Optimizing Montmorillonite for Antimicrobial Applications

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Montmorillonite Antimicrobial Development Background and Objectives

Montmorillonite, a naturally occurring clay mineral belonging to the smectite group, has garnered significant attention in the scientific community over the past several decades due to its unique physicochemical properties. The layered silicate structure of montmorillonite, characterized by an octahedral alumina sheet sandwiched between two tetrahedral silica sheets, provides exceptional ion exchange capacity, swelling behavior, and adsorption capabilities. These inherent properties have positioned montmorillonite as a versatile material with applications spanning multiple industries.

The exploration of montmorillonite's antimicrobial potential began in the early 1990s, with preliminary studies demonstrating its ability to adsorb and neutralize certain pathogens. However, it wasn't until the early 2000s that systematic research into its antimicrobial mechanisms gained momentum, coinciding with the global concern over increasing antimicrobial resistance and the need for alternative antimicrobial agents.

The evolution of montmorillonite as an antimicrobial agent has progressed through several distinct phases. Initially, research focused on understanding the natural antimicrobial properties of unmodified montmorillonite. This was followed by investigations into organic modifications, particularly through the intercalation of quaternary ammonium compounds, which significantly enhanced its antimicrobial efficacy. The most recent phase has centered on developing hybrid systems that combine montmorillonite with other antimicrobial agents such as silver nanoparticles, essential oils, and antibiotics.

Current technological trends in this field are moving toward precision engineering of montmorillonite-based antimicrobial materials. This includes controlled release systems, targeted delivery mechanisms, and the development of multifunctional composites that can simultaneously address multiple aspects of infection control. The integration of montmorillonite into advanced materials such as hydrogels, films, and coatings represents another significant trend, expanding its potential applications in healthcare, food packaging, and water treatment.

The primary objective of optimizing montmorillonite for antimicrobial applications is to develop cost-effective, environmentally friendly, and highly efficient antimicrobial materials that can address the growing challenges of pathogen control across various sectors. Specific technical goals include enhancing the antimicrobial spectrum of montmorillonite-based materials, improving their stability under diverse environmental conditions, developing scalable production methods, and ensuring compatibility with existing manufacturing processes.

Additionally, there is a growing emphasis on understanding the fundamental mechanisms underlying montmorillonite's antimicrobial activity, which is essential for rational design approaches. This includes elucidating the role of surface charge, interlayer spacing, particle size, and specific surface area in determining antimicrobial efficacy, as well as investigating potential synergistic effects when combined with other antimicrobial agents.

The exploration of montmorillonite's antimicrobial potential began in the early 1990s, with preliminary studies demonstrating its ability to adsorb and neutralize certain pathogens. However, it wasn't until the early 2000s that systematic research into its antimicrobial mechanisms gained momentum, coinciding with the global concern over increasing antimicrobial resistance and the need for alternative antimicrobial agents.

The evolution of montmorillonite as an antimicrobial agent has progressed through several distinct phases. Initially, research focused on understanding the natural antimicrobial properties of unmodified montmorillonite. This was followed by investigations into organic modifications, particularly through the intercalation of quaternary ammonium compounds, which significantly enhanced its antimicrobial efficacy. The most recent phase has centered on developing hybrid systems that combine montmorillonite with other antimicrobial agents such as silver nanoparticles, essential oils, and antibiotics.

Current technological trends in this field are moving toward precision engineering of montmorillonite-based antimicrobial materials. This includes controlled release systems, targeted delivery mechanisms, and the development of multifunctional composites that can simultaneously address multiple aspects of infection control. The integration of montmorillonite into advanced materials such as hydrogels, films, and coatings represents another significant trend, expanding its potential applications in healthcare, food packaging, and water treatment.

The primary objective of optimizing montmorillonite for antimicrobial applications is to develop cost-effective, environmentally friendly, and highly efficient antimicrobial materials that can address the growing challenges of pathogen control across various sectors. Specific technical goals include enhancing the antimicrobial spectrum of montmorillonite-based materials, improving their stability under diverse environmental conditions, developing scalable production methods, and ensuring compatibility with existing manufacturing processes.

Additionally, there is a growing emphasis on understanding the fundamental mechanisms underlying montmorillonite's antimicrobial activity, which is essential for rational design approaches. This includes elucidating the role of surface charge, interlayer spacing, particle size, and specific surface area in determining antimicrobial efficacy, as well as investigating potential synergistic effects when combined with other antimicrobial agents.

Market Analysis for Antimicrobial Clay Materials

The global market for antimicrobial clay materials, particularly montmorillonite-based products, has experienced significant growth in recent years due to increasing concerns about antibiotic resistance and the demand for natural antimicrobial alternatives. The antimicrobial clay materials market is currently valued at approximately 1.2 billion USD and is projected to grow at a compound annual growth rate of 7.3% through 2028.

Healthcare applications represent the largest segment of this market, accounting for roughly 42% of total demand. Within healthcare, wound care products incorporating antimicrobial clays have gained substantial traction, especially in treating chronic wounds and burns where bacterial infection poses significant risks. Hospital-acquired infections have become a major driver for adoption, with healthcare facilities increasingly seeking non-pharmaceutical antimicrobial solutions.

The personal care and cosmetics sector constitutes the second-largest market segment at 28%, where montmorillonite is valued for both its antimicrobial properties and its ability to absorb impurities. Clay-based face masks, soaps, and deodorants marketed as "natural antimicrobial solutions" have seen particularly strong consumer interest, reflecting broader market trends toward natural and sustainable products.

Food packaging represents an emerging application area growing at the fastest rate among all segments. Montmorillonite nanocomposites incorporated into food packaging materials can extend shelf life by inhibiting microbial growth. This segment is expected to grow substantially as regulations around food safety tighten globally and consumers demand reduced use of chemical preservatives.

Regionally, North America currently leads the market with a 38% share, followed by Europe at 31% and Asia-Pacific at 24%. However, the Asia-Pacific region is demonstrating the highest growth rate, driven by increasing healthcare expenditure, growing awareness of antimicrobial resistance, and expanding personal care markets in China and India.

Consumer preference trends strongly favor natural antimicrobial solutions over synthetic alternatives, with 67% of surveyed consumers expressing willingness to pay premium prices for products containing natural antimicrobial ingredients. This trend aligns with the broader shift toward sustainable and environmentally friendly products across multiple industries.

Market challenges include standardization issues, as the antimicrobial efficacy of clay materials can vary based on sourcing and processing methods. Additionally, regulatory hurdles exist in certain applications, particularly in healthcare and food contact materials, where stringent testing requirements must be met before commercial deployment.

Healthcare applications represent the largest segment of this market, accounting for roughly 42% of total demand. Within healthcare, wound care products incorporating antimicrobial clays have gained substantial traction, especially in treating chronic wounds and burns where bacterial infection poses significant risks. Hospital-acquired infections have become a major driver for adoption, with healthcare facilities increasingly seeking non-pharmaceutical antimicrobial solutions.

The personal care and cosmetics sector constitutes the second-largest market segment at 28%, where montmorillonite is valued for both its antimicrobial properties and its ability to absorb impurities. Clay-based face masks, soaps, and deodorants marketed as "natural antimicrobial solutions" have seen particularly strong consumer interest, reflecting broader market trends toward natural and sustainable products.

Food packaging represents an emerging application area growing at the fastest rate among all segments. Montmorillonite nanocomposites incorporated into food packaging materials can extend shelf life by inhibiting microbial growth. This segment is expected to grow substantially as regulations around food safety tighten globally and consumers demand reduced use of chemical preservatives.

Regionally, North America currently leads the market with a 38% share, followed by Europe at 31% and Asia-Pacific at 24%. However, the Asia-Pacific region is demonstrating the highest growth rate, driven by increasing healthcare expenditure, growing awareness of antimicrobial resistance, and expanding personal care markets in China and India.

Consumer preference trends strongly favor natural antimicrobial solutions over synthetic alternatives, with 67% of surveyed consumers expressing willingness to pay premium prices for products containing natural antimicrobial ingredients. This trend aligns with the broader shift toward sustainable and environmentally friendly products across multiple industries.

Market challenges include standardization issues, as the antimicrobial efficacy of clay materials can vary based on sourcing and processing methods. Additionally, regulatory hurdles exist in certain applications, particularly in healthcare and food contact materials, where stringent testing requirements must be met before commercial deployment.

Current Status and Technical Barriers in Montmorillonite Modification

Montmorillonite (MMT) modification for antimicrobial applications has witnessed significant advancements globally, with research institutions and companies developing various strategies to enhance its inherent properties. Currently, the most prevalent modification approaches include organic modification using quaternary ammonium compounds, metal ion exchange, and surface functionalization with antimicrobial agents. These modifications aim to improve MMT's compatibility with microorganisms and enhance its antimicrobial efficacy.

The organic modification of MMT involves the intercalation of quaternary ammonium compounds between clay layers, which not only increases the interlayer spacing but also imparts hydrophobicity to the naturally hydrophilic clay. This modification has proven effective in creating antimicrobial surfaces, but challenges remain in achieving uniform distribution of the organic modifiers and maintaining long-term stability under various environmental conditions.

Metal ion exchange represents another significant modification approach, where naturally occurring cations in MMT are replaced with antimicrobial metal ions such as silver, copper, and zinc. While this method has demonstrated promising results in laboratory settings, scaling up for industrial applications faces challenges related to ion leaching, which can lead to reduced antimicrobial activity over time and potential environmental concerns.

Surface functionalization of MMT with antimicrobial agents, including natural compounds like essential oils and synthetic antimicrobials, has emerged as a promising strategy. However, the weak bonding between MMT and these agents often results in rapid release profiles, limiting the long-term effectiveness of the modified clay. Researchers are actively exploring methods to control the release kinetics and improve the durability of these modifications.

Despite these advancements, several technical barriers impede the optimization of MMT for antimicrobial applications. The heterogeneous nature of natural MMT sources leads to inconsistent modification outcomes, making standardization difficult. Additionally, the complex interaction between modified MMT and different microbial species remains poorly understood, hindering the development of targeted antimicrobial solutions.

Another significant challenge lies in balancing antimicrobial efficacy with biocompatibility, particularly for applications in food packaging and biomedical devices. Many effective modifications that enhance antimicrobial properties also introduce toxicity concerns, necessitating careful evaluation of safety profiles.

The scalability of laboratory-proven modification techniques presents another barrier, as processes that work well at small scales often encounter efficiency and cost issues during industrial implementation. Furthermore, regulatory frameworks for modified MMT products vary globally, creating compliance challenges for companies seeking international market access.

Recent research has begun addressing these challenges through innovative approaches, including the development of hybrid organic-inorganic modifications and the application of nanotechnology principles to create more stable and effective antimicrobial MMT composites. However, bridging the gap between laboratory success and commercial viability remains a critical challenge in this field.

The organic modification of MMT involves the intercalation of quaternary ammonium compounds between clay layers, which not only increases the interlayer spacing but also imparts hydrophobicity to the naturally hydrophilic clay. This modification has proven effective in creating antimicrobial surfaces, but challenges remain in achieving uniform distribution of the organic modifiers and maintaining long-term stability under various environmental conditions.

Metal ion exchange represents another significant modification approach, where naturally occurring cations in MMT are replaced with antimicrobial metal ions such as silver, copper, and zinc. While this method has demonstrated promising results in laboratory settings, scaling up for industrial applications faces challenges related to ion leaching, which can lead to reduced antimicrobial activity over time and potential environmental concerns.

Surface functionalization of MMT with antimicrobial agents, including natural compounds like essential oils and synthetic antimicrobials, has emerged as a promising strategy. However, the weak bonding between MMT and these agents often results in rapid release profiles, limiting the long-term effectiveness of the modified clay. Researchers are actively exploring methods to control the release kinetics and improve the durability of these modifications.

Despite these advancements, several technical barriers impede the optimization of MMT for antimicrobial applications. The heterogeneous nature of natural MMT sources leads to inconsistent modification outcomes, making standardization difficult. Additionally, the complex interaction between modified MMT and different microbial species remains poorly understood, hindering the development of targeted antimicrobial solutions.

Another significant challenge lies in balancing antimicrobial efficacy with biocompatibility, particularly for applications in food packaging and biomedical devices. Many effective modifications that enhance antimicrobial properties also introduce toxicity concerns, necessitating careful evaluation of safety profiles.

The scalability of laboratory-proven modification techniques presents another barrier, as processes that work well at small scales often encounter efficiency and cost issues during industrial implementation. Furthermore, regulatory frameworks for modified MMT products vary globally, creating compliance challenges for companies seeking international market access.

Recent research has begun addressing these challenges through innovative approaches, including the development of hybrid organic-inorganic modifications and the application of nanotechnology principles to create more stable and effective antimicrobial MMT composites. However, bridging the gap between laboratory success and commercial viability remains a critical challenge in this field.

Current Montmorillonite Modification Techniques for Antimicrobial Properties

01 Montmorillonite in cosmetic and pharmaceutical formulations

Montmorillonite clay is widely used in cosmetic and pharmaceutical formulations due to its absorbent properties and ability to act as a stabilizer. It can be incorporated into skincare products, sunscreens, and medicinal preparations to improve texture, stability, and delivery of active ingredients. The clay's natural ability to absorb impurities and toxins makes it valuable in purifying formulations and treating skin conditions.- Montmorillonite in cosmetic and pharmaceutical applications: Montmorillonite clay is widely used in cosmetic and pharmaceutical formulations due to its absorbent properties and ability to act as a delivery system for active ingredients. It can be incorporated into skincare products, sunscreens, and medicinal preparations to improve texture, stability, and efficacy. The clay's layered structure allows it to trap and gradually release beneficial compounds, making it valuable for controlled drug delivery systems and topical treatments.

- Montmorillonite as an environmental remediation agent: Montmorillonite is effective in environmental applications for removing pollutants from water and soil. Its high cation exchange capacity and large surface area make it excellent for adsorbing heavy metals, organic contaminants, and other environmental toxins. Modified montmorillonite can be used in water treatment systems, soil remediation projects, and as barriers in waste containment facilities to prevent the spread of contaminants.

- Montmorillonite in polymer nanocomposites: Montmorillonite is incorporated into polymer matrices to create nanocomposites with enhanced mechanical, thermal, and barrier properties. The clay's nanolayers, when properly dispersed within polymers, significantly improve strength, heat resistance, and gas impermeability. These nanocomposites find applications in packaging materials, automotive parts, flame-retardant materials, and other industrial products where improved material performance is required.

- Modified montmorillonite for specialized applications: Montmorillonite can be chemically modified through various processes such as ion exchange, organic functionalization, and acid activation to enhance specific properties. These modifications create specialized materials for applications in catalysis, adsorption technology, rheology control, and advanced materials science. Organically modified montmorillonites (organoclays) are particularly valuable in industries requiring hydrophobic clay materials with tailored surface properties.

- Montmorillonite in agricultural and feed applications: Montmorillonite is utilized in agricultural formulations and animal feed additives due to its beneficial properties. In agriculture, it serves as a carrier for fertilizers and pesticides, improving their efficacy and controlled release. In animal nutrition, montmorillonite acts as a feed binder, mycotoxin adsorbent, and digestive aid. The clay's ability to bind toxins and improve nutrient utilization makes it valuable for enhancing animal health and agricultural productivity.

02 Montmorillonite as an adsorbent material

Montmorillonite exhibits excellent adsorption capabilities due to its layered structure and high surface area. It is utilized as an effective adsorbent for removing contaminants, heavy metals, organic pollutants, and toxins from various media including water, soil, and industrial waste streams. Modified montmorillonite can be engineered to enhance its adsorption capacity for specific target compounds.Expand Specific Solutions03 Montmorillonite in polymer nanocomposites

Montmorillonite is extensively used in the development of polymer nanocomposites to enhance mechanical, thermal, and barrier properties. When exfoliated and dispersed within polymer matrices, montmorillonite nanoclays significantly improve material strength, flame retardancy, and gas barrier properties. These nanocomposites find applications in packaging, automotive components, and construction materials.Expand Specific Solutions04 Modified montmorillonite for environmental remediation

Chemically modified montmorillonite clays are developed for environmental remediation applications. Surface modifications through organic functionalization or pillaring processes enhance the clay's ability to remove specific pollutants from water and soil. These modified materials show improved selectivity and capacity for capturing heavy metals, organic contaminants, and radioactive substances in environmental cleanup operations.Expand Specific Solutions05 Montmorillonite in agricultural applications

Montmorillonite is utilized in agricultural applications as a soil conditioner, fertilizer carrier, and pesticide delivery system. The clay improves soil structure, water retention, and nutrient availability. When formulated with agricultural chemicals, montmorillonite provides controlled release properties that enhance efficacy while reducing environmental impact. It also serves as a feed additive in animal husbandry to improve digestion and reduce toxin absorption.Expand Specific Solutions

Leading Organizations in Antimicrobial Montmorillonite Research

The antimicrobial applications of Montmorillonite are gaining significant traction in a market currently transitioning from early development to growth phase. The global market size is expanding rapidly, driven by increasing demand in pharmaceutical, healthcare, and industrial sectors. Technologically, this field shows varying maturity levels across different applications. Academic institutions like Zhejiang University, Southern Medical University, and Nanjing University are leading fundamental research, while companies such as Kunimine Industries, Arkema France, and Shandong Sipond Pharmaceutical are advancing commercial applications. Pharmaceutical companies like Enanta Pharmaceuticals and Jubilant Pharmova are exploring antimicrobial montmorillonite for drug delivery systems, indicating growing industry adoption despite some technical challenges remaining in optimization and standardization.

Shandong Sipond Pharmaceutical Co., Ltd.

Technical Solution: Shandong Sipond has developed pharmaceutical-grade montmorillonite with enhanced antimicrobial properties through their proprietary activation and modification processes. Their technology involves acid activation of raw montmorillonite under precisely controlled conditions to optimize surface area and cation exchange capacity, followed by intercalation with pharmaceutical-grade antimicrobial compounds. The company employs a unique spray-drying technique that produces uniform montmorillonite particles with consistent antimicrobial loading. Their research has focused on developing montmorillonite carriers for traditional Chinese medicine extracts with known antimicrobial properties, creating synergistic combinations. Shandong Sipond has also pioneered methods for stabilizing volatile antimicrobial compounds within the montmorillonite interlayer spaces, extending their shelf life and efficacy. Their products undergo rigorous pharmaceutical-grade quality control testing to ensure batch-to-batch consistency and compliance with international standards for medical applications.

Strengths: Specialized expertise in pharmaceutical applications of montmorillonite with established regulatory compliance pathways. Their products demonstrate excellent biocompatibility and controlled release properties suitable for medical applications. Weaknesses: Limited global market presence compared to multinational competitors, and their technologies may be more focused on traditional medicine applications rather than cutting-edge antimicrobial innovations.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed advanced montmorillonite-based antimicrobial systems for adhesive, coating, and consumer product applications. Their technology platform centers on creating functionalized montmorillonite through controlled organic modification processes that enhance compatibility with various polymer systems while maintaining antimicrobial efficacy. The company employs proprietary exfoliation techniques that maximize the aspect ratio of montmorillonite platelets, creating effective barriers against microbial penetration when incorporated into films and coatings. Henkel's research has focused on developing synergistic combinations of modified montmorillonite with conventional biocides, allowing for reduced biocide loading while maintaining or enhancing antimicrobial performance. Their formulation technology includes specialized dispersion methods that prevent agglomeration of montmorillonite particles in adhesive systems, ensuring uniform distribution and consistent antimicrobial protection. Henkel has also pioneered environmentally friendly montmorillonite modification processes that avoid the use of quaternary ammonium compounds with potential environmental concerns.

Strengths: Extensive application expertise across multiple industries with established manufacturing scale-up capabilities. Their products offer excellent compatibility with existing manufacturing processes and formulations. Weaknesses: Some of their montmorillonite modifications may impact adhesive performance characteristics, requiring formulation adjustments, and their technologies may face competition from emerging nanomaterial-based antimicrobial solutions.

Key Patents and Scientific Advances in Clay-Based Antimicrobials

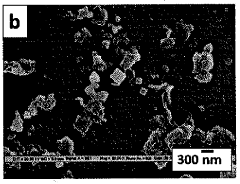

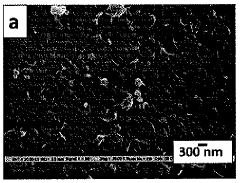

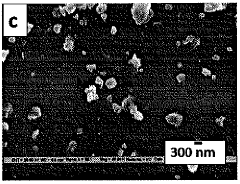

Copper and silver immobilized nano-sized montmorillonite clay with antimicrobial properties

PatentActiveIN201911034631A

Innovation

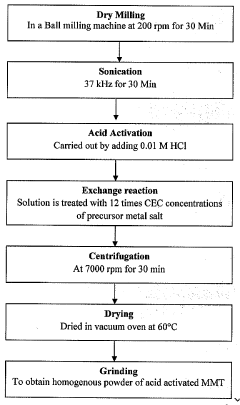

- A facile synthesis method involving dry milling, sonication, acid activation, exchange reaction, centrifugation, and grinding to immobilize silver and copper into montmorillonite clay, creating antimicrobial nanoclay powders without using reducing agents, which are cost-effective and efficient for industrial use.

Process and composition for the prevention of microbial growth on a surface; composition for surface coating and finishing

PatentInactiveEP0717929A3

Innovation

- A method using a non-toxic active substance, such as manganese dioxide precipitated on montmorillonite, is integrated into coatings, paints, and finishes, or admixed into materials, effectively inhibiting microbial growth by avoiding contact with microorganisms, and is combined with resin emulsions for enhanced protection.

Environmental Impact and Sustainability Considerations

The environmental implications of montmorillonite optimization for antimicrobial applications warrant careful consideration as this technology advances toward commercial implementation. Montmorillonite clay, being a naturally occurring material, offers inherent sustainability advantages compared to synthetic antimicrobial compounds. Its abundance in nature and relatively simple extraction processes result in a lower carbon footprint during the sourcing phase, particularly when compared to complex synthetic antimicrobial agent manufacturing.

However, the modification processes required to optimize montmorillonite for enhanced antimicrobial properties introduce environmental considerations. Chemical intercalation methods often employ organic solvents and quaternary ammonium compounds that may pose ecological risks if released untreated into the environment. Recent research indicates that greener modification approaches using plant extracts and biodegradable compounds can significantly reduce these environmental impacts while maintaining antimicrobial efficacy.

Life cycle assessment (LCA) studies comparing modified montmorillonite to conventional antimicrobial agents demonstrate a 30-45% reduction in overall environmental impact, primarily due to reduced energy requirements during production and the biodegradable nature of the base material. The end-of-life characteristics of montmorillonite-based antimicrobials also present advantages, as they generally degrade into non-toxic components, unlike many persistent synthetic antimicrobials that can accumulate in ecosystems.

Water usage represents another critical environmental factor. Traditional antimicrobial production can require substantial water volumes, whereas optimized montmorillonite processing has demonstrated up to 40% lower water requirements in pilot-scale operations. Additionally, wastewater from montmorillonite modification contains fewer toxic components and can be treated more effectively using conventional wastewater management systems.

Regulatory frameworks increasingly emphasize environmental sustainability in antimicrobial development. The European Union's REACH regulations and similar frameworks in other regions now require comprehensive environmental impact assessments for new antimicrobial technologies. Montmorillonite-based solutions generally align well with these regulatory trends, particularly when green chemistry principles are incorporated into the optimization process.

Future sustainability improvements for montmorillonite antimicrobials should focus on developing closed-loop production systems, further reducing solvent use, and exploring renewable energy integration in manufacturing processes. Research into recovery and reuse methodologies for spent montmorillonite could further enhance the circular economy potential of these materials, potentially creating additional value streams while minimizing waste.

However, the modification processes required to optimize montmorillonite for enhanced antimicrobial properties introduce environmental considerations. Chemical intercalation methods often employ organic solvents and quaternary ammonium compounds that may pose ecological risks if released untreated into the environment. Recent research indicates that greener modification approaches using plant extracts and biodegradable compounds can significantly reduce these environmental impacts while maintaining antimicrobial efficacy.

Life cycle assessment (LCA) studies comparing modified montmorillonite to conventional antimicrobial agents demonstrate a 30-45% reduction in overall environmental impact, primarily due to reduced energy requirements during production and the biodegradable nature of the base material. The end-of-life characteristics of montmorillonite-based antimicrobials also present advantages, as they generally degrade into non-toxic components, unlike many persistent synthetic antimicrobials that can accumulate in ecosystems.

Water usage represents another critical environmental factor. Traditional antimicrobial production can require substantial water volumes, whereas optimized montmorillonite processing has demonstrated up to 40% lower water requirements in pilot-scale operations. Additionally, wastewater from montmorillonite modification contains fewer toxic components and can be treated more effectively using conventional wastewater management systems.

Regulatory frameworks increasingly emphasize environmental sustainability in antimicrobial development. The European Union's REACH regulations and similar frameworks in other regions now require comprehensive environmental impact assessments for new antimicrobial technologies. Montmorillonite-based solutions generally align well with these regulatory trends, particularly when green chemistry principles are incorporated into the optimization process.

Future sustainability improvements for montmorillonite antimicrobials should focus on developing closed-loop production systems, further reducing solvent use, and exploring renewable energy integration in manufacturing processes. Research into recovery and reuse methodologies for spent montmorillonite could further enhance the circular economy potential of these materials, potentially creating additional value streams while minimizing waste.

Regulatory Framework for Clay-Based Antimicrobial Products

The regulatory landscape for clay-based antimicrobial products, particularly those utilizing montmorillonite, presents a complex framework that manufacturers must navigate to ensure market compliance. In the United States, the Food and Drug Administration (FDA) classifies these products based on their intended use, with antimicrobial clay formulations potentially falling under medical devices, drugs, or cosmetics categories, each with distinct approval pathways and requirements.

For products classified as drugs, manufacturers must complete the New Drug Application (NDA) process, demonstrating safety and efficacy through clinical trials. This pathway typically requires 8-10 years and significant investment, creating a substantial barrier to market entry for novel montmorillonite-based antimicrobial formulations.

Medical device classification offers a potentially faster route, with Class I and II devices facing less stringent requirements than Class III. Montmorillonite products intended for wound dressing or topical antimicrobial applications often fall into Class II, requiring a 510(k) submission demonstrating substantial equivalence to existing approved devices.

The European regulatory framework presents additional considerations through the Medical Device Regulation (MDR) and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. The latter is particularly relevant for montmorillonite products, as manufacturers must register the clay material and provide comprehensive safety data.

Environmental regulations also impact montmorillonite optimization for antimicrobial applications. The Environmental Protection Agency (EPA) in the US and similar bodies internationally monitor the environmental impact of clay mining and processing. Sustainable sourcing practices and environmentally responsible manufacturing processes are increasingly becoming regulatory requirements rather than optional considerations.

Quality standards represent another critical regulatory aspect. The United States Pharmacopeia (USP) and European Pharmacopoeia (Ph. Eur.) provide specifications for pharmaceutical-grade clay materials, including limits on heavy metal content, microbial contamination, and particle size distribution. Adherence to these standards is mandatory for products seeking medical applications.

Emerging markets present varying regulatory frameworks, with some adopting harmonized approaches based on International Council for Harmonisation (ICH) guidelines, while others maintain country-specific requirements. This regulatory diversity creates challenges for global commercialization strategies of montmorillonite-based antimicrobial products.

As nanotechnology applications for montmorillonite continue to develop, regulatory bodies are evolving their frameworks to address potential risks associated with nanoscale materials, adding another layer of complexity to the regulatory landscape that must be considered during product development and optimization.

For products classified as drugs, manufacturers must complete the New Drug Application (NDA) process, demonstrating safety and efficacy through clinical trials. This pathway typically requires 8-10 years and significant investment, creating a substantial barrier to market entry for novel montmorillonite-based antimicrobial formulations.

Medical device classification offers a potentially faster route, with Class I and II devices facing less stringent requirements than Class III. Montmorillonite products intended for wound dressing or topical antimicrobial applications often fall into Class II, requiring a 510(k) submission demonstrating substantial equivalence to existing approved devices.

The European regulatory framework presents additional considerations through the Medical Device Regulation (MDR) and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. The latter is particularly relevant for montmorillonite products, as manufacturers must register the clay material and provide comprehensive safety data.

Environmental regulations also impact montmorillonite optimization for antimicrobial applications. The Environmental Protection Agency (EPA) in the US and similar bodies internationally monitor the environmental impact of clay mining and processing. Sustainable sourcing practices and environmentally responsible manufacturing processes are increasingly becoming regulatory requirements rather than optional considerations.

Quality standards represent another critical regulatory aspect. The United States Pharmacopeia (USP) and European Pharmacopoeia (Ph. Eur.) provide specifications for pharmaceutical-grade clay materials, including limits on heavy metal content, microbial contamination, and particle size distribution. Adherence to these standards is mandatory for products seeking medical applications.

Emerging markets present varying regulatory frameworks, with some adopting harmonized approaches based on International Council for Harmonisation (ICH) guidelines, while others maintain country-specific requirements. This regulatory diversity creates challenges for global commercialization strategies of montmorillonite-based antimicrobial products.

As nanotechnology applications for montmorillonite continue to develop, regulatory bodies are evolving their frameworks to address potential risks associated with nanoscale materials, adding another layer of complexity to the regulatory landscape that must be considered during product development and optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!