How to Strengthen HDPE Environmental Credentials?

HDPE Sustainability Background and Objectives

High-density polyethylene (HDPE) has been a cornerstone material in various industries for decades, prized for its durability, versatility, and cost-effectiveness. However, as global environmental concerns intensify, the plastic industry faces mounting pressure to improve its sustainability credentials. This technological challenge presents both obstacles and opportunities for HDPE manufacturers and users alike.

The evolution of HDPE has been marked by continuous improvements in production processes and material properties since its commercial introduction in the 1950s. Initially developed as a lightweight, strong alternative to traditional materials, HDPE quickly found applications in packaging, construction, and consumer goods. As environmental awareness grew in the latter part of the 20th century, the focus shifted towards reducing the environmental impact of HDPE throughout its lifecycle.

Current trends in HDPE development are primarily driven by the need to address its end-of-life issues and reduce its carbon footprint. Key areas of focus include enhancing recyclability, incorporating bio-based content, and improving energy efficiency in production. The industry is also exploring ways to extend the lifespan of HDPE products, thereby reducing overall plastic waste.

The primary objective in strengthening HDPE's environmental credentials is to transform it from a perceived environmental liability into a sustainable material choice. This involves tackling challenges across the entire value chain, from raw material sourcing to end-of-life management. Specific goals include increasing the percentage of recycled content in HDPE products, developing more efficient recycling technologies, and creating closed-loop systems for HDPE use and reuse.

Another critical objective is to improve the public perception of HDPE through transparent communication about its environmental impact and ongoing sustainability efforts. This includes educating consumers about proper disposal and recycling practices, as well as highlighting the material's benefits in terms of resource efficiency and durability compared to alternatives.

The path forward for HDPE sustainability also involves collaboration across industries and with regulatory bodies. Establishing standardized metrics for environmental performance and creating incentives for sustainable practices are crucial steps in this journey. As the demand for eco-friendly materials grows, the ability to demonstrate and improve HDPE's environmental credentials will become increasingly important for maintaining market share and meeting regulatory requirements.

Market Demand for Eco-Friendly Plastics

The global market for eco-friendly plastics has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. High-Density Polyethylene (HDPE), a versatile and widely used plastic, is at the forefront of this shift towards more sustainable materials. The demand for environmentally friendly HDPE products has surged across various industries, including packaging, construction, and automotive sectors.

Consumer preferences have played a crucial role in shaping this market trend. A growing number of environmentally conscious consumers are actively seeking products made from sustainable materials, putting pressure on manufacturers to adopt eco-friendly alternatives. This shift in consumer behavior has led to a ripple effect throughout the supply chain, with retailers and brand owners increasingly demanding sustainable packaging solutions from their suppliers.

The packaging industry, in particular, has seen a substantial increase in demand for eco-friendly HDPE products. Food and beverage companies, personal care product manufacturers, and household goods producers are all looking for ways to reduce their environmental footprint while maintaining the performance characteristics of traditional HDPE packaging. This has led to innovations in recyclable and biodegradable HDPE formulations, as well as the development of packaging designs that use less material without compromising structural integrity.

In the construction sector, there is a growing interest in HDPE products with enhanced environmental credentials for applications such as pipes, fittings, and geomembranes. The durability and chemical resistance of HDPE make it an attractive option for long-lasting infrastructure projects, but the industry is now seeking ways to improve its sustainability profile through increased recycled content and improved end-of-life recyclability.

The automotive industry has also shown increased demand for eco-friendly HDPE components. As automakers strive to reduce vehicle weight and improve fuel efficiency, they are turning to lightweight plastics like HDPE. However, there is a simultaneous push for these materials to be more sustainable, leading to research into bio-based HDPE alternatives and improved recycling processes for automotive plastic waste.

Government regulations and policies have further bolstered the market demand for eco-friendly HDPE. Many countries have implemented or are considering plastic bag bans, recycling targets, and extended producer responsibility schemes. These regulatory pressures are compelling manufacturers to invest in research and development of more sustainable HDPE formulations and production processes.

The market for eco-friendly HDPE is expected to continue its growth trajectory in the coming years. As technological advancements in recycling and bio-based plastics progress, the opportunities for HDPE to strengthen its environmental credentials will expand. This ongoing evolution presents both challenges and opportunities for HDPE manufacturers, as they strive to meet the increasing demand for sustainable plastics while maintaining the material's desirable properties and cost-effectiveness.

HDPE Environmental Challenges and Limitations

High-density polyethylene (HDPE) faces several environmental challenges and limitations that hinder its sustainability credentials. One of the primary concerns is its non-biodegradable nature, which contributes to long-term environmental pollution. HDPE can persist in the environment for hundreds of years, leading to accumulation in landfills and marine ecosystems.

The production process of HDPE is another significant environmental issue. It relies heavily on fossil fuels, both as a raw material and energy source, contributing to greenhouse gas emissions and climate change. The energy-intensive manufacturing process also results in air and water pollution, further exacerbating its environmental impact.

Recycling HDPE presents its own set of challenges. While technically recyclable, the efficiency and widespread implementation of HDPE recycling systems remain limited. Contamination issues, mixed plastic types, and the degradation of material quality through multiple recycling cycles pose obstacles to creating a closed-loop system for HDPE products.

The use of additives and colorants in HDPE products further complicates recycling efforts. These additives can make it difficult to separate and process HDPE effectively, reducing the quality and value of recycled materials. Additionally, some additives may leach into the environment, potentially causing harm to ecosystems and human health.

HDPE's lightweight nature, while beneficial for transportation and handling, can lead to issues with litter and marine pollution. When improperly disposed of, HDPE products can easily be carried by wind or water, contributing to the global problem of plastic pollution in oceans and waterways.

The durability of HDPE, often seen as an advantage, becomes a double-edged sword from an environmental perspective. While it allows for long-lasting products, it also means that HDPE waste persists in the environment for extended periods, potentially harming wildlife and ecosystems.

Addressing these environmental challenges requires a multifaceted approach. Innovations in production processes, such as using renewable energy sources and bio-based feedstocks, could reduce the carbon footprint of HDPE manufacturing. Improving recycling technologies and infrastructure, along with designing products for easier recycling, could enhance the circularity of HDPE materials. Additionally, developing biodegradable alternatives or enhancing the biodegradability of HDPE without compromising its useful properties could mitigate its long-term environmental impact.

Current HDPE Environmental Enhancement Strategies

01 Biodegradable HDPE compositions

Development of biodegradable HDPE compositions that incorporate additives or modifications to enhance environmental degradation. These formulations aim to reduce the persistence of HDPE in the environment while maintaining its desirable properties for various applications.- Recyclability and waste reduction: HDPE is highly recyclable, contributing to waste reduction and circular economy efforts. It can be reprocessed multiple times without significant loss of properties, making it an environmentally friendly material for various applications. Recycling HDPE helps conserve resources and reduce the environmental impact of plastic waste.

- Biodegradable HDPE formulations: Research focuses on developing biodegradable HDPE formulations to address environmental concerns. These formulations incorporate additives or modifications that enhance the material's ability to break down in natural environments, reducing its long-term environmental impact while maintaining desirable physical properties.

- Energy-efficient production processes: Advancements in HDPE production processes aim to reduce energy consumption and greenhouse gas emissions. These improvements include optimized catalysts, more efficient polymerization techniques, and the use of renewable energy sources in manufacturing, enhancing the overall environmental credentials of HDPE.

- Use of recycled content in HDPE products: Incorporating recycled HDPE into new products helps close the loop in plastic recycling and reduces the demand for virgin materials. Techniques are being developed to maintain or improve the properties of HDPE products containing recycled content, making them suitable for a wide range of applications while promoting sustainability.

- HDPE in sustainable packaging solutions: HDPE is utilized in the development of sustainable packaging solutions, including lightweight designs that reduce material usage and transportation emissions. Innovations focus on creating HDPE packaging that is easily recyclable, reusable, or compatible with existing recycling streams, contributing to improved environmental performance in the packaging industry.

02 Recycling and reuse of HDPE

Advancements in recycling technologies and processes for HDPE, including improved sorting, cleaning, and reprocessing methods. These innovations aim to increase the recycling rate of HDPE and promote its reuse in various products, reducing the environmental impact of plastic waste.Expand Specific Solutions03 HDPE with reduced environmental impact

Development of HDPE formulations with improved environmental credentials, such as reduced carbon footprint, lower energy consumption during production, or incorporation of renewable resources. These innovations aim to make HDPE more sustainable while maintaining its performance characteristics.Expand Specific Solutions04 HDPE for eco-friendly packaging

Innovations in HDPE packaging solutions that focus on environmental sustainability, such as lightweight designs, improved barrier properties, or enhanced recyclability. These developments aim to reduce the environmental impact of packaging while maintaining product protection and functionality.Expand Specific Solutions05 HDPE blends with bio-based materials

Creation of HDPE blends that incorporate bio-based or renewable materials to improve environmental credentials. These blends aim to reduce reliance on fossil-based resources while maintaining the desirable properties of HDPE for various applications.Expand Specific Solutions

Key Players in Sustainable HDPE Industry

The competition landscape for strengthening HDPE environmental credentials is evolving rapidly in a maturing industry. The market size is expanding as sustainability becomes a key focus, with major players like Dow Global Technologies, ExxonMobil, and SABIC leading innovation efforts. Technological maturity varies, with established companies like China Petroleum & Chemical Corp. and Borealis AG focusing on advanced recycling techniques, while newer entrants like Shandong Wenyuan Environmental Protection Technology explore novel eco-friendly additives. Universities such as Sichuan University and South China University of Technology are contributing to R&D, indicating a growing emphasis on academic-industry collaboration to enhance HDPE's environmental profile.

Dow Global Technologies LLC

Borealis AG

Innovative HDPE Eco-Friendly Technologies

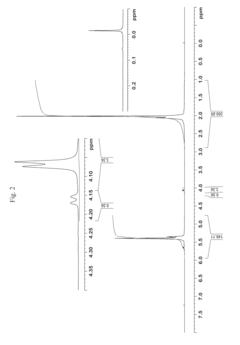

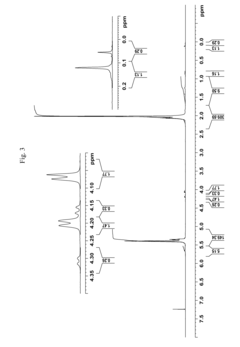

- The synthesis of dendritic polyethylenes through ring opening metathesis polymerization of cyclic olefins with bi-functional alkene chain terminating agents, followed by reaction with multifunctional coupling agents, to produce telechelic hydrocarbon polymers that are then reacted with trifunctional or tetrafunctional coupling agents to create dendritic structures, which can be used as additives in conventional polyethylenes.

- A method involving the prepolymerization of propylene on an activated catalyst to form a polypropylene catalyst seed, followed by polymerizing polypropylene and polyethylene at different catalyst sites, resulting in a high-density polyethylene composition with dispersed polypropylene, which enhances heat resistance and strength.

Regulatory Framework for Plastic Sustainability

The regulatory framework for plastic sustainability is evolving rapidly in response to growing environmental concerns and the need to address the challenges posed by plastic waste. Governments worldwide are implementing stricter regulations to promote sustainable practices in the plastic industry, with a particular focus on High-Density Polyethylene (HDPE) due to its widespread use and environmental impact.

In the European Union, the Circular Economy Action Plan has set ambitious targets for plastic recycling and reuse. By 2030, all plastic packaging in the EU market must be recyclable or reusable. This directive has significant implications for HDPE manufacturers and users, driving innovation in product design and recycling technologies. The EU has also introduced a plastic tax on non-recycled plastic packaging waste, creating a financial incentive for companies to adopt more sustainable practices.

In the United States, regulations vary by state, but there is a growing trend towards more stringent plastic waste management policies. California, for instance, has enacted legislation requiring all plastic packaging to be recyclable, reusable, or compostable by 2032. This has spurred HDPE producers to invest in research and development of more environmentally friendly formulations and production processes.

China, a major player in the global plastics industry, has implemented a ban on importing plastic waste and is phasing out single-use plastics. This policy shift has forced domestic HDPE manufacturers to focus on developing more sustainable products and improving recycling infrastructure.

International agreements, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, have been amended to include plastic waste. This has led to increased scrutiny of the global trade in plastic materials, including HDPE, and has prompted countries to develop more robust domestic recycling capabilities.

The regulatory landscape also includes Extended Producer Responsibility (EPR) schemes, which are being adopted by many countries. These programs hold manufacturers responsible for the entire lifecycle of their products, including disposal and recycling. For HDPE producers, this means a greater emphasis on designing products for recyclability and investing in collection and recycling systems.

Certification standards and eco-labels are becoming increasingly important in the regulatory framework. Programs like the Global Recycled Standard (GRS) and the Recycled Claim Standard (RCS) provide guidelines for incorporating recycled content into products, including HDPE items. Compliance with these standards is becoming a de facto requirement for companies looking to strengthen their environmental credentials and meet regulatory expectations.

As the regulatory framework continues to evolve, HDPE manufacturers and users must stay informed and proactive in adapting their practices to meet new sustainability requirements. This includes investing in research and development of more environmentally friendly HDPE formulations, improving recycling technologies, and collaborating with stakeholders across the value chain to create closed-loop systems for plastic use and recovery.

Life Cycle Assessment of HDPE Products

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of HDPE products throughout their entire lifecycle. This comprehensive approach considers all stages, from raw material extraction to end-of-life disposal, providing valuable insights into the environmental credentials of HDPE.

The production phase of HDPE typically accounts for a significant portion of its environmental impact. This stage involves the extraction and processing of raw materials, primarily derived from fossil fuels. The energy-intensive nature of these processes contributes to greenhouse gas emissions and resource depletion. However, advancements in production technologies and the increasing use of renewable energy sources in manufacturing facilities are helping to mitigate these impacts.

During the use phase, HDPE products generally exhibit favorable environmental performance due to their durability and longevity. The lightweight nature of HDPE also contributes to reduced transportation-related emissions when compared to heavier alternative materials. Additionally, HDPE's resistance to corrosion and chemical degradation often results in extended product lifespans, reducing the need for frequent replacements and associated environmental burdens.

End-of-life management plays a critical role in the overall environmental profile of HDPE products. Recycling offers significant potential for reducing the environmental impact of HDPE. When properly collected and processed, recycled HDPE can be used to manufacture new products, thereby reducing the demand for virgin materials and associated environmental burdens. However, challenges remain in improving collection rates and developing more efficient recycling technologies.

LCA studies have shown that the environmental impact of HDPE can vary significantly depending on specific product applications and end-of-life scenarios. For instance, HDPE packaging used in food applications may have different environmental implications compared to HDPE pipes used in construction. Factors such as transportation distances, product lifespan, and local waste management practices can all influence the overall environmental performance.

To strengthen HDPE's environmental credentials, several strategies can be employed based on LCA findings. These include optimizing production processes to reduce energy consumption and emissions, increasing the use of recycled content in HDPE products, improving product design for easier recyclability, and enhancing end-of-life management systems. Additionally, exploring bio-based alternatives for HDPE production and investing in advanced recycling technologies can further improve its environmental profile.

By conducting comprehensive LCAs and implementing targeted improvements across the lifecycle, the environmental credentials of HDPE can be significantly strengthened, positioning it as a more sustainable material choice in various applications.