volumes while establishing market presence, then scale incrementally as demand grows. Such flexibility proves particularly valuable for specialty applications where market development may occur gradually as enhanced montmorillonite products demonstrate their performance advantages in commercial settings.

Industrial implementation necessitates the development of continuous processing systems rather than batch operations typically used in research settings. Continuous extrusion technologies, adapted from polymer processing industries, show promise for large-scale montmorillonite modification. These systems can maintain consistent mixing, temperature control, and residence time—critical factors for achieving uniform compressive strength enhancement across production batches.

Cost-effectiveness remains a paramount concern for industrial adoption. Economic analyses indicate that while initial capital investment for specialized equipment is substantial, the operational costs can be optimized through process integration. Utilizing waste heat from existing manufacturing processes for thermal treatments and implementing closed-loop solvent recovery systems for chemical modifications can significantly reduce ongoing expenses.

Quality control protocols must evolve alongside scaling efforts. In-line monitoring technologies, including real-time X-ray diffraction and rheological measurements, enable continuous assessment of modification effectiveness. These systems allow for immediate process adjustments to maintain target compressive strength properties despite variations in raw material characteristics.

Environmental considerations also shape scalability strategies. Closed-system approaches that minimize emissions and effluent discharge are increasingly essential for regulatory compliance and sustainability goals. Water recycling systems and solvent recovery units not only reduce environmental impact but also improve economic viability through resource conservation.

Supply chain integration presents both challenges and opportunities for industrial implementation. Securing consistent sources of high-quality montmorillonite becomes more critical at industrial scales. Vertical integration strategies, where manufacturers control both clay mining operations and modification processes, show promise for ensuring raw material quality and supply stability.

Modular plant designs offer flexibility for phased implementation and capacity expansion. This approach allows manufacturers to begin with smaller production volumes while establishing market presence, then scale incrementally as demand grows. Such flexibility proves particularly valuable for specialty applications where market development may occur gradually as enhanced montmorillonite products demonstrate their performance advantages in commercial settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!