How to Tackle HDPE Integration in Complex Systems?

HDPE Integration Background and Objectives

High-density polyethylene (HDPE) integration in complex systems has become a critical challenge in various industries, particularly in manufacturing, construction, and engineering. The evolution of HDPE technology has been marked by significant advancements in material science and processing techniques, leading to its widespread adoption in diverse applications. As we delve into this technological landscape, it is essential to understand the historical context and current trajectory of HDPE integration.

HDPE, first developed in the 1950s, has since undergone numerous improvements in its properties and production methods. The primary goal of integrating HDPE into complex systems is to leverage its unique characteristics, such as high strength-to-density ratio, chemical resistance, and durability, to enhance overall system performance and longevity. This integration aims to address specific challenges in various sectors, including but not limited to, fluid handling systems, structural components, and protective enclosures.

The technological evolution of HDPE integration has been driven by the need for lightweight, corrosion-resistant, and cost-effective solutions in complex systems. Recent advancements have focused on improving HDPE's mechanical properties, thermal stability, and compatibility with other materials. These developments have expanded the potential applications of HDPE in increasingly sophisticated and demanding environments.

One of the key objectives in tackling HDPE integration is to overcome the material's inherent limitations, such as its relatively low temperature resistance and susceptibility to stress cracking. Researchers and engineers are actively working on developing new HDPE formulations and processing techniques to address these challenges. Additionally, there is a growing emphasis on enhancing the material's recyclability and environmental sustainability, aligning with global trends towards circular economy principles.

The integration of HDPE in complex systems also necessitates the development of advanced joining and bonding technologies. This includes innovations in welding techniques, adhesive technologies, and mechanical fastening methods specifically tailored for HDPE components. The goal is to ensure seamless integration with other materials and subsystems while maintaining the integrity and performance of the HDPE elements.

As we look towards the future, the objectives for HDPE integration are becoming increasingly ambitious. There is a push towards developing smart HDPE materials that can incorporate sensors and responsive elements, enabling real-time monitoring and adaptive behavior in complex systems. Furthermore, the integration of HDPE in additive manufacturing processes is opening new avenues for customized and complex geometries, potentially revolutionizing design approaches in various industries.

Market Analysis for HDPE in Complex Systems

The integration of High-Density Polyethylene (HDPE) in complex systems has seen significant market growth and demand across various industries. HDPE's unique properties, including high strength-to-density ratio, chemical resistance, and durability, make it an attractive material for diverse applications in complex systems.

The global HDPE market has been experiencing steady growth, driven by increasing demand in sectors such as packaging, construction, automotive, and industrial applications. The market size for HDPE in complex systems is projected to expand further, with a compound annual growth rate (CAGR) exceeding the overall plastics industry average.

In the packaging sector, HDPE integration in complex systems has gained traction due to its excellent barrier properties and recyclability. The food and beverage industry, in particular, has shown a growing preference for HDPE in packaging solutions that require enhanced protection and extended shelf life.

The construction industry has also embraced HDPE integration in complex systems, particularly in piping and geomembrane applications. The material's resistance to corrosion, chemicals, and environmental factors has led to increased adoption in water management systems, underground storage tanks, and landfill liners.

Automotive manufacturers are increasingly incorporating HDPE into complex vehicle systems to reduce weight and improve fuel efficiency. The material's use in fuel tanks, interior components, and under-the-hood applications has grown significantly, driven by stringent environmental regulations and the push for lighter, more fuel-efficient vehicles.

In the industrial sector, HDPE integration in complex systems has found applications in chemical processing equipment, storage tanks, and material handling systems. The material's chemical resistance and durability make it ideal for use in harsh industrial environments.

The market for HDPE in complex systems is characterized by intense competition among key players, including major petrochemical companies and specialized plastics manufacturers. These companies are investing heavily in research and development to enhance HDPE properties and expand its applications in complex systems.

Emerging trends in the HDPE market for complex systems include the development of high-performance grades with improved mechanical properties, enhanced processability, and better environmental sustainability. There is also a growing focus on recycling and circular economy initiatives, driving the demand for recycled HDPE in complex system applications.

Geographically, Asia-Pacific remains the largest and fastest-growing market for HDPE in complex systems, driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe follow closely, with mature markets focusing on technological advancements and sustainable solutions.

HDPE Integration Challenges and Limitations

The integration of High-Density Polyethylene (HDPE) into complex systems presents several significant challenges and limitations that must be carefully considered. One of the primary obstacles is the material's inherent chemical resistance, which, while beneficial in many applications, can make bonding and adhesion to other materials difficult. This characteristic often necessitates specialized surface treatments or adhesives, adding complexity and cost to the integration process.

Another major challenge lies in HDPE's thermal properties. The material has a relatively low melting point and high thermal expansion coefficient, which can lead to dimensional instability in complex systems exposed to varying temperatures. This thermal behavior can cause misalignment, stress, or even failure in integrated components, particularly in applications where precise tolerances are critical.

The mechanical properties of HDPE also pose integration challenges. While the material offers excellent impact resistance and flexibility, its lower stiffness compared to metals or some other plastics can complicate load-bearing applications. Engineers must carefully consider stress distribution and potential deformation when incorporating HDPE into structural components of complex systems.

Furthermore, HDPE's susceptibility to UV degradation presents a limitation in outdoor or high-exposure applications. Without proper additives or protective measures, HDPE components can experience reduced lifespan and performance degradation, potentially compromising the integrity of the entire system.

The processing and fabrication of HDPE for integration into complex systems also present challenges. The material's high melt viscosity can make precision molding or extrusion difficult, especially for intricate parts or thin-walled sections. This can limit design flexibility and increase manufacturing complexity.

Recycling and end-of-life considerations add another layer of complexity to HDPE integration. While HDPE is recyclable, its use in complex systems often involves combining it with other materials, making separation and recycling more challenging. This can conflict with sustainability goals and circular economy initiatives, requiring careful design considerations from the outset.

Regulatory compliance and material certification can also pose significant hurdles, particularly in highly regulated industries such as aerospace, automotive, or medical devices. Ensuring that HDPE components meet stringent performance and safety standards while integrated into complex systems often requires extensive testing and documentation.

In conclusion, while HDPE offers many advantageous properties, its integration into complex systems is fraught with challenges that span material properties, processing limitations, environmental considerations, and regulatory requirements. Overcoming these obstacles requires a multidisciplinary approach, innovative design strategies, and often, the development of new technologies or processes to fully leverage HDPE's potential in advanced applications.

Current HDPE Integration Solutions

01 HDPE Composite Materials

Development of composite materials incorporating HDPE to enhance material properties. These composites often combine HDPE with other materials such as fibers, fillers, or other polymers to improve strength, durability, or specific functional characteristics.- HDPE Composite Materials: High-density polyethylene (HDPE) is often integrated with other materials to create composite materials with enhanced properties. These composites can combine the strength and durability of HDPE with the unique characteristics of other materials, resulting in improved performance for various applications.

- HDPE Recycling and Reuse: Integration of recycled HDPE into new products is a growing trend in sustainable manufacturing. This process involves collecting, sorting, and processing used HDPE products to create new materials or products, reducing waste and conserving resources.

- HDPE in Packaging Solutions: HDPE is widely integrated into packaging solutions due to its excellent barrier properties, chemical resistance, and durability. Innovations in HDPE packaging focus on improving sustainability, reducing material usage, and enhancing product protection.

- HDPE in Construction and Infrastructure: The integration of HDPE in construction and infrastructure projects is increasing due to its corrosion resistance, flexibility, and long service life. Applications include pipes, geomembranes, and structural components for buildings and civil engineering projects.

- HDPE Modification Techniques: Various modification techniques are employed to enhance the properties of HDPE for specific applications. These may include chemical modifications, blending with other polymers, or the addition of reinforcing agents to improve mechanical, thermal, or barrier properties.

02 HDPE Processing Techniques

Advancements in processing techniques for HDPE, including extrusion, injection molding, and blow molding. These methods focus on improving the efficiency of HDPE production and enhancing the quality of the final products.Expand Specific Solutions03 HDPE Blends and Alloys

Creation of HDPE blends and alloys with other polymers or additives to achieve specific material properties. These blends can improve characteristics such as impact resistance, chemical resistance, or processability of the resulting material.Expand Specific Solutions04 HDPE Recycling and Sustainability

Development of methods for recycling HDPE and incorporating recycled HDPE into new products. This includes techniques for improving the quality of recycled HDPE and finding new applications for recycled materials to enhance sustainability.Expand Specific Solutions05 HDPE Applications in Specific Industries

Integration of HDPE into specific industrial applications, such as packaging, automotive parts, construction materials, and medical devices. This involves tailoring HDPE properties to meet the unique requirements of each industry.Expand Specific Solutions

Key Players in HDPE Integration Industry

The integration of HDPE in complex systems presents a competitive landscape in a mature yet evolving industry. The market is characterized by established players like ExxonMobil, Dow, and SABIC, alongside emerging companies from China and other regions. The technology's maturity varies across applications, with ongoing research focusing on enhancing HDPE's properties and integration methods. Market size is substantial, driven by diverse industrial applications. Companies like Chevron Phillips and Borealis are advancing polymer science, while institutions such as Sichuan University and the Chinese Academy of Science are contributing to innovation. The industry is in a phase of incremental improvements, with a focus on sustainability and performance optimization in complex system integration.

SABIC Global Technologies BV

Dow Global Technologies LLC

Innovative HDPE Integration Techniques

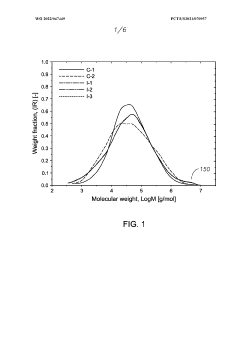

- A unimodal polyethylene composition with a density range of 0.935 to 0.975 g/cm³ and melt index of 0.1 to 1 g/10 min, exhibiting high Environmental Stress Crack Resistance (ESCR) values comparable to bimodal compositions, and featuring multiple distinct crystalline fractions, is developed. This composition is made in a single reactor with trace amounts of titanium and/or chromium, achieving a balance of properties typically associated with multimodal distributions at a lower cost.

- Compounding HDPE with a highly concentrated polyamide/layered silicate masterbatch and optionally adding a maleic anhydride-grafted polyolefin in a two-stage process, using a twin-screw extruder to achieve intercalation and exfoliation, thereby enhancing mechanical properties.

Environmental Impact of HDPE Integration

The integration of High-Density Polyethylene (HDPE) in complex systems presents both opportunities and challenges from an environmental perspective. HDPE, known for its durability and versatility, has become increasingly prevalent in various industries. However, its widespread use raises concerns about its environmental impact throughout its lifecycle.

One of the primary environmental considerations is the production process of HDPE. The manufacturing of HDPE relies heavily on fossil fuels, contributing to greenhouse gas emissions and resource depletion. The energy-intensive nature of HDPE production poses a significant challenge in terms of carbon footprint reduction and sustainable resource management.

Once integrated into complex systems, HDPE components often demonstrate excellent longevity and resistance to degradation. This durability can be viewed as a double-edged sword from an environmental standpoint. On one hand, the extended lifespan of HDPE parts reduces the need for frequent replacements, potentially lowering overall resource consumption and waste generation. On the other hand, this persistence can lead to long-term environmental accumulation when HDPE components are not properly managed at the end of their useful life.

The recyclability of HDPE is a crucial factor in mitigating its environmental impact. While HDPE is theoretically recyclable, the integration into complex systems often complicates the recycling process. The presence of other materials, additives, or contaminants can make it challenging to separate and recycle HDPE components effectively. This issue highlights the importance of designing for disassembly and implementing efficient recycling technologies to maximize material recovery.

When HDPE components are not recycled, they may end up in landfills or, worse, in natural environments. The slow degradation rate of HDPE can lead to long-term pollution, particularly in marine ecosystems where plastic waste accumulation is a growing concern. Microplastic formation from weathered HDPE poses additional risks to wildlife and potentially enters the food chain.

To address these environmental challenges, several strategies can be employed. Firstly, optimizing the design of HDPE components within complex systems to facilitate easier disassembly and recycling is crucial. This may involve using compatible materials, minimizing the use of additives, and implementing modular designs that allow for component replacement rather than entire system disposal.

Secondly, advancing recycling technologies specifically tailored for HDPE in complex systems can significantly improve material recovery rates. This includes developing more efficient sorting methods, chemical recycling processes, and upcycling techniques to maintain the value of recycled HDPE.

Lastly, exploring bio-based alternatives or composite materials that offer similar performance characteristics to HDPE but with reduced environmental impact could provide long-term solutions. These alternatives should be evaluated not only for their immediate environmental benefits but also for their overall lifecycle impact, including production energy requirements and end-of-life management.

HDPE Recycling and Circular Economy Strategies

The integration of High-Density Polyethylene (HDPE) recycling into complex systems is a crucial step towards achieving a circular economy. This strategy focuses on maximizing the value of HDPE throughout its lifecycle, from production to disposal and reuse. The circular economy approach for HDPE aims to minimize waste, reduce environmental impact, and create sustainable value chains.

One of the primary strategies for HDPE recycling is the implementation of advanced sorting technologies. These systems utilize near-infrared spectroscopy, X-ray fluorescence, and artificial intelligence to accurately identify and separate HDPE from other materials in waste streams. This precise sorting is essential for producing high-quality recycled HDPE that can be reintegrated into complex manufacturing processes.

Chemical recycling techniques are gaining traction as a complementary approach to mechanical recycling. These processes break down HDPE into its molecular components, allowing for the production of virgin-quality recycled material. This is particularly valuable for complex systems that require high-purity HDPE, such as food packaging or medical devices.

Design for recyclability is another key strategy in the circular economy for HDPE. This involves creating products with end-of-life considerations in mind, ensuring that HDPE components can be easily separated and recycled. Standardization of HDPE grades and additives across industries can further facilitate recycling efforts and improve the quality of recycled materials.

The development of closed-loop systems within industries is a promising approach for HDPE recycling. In these systems, manufacturers take responsibility for collecting and recycling their own HDPE products, ensuring a consistent supply of high-quality recycled material. This strategy not only reduces waste but also provides economic benefits through resource efficiency.

Blockchain technology is emerging as a tool to enhance transparency and traceability in HDPE recycling supply chains. By tracking the journey of HDPE from production to recycling, stakeholders can verify the origin and quality of recycled materials, building trust and facilitating the integration of recycled HDPE into complex systems.

Policy initiatives play a crucial role in promoting HDPE recycling and circular economy strategies. Extended Producer Responsibility (EPR) schemes, recycled content mandates, and tax incentives for using recycled materials are driving the adoption of circular economy principles in HDPE-intensive industries.