How to Transition to Renewable Resources in LDPE Manufacturing?

LDPE Renewable Transition Background and Objectives

Low-density polyethylene (LDPE) has been a cornerstone of the plastics industry for decades, primarily due to its versatility, low cost, and ease of production. However, the traditional manufacturing process for LDPE relies heavily on fossil fuel-based feedstocks, contributing significantly to greenhouse gas emissions and environmental concerns. As global awareness of climate change and sustainability issues grows, there is an increasing imperative for the plastics industry to transition towards more environmentally friendly production methods.

The objective of transitioning to renewable resources in LDPE manufacturing is multifaceted. Primarily, it aims to reduce the carbon footprint of LDPE production by replacing fossil fuel-based raw materials with bio-based alternatives. This shift aligns with global efforts to mitigate climate change and adheres to increasingly stringent environmental regulations. Additionally, it seeks to ensure the long-term sustainability of LDPE production by reducing dependence on finite fossil resources.

The evolution of LDPE manufacturing technology has seen several key milestones since its inception in the 1930s. Initially produced using high-pressure processes, LDPE manufacturing has undergone continuous improvements in efficiency and scale. However, the fundamental reliance on petroleum-derived ethylene has remained largely unchanged. Recent technological advancements in bio-based feedstock production and catalysis have opened new avenues for incorporating renewable resources into LDPE manufacturing.

Current trends in the field indicate a growing interest in bio-based ethylene production, utilizing feedstocks such as sugarcane, corn, or cellulosic biomass. These renewable sources can be converted into ethanol and subsequently dehydrated to produce ethylene, the primary monomer for LDPE. Parallel to this, research is ongoing in the development of novel catalysts that can efficiently polymerize bio-based ethylene, ensuring that the final LDPE product maintains the desired physical and chemical properties.

The transition to renewable resources in LDPE manufacturing faces several technical challenges. These include optimizing the conversion efficiency of biomass to ethylene, scaling up bio-based production processes to meet industrial demands, and ensuring consistent product quality across different renewable feedstocks. Moreover, the economic viability of renewable LDPE production compared to traditional methods remains a significant consideration, particularly in the context of fluctuating oil prices and varying regional availability of biomass resources.

Looking ahead, the successful transition to renewable resources in LDPE manufacturing will likely require a combination of technological innovation, policy support, and market demand for sustainable plastics. This shift represents not only a technical challenge but also an opportunity for the plastics industry to reinvent itself in the face of growing environmental concerns and resource constraints.

Market Demand for Sustainable LDPE Products

The market demand for sustainable LDPE (Low-Density Polyethylene) products has been steadily increasing in recent years, driven by growing environmental awareness and stricter regulations on plastic usage. Consumers and businesses alike are seeking more eco-friendly alternatives to traditional petroleum-based plastics, creating a significant opportunity for manufacturers to transition to renewable resources in LDPE production.

One of the key factors fueling this demand is the rising concern over plastic pollution and its impact on marine ecosystems. As a result, many countries have implemented or are considering bans on single-use plastics, which has led to a surge in demand for sustainable alternatives. This shift in consumer behavior and regulatory landscape has prompted major retailers and brands to commit to using more sustainable packaging materials, including bio-based LDPE.

The food and beverage industry, in particular, has shown a strong interest in sustainable LDPE products. As one of the largest consumers of plastic packaging, this sector is under increasing pressure to reduce its environmental footprint. Sustainable LDPE offers an attractive solution, as it can maintain the necessary barrier properties and flexibility required for food packaging while reducing reliance on fossil fuels.

Another significant market driver is the cosmetics and personal care industry, where consumers are increasingly demanding sustainable packaging options. Many leading brands in this sector have set ambitious targets for incorporating recycled or bio-based materials into their packaging, creating a substantial market for sustainable LDPE products.

The agricultural sector also presents a growing market for sustainable LDPE, particularly in mulch films and greenhouse coverings. Farmers are increasingly looking for biodegradable or bio-based alternatives to traditional plastic films, which can help reduce soil contamination and improve overall sustainability in agriculture.

In the automotive industry, there is a growing demand for lightweight, sustainable materials to improve fuel efficiency and reduce carbon emissions. Sustainable LDPE products can play a role in this transition, particularly in interior components and non-structural parts.

The e-commerce boom has further accelerated the demand for sustainable packaging materials, including LDPE-based products. As online shopping continues to grow, there is an increasing need for packaging solutions that are both protective and environmentally friendly, creating additional opportunities for sustainable LDPE manufacturers.

While the market demand for sustainable LDPE products is strong, it is important to note that price sensitivity remains a challenge. Many businesses and consumers are willing to pay a premium for sustainable options, but this premium must be balanced against performance and cost-effectiveness. As production scales up and technologies improve, it is expected that the cost gap between traditional and sustainable LDPE will narrow, further driving market adoption.

Current Challenges in Renewable LDPE Manufacturing

The transition to renewable resources in LDPE manufacturing faces several significant challenges. One of the primary obstacles is the high cost associated with renewable feedstocks compared to traditional petroleum-based raw materials. This cost differential makes it difficult for manufacturers to maintain competitive pricing while adopting sustainable practices.

Another major challenge is the limited availability of renewable feedstocks suitable for LDPE production. While bio-based alternatives exist, such as sugarcane-derived ethanol, their supply chains are not as well-established as those for fossil fuel-based feedstocks. This can lead to supply inconsistencies and potential production disruptions.

The quality and performance of renewable LDPE also present challenges. Achieving the same material properties and consistency as traditional LDPE can be difficult with bio-based feedstocks. This is particularly crucial in industries with stringent quality requirements, such as food packaging and medical applications.

Energy consumption in the production process remains a significant hurdle. While renewable feedstocks may offer environmental benefits, the energy-intensive nature of LDPE manufacturing often relies on fossil fuel-based power sources. Transitioning to renewable energy for production processes adds another layer of complexity and cost.

Infrastructure adaptation is another challenge. Existing LDPE manufacturing facilities are optimized for petroleum-based feedstocks, and retrofitting or replacing equipment to handle renewable resources can be capital-intensive and time-consuming.

Regulatory compliance and certification pose additional challenges. As the industry shifts towards renewable resources, navigating evolving environmental regulations and obtaining necessary certifications for new production methods can be complex and time-consuming.

Market acceptance and consumer perception also play a role. While there is growing demand for sustainable products, some customers may be hesitant to adopt renewable LDPE if there are concerns about its performance or if it comes at a higher cost.

Lastly, the technological gap in efficient conversion processes for renewable feedstocks into LDPE presents a significant research and development challenge. Developing catalysts and processes that can effectively and economically convert bio-based materials into high-quality LDPE is an ongoing area of focus for the industry.

Existing Renewable LDPE Manufacturing Solutions

01 Production of LDPE from renewable resources

Methods for producing low-density polyethylene (LDPE) from renewable resources, such as plant-based materials or biomass. These processes aim to reduce dependence on fossil fuels and decrease the carbon footprint of LDPE production. The renewable resources are converted into monomers, which are then polymerized to form LDPE with properties similar to conventional petroleum-based LDPE.- Production of LDPE from renewable resources: Methods for producing low-density polyethylene (LDPE) from renewable resources, such as plant-based materials or biomass. These processes aim to reduce dependence on fossil fuels and decrease the carbon footprint of LDPE production. The renewable resources are converted into ethylene monomers, which are then polymerized to form LDPE.

- Blending LDPE with bio-based polymers: Techniques for blending LDPE with bio-based polymers derived from renewable resources to create composite materials with improved environmental profiles. These blends can maintain the desirable properties of LDPE while incorporating renewable content. The bio-based polymers may include polylactic acid (PLA), polyhydroxyalkanoates (PHAs), or starch-based polymers.

- Recycling and upcycling of LDPE: Methods for recycling and upcycling LDPE products to reduce waste and promote circular economy principles. These processes may involve mechanical recycling, chemical recycling, or the conversion of LDPE waste into higher-value products. The recycled LDPE can be used in various applications, reducing the need for virgin materials derived from non-renewable sources.

- LDPE additives from renewable sources: Development of additives derived from renewable resources for use in LDPE formulations. These additives can enhance the properties of LDPE or improve its compatibility with other materials. Examples may include bio-based plasticizers, antioxidants, or compatibilizers that can replace petroleum-based additives traditionally used in LDPE production.

- LDPE applications using renewable energy: Innovative approaches to manufacturing LDPE products using renewable energy sources. This includes the use of solar, wind, or other clean energy technologies in the production process of LDPE or its products. These methods aim to reduce the overall environmental impact of LDPE manufacturing by decreasing reliance on fossil fuel-based energy sources.

02 Blending LDPE with bio-based polymers

Techniques for blending LDPE with bio-based polymers derived from renewable resources to create composite materials. These blends aim to improve the sustainability of LDPE products while maintaining or enhancing their performance characteristics. The bio-based polymers can be sourced from various plant materials and are compatible with LDPE in different ratios.Expand Specific Solutions03 Recycling and upcycling of LDPE

Methods for recycling and upcycling LDPE products to reduce waste and promote circular economy principles. These processes involve collecting, sorting, and processing used LDPE materials to create new products or raw materials. Some techniques focus on chemical recycling to break down LDPE into its constituent monomers, which can then be used to produce new polymers.Expand Specific Solutions04 LDPE additives from renewable sources

Development of additives derived from renewable resources for use in LDPE formulations. These additives can improve various properties of LDPE, such as UV resistance, biodegradability, or mechanical strength. The use of renewable additives aims to increase the overall sustainability of LDPE products while maintaining or enhancing their performance.Expand Specific Solutions05 Applications of renewable resource-based LDPE

Innovative applications for LDPE produced from renewable resources or blended with bio-based materials. These applications span various industries, including packaging, agriculture, and consumer goods. The focus is on developing products that leverage the sustainability benefits of renewable resource-based LDPE while meeting performance requirements comparable to conventional LDPE products.Expand Specific Solutions

Key Players in Sustainable LDPE Production

The transition to renewable resources in LDPE manufacturing is currently in an early development stage, with the market size still relatively small but growing rapidly. The technology maturity varies among key players, with companies like Dow Global Technologies LLC, SABIC Global Technologies BV, and Braskem SA leading in innovation. These firms are investing heavily in research and development to improve the efficiency and scalability of renewable LDPE production. Emerging players such as Zhejiang University and Hunan University of Technology are contributing to technological advancements through academic research. The competitive landscape is dynamic, with both established petrochemical giants and new entrants vying for market share in this evolving sector.

Dow Global Technologies LLC

SABIC Global Technologies BV

Innovative Approaches to Renewable LDPE Synthesis

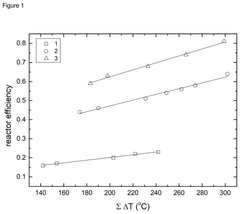

- A process for preparing LDPE in a tubular reactor with peak temperatures ranging from 180° C. to 350° C. and pressures from 150 to 350 MPa, where the total effective reactor length divided by the number of reaction zones is between 230 to 350 m, achieving high conversion and LCB content.

- A process control method that couples chemo-kinetic characteristics of reactive starting materials with fluid-mechanical characteristics of the reactor, limiting the mass fraction of disruptive hydroperoxides by setting defined concentration and dosage ratios of organic peroxides and aldehydes, ensuring stable process conditions and high monomer conversions.

Environmental Impact Assessment of Renewable LDPE

The transition to renewable resources in LDPE manufacturing presents both challenges and opportunities for environmental impact reduction. A comprehensive environmental impact assessment is crucial to understand the full scope of potential benefits and drawbacks associated with this shift.

Renewable LDPE production primarily focuses on utilizing bio-based feedstocks, such as sugarcane, corn, or other plant-derived materials. This approach aims to reduce dependency on fossil fuels and decrease overall carbon emissions. However, the environmental implications extend beyond just carbon footprint reduction.

One significant positive impact is the potential for carbon sequestration during the growth of biomass feedstocks. Plants used for bio-based LDPE production absorb CO2 from the atmosphere, potentially offsetting emissions from the manufacturing process. This creates a more circular carbon cycle compared to traditional petroleum-based LDPE production.

Water usage and land use changes are critical factors to consider in the environmental assessment. While renewable feedstocks may reduce water pollution associated with oil extraction, they often require significant water resources for cultivation. Additionally, the expansion of agricultural land for feedstock production could lead to deforestation or competition with food crops, impacting biodiversity and food security.

The energy requirements for processing bio-based feedstocks into LDPE must be carefully evaluated. If renewable energy sources are not used in the manufacturing process, the overall environmental benefits may be diminished. Life cycle assessments (LCAs) are essential to quantify the net environmental impact, considering factors such as transportation, processing, and end-of-life disposal.

Soil health and agricultural practices associated with feedstock production play a crucial role in the environmental impact. Sustainable farming methods, crop rotation, and responsible use of fertilizers and pesticides can significantly influence the overall sustainability of renewable LDPE.

The end-of-life scenario for renewable LDPE is another important consideration. While the material itself may be similar to conventional LDPE, the perception of bio-based plastics as more environmentally friendly could influence disposal behaviors. Proper education and waste management infrastructure are necessary to ensure that renewable LDPE is recycled or disposed of appropriately.

In conclusion, the environmental impact assessment of renewable LDPE must consider a wide range of factors beyond just greenhouse gas emissions. A holistic approach that examines the entire life cycle, from feedstock production to end-of-life management, is essential for a comprehensive understanding of the environmental implications of transitioning to renewable resources in LDPE manufacturing.

Regulatory Framework for Sustainable Plastics Production

The regulatory framework for sustainable plastics production plays a crucial role in the transition to renewable resources in LDPE manufacturing. Governments worldwide are implementing policies and regulations to promote sustainable practices and reduce the environmental impact of plastic production.

In the European Union, the Circular Economy Action Plan sets ambitious targets for plastic recycling and reuse. It mandates that all plastic packaging must be recyclable or reusable by 2030. This directive has significant implications for LDPE manufacturers, pushing them to explore renewable alternatives and improve recycling processes.

The United States has introduced the Save Our Seas 2.0 Act, which focuses on reducing plastic waste and promoting research into alternative materials. This legislation provides funding for research and development of sustainable plastics, including bio-based LDPE alternatives.

China's ban on imported plastic waste has led to stricter regulations on domestic plastic production. The country has implemented a plan to reduce single-use plastics and promote biodegradable alternatives, which impacts LDPE manufacturers and encourages the adoption of renewable resources.

Many countries have introduced plastic taxes or levies to discourage the use of non-renewable plastics. For instance, the UK's Plastic Packaging Tax charges manufacturers and importers for packaging with less than 30% recycled content. This financial incentive drives LDPE producers to incorporate more recycled or renewable materials in their products.

Extended Producer Responsibility (EPR) schemes are becoming increasingly common globally. These regulations hold manufacturers responsible for the entire lifecycle of their products, including disposal and recycling. This approach encourages LDPE producers to design products with recyclability and sustainability in mind from the outset.

International agreements, such as the Basel Convention on plastic waste, have established global frameworks for managing plastic waste and promoting sustainable production. These agreements influence national policies and drive the adoption of renewable resources in LDPE manufacturing across borders.

Certification systems and eco-labels, while not strictly regulatory, play a significant role in shaping industry practices. Standards like ISO 14001 for environmental management systems and the Global Recycled Standard (GRS) provide frameworks for sustainable production and can influence regulatory requirements.

As the regulatory landscape continues to evolve, LDPE manufacturers must stay informed and adapt their production processes to comply with new standards and capitalize on incentives for sustainable practices. The transition to renewable resources in LDPE manufacturing is not just an environmental imperative but increasingly a regulatory necessity.